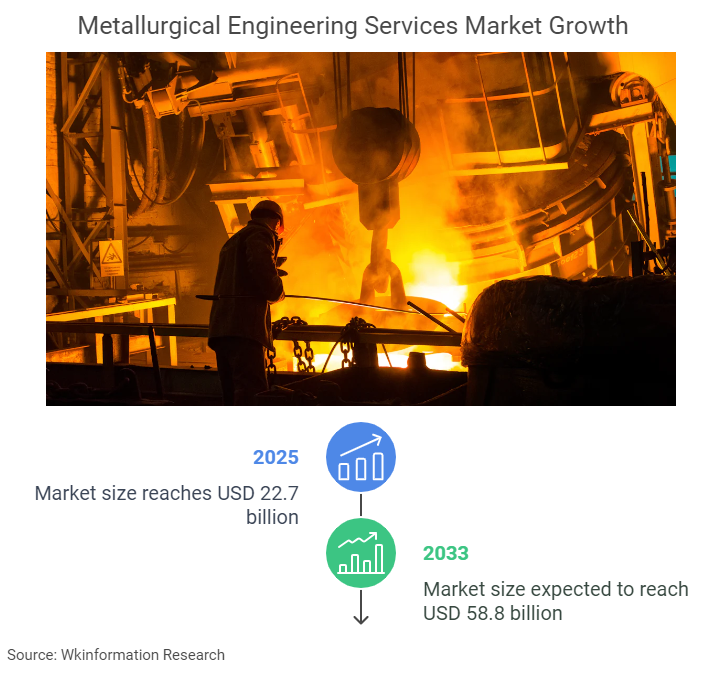

The metallurgical engineering services market is experiencing significant growth, fueled by advancements in technology and sustainability efforts. Innovations like additive manufacturing enable the creation of intricate designs, reducing waste and enhancing material performance. AI and machine learning improve production efficiency by optimizing parameters in real-time, while IoT devices boost operational efficiency by over 20% in adopting companies. Additionally, the development of eco-friendly materials and recycling techniques addresses environmental concerns. The market size will reach USD 22.7 billion in 2025 and is expected to reach USD 58.8 billion by 2033, with a CAGR of 12.63% from 2025 to 2033. These trends, combined with regional growth in Asia-Pacific and North America, highlight the market’s dynamic evolution and its critical role in modern industries.

Key Insights

- Embrace digital transformation: Leverage AI and IoT technologies to optimize metallurgical processes, enhance production efficiency, and reduce costs.

- Prioritize sustainability: Focus on developing eco-friendly materials and recycling practices to meet growing consumer demand for greener products and comply with environmental regulations.

- Invest in advanced testing techniques: Utilize non-destructive testing and high-precision simulations to ensure material integrity and improve product quality without incurring high costs.

- Capitalize on industry growth: Target sectors like aerospace and automotive that are driving demand for lightweight, high-performance materials, particularly in the context of electric vehicles.

- Address workforce challenges: Tackle the shortage of skilled professionals by investing in training programs and considering outsourcing to access specialized expertise.

Current Trends in the Metallurgical Engineering Services Market

Digital Transformation

Role of AI and Machine Learning

Artificial intelligence (AI) and machine learning are revolutionizing the metallurgical engineering services market. These technologies enable material selection and process optimization by analyzing vast datasets. For instance, AI algorithms can predict material behavior under various conditions, reducing trial-and-error approaches. Machine learning models also enhance production efficiency by identifying optimal processing parameters in real-time. Companies leveraging these tools report significant cost savings and improved product quality. Additionally, the rise of additive manufacturing, or 3D printing, complements AI by enabling the creation of lightweight components with complex geometries, particularly in aerospace and automotive applications.

