Zirconia Oxygen Analyzer Market to Reach $434.5 Million by 2025: Industrial and Environmental Applications in the U.S., Japan, and Germany

The Zirconia Oxygen Analyzer Market is projected to reach $434.5 million by 2025, driven by increasing industrial and environmental applications in the U.S., Japan, and Germany. These analyzers are critical for combustion control, environmental monitoring, and ensuring safety in various industries such as power, iron & steel, and petrochemical.

- Last Updated:

Zirconia Oxygen Analyzer Market Outlook for Q1 and Q2 2025

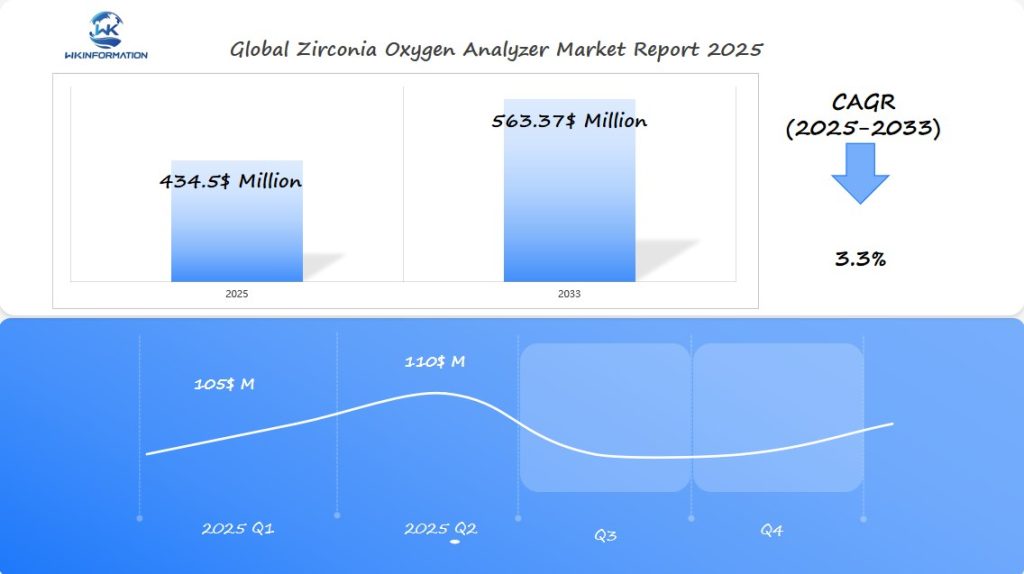

The Zirconia Oxygen Analyzer market is expected to reach $434.5 million in 2025, with a CAGR of 3.3% from 2025 to 2033.

In Q1 2025, the market is expected to be valued at $105 million, driven by the need for accurate oxygen level measurement in industrial processes in the U.S., Japan, and Germany. Zirconia oxygen analyzers are critical for monitoring combustion efficiency and emissions in power plants and other industries.

By Q2 2025, the market is projected to grow to $110 million, with Japan leading the way in industrial applications, followed by Germany, where stringent emission regulations are increasing demand for advanced monitoring systems. The U.S. market will also see growth due to the ongoing modernization of industrial infrastructure.

Zirconia Oxygen Analyzer upstream and downstream industry chain analysis

To understand how the Zirconia Oxygen Analyzer market works, we need to look at its upstream industry chain. This chain includes the suppliers of raw materials and parts needed to make oxygen analyzers.

Upstream industry chain analysis

The upstream industry chain is critical in determining the quality, reliability, and cost of Zirconia Oxygen Analyzers. Key components include zirconia sensors, electronic components, and housing materials. Suppliers of these raw materials play a significant role in the production process.

Raw material suppliers

Raw material suppliers are vital to the production of Zirconia Oxygen Analyzers. The quality of zirconia sensors, for instance, directly affects the accuracy and reliability of the analyzers. Other essential components include electronic parts and durable housing materials.

Some of the key raw materials and their suppliers include:

- Zirconia sensors from specialized manufacturers

- Electronic components from reputable suppliers

- Housing materials that are durable and resistant to environmental factors

The reliability of these suppliers is crucial for maintaining the quality of the final product. Any disruptions in the supply chain can impact the production and availability of Zirconia Oxygen Analyzers.

