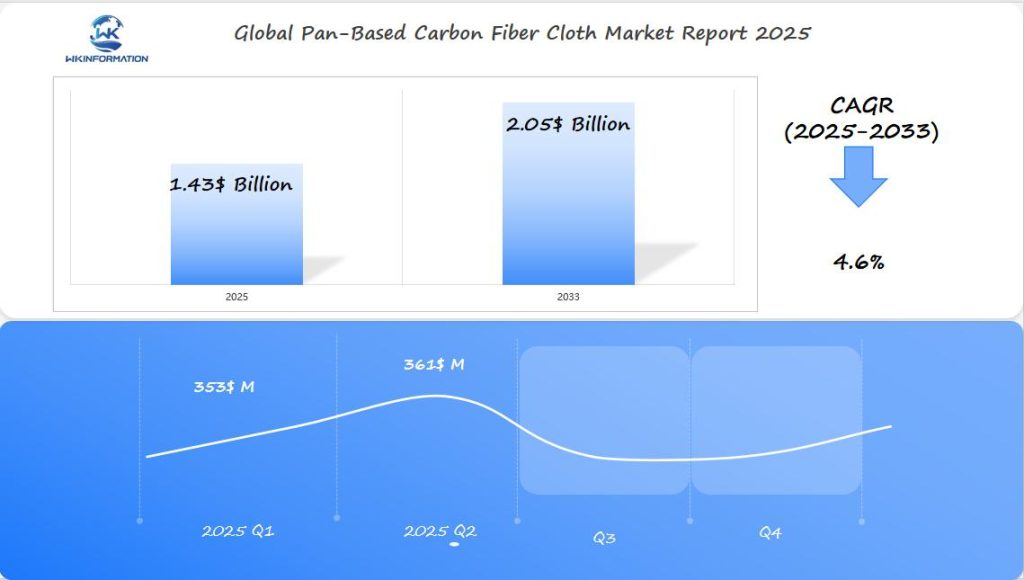

Pan-Based Carbon Fiber Cloth Market to Reach $1.43 Billion by 2025: Key Insights from the U.S., Japan, and Germany

The Pan-Based Carbon Fiber Cloth Market is projected to reach $1.43 billion by 2025. The market is driven by the growing need for lightweight, high-strength materials across industries such as automotive, aerospace, and construction.

- Last Updated:

Pan-Based Carbon Fiber Cloth Market in Q1 and Q2 of 2025

The Pan-Based Carbon Fiber Cloth market is on track to hit $1.43 billion in 2025, expanding at a CAGR of 4.6% through 2033.

In Q1 2025, the market value is projected at $353 million, increasing to nearly $361 million in Q2 due to heightened adoption in aerospace, energy, and industrial sectors.

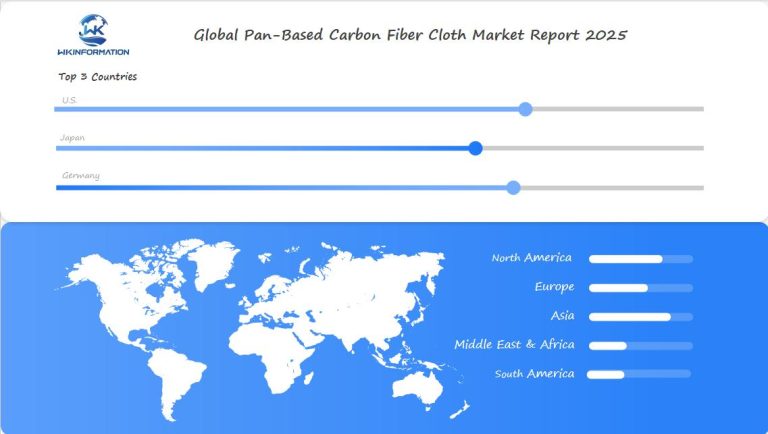

The U.S. leads in defense and aerospace applications, using the material for lightweight, high-strength structural components. In Japan, technological refinement and premium-grade carbon fiber production continue to drive domestic and export demand. Germany is focusing on automotive and wind energy applications, leveraging its advanced composites industry.