IoT Integration in Metallurgical Processes

The integration of the Internet of Things (IoT) into metallurgical processes has transformed operational efficiency. IoT sensors collect real-time data from furnaces, smelters, and other equipment, ensuring optimal performance and quick anomaly detection. Predictive maintenance, powered by IoT, minimizes downtime and reduces maintenance costs by analyzing trends in sensor data. Furthermore, IoT devices optimize energy consumption, contributing to eco-friendly production processes. Automated production lines, enhanced by IoT, improve precision in smelting and casting, while wearable technology ensures worker safety in hazardous environments.

Sustainability in Metallurgical Engineering

Eco-Friendly Material Development

Sustainability drives innovation in metallurgy, with a focus on eco-friendly material development. Technologies that reduce energy consumption and emissions are advancing rapidly. For example, Boston Metal has pioneered a carbon-free process for producing metals and alloys. Recycling metals like aluminum and copper conserves resources and reduces energy use. Additionally, biodegradable composites and aluminum-steel hybrid materials are gaining traction, particularly in transportation, where they reduce fuel consumption and emissions. These advancements align with the growing demand for sustainable metallurgy practices.

Recycling and Circular Economy Practices

Recycling and circular economy practices are reshaping the industry. Closed-loop recycling systems for materials like copper have significantly reduced emissions and the need for new mining operations. These systems enable manufacturers to reclaim and reuse materials efficiently, minimizing waste. Ethical sourcing of raw materials and responsible supply chains further enhance sustainability efforts. Governments and industry bodies are also implementing regulations to support sustainable metallurgy, fostering compliance and improving the industry’s reputation.

Advanced Testing and Analysis Techniques

Non-Destructive Testing (NDT) Innovations

Non-destructive testing (NDT) techniques have seen remarkable advancements, ensuring the integrity of materials without causing damage. Methods like the Total Focusing Method (TFM), laser shearography, infrared thermography, and terahertz NDE are gaining prominence. These innovations enhance the accuracy and reliability of inspections, making them indispensable in industries like aerospace and construction. The integration of emerging technologies into NDT ensures its adaptability to evolving industrial needs, reinforcing its role in quality assurance.

High-Precision Metallurgical Simulations

High-precision metallurgical simulations are transforming testing and analysis. These simulations allow engineers to conduct virtual tests on materials and processes, significantly reducing the time and cost associated with physical trials. By simulating various scenarios, engineers can identify optimal processing conditions, leading to improved product quality and consistency. The ability to visualize material behavior in a virtual environment fosters rapid innovation, enabling the development of advanced alloys and composites tailored to specific industry requirements.

Rising Demand Across Industries

Growth in Aerospace and Automotive Sectors

The aerospace and automotive sectors are driving significant demand in the metallurgical engineering services market. Aerospace manufacturers increasingly rely on high-strength, lightweight alloys to enhance fuel efficiency and reduce emissions. Additive manufacturing plays a pivotal role in this sector by enabling the production of intricate geometries for aircraft components, minimizing material waste. Similarly, the automotive industry demands advanced materials to improve vehicle safety and fuel efficiency. The rise of electric vehicles further amplifies the need for innovative metallurgical solutions, particularly in battery technology and lightweight structural components.

Technological advancements such as artificial intelligence and IoT integration optimize metallurgical processes in these industries. AI enhances quality control by reducing defects, while IoT devices improve operational efficiency through real-time monitoring. Sustainability initiatives also influence these sectors. The adoption of eco-friendly materials and recycling practices aligns with consumer preferences for greener products. The circular economy model, which emphasizes reclaiming and reusing materials, reduces reliance on virgin resources and supports long-term sustainability goals.

Infrastructure Development in Emerging Economies

Emerging economies are witnessing rapid infrastructure development, creating a surge in demand for metallurgical engineering services. Countries in Asia-Pacific and Africa are investing heavily in construction projects, including bridges, railways, and urban developments. Metallurgy plays a critical role in these projects by providing durable and cost-effective materials. Steel and aluminum, for instance, are essential for constructing resilient structures capable of withstanding environmental stresses.