Understanding the upstream industry chain helps in identifying potential bottlenecks and opportunities for cost optimization. It also highlights the importance of supplier reliability and component quality in the production of Zirconia Oxygen Analyzers.

Growing Need for Oxygen Analyzers in Industries and Environmental Monitoring

Oxygen analyzers are experiencing a significant increase in demand due to their essential role in both industrial and environmental monitoring. This surge is primarily driven by the growing requirement for accurate measurement of oxygen levels across different industries.

Importance of Oxygen Analyzers in Industries

The industrial sector plays a major role in this rising demand for oxygen analyzers. These devices are being utilized in various industrial processes to maintain efficiency and ensure safety.

Industrial applications

In industrial settings, oxygen analyzers play a crucial role in optimizing combustion processes, thereby enhancing efficiency and reducing emissions. Their ability to provide accurate oxygen level measurements makes them indispensable in industries such as power generation, chemical processing, and oil refining.

Process control and emissions monitoring

Process control is a critical aspect of industrial operations, where oxygen analyzers help in maintaining the optimal oxygen levels for efficient combustion. This not only improves the process efficiency but also reduces fuel consumption and minimizes emissions.

Emissions monitoring is another vital application of oxygen analyzers. By accurately measuring oxygen levels in flue gases, these analyzers help industries comply with environmental regulations and reduce their environmental footprint.

| Industry | Application | Benefit |

| Power Generation | Combustion Optimization | Improved Efficiency, Reduced Emissions |

| Chemical Processing | Process Control | Enhanced Product Quality, Reduced Costs |

| Oil Refining | Emissions Monitoring | Regulatory Compliance, Environmental Protection |

The table above highlights the diverse industrial applications of oxygen analyzers and their benefits. As industries continue to focus on efficiency, safety, and environmental compliance, the demand for oxygen analyzers is expected to grow.

Challenges in sensor accuracy, durability, and maintenance

The effectiveness of zirconia oxygen analyzers is heavily influenced by factors such as sensor accuracy and maintenance requirements. Despite advancements in technology, these devices still face challenges that impact their performance and reliability.

One of the primary concerns is sensor accuracy, which is crucial for obtaining reliable oxygen measurements. Ensuring the accuracy of these sensors is vital, particularly in industrial and environmental monitoring applications where precise data is essential.

Sensor accuracy and calibration

Calibration plays a key role in maintaining sensor accuracy. Regular calibration ensures that the sensors provide accurate readings, which is critical for process control and emissions monitoring. Factors such as sensor drift and aging can affect accuracy, making regular calibration a necessity.

To maintain accuracy, it is also important to understand the calibration process and the factors that influence it. This includes understanding the sensor’s response to different oxygen concentrations and temperatures.

Maintenance and troubleshooting

Effective maintenance is crucial for minimizing downtime and ensuring the continuous operation of oxygen analyzers. Regular maintenance tasks include checking for sensor damage, cleaning the sensor, and verifying that the calibration is up to date.

Troubleshooting involves identifying issues such as sensor failure or calibration drift. By having effective troubleshooting strategies in place, users can quickly address problems and minimize the impact on their operations.

- Regularly check and maintain the sensor to prevent damage.

- Verify calibration regularly to ensure accuracy.

- Understand the troubleshooting process to quickly address issues.

Geopolitical Analysis of Industrial Regulations and Environmental Policies

Geopolitical dynamics play a crucial role in shaping the demand for zirconia oxygen analyzers across different regions. The varying industrial regulations and environmental policies across the globe significantly influence the market trends for these analyzers.

The regional regulations and policies governing industrial emissions and environmental protection are diverse and often stringent. For instance, in regions with high industrial activity, such as North America and Europe, there is a growing emphasis on reducing emissions and improving air quality. This has led to an increased demand for accurate and reliable oxygen analyzers.

Regional Regulations and Policies

Different regions have their own set of regulations and policies regarding industrial emissions and environmental protection. In the United States, for example, the Environmental Protection Agency (EPA) sets strict standards for emissions and air quality. Similarly, in Europe, the European Union’s environmental policies drive the demand for oxygen analyzers in various industrial applications.

