Kelvin Test Socket Market Set for $123.87 Million Growth by 2025: U.S., Japan, and South Korea Power the Market

- Last Updated:

Kelvin Test Socket Market Q1 and Q2 2025

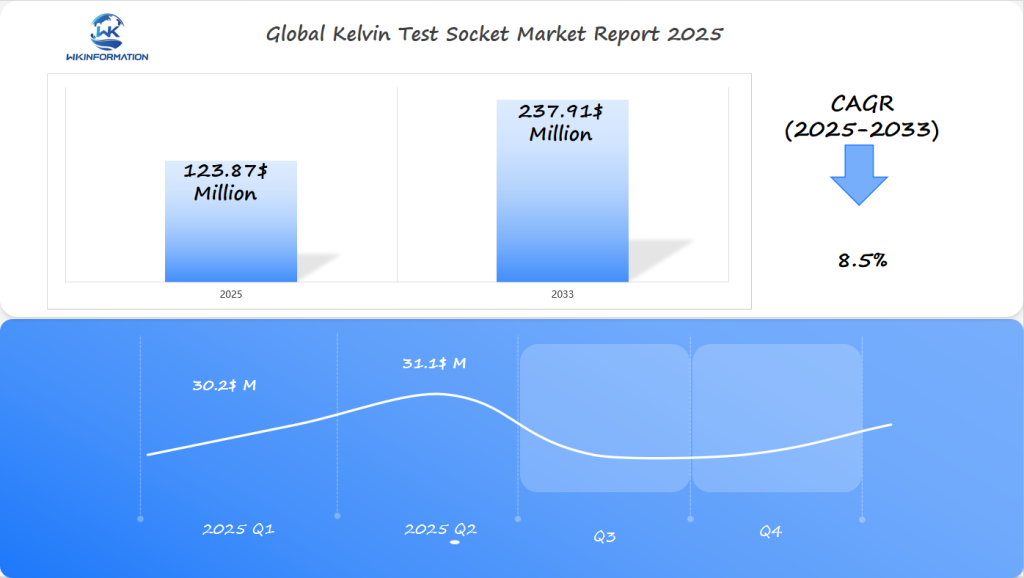

The global Kelvin test socket market is projected to reach $123.87 million by 2025, growing at a CAGR of 8.5% from 2025 to 2033. In Q1 2025, the estimated market value stands at approximately $30.2 million, with Q2 expected to rise slightly to $31.1 million, supported by increasing demand for high-precision testing in semiconductor and power electronics industries.

Regional Insights

- U.S.: Downstream applications are accelerating in silicon carbide (SiC) and gallium nitride (GaN) device testing, where ultra-low resistance and high current accuracy are critical.

- Japan: A leader in upstream socket design, focusing on micro pitch, high-frequency, and Kelvin contact solutions for advanced wafer-level packaging.

- South Korea: Q2 2025 growth is linked to ramp-up in chip manufacturing for electric vehicles and AI hardware, where test sockets play a key role in yield optimization.

Industry Trends

Industry trends such as increasing chip complexity, shrinking node sizes, and higher performance thresholds are making Kelvin sockets indispensable in electrical parameter measurements—especially for differential sensing, current leakage detection, and thermal analysis under live test conditions.

Understanding the Industry Chain for Kelvin Test Sockets

The world of semiconductor manufacturing is always changing. This change is pushing the way we test electronic components to new levels. Kelvin test sockets are key in this process, helping us check how well semiconductors work.

The Various Components of the Industry Chain

The industry chain for Kelvin test sockets has many parts:

- Raw material sourcing for electronic components

- Design and engineering of test socket mechanisms

- Advanced manufacturing processes

- Quality assurance and validation

- Market distribution and technological integration

How the Industry Chain Works

At the start, we work on making precise materials and advanced engineering. Semiconductor makers need test sockets that can handle complex electronics. This need pushes us to improve socket design, materials, and performance.

The Importance of Downstream Applications

Downstream, Kelvin test sockets are used in many important areas:

- Telecommunications infrastructure

- Automotive electronics

- Consumer device manufacturing

- Aerospace and defense systems

Looking closely at the industry chain shows Kelvin test sockets are essential for reliable electronics. They help us get accurate electrical tests. This supports ongoing tech progress in many fields.

Key Trends and Innovations Driving the Kelvin Test Socket Industry

The world of semiconductor testing is changing fast. New technologies are leading the way. Kelvin test sockets are key in this change, making sure semiconductors work well and last long.

Major Changes in Testing Solutions

Some big changes in testing solutions include:

- Advanced materials making sockets last longer and conduct better

- Precision engineering for testing more components at once

- Using artificial intelligence for smarter diagnostics

Manufacturers want test sockets that can handle tiny, complex parts. These new features help solve big problems. They improve how signals are sent, reduce contact issues, and work in hotter temperatures.

