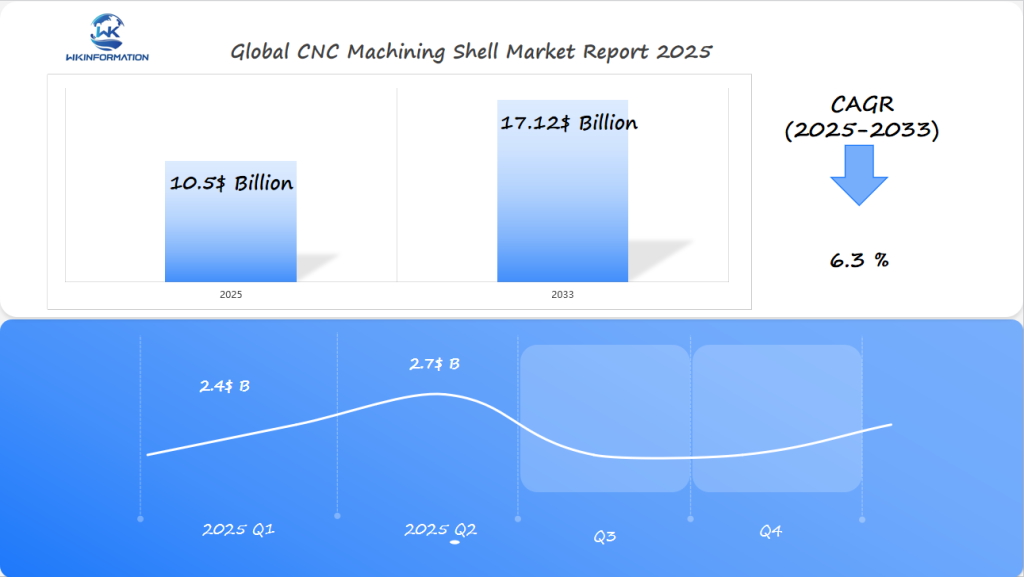

CNC Machining Shell Market Projected to Hit $10.5 Billion by 2025: Strategic Growth Across the U.S., Germany, and Japan

Discover latest trends in CNC Machining Shell Market as industry experts forecast substantial growth. Analysis covers technological advancements, key players, and market dynamics.

- Last Updated:

CNC Machining Shell Market Q1 and Q2 of 2025

The CNC Machining Shell market is projected to reach $10.5 billion by the end of 2025, with a CAGR of 6.3% from 2025 to 2033. In Q1 2025, market revenue is anticipated to be around $2.4 billion, with Q2 rising to approximately $2.7 billion as industrial production rebounds across key sectors.

Demand is being propelled by precision engineering requirements in aerospace, automotive, and consumer electronics. The U.S., Germany, and Japan dominate this space, driven by automation trends, advanced manufacturing ecosystems, and investments in high-spec machining solutions. Growth is further supported by the expansion of prototyping applications and the rising need for component standardization across industries.

Key Takeaways

- The CNC machining shell market is expected to reach $10.5 billion by 2025.

- Technological innovations are driving market expansion.

- The United States, Germany, and Japan are leading global manufacturing trends.

- Precision manufacturing is becoming increasingly critical across industries.

- Advanced CNC technologies are enabling more efficient production processes.

Upstream and Downstream Industry Chain Analysis for CNC Machining Shell

The CNC machining shell industry is a complex web of suppliers, manufacturers, and markets. It shows how upstream suppliers and downstream markets work together. This teamwork boosts innovation and economic growth.

Upstream Suppliers

Upstream suppliers are key in the CNC machining shell market. They include:

- Raw material providers specializing in metal alloys

- Precision engineering technology developers

- Advanced software and design tool manufacturers

- Cutting-edge machinery equipment suppliers

Downstream Markets

Downstream markets have a big need for CNC machining shells. The automotive industry is a big player, making up about 30% of total market demand. Other important markets are:

- Aerospace manufacturing

- Consumer electronics

- Medical device production

- Industrial machinery

| Downstream Market | Market Share (%) | Growth Potential |

| Automotive | 30% | High |

| Aerospace | 22% | Medium-High |

| Consumer Electronics | 18% | High |

| Medical Devices | 15% | Very High |

| Industrial Machinery | 15% | Medium |

The connection between upstream suppliers and downstream markets leads to new tech in CNC machining shells. Partnerships and innovation are changing the industry. They open up new chances for growth and specialization.

Key Trends Shaping the CNC Machining Shell Market in 2025

The CNC machining industry is about to undergo a significant transformation. Emerging technologies are revolutionizing the manufacturing process, making it faster and more efficient, while also creating new opportunities for creators and engineers.