Engineering services outsourcing has become a strategic approach for companies in these regions to meet growing demands. Outsourcing allows firms to access specialized expertise and advanced technologies without incurring high costs. This trend supports the development of high-performance materials tailored to specific infrastructure needs. Additionally, the focus on sustainability in construction drives the adoption of recycled metals and energy-efficient production methods. These practices not only reduce environmental impact but also enhance the economic viability of large-scale projects.

Market Share Analysis in Metallurgical Engineering Services

Key Industry Players

Leading Companies and Their Innovations

The metallurgical engineering services market is dominated by several key players that drive innovation and growth. Prominent companies include:

- Vista Engineering

- Modern Group

- Stress Engineering Services, Inc

- SGS Msi

- WJE

- ASAP Metal Testing

- Colorado Metallurgical Services

- HTTE

- Eurofins

- GBM Group

In 2024, the top three vendors captured a significant portion of the market’s revenue. These companies have introduced groundbreaking technologies, such as artificial intelligence for material selection and additive manufacturing for creating lightweight components. Sustainability initiatives, including eco-friendly material development and closed-loop recycling systems, further highlight their commitment to environmental stewardship. Advanced simulation software and IoT-enabled sensors also enhance operational efficiency and product quality.

Competitive Strategies in the Market

Leading companies employ diverse strategies to maintain their competitive edge. Many leverage technological advancements like AI and machine learning to optimize services. Sustainability remains a priority, with firms adopting renewable energy and recycling practices. Strategic collaborations with research institutions accelerate innovation, while investments in R&D foster the development of high-performance materials. Companies also focus on talent development through training programs, ensuring a skilled workforce to meet industry demands.

Regional Market Contributions

Growth in North America and Europe

North America and Europe play pivotal roles in the metallurgical engineering services market. In North America, robust industrial sectors and technological advancements drive growth, particularly in the U.S. and Canada. Europe, led by countries like Germany and Sweden, emphasizes green metallurgy practices due to stringent environmental regulations. These regions benefit from strong infrastructure and a focus on innovation, ensuring steady market contributions.

Expansion in Asia-Pacific

Asia-Pacific emerges as a key growth region, fueled by rapid industrialization in countries like China and India. Significant investments in metallurgical infrastructure and engineering services outsourcing support this expansion. The region’s focus on infrastructure development, including bridges and urban projects, creates substantial demand for advanced materials and expertise. This growth positions Asia-Pacific as a critical player in the global market.

Industry Segmentation

Service Type Segmentation

The metallurgical engineering services market offers diverse services tailored to specific applications. Key service types include:

Independent materials testing ensures the quality of precious metals, while non-destructive testing focuses on base metals. Consulting services provide expert guidance for complex projects, addressing unique industry challenges.

End-Use Industry Segmentation

The market caters to various industries, each with distinct requirements:

- Aerospace: High-strength, lightweight alloys for aircraft components.

- Automotive: Advanced materials for safety and fuel efficiency.

- Energy: Materials research for renewable and nuclear energy.

- Manufacturing: Optimization of metal component production.

- Healthcare: Biocompatible materials for medical devices.

These industries rely on metallurgical engineering services to enhance performance, sustainability, and innovation.

Challenges and Opportunities in the Metallurgical Engineering Services Market

Industry Challenges

High Costs of Advanced Technologies

The adoption of advanced technologies in the metallurgical engineering services market often involves significant upfront costs. While innovations like predictive maintenance and simulation software reduce long-term expenses, the initial investment can strain budgets, especially for smaller firms. For instance, implementing additive manufacturing requires specialized equipment and training, which increases operational costs. However, these technologies enhance productivity and reduce downtime, offering long-term financial benefits.

Shortage of Skilled Professionals

The industry faces a critical shortage of skilled professionals, which affects service quality and innovation. Many companies struggle to find experts proficient in emerging technologies like AI and IoT. This talent gap slows the adoption of advanced processes and limits the industry’s ability to meet growing demand. Outsourcing has become a common strategy to address this issue, allowing firms to access specialized expertise without extensive in-house training.