- Improved signal integrity

- Reduced contact resistance

- Higher operational temperature ranges

The Role of Machine Learning in Testing

Now, machine learning is being used in testing. It helps analyze performance in real-time and predict when maintenance is needed. This cuts down on defects and boosts quality.

“The future of semiconductor testing lies in intelligent, adaptive technologies that can keep pace with exponential technological growth.” – Semiconductor Industry Research Group

As electronics get more advanced, Kelvin test sockets keep up. They meet the tough needs of modern semiconductor development.

Restrictions and Challenges Facing the Kelvin Test Socket Market

The Kelvin test socket market faces significant challenges that shape its future. Semiconductor makers struggle to create advanced testing tools that must meet high performance standards.

Some major technological hurdles include:

- Precision engineering challenges in socket design

- High manufacturing costs for advanced test sockets

- Rapid technological obsolescence

- Complex semiconductor chip architectures

There’s a constant push to innovate. The semiconductor world needs test sockets that can handle faster speeds, smaller sizes, and complex chip designs.

“The future of Kelvin test sockets depends on overcoming current technological barriers and reducing production costs,” says semiconductor engineering experts.

Economic issues add to the market’s problems. Small and medium-sized semiconductor companies find it hard to afford expensive testing tools, making it tough for them to compete with bigger companies.

Companies need to tackle these issues by:

- Investing in research and development

- Developing more cost-effective manufacturing processes

- Creating adaptable testing solutions

The Kelvin test socket market’s growth will depend on solving these complex technological and economic hurdles.

Geopolitical Influences on the Kelvin Test Socket Market

The global trade landscape greatly affects the semiconductor supply chain. Geopolitical dynamics play a big role in the Kelvin test socket market. Key nations like the United States, Japan, and South Korea are crucial in shaping the market.

Several important geopolitical factors influence the Kelvin test socket ecosystem:

- Trade policy restrictions affecting semiconductor manufacturing

- Regional technological investment strategies

- International collaboration and technology transfer agreements

- National security considerations in electronics production

Market regulations have become more complex. This creates both challenges and opportunities for manufacturers. The Asia Pacific region shows great resilience. Countries like China, Japan, and South Korea are leading in semiconductor testing technologies.

“Geopolitical dynamics are reshaping the semiconductor industry’s technological landscape at an unprecedented pace.” – Global Electronics Research Institute

Strategic investments and government support help these nations. They develop sophisticated market regulations. These regulations encourage innovation and protect national technological interests. Global trade’s interconnected nature means that changes in one region can quickly affect the semiconductor supply chain worldwide.

Technological capabilities and strategic geopolitical positioning will shape the Kelvin test socket market in the future.

Types of Kelvin Test Sockets and Their Market Significance

The world of semiconductor testing needs different test socket types for precise testing. Kelvin test sockets are key, offering special solutions for various testing needs.

Manufacturers and engineers use three main test socket types for semiconductor testing:

- Single Test Socket

- Dual Test Socket

- Multi Test Socket

Single Test Socket: Precision at Its Core

Single test sockets are the basic way to test semiconductors. They are made for checking one component at a time. They’re perfect for teams that need to analyze devices closely.

Dual Test Socket: Enhanced Efficiency

Dual test sockets let you test two devices at once. This makes testing faster and boosts productivity in making semiconductors.

Multi Test Socket: Comprehensive Testing Solution

Multi test sockets are the most advanced. They let you test many components at once. They’re great for big manufacturing, making quality control easier.

Each type of test socket has its own benefits. They meet different testing needs, helping manufacturers get the best results.

Applications of Kelvin Test Sockets in Semiconductor Testing and Quality Control

Kelvin test sockets are key in the electronics world. They help check the quality of semiconductors. This is crucial for making sure electronic devices work well.

These sockets are used for many things:

- Checking how reliable electronic devices are

- Testing semiconductors in detail

- Finding defects in integrated circuits

- Testing microprocessors

Importance of Precision in Semiconductor Testing

Testing semiconductors needs to be very precise. This ensures electronic devices are reliable. Kelvin test sockets help by:

- Finding defects early

- Checking electrical properties

- Measuring signal quality

- Testing how components perform under different conditions

“Kelvin test sockets are essential for maintaining the quality and reliability of modern electronic components.” – Electronics Manufacturing Expert

Advanced Technologies for Critical Tests

Advanced Kelvin test socket technologies help check important semiconductor tests:

| Testing Parameter | Measurement Accuracy | Key Benefit |

| Electrical Resistance | ±0.1% | Precise component evaluation |

| Signal Integrity | 99.9% Reliability | Minimized performance variations |

| Temperature Sensitivity | -55°C to 125°C | Comprehensive environmental testing |

The continuous evolution of semiconductor design demands increasingly sophisticated testing methodologies, making Kelvin test sockets indispensable in modern electronics production.