In the coming years, several key trends will influence the CNC machining shell market. These trends are expected to have a substantial impact on the industry:

Technological Advancements Driving Market Growth

New technology is transforming the capabilities of CNC machines. Companies are investing heavily in advanced engineering and computer technology. This enables them to:

- Achieve greater precision and consistency in production

- Increase operational speed

- Accommodate intricate shapes

- Improve material processing techniques

Shift Towards Sustainable Manufacturing Practices

Now, making things in a green way is a big deal in CNC machining. Companies are using eco-friendly methods to cut down on harm to the environment. They keep making things well while doing it.

- Using machines that save energy

- Wasting less material

- Creating solutions that can be recycled

- Powering up with green energy

Integration of AI and Machine Learning in CNC Machines

AI and machine learning are making CNC machines smarter. Smart manufacturing lets machines learn from data. They can then improve processes and guess when they need fixing.

- Watching how things perform in real time

- Knowing when to do maintenance

- Adjusting how things are made

- Keeping quality high

These trends together are setting the CNC machining shell market up for big growth. They’re pushing innovation in manufacturing all over the world.

Market Restrictions and Structural Challenges in CNC Machining Shell Adoption

The CNC machining shell market has big hurdles to overcome. These challenges affect manufacturers in many fields. The high cost of starting up is a big problem for companies wanting to use new tech.

Some major CNC machining challenges are:

- High capital expenditure for advanced equipment

- Complex technological integration requirements

- Workforce skill development needs

- Regulatory compliance complexities

Small businesses find it hard to afford the cost of CNC machining shell tech. Many factors make it hard for this tech to be widely used.

Having the right skills is a big issue. Companies need to spend a lot on training to get people who can use these complex systems. Workforce preparedness is key to success.

Rules vary by region, making it harder to grow. Each area has its own rules, which can slow down the use of new tech. This adds to the barriers for companies.

Even with these hurdles, smart companies see the long-term gains. Those who get past these challenges can stay ahead in a tech-driven world.

Geopolitical Influences Impacting the CNC Machining Shell Supply Chain

The global CNC machining shell market is facing big challenges from complex geopolitical factors. These factors are changing how supply chains work. Trade tensions between big manufacturing countries have caused big problems in getting raw materials and making products.

Key geopolitical impacts on the CNC machining shell market include:

- Shifting trade policies affecting material procurement

- Regional manufacturing restrictions

- Strategic realignment of global supply chains

- Increased tariffs on technological components

North America, Europe, and Asia-Pacific are seeing big changes in their manufacturing. Companies are finding ways to deal with these changes. They are using different sources for materials and making products closer to where they are sold.

| Region | Supply Chain Strategy | Primary Challenge |

| North America | Nearshoring production | Technology transfer restrictions |

| Europe | Diversified supplier networks | Energy cost fluctuations |

| Asia-Pacific | Domestic manufacturing expansion | Semiconductor supply constraints |

Manufacturers are moving to adaptive supply chain models to deal with these complex issues. These models help reduce disruptions and keep companies competitive in the fast-changing CNC machining shell market.

Type-Based Segmentation and Insights in the CNC Machining Shell Industry

The CNC machining types landscape is always changing. It brings new tech to the table, changing how we make things. Market segmentation shows us how different CNC machining shells work.

Today’s manufacturing needs CNC solutions that can handle complex tasks. The industry has identified several main CNC machining types:

- Milling Machines

- Turning Centers

- Multi-Axis Machining Systems

- Hybrid Machining Platforms

Analysis of Different CNC Machining Shell Types

Each CNC type has special abilities for different needs. Precision engineering leads to new ideas. This helps manufacturers make things more efficiently.

| Machine Type | Primary Applications | Growth Projection |

| Milling Machines | Aerospace, Automotive | 7.5% Annual Growth |

| Turning Centers | Medical Devices, Electronics | 6.2% Annual Growth |

| Multi-Axis Systems | Advanced Manufacturing | 9.3% Annual Growth |

Market Share and Growth Projections by Type

Multi-axis and hybrid machines are expected to grow a lot. The trend towards multi-functional CNC machines shows the industry’s focus on tech and efficiency.

Investing in research and development keeps CNC machining moving forward. This puts manufacturers in a great spot for future tech.

Application-Oriented Analysis in the CNC Machining Shell Market

The CNC machining industry is rapidly evolving, bringing improvements to various sectors through its advanced technology. Recent developments are addressing complex production challenges across multiple industries.

CNC machining shells play a crucial role in high-quality manufacturing, offering unparalleled accuracy and efficiency.