Growth Opportunities

Demand for High-Performance Materials

The rising demand for lightweight and high-strength materials presents significant growth opportunities. Industries like aerospace and automotive increasingly rely on advanced alloys to improve fuel efficiency and performance. Additive manufacturing further supports this trend by enabling the creation of custom components with complex geometries. The shift toward electric vehicles also drives the need for innovative metallurgical solutions, particularly in battery technology and structural components.

Expansion of Renewable Energy Projects

Renewable energy projects are reshaping the metallurgical engineering services market. The development of wind turbines, solar panels, and energy storage systems requires specialized materials and expertise. Companies are prioritizing sustainable metallurgy practices, such as recycling scrap metals and utilizing renewable energy sources in production. These efforts align with global sustainability goals and create new opportunities for growth.

Impact of Government Policies

Support for Sustainable Practices

Governments worldwide are promoting sustainable practices to reduce environmental impact. The European Union, for example, invests heavily in green metallurgy initiatives, including hydrogen-based steelmaking. These policies encourage companies to adopt environmentally responsible methods, fostering innovation and compliance with sustainability standards.

Incentives for Technological Innovation

Many governments offer incentives to accelerate technological advancements in metallurgy. Tax breaks and grants support research and development, enabling companies to explore new materials and processes. These initiatives drive progress in areas like additive manufacturing and AI integration, ensuring the industry’s continued evolution.

The metallurgical engineering services market faces challenges like high costs and labor shortages but also benefits from opportunities in high-performance materials and renewable energy projects. Government policies further support sustainable and innovative practices, ensuring the industry’s growth and alignment with environmental responsibility.

Future Outlook for the Metallurgical Engineering Services Market

Emerging Technologies

Quantum Computing Applications in Metallurgy

Quantum computing is poised to revolutionize metallurgical engineering by solving complex problems that traditional computing cannot handle. This technology enables precise simulations of atomic interactions, which accelerates the development of advanced materials. For example, engineers can predict the behavior of alloys under extreme conditions, reducing the need for extensive physical testing. Quantum computing also enhances process optimization, ensuring efficient resource utilization and minimizing waste. As this technology matures, its integration into metallurgical processes will likely redefine industry standards.

Advancements in Additive Manufacturing

Additive manufacturing continues to reshape the metallurgical landscape by enabling the creation of intricate geometries and lightweight components. This technology supports industries like aerospace and automotive, where performance and weight reduction are critical. Engineers can now design custom components tailored to specific applications, enhancing functionality and reducing material waste. The digitalization and smart materials integration within additive manufacturing further streamline production processes, ensuring precision and sustainability. This innovation aligns with the growing demand for eco-friendly and high-performance materials.

Market Growth Projections

Expected CAGR and Revenue Trends

The metallurgical engineering services market is expected to witness robust growth from 2025 to 2033. The global market, valued at millions of dollars in 2024, is projected to grow at a significant compound annual growth rate (CAGR) during the forecast period. North America and Asia-Pacific are anticipated to lead this growth, driven by advancements in digital transformation and infrastructure development. The market for precious metal metallurgy is also expected to expand, reflecting increased demand for specialized services.

Key Drivers of Market Growth

Several factors drive the growth of the metallurgical engineering services market:

- Advanced technologies like artificial intelligence and machine learning optimize material selection and processes.

- Additive manufacturing enables the production of lightweight, complex components.

- Sustainability initiatives promote the use of recycled metals and eco-friendly practices.

- Simulation software reduces costs by enabling virtual testing of materials.

- The Internet of Things enhances operational efficiency through real-time monitoring.

These drivers highlight the industry’s focus on innovation and efficiency, ensuring sustained growth.

Shifting Consumer Demands

Customization and Quality Focus

Consumers increasingly demand customized solutions and high-quality materials. This trend drives metallurgical engineers to develop tailored alloys and components that meet specific requirements. The rise of electric vehicles exemplifies this shift, as manufacturers seek lightweight, durable materials to enhance performance. Outsourcing specialized services allows companies to meet these demands efficiently, leveraging external expertise to deliver superior results.