Analysis of the Upstream and Downstream Industry Chain in the Pan-Based Carbon Fiber Cloth Market

The industry chain of the Pan-Based Carbon Fiber Cloth market is a complex structure that involves various stakeholders, from raw material suppliers to end-users.

Analyzing the industry chain is important for understanding the market dynamics and identifying opportunities for growth.

Upstream Industry Analysis

The upstream industry includes raw material suppliers, who play a vital role in determining the quality and cost of the final product.

Raw Material Suppliers

The raw material suppliers provide the necessary materials for the production of Pan-Based Carbon Fiber Cloth.

The key raw materials used in the production of Pan-Based Carbon Fiber Cloth include:

- Polyacrylonitrile (PAN)

- Pitch

- Other specialty chemicals

The quality and cost of these raw materials have a significant impact on the final product.

A detailed analysis of the upstream industry reveals the importance of raw material suppliers in the Pan-Based Carbon Fiber Cloth market.

Understanding the upstream industry is essential for manufacturers to ensure a stable supply chain and maintain competitiveness in the global carbon fiber cloth market.

Emerging Trends in the Pan-Based Carbon Fiber Cloth Market in 2025

Emerging trends in the Pan-Based Carbon Fiber Cloth market are set to redefine the landscape in 2025, with a focus on sustainability and innovative applications. The market is expected to witness significant growth due to the increasing adoption of carbon fiber cloth in various industries.

Trends in Production and Consumption

The production of Pan-Based Carbon Fiber Cloth is undergoing a significant transformation, driven by advancements in technology and the need for more sustainable manufacturing processes. Some of the key trends include:

- Increased use of recycled materials in production

- Adoption of more energy-efficient manufacturing technologies

- Growing demand for high-performance carbon fiber cloth in aerospace and automotive applications

On the consumption side, the demand for Pan-Based Carbon Fiber Cloth is expected to rise across various industries, including:

- Aerospace, where it is used for lightweight, high-strength components

- Automotive, for the production of electric vehicles and high-performance parts

- Construction, for reinforcing buildings and infrastructure projects

These trends are expected to drive the growth of the Pan-Based Carbon Fiber Cloth market in 2025, with a focus on sustainability and innovation.

Challenges in the Production and Sourcing of Pan-Based Carbon Fiber Cloth

Despite its growing demand, the Pan-Based Carbon Fiber Cloth market is facing significant production and sourcing challenges. The industry is dealing with obstacles that affect the overall market dynamics and its ability to meet the increasing demand from various sectors such as aerospace, automotive, and construction.

Production Challenges

The production of Pan-Based Carbon Fiber Cloth is a complex process that involves several stages, from precursor production to the final carbonization process. High production costs are a significant challenge, primarily due to the expensive raw materials and the energy-intensive nature of the manufacturing process.

Complex manufacturing processes also pose a challenge. The production requires precise control over various parameters to ensure the quality of the final product. Any deviation in the process can lead to defects, thereby increasing the cost and reducing the efficiency of production.

Quality control is another critical issue. Ensuring consistent quality in the production of Pan-Based Carbon Fiber Cloth is challenging due to the variability in raw materials and the intricacies of the manufacturing process.

Sourcing Challenges

Sourcing high-quality Pan-Based Carbon Fiber Cloth is fraught with challenges. One of the primary issues is finding reliable suppliers who can consistently deliver high-quality materials. The variability in supplier quality can significantly impact the final product’s performance and reliability.

Managing lead times is another sourcing challenge. The production of Pan-Based Carbon Fiber Cloth involves a lengthy process, and any delays in sourcing raw materials or in the manufacturing process can lead to significant delays in delivery.