Key Industries Driving Demand

Several key sectors are driving the demand for CNC machining:

- Aerospace: Manufacturing lightweight and durable components

- Medical Devices: Producing intricate surgical instruments

- Automotive: Fabricating intricate engine and transmission components

- Electronics: Constructing specialized semiconductor equipment

Emerging Applications and Their Impact

New uses for CNC machining shells are popping up in exciting areas, like:

- Renewable Energy: Making wind turbine parts

- Advanced Robotics: Building precise mechanical parts

- Quantum Computing: Creating special research tools

The CNC machining future looks bright. New tech keeps pushing what’s possible in making things precise.

Global Landscape and Regional Highlights for CNC Machining Shell in 2025

The global CNC machining shell market is going through big changes. Different parts of the world are changing how the industry works. North America, Europe, and Asia-Pacific are leading the way with new tech and smart investments.

Looking at the market, we see different trends in each area. The United States is ahead with its advanced making skills. New markets are also showing a lot of potential for CNC making. Each area has its own strengths:

- North America: Technological innovation and precision engineering

- Europe: Advanced manufacturing infrastructure

- Asia-Pacific: Rapid industrialization and scalable production

Manufacturing is changing, with countries like China, Germany, and the United States playing big roles. Policies, tech investments, and the economy are making each area more competitive.

Emerging markets in Southeast Asia and India are growing fast. This opens up new chances for CNC machining shell makers worldwide. Today’s making world needs smart, connected strategies for tech growth.

U.S. CNC Machining Shell Market: Precision Growth and Technological Shifts

The U.S. CNC market is leading in precision manufacturing. It’s driving big changes in many industries. The U.S. is now a top player in making CNC machining shells.

There have been big steps forward in the U.S. CNC market. These include:

- Advanced automation integration

- Enhanced digital manufacturing processes

- Increased adoption of smart manufacturing principles

- Sophisticated IoT-enabled CNC systems

Aerospace, automotive, and defense industries are seeing big benefits. They use new CNC machining tech to get better accuracy and speed.

The U.S. precision manufacturing scene is always changing. Companies are investing in research and development. They focus on:

- Reducing production cycle times

- Improving manufacturing precision

- Implementing AI-driven quality control mechanisms

- Developing more sustainable manufacturing practices

Technological advancements are changing the U.S. CNC machining shell market. They’re setting new standards for global manufacturing.

Germany's CNC Machining Shell Market: Engineering Demand and Innovation Trends

The German CNC market leads in global engineering, pushing manufacturing trends forward. Germany’s focus on precision engineering drives the growth of advanced CNC machining shells.

Key traits of Germany’s manufacturing scene include:

- Strong focus on Industry 4.0 integration

- Commitment to sustainable manufacturing practices

- Advanced technological research and development

- High-precision engineering capabilities

Investments in green tech have changed the German CNC market. Companies now use eco-friendly materials and energy-saving processes. The auto and industrial machinery sectors lead in tech advancements.

Germany’s innovations set global standards for precision and efficiency. Research centers and companies work together to create new CNC technologies. These meet complex industrial needs.

Germany’s approach to manufacturing focuses on constant improvement and digital transformation. This makes Germany a key player in the CNC machining shell market.

Japan's CNC Machining Shell Market: Domestic Manufacturing and Export Opportunities

The Japanese CNC market is a leader in global manufacturing. It uses decades of precision engineering skills. Japan’s domestic manufacturing is known for its top-notch CNC machining shell production.

Key strengths of the Japanese CNC market include:

- Cutting-edge robotics integration

- High-precision manufacturing techniques

- Robust research and development infrastructure

- Strong commitment to technological excellence

Export opportunities for Japanese CNC manufacturers have grown a lot lately. Precision engineering is a big part of Japan’s industrial success. This has made their machining technologies popular worldwide.

Japanese companies have made a big impact in Asia, North America, and Europe. They offer high-quality and innovative designs.

Strategic approaches to staying ahead in the global market include:

- Continuous technological innovation

- Investment in advanced manufacturing processes

- Developing specialized CNC machining solutions

- Expanding international partnerships

The domestic manufacturing scene in Japan is always changing. Japanese makers are working on making CNC machining more efficient, sustainable, and flexible. This keeps them at the top of the global manufacturing world.

Future Development Pathways and Technological Roadmap for CNC Machining Shell

The CNC world is changing rapidly thanks to the emergence of new technologies. Companies are finding new ways to make things more precise. Advanced technology roadmaps are changing the way we machine things.

Experts say there are a few key areas to watch:

- Artificial Intelligence Integration: Smart CNC systems are getting smarter, using machine learning to make production better

- Quantum Computing Applications: New computers are coming that will make complex calculations easier

- Hyper-Connected Manufacturing: 5G and cloud tech let us watch and control machines from anywhere

New materials and tech are making CNC machining better. Nanotechnology and advanced sensors are making things more accurate and efficient.