The impact of these regulations is multifaceted. Stricter regulations lead to an increased demand for high-quality oxygen analyzers, as industries seek to comply with the standards. This, in turn, drives innovation in sensor technology and manufacturing processes.

Impact on Market Trends

The impact on market trends is significant, as regions with stricter regulations tend to drive the demand for advanced oxygen analyzers. This creates opportunities for manufacturers to innovate and expand their product offerings. For instance, the growing demand for oxygen analyzers in the U.S. and Europe has led to advancements in sensor technology, making these analyzers more accurate and reliable.

As the global landscape continues to evolve, understanding the geopolitical dynamics and their impact on the zirconia oxygen analyzer market will be crucial for manufacturers, suppliers, and end-users alike. By staying abreast of regional regulations and policies, stakeholders can better navigate the market and capitalize on emerging opportunities.

Segmentation by sensor technology, and performance range

Understanding the segmentation by sensor technology and performance range is crucial for manufacturers and customers in the Zirconia Oxygen Analyzer market. This segmentation allows for a more nuanced understanding of the market’s needs and trends.

Sensor technology advancements

Advances in sensor technology have significantly improved the accuracy, reliability, and durability of oxygen analyzers. Modern zirconia sensors offer enhanced performance characteristics, such as faster response times and greater resistance to harsh environments.

The development of new materials and manufacturing techniques has also contributed to the evolution of sensor technology. For instance, improvements in zirconia ceramic technology have led to more stable and consistent sensor performance.

Performance range and applications

Different performance ranges cater to various applications, from industrial process control to environmental monitoring. For example, high-precision oxygen analyzers are used in laboratory settings, while more robust models are designed for harsh industrial environments.

| Performance Range | Application | Characteristics |

| High Precision | Laboratory Settings | High accuracy, fast response time |

| Industrial Grade | Process Control, Emissions Monitoring | Robust, resistant to harsh environments |

| Portable | Field Measurements, Environmental Monitoring | Compact, battery-powered, easy to use |

The variety of performance ranges available in the market allows customers to select the most appropriate analyzer for their specific needs, enhancing the overall efficiency and effectiveness of their operations.

Key applications in process control, emissions monitoring, and safety systems

Zirconia oxygen analyzers are used in many industries for:

- Process control: They help optimize industrial processes by providing real-time feedback on oxygen levels, ensuring efficient combustion and minimizing energy waste.

- Emissions monitoring: These analyzers play a vital role in monitoring and controlling emissions from various sources, such as power plants and manufacturing facilities, to meet environmental regulations.

- Safety systems: Zirconia oxygen analyzers are integrated into safety systems to detect potentially hazardous conditions, such as low oxygen levels in confined spaces, ensuring the safety of personnel and operations.

In these applications, zirconia oxygen analyzers offer several advantages:

- Accuracy: They provide precise measurements of oxygen concentrations, enabling better control and optimization of processes.

- Speed: Zirconia analyzers deliver rapid response times, allowing for immediate adjustments to be made in dynamic environments.

- Robustness: Designed to withstand harsh conditions, these analyzers can operate reliably in high-temperature and high-pressure environments commonly found in industrial settings.

By leveraging the capabilities of zirconia oxygen analyzers in process control, emissions monitoring, and safety systems, industries can achieve greater efficiency, reduce environmental impact, and enhance overall operational safety.

Process Control Applications

In process control, zirconia oxygen analyzers help maintain optimal combustion conditions, thereby enhancing efficiency and reducing fuel consumption. By continuously monitoring oxygen levels, these analyzers enable adjustments to be made in real-time, ensuring that processes operate within desired parameters.

For instance, in the steel industry, zirconia oxygen analyzers are used to control the oxygen levels in furnaces, which is critical for achieving the desired chemical composition of steel. Similarly, in the power generation sector, these analyzers help in optimizing the combustion process, leading to improved efficiency and reduced emissions.

Emissions Monitoring and Safety Systems

Emissions monitoring is another critical application of zirconia oxygen analyzers. By measuring oxygen levels in flue gases, these analyzers help industries assess their compliance with environmental regulations. This is particularly important in sectors such as power generation, cement production, and waste incineration.

