Automotive Differential Bevel Gear Sets Market Set to Surpass $10.67 Billion by 2025: U.S., China, and Germany Lead the Charge

Explore the automotive differential bevel gear sets market analysis for 2025, with projected growth to $10.67 billion. Learn about industry trends, challenges, and opportunities across major markets including the U.S., China, and Germany, plus insights on technological innovations and competitive landscape.

- Last Updated:

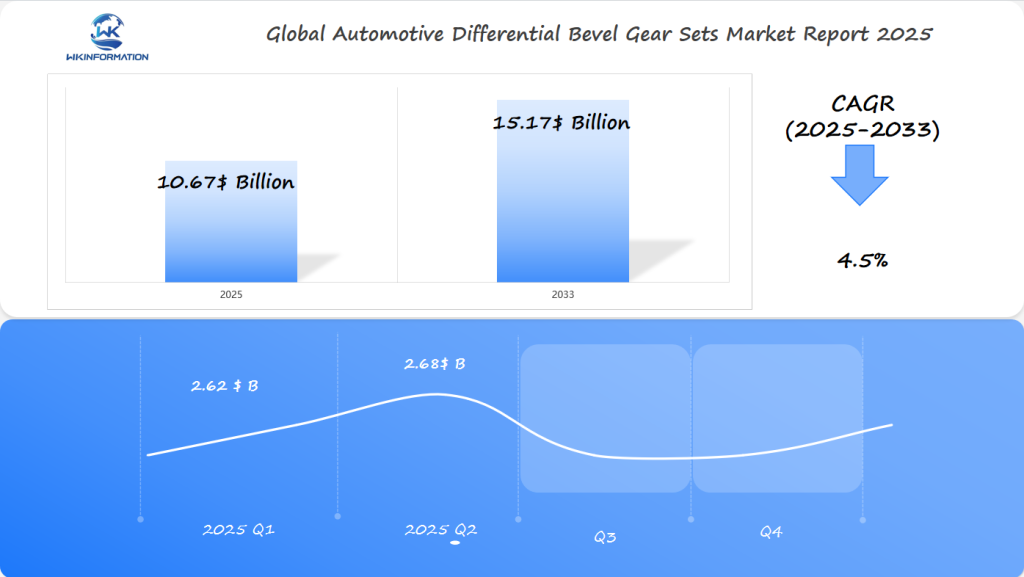

Automotive Differential Bevel Gear Sets Market Q1 and Q2 2025

The global market for automotive differential bevel gear sets is projected to reach $10.67 billion in 2025, with a CAGR of 4.5% from 2025 to 2033. Q1 2025 is expected to generate around $2.62 billion, increasing to $2.68 billion in Q2, backed by expanding vehicle production and drivetrain electrification trends.

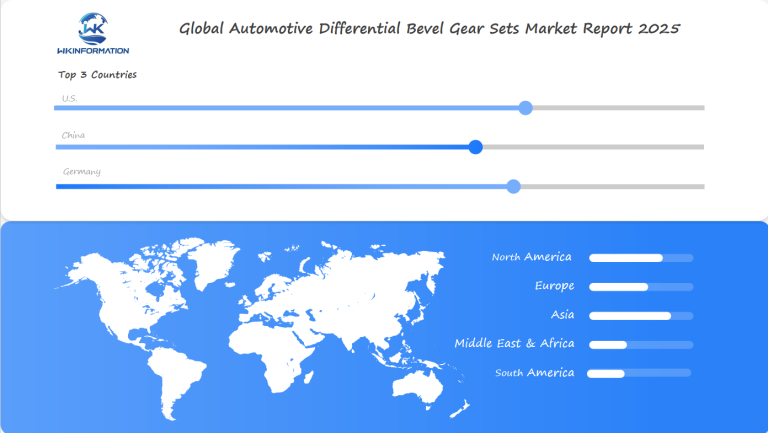

In the U.S., demand remains strong for SUVs and light trucks, with domestic manufacturers upgrading gear systems to minimize noise, vibration, and harshness (NVH). China leads in the upstream value chain, producing large quantities of bevel gear sets for both local and global automakers. Germany maintains a specialized market by manufacturing heat-treated gears with precise measurements for luxury and motorsport vehicles.

The growing complexity of electric and hybrid drivetrains requires more compact, lightweight, and efficient differential designs—leading to increased research and development investment and supply chain collaborations across different continents.

Upstream and Downstream Industry Chain Analysis of Automotive Differential Bevel Gear Sets

The automotive differential bevel gear sets industry is a complex web of processes. It turns raw materials into essential car parts. The supply chain shows how these parts improve car performance and innovation.