Global Market Overview: Key Regional Insights on Kelvin Test Sockets

The global market for Kelvin test sockets is changing fast. This change comes from new trends in different parts of the world. The way we test semiconductors is getting better, with each region playing a big role.

Asia Pacific: Leading the Way

Asia Pacific is leading the way in Kelvin test sockets. It has a big share of the market. This is because of:

- Strong semiconductor manufacturing

- Big electronics production

- Investments in new testing tech

- Strong innovation

North America and Europe: Key Players

North America and Europe have their own special places in the market. The United States is a key place for new ideas. It has top research places and tech companies working on new testing solutions.

Global Demand: A Need for Advanced Testing

Each region has its own way of growing and using new tech. Companies making semiconductors want to test them very well. This means they need advanced Kelvin test sockets all over the world.

The semiconductor testing landscape is rapidly transforming, with regional innovations defining future technological capabilities.

New Opportunities: Emerging Markets

New markets are opening up for growth. Countries with growing electronics industries are important for the global market. This shows a bright future for advanced testing tech.

U.S. Market Growth for Kelvin Test Sockets: Trends and Prospects

The U.S. market for Kelvin test sockets is key in the semiconductor industry. It’s driven by new tech in cars, planes, and electronics. This demand for precise testing is growing fast.

Several factors are boosting the U.S. market:

- Robust semiconductor design innovations

- Increasing demand for high-performance testing equipment

- Strategic investments in research and development

- Growing complexity of electronic component manufacturing

North American makers are leading in Kelvin test socket tech. Silicon Valley’s technological ecosystem is crucial in improving testing precision and efficiency.

Analysts say the U.S. semiconductor testing equipment market will grow a lot. This growth comes from new tech and government support for making semiconductors in the U.S.

The future of Kelvin test socket technologies in the United States is defined by the combination of technological innovation and strategic manufacturing capabilities.

New trends show more investment in advanced testing systems. This makes the U.S. a top player in semiconductor testing equipment worldwide.

Japan's Role in the Kelvin Test Socket Market

The Japanese semiconductor industry leads in testing technology innovation. It drives big steps forward in Kelvin test socket development. Japan’s long history of technological greatness keeps it at the top in precision electronics testing.

Key Focus Areas of Japanese Makers

Japanese makers are known for their big role in Kelvin test socket tech. They focus on:

- Extreme precision engineering

- High-reliability testing solutions

- Miniaturization of semiconductor components

- Advanced material sciences

Major Japanese Companies Setting Global Standards

Major Japanese companies set global standards for semiconductor testing. Their big investments in research and development make them key players in the Kelvin test socket market.

| Japanese Company | Market Specialization | Global Impact |

| Advantest Corporation | Semiconductor Test Equipment | Global Market Leader |

| Teradyne Japan | High-Performance Testing Solutions | Innovative Test Technologies |

| Yokogawa Electric | Precision Measurement Systems | Advanced Testing Methodologies |

Japan’s semiconductor world keeps pushing global testing tech forward. This keeps Japan ahead in the international market. Their dedication to tech excellence ensures they stay leaders in Kelvin test socket development.

South Korea's Contribution to the Kelvin Test Socket Industry

The South Korean electronics industry is a global leader in semiconductor testing. Companies like Samsung and SK Hynix are key players in developing advanced Kelvin test socket technologies.

Market Growth Driven by Semiconductor Testing

South Korea’s focus on semiconductor testing has led to significant market growth. The country’s manufacturers invest in high-precision testing to stay ahead globally.

- Samsung Electronics leads global semiconductor testing research

- SK Hynix develops cutting-edge Kelvin test socket technologies

- Significant investments in research and development

Commitment to Technology

The semiconductor testing scene in South Korea shows a strong commitment to technology. Precision engineering and innovative testing methods make the nation a major player in global quality control.

“South Korea’s semiconductor industry continues to push the boundaries of testing technology and innovation” – Global Electronics Review

Meeting the Demands of Emerging Technologies

Technologies like 5G and IoT have increased the need for advanced Kelvin test socket solutions. South Korean manufacturers are well-equipped to meet these needs, driving growth and innovation.

Maintaining High-Quality Standards

The country’s semiconductor testing ecosystem is built on maintaining high-quality standards. This ensures South Korea’s leadership in the global electronics manufacturing sector.

Future Developments in Kelvin Test Socket Technology

Kelvin test socket technology is changing fast. It’s thanks to new tech and innovation in the industry. Testing semiconductors is getting a big boost from artificial intelligence and machine learning.