In safety systems, zirconia oxygen analyzers play a vital role in detecting potential hazards such as oxygen deficiencies or enrichments. This is crucial in industries where workers are exposed to confined spaces or where oxygen levels can fluctuate. By providing real-time oxygen level monitoring, these analyzers help prevent accidents and ensure a safe working environment

Regional growth trends in environmental protection and industrial automation

The Zirconia Oxygen Analyzer Market is shaped by regional growth trends that are influenced by environmental protection policies and the level of industrial automation. Regions with stringent environmental regulations and a high degree of industrial automation tend to have a higher demand for oxygen analyzers.

To understand the regional market analysis, it’s essential to examine the varying growth patterns across different regions. The demand for Zirconia Oxygen Analyzers is not uniform and is largely driven by regional factors.

Regional market analysis

A closer look at the regional market reveals that regions with strong environmental protection policies and advanced industrial automation tend to drive the demand for oxygen analyzers. For example, regions with strict emissions monitoring requirements tend to adopt more sophisticated oxygen analyzers.

- Regions with high industrial automation levels tend to have a higher demand for oxygen analyzers.

- Environmental protection policies play a crucial role in shaping the demand for oxygen analyzers.

- Regional regulations and policies influence the adoption of oxygen analyzers in various industries.

Growth trends and forecasts

Analyzing growth trends and forecasts is crucial for businesses to identify opportunities and challenges in different markets. By understanding the regional growth trends, companies can better navigate the complex landscape of the Zirconia Oxygen Analyzer Market.

- Emerging markets with growing industrial automation needs are expected to drive growth in the oxygen analyzer market.

- Regions with stringent environmental regulations will continue to drive demand for high-quality oxygen analyzers.

- Technological advancements in oxygen analyzer technology will further influence regional growth trends.

U.S. regulations driving demand for oxygen analyzers in process control

Strict U.S. regulations are driving the need for precise oxygen analyzers in process control applications. The regulatory landscape in the U.S. is complex, with various federal and state regulations governing industrial processes and environmental protection. As a result, industries are required to follow strict guidelines, which makes it necessary to use accurate and reliable oxygen analyzers.

The demand for oxygen analyzers is particularly high in industries where process control is critical, such as power generation, chemical processing, and manufacturing. Accurate oxygen analysis is essential for optimizing processes, ensuring safety, and minimizing environmental impact.

U.S. environmental regulations

U.S. environmental regulations play a significant role in driving the demand for oxygen analyzers. Regulations such as the Clean Air Act and the Clean Water Act require industries to monitor and control emissions, effluent quality, and other environmental parameters. Oxygen analyzers are crucial for monitoring oxygen levels in various industrial processes, enabling companies to comply with these regulations.

Impact on process control

The impact of U.S. regulations on process control is multifaceted. By requiring industries to monitor and control oxygen levels, regulations drive the adoption of oxygen analyzers, which in turn enables more efficient and safe process control. This has a positive effect on industrial productivity, as well as environmental protection.The growth of the oxygen analyzer market in the U.S. is expected to continue, driven by the need for regulatory compliance and process optimization. As industries strive to improve efficiency and reduce environmental impact, the demand for accurate and reliable oxygen analyzers will remain strong.

Japan's industrial advancements and environmental monitoring needs

Japan’s industrial advancements and environmental monitoring needs are fueling the growth of the oxygen analyzer market. The country’s industrial sector, including manufacturing and power generation, relies heavily on advanced oxygen analyzers for process control and emissions monitoring.

The demand for high-quality oxygen analyzers in Japan is driven by the need for efficient and environmentally friendly industrial processes. Zirconia oxygen analyzers are particularly valued for their accuracy and durability in harsh industrial environments.

Japan’s industrial landscape

Japan is known for its technological innovations and has a robust industrial base that includes automotive manufacturing, steel production, and power generation. These industries require precise oxygen analysis to optimize processes and minimize environmental impact.

Advanced manufacturing technologies and stringent environmental regulations are key factors driving the adoption of oxygen analyzers in Japan. The country’s focus on reducing emissions and improving energy efficiency further boosts the demand for these devices.

Environmental monitoring requirements

Japan has implemented stringent environmental regulations to reduce emissions and improve air quality. Oxygen analyzers play a crucial role in monitoring and controlling emissions from industrial sources.