Upstream: The Beginning of the Process

Raw materials are the start of making differential bevel gear sets. Companies use top-quality alloy steels and special metal mixes for strength and accuracy. The early stages include:

- Metal sourcing from global suppliers

- Metallurgical testing and quality control

- Precision material selection for gear manufacturing

Downstream: The Final Steps

Making these gear sets needs a lot of technical skill. Advanced tools turn raw materials into detailed gear parts in several steps:

- Computer-aided design (CAD) modeling

- Precision casting and forging

- Heat treatment and surface finishing

- Rigorous quality assurance testing

After making, the gears are sent to car makers. Tier-1 automotive suppliers are key in linking makers with car assembly lines. They help fit these gears into many car brands and models smoothly.

Collaboration for Improvement

Working together, raw material suppliers, gear makers, and car companies push for better gear sets. This teamwork leads to constant improvement in gear technology and better car performance.

Key Trends Driving the Automotive Differential Bevel Gear Set Market Forward

The automotive world is changing fast. New market trends and tech advancements are leading the way. Electric vehicles are playing a big role in this change.

Here are the main trends pushing the market ahead:

- Growing demand for electric and hybrid vehicle powertrains

- Advanced materials making gears better and lasting longer

- Precision engineering cutting down on costs

- Lightweight gear designs becoming more popular

New tech is changing how gears are made. Engineers are working on better gear shapes. These shapes help move power more efficiently and cut down on losses.

This push for electric cars is driving research on better gears. Companies are spending a lot on making gears that can handle electric powertrains.

The future of automotive gear systems lies in innovative design and materials that support electric mobility.

What’s coming next in the gear market includes:

- Lighter gears

- Better power transfer

- Gears that last longer in electric cars

These trends show the auto industry’s dedication to new tech and green transport.

Overcoming Challenges and Restrictions in the Automotive Gear Set Industry

The automotive differential bevel gear set industry faces big challenges. These challenges test the strength of manufacturers and suppliers. Keeping up with regulatory compliance is a big pressure for companies.

Key challenges include:

- Stringent environmental regulations impacting gear manufacturing

- Rapidly evolving technological requirements

- Increasing competition from global manufacturers

- Rising production costs

Manufacturers are finding ways to deal with these issues. Innovative design techniques and new materials help meet standards. They also keep product performance high.

“The future belongs to manufacturers who can adapt quickly and efficiently to changing industry demands.” – Automotive Engineering Expert

Competition pushes the industry to get better. Companies spend a lot on research and development. They aim to make gear solutions more efficient, lightweight, and green.

By using new tech and keeping quality high, they can beat challenges.

Strategic responses to market pressures include:

- Implementing advanced manufacturing technologies

- Investing in workforce training

- Developing more sustainable production methods

- Expanding global collaboration networks

The automotive differential bevel gear set industry shows great adaptability. It faces complex regulatory and market challenges head-on.

Geopolitical Impacts on the Automotive Differential Bevel Gear Set Market

The automotive differential bevel gear set market is at a key point. Global trade policies and international market dynamics play big roles. Geopolitical tensions are changing the industry, bringing both challenges and chances for makers around the world.

Important geopolitical factors affecting the global supply chain include:

- Shifting trade regulations between major automotive manufacturing countries

- Economic sanctions affecting raw material procurement

- Strategic investments in regional manufacturing capabilities

Recent events show how complex international relations and car gear making are linked. Emerging market economies are becoming key in the global supply chain. They are challenging the usual leaders in the US, Germany, and Japan.

Strategic moves for makers of automotive differential bevel gear sets include:

- Diversifying supply chain networks

- Developing localized manufacturing strategies

- Investing in technological innovation

- Navigating complex international trade policies

The market is always changing, with politics playing a big role. This is leading to big changes in how things are made, where money is put, and who competes globally.

Types of Automotive Differential Bevel Gears and Their Market Influence

Automotive differential bevel gears are key in vehicle drivetrain systems. They come in different types, each with its own role. This variety helps meet changing performance needs and what customers want.

The main gear types in car differential systems are:

- Spiral Bevel Gears: They have curved teeth for smoother power transfer

- Straight Bevel Gears: They have straight teeth, a classic design

- Hypoid Bevel Gears: They allow for lower vehicle profiles

Choosing the right gear type is important. Luxury cars need precise gears, while more affordable cars focus on cost.

“The right differential bevel gear can significantly enhance vehicle performance and efficiency,” says automotive engineering expert Dr. Emily Rodriguez.

Manufacturers use different gears for different cars. High-performance cars need precise spiral bevel gears. Commercial trucks need strong, heavy-duty gears.

| Gear Type | Performance Characteristics | Typical Application |

| Spiral Bevel | High precision, smooth power transfer | Sports cars, luxury vehicles |

| Straight Bevel | Simple design, cost-effective | Standard passenger vehicles |

| Hypoid Bevel | Low profile, versatile mounting | SUVs, crossover vehicles |

Knowing about these gears helps engineers and makers improve car performance. They do this by focusing on the right gear for the job and understanding the market.