The next ten years will bring big changes in CNC machining. Companies that use these new ways will stay ahead in a complex world.

Competitive Positioning and Strategic Moves in the CNC Machining Shell Market

The CNC machining shell market is very competitive. Leaders like Sandvik, Kennametal, and Iscar are staying ahead by innovating. They use advanced technology and smart strategies to keep their lead.

Some key strategies in the market are:

- Investing a lot in research and development

- Forming partnerships with tech companies

- Entering new markets in emerging regions

- Creating unique products to stand out

Being at the forefront of technology is key for leaders. They are researching better and more efficient solutions for high-precision machining. Global market research shows that investments in smart manufacturing help companies grow.

Now, being strategic means more than just new products. It’s also about being green and sustainable. Companies are using eco-friendly tech and circular economy ideas to stay ahead in the CNC machining shell market.

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global CNC Machining Shell Market Report |

| Base Year | 2024 |

| Segment by Type |

· Milling Machines · Turning Centers · Multi-Axis Machining Systems · Hybrid Machining Platforms |

| Segment by Application |

· Key Industries Driving Demand · Emerging Applications and Their Impact · Others |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The CNC machining shell market is full of growth chances for investors and industry players. New technologies are changing how we make things, opening up new chances in many fields. Investing in advanced materials, precise engineering, and automated systems is key for businesses looking to grow.

New markets in the United States, Germany, and Japan are pushing CNC machining shell tech forward. There are great investment chances in software, special manufacturing uses, and green production methods. Companies that use artificial intelligence and machine learning in their CNC work will likely get ahead.

The CNC machining shell industry is set for strong growth. Areas like aerospace, cars, and medical devices will drive demand for advanced machining. Investors should watch for tech changes, rules, and new materials that could change the industry.

The next ten years will be big for CNC machining shell tech. Companies that invest in research and cutting-edge manufacturing will do well. They need to keep up with tech changes and green production to succeed in this growing field.

Global CNC Machining Shell Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: CNC Machining Shell Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- CNC Machining Shell Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global CNC Machining Shell Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: CNC Machining Shell Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: CNC Machining Shell Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: CNC Machining Shell Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of CNC Machining Shell Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market value for CNC Machining Shell by 2025?

The CNC Machining Shell Market is expected to hit $10.5 billion by 2025. This growth is fueled by new technology and a rising need for precise parts in many fields.

Which industries are the primary drivers of CNC Machining Shell demand?

The car industry is the biggest user, making up 30% of the market. Aerospace, medical devices, and electronics also drive demand. They all need CNC machining for their precise parts.

What are the key technological trends in CNC Machining Shell?

The main trends in CNC Machining Shell include:

- Artificial Intelligence (AI): AI is being used to optimize machining processes, improve quality control, and predict maintenance needs.

- Machine Learning: Machine learning algorithms are being employed to analyze large amounts of data generated during machining operations, leading to better decision-making and process improvements.

- Multi-functional CNC Machines: There is a growing demand for CNC machines that can perform multiple operations such as milling, turning, and drilling in a single setup, reducing production time and costs.

- Green Manufacturing: There is an increasing focus on sustainable manufacturing practices, with companies looking for ways to reduce energy consumption, waste generation, and carbon emissions in their CNC machining processes.

These technological advancements are making production processes more efficient, flexible, and environmentally friendly.

What challenges do manufacturers face in CNC Machining Shell adoption?

The main challenges include:

- High start-up costs

- The need for skilled workers

- Complex setup

Additionally, different rules in each area add to the challenge.

How are geopolitical factors impacting the CNC Machining Shell market?

Trade issues, tariffs, and shifting alliances have a significant impact on the CNC Machining Shell market. These factors influence the movement of goods, particularly in North America, Europe, and Asia.

Which regions are most significant in the CNC Machining Shell market?

The U.S., Germany, and Japan are key players. They offer unique strengths in tech, precision, and manufacturing.

What types of CNC machines are most in demand?

Milling, turning, and multi-axis machines are top choices. There’s growing interest in machines that can do many tasks at once.

How is sustainability influencing CNC Machining Shell development?

Makers are focusing on green practices. They’re making machines that use less energy and exploring eco-friendly ways to make things.

What emerging technologies might impact future CNC Machining Shell capabilities?

New tech like advanced materials, 5G, quantum computing, and IoT could change things. They could make CNC machines even more powerful.

Are there investment opportunities in the CNC Machining Shell market?

Yes, there are chances in software, materials research, special tech, and growing markets. These areas could see big growth.