The table below highlights the key industrial sectors in Japan and their requirements for oxygen analyzers:

| Industrial Sector | Oxygen Analyzer Requirements | Key Applications |

| Power Generation | High accuracy, durability | Emissions monitoring, combustion control |

| Automotive Manufacturing | Precision, reliability | Process control, quality assurance |

| Steel Production | Robustness, fast response time | Process optimization, emissions monitoring |

As shown in the table, different industrial sectors have specific requirements for oxygen analyzers, driving the demand for a range of technologies and solutions.

Japan oxygen analyzer market

The oxygen analyzer market in Japan is significantly influenced by these industrial needs. With the ongoing advancements in technology and the increasing emphasis on environmental sustainability, the market is expected to witness substantial growth.

Germany’s commitment to sustainability and air quality standards

Germany is a leader in environmental technology, and its policies and regulations have a significant impact on the oxygen analyzer market. The country is at the forefront of environmental protection, with a strong commitment to maintaining high air quality standards. This commitment drives the demand for oxygen analyzers in various sectors, including industrial and automotive.

Germany’s environmental policies

Germany’s environmental policies are designed to reduce emissions and promote sustainability. The country’s stringent regulations create opportunities for the growth of the oxygen analyzer market. Key policies include:

- Implementation of strict air quality standards

- Promotion of clean technologies

- Support for research and development in environmental monitoring

Germany’s environmental policies

Germany’s environmental policies have a significant impact on the demand for oxygen analyzers. The country’s emphasis on reducing emissions and promoting sustainability drives the need for accurate and reliable oxygen analyzers.

These policies include measures to:

- Reduce greenhouse gas emissions

- Improve air quality in urban areas

- Promote the use of clean technologies

The impact of these policies on the oxygen analyzer market is significant. As Germany continues to lead in environmental technology, the demand for oxygen analyzers is expected to grow.

Impact on oxygen analyzer market

The growth of the oxygen analyzer market in Germany is driven by the country’s commitment to sustainability and air quality standards. As the demand for oxygen analyzers continues to rise, manufacturers are focusing on developing advanced technologies to meet the needs of various industries.

The key trends in the market include:

- Increasing demand for high-precision oxygen analyzers

- Growing adoption of zirconia oxygen analyzers

- Advancements in sensor technology

Innovations in zirconia sensor technology and miniaturization

Zirconia sensor technology has seen significant advancements in recent years, leading to improved oxygen analyzers. These advancements have enabled the development of more compact and efficient oxygen analyzers, expanding their application range and improving their performance.

Advancements in sensor technology

The advancements in zirconia sensor technology have been driven by innovations in materials and design. New materials and manufacturing techniques have improved the accuracy and reliability of zirconia sensors, making them more suitable for a wide range of applications.

Furthermore, advancements in sensor technology have led to the development of more compact and efficient oxygen analyzers. This has enabled the integration of oxygen analyzers into a wider range of devices and systems, further expanding their application range.

Miniaturization trends

The trend towards miniaturization is particularly significant, as it allows for the integration of oxygen analyzers into smaller devices and systems. Miniaturized oxygen analyzers are more versatile and can be used in a variety of applications, from industrial process control to environmental monitoring.

According to industry experts, “The miniaturization of oxygen analyzers is a key trend in the market, enabling the development of more compact and efficient systems.” This trend is expected to continue, driving further innovations in zirconia sensor technology.

- Improved accuracy and reliability

- Increased compactness and efficiency

- Expanded application range

As the zirconia oxygen analyzer market continues to evolve, we can expect to see further innovations in zirconia sensor technology and miniaturization. These advancements will likely lead to even more compact and efficient oxygen analyzers, further expanding their application range and improving their performance.

Key competitors in the zirconia oxygen analyzer market

The zirconia oxygen analyzer market is highly competitive, with several major players competing for market share. These industry leaders are driving innovation and growth in the field.