Applications of Differential Bevel Gear Sets in Modern Automotive Systems

Differential bevel gear sets are key in modern cars. They help improve how power is sent to the wheels. This makes driving smoother and more stable.

These gear sets are used in many types of cars:

- Passenger vehicles with rear-wheel and all-wheel drive

- Performance sports cars needing better power control

- Heavy-duty trucks and commercial vehicles

- New electric and hybrid cars

They offer several benefits:

- Better torque distribution

- Improved cornering stability

- Less mechanical friction

- Better power transfer between wheels

Car engineers keep making drivetrain systems better. They use advanced differential bevel gear sets. This leads to better power management and vehicle performance.

| Vehicle Type | Gear Set Application | Performance Impact |

| Sports Cars | High-precision differential | Enhanced cornering and acceleration |

| Electric Vehicles | Multi-axis power distribution | Improved energy efficiency |

| Commercial Trucks | Heavy-duty gear sets | Increased load-bearing capacity |

The ongoing development of differential bevel gear sets is a major breakthrough in car engineering. It boosts performance and efficiency in many types of vehicles.

Global Market Insights: Regional Overview of Automotive Gear Sets

The global market for automotive differential bevel gear sets is complex. Different regions have their own growth opportunities and market shares. These factors shape the industry’s overall picture.

Key regions show different strengths in the automotive gear set sector:

- North America leads in tech innovation

- Europe excels in precision engineering

- Asia-Pacific sees fast growth in manufacturing

Looking closely at each region, we see big differences in market reach and tech progress. The competition varies a lot between developed and new markets. This creates special chances for gear set makers.

For gear set makers, knowing the regional markets is key to growth. Each area has its own challenges and chances for success. This knowledge helps in expanding market reach and improving tech.

U.S. Market Trends and Opportunities in Automotive Differential Bevel Gears

The U.S. auto industry is changing fast in differential bevel gear tech. Making gears in the U.S. is key for better performance and efficiency. Companies are investing in automotive gear manufacturing in the U.S.

Key trends in the U.S. market include:

- Advanced manufacturing techniques

- Increased precision in gear design

- Integration of lightweight materials

- Enhanced durability and performance

Automotive trends show a big push for precision engineering. Companies are making advanced bevel gear sets. These improve vehicle transmission and cut down mechanical losses.

| Market Segment | Growth Potential | Key Drivers |

| Passenger Vehicles | High | Electric Vehicle Transitions |

| Commercial Vehicles | Medium | Fuel Efficiency Regulations |

| Performance Vehicles | Very High | Advanced Transmission Technologies |

Technological innovation is key in the U.S. automotive differential bevel gear market. Investments in research and development open new chances for U.S. makers to lead in gear tech.

The U.S. market is becoming a big player in auto gear production. Thanks to digital transformation and advanced manufacturing, U.S. makers are focusing on high-precision gear systems. These meet the needs of modern auto engineering.

China's Role in the Automotive Differential Bevel Gear Set Market

The Chinese market has become a key player in the automotive differential bevel gear set industry. China has grown from a small part to a major leader in making car parts.

China’s smart approach to making cars has put it at the top of global supply chains. The country’s exports of differential bevel gear sets have skyrocketed. This is thanks to several important factors:

- Advanced technological infrastructure

- Competitive production costs

- Significant investment in research and development

- Skilled engineering workforce

China’s manufacturing shows amazing precision and scale. Chinese makers have developed advanced ways to make high-quality differential bevel gear sets. These meet international standards.

China’s automotive component market has several key strengths:

- Rapid technological adaptation

- Scalable production capabilities

- Competitive pricing strategies

- Growing domestic automotive demand

Technological innovation is a big reason for China’s success in the automotive differential bevel gear set market. Chinese makers keep investing in the latest research. This makes them big players in global car supply chains.

China’s automotive component industry is a fast-changing world of manufacturing excellence.

The export potential of Chinese differential bevel gear sets keeps growing. More countries are recognizing their quality and reliability. Strategic partnerships and ongoing tech improvements will help China stay ahead in the global car parts market.

Germany's Contribution to the Automotive Gear Set Industry

German engineering leads in automotive technology, bringing new ideas to gear set making. The country’s car industry is a top player in Europe. It always looks for ways to improve precision and technology.

Big names like Schaeffler play a big role in making better differential bevel gears. Their focus on quality has changed the car world. They set new levels for how cars perform and use energy.