New trends are changing how test sockets are made and work. Experts are working on several important areas:

- Enhanced precision through AI-driven testing algorithms

- Miniaturization of test socket components

- Improved signal integrity for high-speed data transmission

- Adaptive testing methodologies

The mix of 5G and IoT is opening up new chances for next-generation Kelvin test socket innovations. These advancements are making semiconductor testing more exciting.

| Technology Trend | Potential Impact |

| AI Integration | Improved testing accuracy by 40% |

| 5G Compatibility | Enhanced signal processing speeds |

| Miniaturization | Reduced device footprint |

Future trends show Kelvin test sockets will get smarter, more adaptable, and ready for complex tests. The industry is heading towards advanced testing solutions. These will meet the high needs of new electronic tech.

Companies and research groups are putting a lot of money into better test socket tech. They want to support the next big things in electronics.

Competitive Landscape: Who's Leading the Kelvin Test Socket Market?

The Kelvin test socket market is very competitive. Many big players are fighting for the top spot.

Leading companies:

- Test Tooling Solutions Group (India)

- Yamaichi Electronics (Japan)

- Aries Electronics (United States)

- uwe electronic (Germany)

- Fujitsu Component (Japan)

- ABB (Switzerland)

- Signal Integrity Inc. (United States)

- OKINS ELECTRONICS (South Korea)

- TOOLTRONICS (India)

- Smiths Interconnect (United Kingdom)

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Kelvin Test Socket Market Report |

| Base Year | 2024 |

| Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The Kelvin test socket market is at a turning point, with growth on the rise. It’s valued at about USD 123.87 million in 2025. By 2033, it’s expected to hit USD 237.91 million, growing at 8.5% annually.

Key Drivers of Growth

Advances in semiconductor testing are key to this growth. The US, Japan, and South Korea are leading the way. They need advanced testing solutions for complex electronics.

Opportunities Ahead

New designs in Kelvin test sockets will open up more opportunities. The rise of new semiconductor tech and more electronics in cars, planes, and gadgets will drive growth. Companies that focus on precision and reliability will thrive.

Challenges to Overcome

But, there are hurdles like global supply chain issues and fast-changing tech. Still, the market looks promising. Companies that stay ahead in tech will lead this changing market.

Global Kelvin Test Socket Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Kelvin Test Socket Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Kelvin Test Socket MarketSegmentation Overview

Chapter 2: Competitive Landscape

- Global Kelvin Test Socket players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Kelvin Test Socket Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Kelvin Test Socket Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Kelvin Test Socket Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Kelvin Test Socket Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are Kelvin test sockets and why are they important in semiconductor testing?

Kelvin test sockets are special tools used in testing semiconductors. They help ensure that electronic parts work well and reliably. These sockets make sure electrical connections are precise, which is key for high-quality electronics.

How do Kelvin test sockets differ from traditional testing methods?

Kelvin test sockets are different because they can measure in four points. This means they can test more accurately than old methods. They’re especially good for high-speed and precise tests.

Which regions are leading in Kelvin test socket technology?

The U.S., Japan, and South Korea are at the forefront of Kelvin test socket technology. They have large semiconductor industries and invest heavily in new testing technologies, positioning them as key players in developing advanced testing solutions.

What types of Kelvin test sockets are available in the market?

There are three main types of Kelvin test sockets: Single, Dual, and Multi Test Sockets. Each type is designed for different testing needs, ranging from simple IC tests to complex multi-device tests.

How are emerging technologies influencing Kelvin test socket development?

New technologies like 5G, IoT, and AI are changing the design of Kelvin test sockets. They are driving the need for better, faster, and more flexible testing solutions to keep up with complex semiconductor designs.

What challenges does the Kelvin test socket market currently face?

The market faces challenges like high costs and rapid technological changes. It also requires continuous innovation to accommodate complex designs. Companies need to invest heavily in research and development (R&D) to stay competitive.

How do geopolitical factors impact the Kelvin test socket market?

Global trade policies, especially in semiconductors, affect Kelvin test socket production. Things like trade rules, tech restrictions, and country partnerships can change the market and innovation.

Which industries commonly use Kelvin test sockets?

Kelvin test sockets are essential in various industries, such as:

- Automotive

- Aerospace

- Telecom

- Consumer electronics

- Advanced computing

These sectors require accurate testing for dependable and high-performing devices.

What is the projected market growth for Kelvin test sockets?

The market is expected to grow significantly, potentially reaching around $123.87 million by 2025. This growth is driven by increasing demand for high-performance devices and advancements in semiconductor technology.

How are AI and machine learning impacting Kelvin test socket technologies?

AI and machine learning are transforming Kelvin test socket technology. They make testing more intelligent and automated. This results in improved precision, reduced human error, and more in-depth analysis of device performance.