Key Players:

-

ABB – Switzerland

-

Yokogawa – Japan

-

AMETEK – USA

-

Fuji Electric – Japan

-

General Electric – USA

-

Energy Support Corporation – USA

-

Teledyne Analytical Instruments – USA

-

Toray Engineering – Japan

-

Meikang – China

-

Emerson – USA

-

Systech Illinois – UK

-

Servomex – UK

-

NZ Instruments – New Zealand

-

METEK Process Instruments – Germany

-

Teledyne Monitor Labs – USA

-

RKI Instruments – USA

-

AOI Corp – USA

-

Ecotech – Australia

-

COSA Xentaur – USA

-

HORIBA – Japan

-

Daiichinekken – Japan

-

Shanghai Meikai Youdi Instrument – China

Overall

| Report Metric | Details |

|---|---|

| Report Name | Zirconia Oxygen Analyzer Market |

| Base Year | 2024 |

| Segment by Type | · High Precision

· Industrial Grade · Portable |

| Segment by Application | · Process Control

· Emissions Monitoring · Safety Systems |

| Geographies Covered | · North America (United States, Canada)

· Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The competitive landscape is expected to remain intense, with companies investing in research and development to improve their product offerings. Understanding the competitive landscape is crucial for businesses to identify opportunities, challenges, and potential partnerships in the zirconia oxygen analyzer market.

Global Zirconia Oxygen Analyzer Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Zirconia Oxygen Analyzer Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Zirconia Oxygen Analyzer MarketSegmentation Overview

Chapter 2: Competitive Landscape

- Global Zirconia Oxygen AnalyzerPlayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Zirconia Oxygen Analyzer Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Zirconia Oxygen Analyzer Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Zirconia Oxygen Analyzer Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Zirconia Oxygen Analyzer MarketInsights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is a Zirconia Oxygen Analyzer?

A Zirconia Oxygen Analyzer is a device used to measure the concentration of oxygen in a gas mixture, utilizing zirconia sensor technology for accurate and reliable measurements.

What are the primary applications of Zirconia Oxygen Analyzers?

Zirconia Oxygen Analyzers are used in various industrial and environmental applications, including process control, emissions monitoring, and safety systems, particularly in industries such as manufacturing, power generation, and environmental monitoring.

How does zirconia sensor technology work?

Zirconia sensor technology works by allowing oxygen ions to move through a zirconia ceramic material at high temperatures. This movement of ions enables precise measurement of oxygen levels in gas mixtures.

What are the benefits of using Zirconia Oxygen Analyzers?

Zirconia Oxygen Analyzers offer several advantages, including:

- High accuracy: These analyzers provide precise measurements of oxygen levels, ensuring reliable data for various applications.

- Reliability: Zirconia sensors are known for their stability and long-term performance, making them dependable for continuous monitoring.

- Durability: Designed to withstand harsh conditions, these analyzers can operate effectively in extreme temperatures and corrosive environments.

- Versatility: The ability to function in challenging settings makes Zirconia Oxygen Analyzers suitable for diverse industries such as oil and gas, power generation, and waste treatment.

- Environmental monitoring: These analyzers play a crucial role in assessing air quality and emissions, contributing to environmental protection efforts.

What factors are driving the growth of the Zirconia Oxygen Analyzer Market?

The market’s growth is driven by:

- increasing demand for accurate oxygen measurement

- advancements in sensor technology

- the need for compliance with environmental regulations, particularly in regions with stringent environmental policies

What are the challenges faced by the Zirconia Oxygen Analyzer Market?

Challenges include ensuring sensor accuracy, durability, and maintenance, as well as navigating varying regional regulations and environmental policies that impact market demand.

How do regional regulations impact the demand for Zirconia Oxygen Analyzers?

Regional regulations, especially those related to environmental protection and emissions control, significantly influence the demand for Zirconia Oxygen Analyzers. Regions with stricter regulations typically show higher demand.

What advancements are being made in Zirconia Oxygen Analyzer technology?

Advancements include improvements in sensor accuracy, reliability, and miniaturization, enabling the development of more compact and efficient oxygen analyzers with expanded application ranges.

Who are the key competitors in the Zirconia Oxygen Analyzer Market?

The market includes established manufacturers and emerging players, with key competitors focusing on strategies such as product innovation, market expansion, and distribution network enhancement.

What is the outlook for the Zirconia Oxygen Analyzer Market?

The market is projected to grow, driven by increasing industrial and environmental applications, particularly in regions with stringent environmental regulations and a high degree of industrial automation.