Demand for Durable and Sustainable Materials

The emphasis on durability and sustainability shapes the metallurgical engineering market. Engineers focus on developing materials that comply with environmental regulations while maintaining high performance. Recycling processes, such as aluminum recovery, conserve resources and reduce energy consumption. These practices align with consumer preferences for greener products, reinforcing the industry’s commitment to sustainability.

The future of metallurgical engineering services lies in embracing emerging technologies and addressing evolving consumer demands. Innovations like quantum computing and additive manufacturing will redefine industry capabilities, while sustainability and customization will remain central to market dynamics.

Overview

The metallurgical engineering services market continues to evolve, driven by digitalization, sustainability, and advanced technologies. Key players and regions contribute significantly to growth, while emerging economies unlock new opportunities. High costs and a shortage of skilled professionals present challenges, yet innovations like AI and additive manufacturing promise a bright future. Stakeholders must monitor market trends and leverage insights to remain competitive. By embracing technological advancements and sustainable practices, businesses can position themselves for long-term success in this dynamic industry.

| Report Attributes | Details |

|---|---|

| Base Year | 2024 |

| Market Size 2025 | 22.7 Billion USD |

| Market Size 2033 | 58.8 Billion USD |

| CAGR | 12.63% |

| Historical Year | 2019 – 2024 |

| Forecast Year | 2025 – 2033 |

| Report Coverage | Revenue Forecast, Market Competitive Landscape, Growth Factors, and Trends |

| Segments Covered | Type, Applications, and Region |

| Geographies Covered | North America, Europe, Asia Pacific, and the Rest of the World |

FAQ

What is the role of metallurgical engineering services in construction and engineering?

Metallurgical engineering services ensure the quality and durability of materials used in construction and engineering projects. These services optimize material performance, enabling structures to withstand environmental stresses and meet safety standards. They also support sustainable practices by promoting the use of recycled metals.

How do advanced technologies impact the metallurgical engineering services market?

Advanced technologies like AI and IoT enhance efficiency and precision in metallurgical processes. They enable real-time monitoring, predictive maintenance, and material optimization. These innovations reduce costs and improve the quality of materials used in construction and engineering applications.

Why is sustainability important in metallurgical engineering?

Sustainability addresses environmental concerns by reducing emissions and conserving resources. Metallurgical engineering services promote recycling and the development of eco-friendly materials. These efforts align with global sustainability goals and benefit industries like construction and engineering by ensuring compliance with environmental regulations.

Which industries benefit most from metallurgical engineering services?

Industries such as aerospace, automotive, energy, and construction and engineering rely heavily on metallurgical engineering services. These services provide high-performance materials, improve safety, and support innovation. For example, construction projects benefit from durable and cost-effective materials tailored to specific needs.

What challenges does the metallurgical engineering services market face?

The market faces challenges like high costs of advanced technologies and a shortage of skilled professionals. These issues slow the adoption of innovations critical to industries like construction and engineering. Outsourcing and government incentives help mitigate these challenges by providing access to expertise and financial support.

Global Metallurgical Engineering Services Market Report – Table of Contents

1 Market Study Overview

2 Basic Product Information

3 Market Analysis

4 Metallurgical Engineering Services Related Market Analysis

5 Global Trend Summary

6 Competition by Manufacturer

7 Analysis of Key Players

8 Global Metallurgical Engineering Services Revenue, Sales Categorized by Regions

9 North America Metallurgical Engineering Services Market Size Categorized by Countries

10 Europe Metallurgical Engineering Services Market Size Categorized by Countries

11 Asia-pacific Metallurgical Engineering Services Market Size Categorized by Countries

12 South America Metallurgical Engineering Services Market Size Categorized by Countries

13 Middle East and Africa Metallurgical Engineering Services Market Size Categorized by Countries

14 Global Metallurgical Engineering Services Industry Segment Analysis

15 Global Metallurgical Engineering Services Market Forecast

16 Research Findings and Conclusion

17 Appendix