- Advanced precision manufacturing techniques

- Highly sophisticated research and development processes

- Commitment to sustainable automotive solutions

The German car tech sector is known for its focus on details and new ideas. Companies spend a lot on research. They make gear sets that make cars run better, are lighter, and use less energy.

German engineering represents the gold standard in automotive technological innovation.

German companies lead the world in making advanced gear sets for cars. They work on many areas, from old-fashioned engines to new electric cars.

Future Developments and Innovations in the Automotive Differential Bevel Gear Set Market

The market for automotive differential bevel gear sets is changing fast. New technologies are leading to big changes. We’re seeing the use of advanced materials and smart ways to make gears.

Experts predict some big changes:

- Using lightweight materials to make cars lighter

- Creating gears with super-accurate designs

- Using AI to make gears work better

New tech is changing how gears are made. Nanotechnology and advanced metallurgy are making gears last longer and work better.

“The next generation of automotive differential bevel gear sets will redefine automotive engineering performance,” says Dr. Michael Reynolds, automotive technology expert.

Companies are spending a lot on research to keep up. The future of gear sets looks bright, thanks to new tech.

Competitive Landscape: Key Players and Strategies in the Gear Set Industry

The automotive differential bevel gear set industry is very competitive. Global market leaders are fighting hard to stay on top. They need to be smart and keep innovating to keep their place in the market.

Market leaders:

1. NEWSTART MOTION INDUSTRIES LTD. —— China

2. Dayton Gear & Tool —— United States

3. The Adams Company —— United States

4. Gear Motions —— United States

5. Butler Gear Enterprises —— United States

6. Cleveland Gear Company —— United States

7. Rush Gear Inc. —— United States

8. American Precision Gear Co. —— United States

9. Circle Gear & Machine Co. —— United States

10. SDP/SI —— United States

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Automotive Differential Bevel Gear Sets Market Market Report |

| Base Year | 2024 |

| Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The automotive differential bevel gear set market is at a key point. It’s where technology meets economic growth. Market forecasts show strong growth, with big increases expected in global car making.

Investments in new gear tech are changing how cars work and how well they perform. This is making cars better and more efficient.

China and the US are leading the way with new car tech. Companies like ZF Friedrichshafen AG and Schaeffler Group are ready to take advantage of these trends. They’re focusing on semiconductors and lighter materials for the future.

Politics and the move to electric cars are changing the gear set market. New tech in making parts and more demand for green cars are opening up big chances. Keeping up with these changes will be key for success.

The future of the industry depends on innovation and green making. It also needs to be ready for new tech. Companies must stay quick to change and invest in the latest research to stay ahead.

Global Automotive Differential Bevel Gear Sets Market Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Automotive Differential Bevel Gear Sets Market Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Automotive Differential Bevel Gear Sets Market MarketSegmentation Overview

Chapter 2: Competitive Landscape

- Global Automotive Differential Bevel Gear Sets Market players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Automotive Differential Bevel Gear Sets Market Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Automotive Differential Bevel Gear Sets Market Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Automotive Differential Bevel Gear Sets Market Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Automotive Differential Bevel Gear Sets Market Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market value for automotive differential bevel gear sets by 2025?

The market for automotive differential bevel gear sets is expected to hit $10.67 billion by 2025. This growth is mainly driven by the United States, China, and Germany.

What are the main trends shaping the automotive differential bevel gear set market?

The market is changing because of:

- New gear designs

- The increase in electric and hybrid vehicles

- A rising demand for fuel-efficient technologies

What challenges does the automotive differential bevel gear set industry face?

The industry faces challenges like strict regulations, fierce competition, and the need for constant innovation to stay ahead.

How do geopolitical factors impact the automotive differential bevel gear set market?

Geopolitical factors such as trade policies, international relations, and tariffs influence the global supply chain and market dynamics for automotive gear sets.

What types of automotive differential bevel gears are available in the market?

The market offers various gear designs tailored to specific vehicle needs. These designs address unique performance requirements and vehicle applications.

How are differential bevel gear sets used in modern automotive systems?

These gear sets improve vehicle performance, handling, and drivetrain efficiency. They also play a role in electric and hybrid vehicle technologies.

Which countries are leading the automotive differential bevel gear set market?

The United States, China, and Germany lead the market growth. Each country brings unique manufacturing capabilities, technological innovations, and demand.

What future developments are expected in the automotive differential bevel gear set industry?

Future developments include advanced materials, smart manufacturing, emerging technologies, and potential disruptive innovations. These could significantly change the industry.

How competitive is the automotive differential bevel gear set market?

The market is highly competitive. It sees strategic mergers, acquisitions, partnerships, and efforts by key players to lead in growth and technology.

What role does China play in the automotive differential bevel gear set market?

China is a key player with large manufacturing capabilities, domestic market growth, and potential as a major global exporter of gear set technologies.