Ensuring consistent quality in the sourced materials is also crucial. Any inconsistency can affect the performance of the final product, leading to potential failures and increased maintenance costs.

The Pan-Based Carbon Fiber Cloth market faces significant challenges in both production and sourcing. Addressing these challenges is crucial for the sustainable growth of the industry and for meeting the increasing demand from various sectors.

Geopolitical Impact on the Global Supply of Pan-Based Carbon Fiber Cloth

The global supply of Pan-Based Carbon Fiber Cloth is significantly influenced by geopolitical factors. These factors can disrupt the production and distribution of this critical material, affecting various industries that rely on it.

Trade policies and tariffs are among the key geopolitical elements that impact the Pan-Based Carbon Fiber Cloth market. Countries imposing tariffs on imported carbon fiber cloth can alter the competitive landscape, making it challenging for manufacturers to maintain their market share.

Trade Policies and Tariffs

Trade policies can either help or hinder the growth of the global carbon fiber cloth market. For example, tariffs imposed on carbon fiber imports can increase production costs for manufacturers, potentially leading to higher prices for end-users.

The impact of trade policies on the Pan-Based Carbon Fiber Cloth market can be seen in the following table:

| Country | Trade Policy | Impact on Market |

| United States | Tariffs on imported carbon fiber | Increased production costs |

| China | Subsidies for domestic producers | Increased competition for global manufacturers |

| European Union | Regulatory standards for carbon fiber imports | Compliance costs for manufacturers |

The geopolitical impact on the global supply of Pan-Based Carbon Fiber Cloth is complex, involving various factors that can affect market dynamics. Manufacturers must navigate these complexities to stay competitive in the global market.

As the global demand for Pan-Based Carbon Fiber Cloth continues to grow, understanding the geopolitical factors at play will be crucial for stakeholders in the industry. By staying informed about trade policies and tariffs, manufacturers can better anticipate and respond to changes in the market.

Type Segmentation: Prepreg vs. Woven Pan-Based Carbon Fiber Cloth

The Pan-Based Carbon Fiber Cloth market is divided into two main types: prepreg and woven carbon fiber cloth, each with its own unique features and uses. It’s important for manufacturers and end-users to understand these types in order to make informed choices.

Prepreg Carbon Fiber Cloth

The Pan-Based Carbon Fiber Cloth market is primarily categorized into prepreg and woven carbon fiber cloth. Prepreg carbon fiber cloth is pre-impregnated with a resin system, ready for curing, which simplifies the manufacturing process for composite parts.

Advantages of Prepreg Carbon Fiber Cloth:

- Uniform resin distribution

- Simplified manufacturing process

- High-quality finish

Woven Carbon Fiber Cloth

Woven carbon fiber cloth, on the other hand, offers flexibility in terms of resin selection and application. It is used in various industries, including aerospace, automotive, and construction.

The characteristics of woven carbon fiber cloth include:

- Flexibility in resin choice

- Suitable for complex geometries

- Cost-effective for certain applications

| Characteristics | Prepreg Carbon Fiber Cloth | Woven Carbon Fiber Cloth |

| Resin Impregnation | Pre-impregnated | User-impregnated |

| Manufacturing Complexity | Low | Moderate to High |

| Application Flexibility | Limited | High |

By understanding the differences between prepreg and woven carbon fiber cloth, manufacturers can better cater to the needs of various industries. The choice between these types depends on the specific requirements of the application, including performance, cost, and manufacturing complexity.

Applications for Pan-Based Carbon Fiber Cloth in Aerospace, Automotive, and Construction

The versatility of pan-based carbon fiber cloth has led to its adoption in various industries, including aerospace, automotive, and construction. Its unique combination of high strength, low weight, and resistance to fatigue makes it an ideal material for applications where performance and durability are critical.

Aerospace Applications

In the aerospace industry, pan-based carbon fiber cloth is used extensively in the manufacture of aircraft components, such as wings, fuselage, and control surfaces. The use of carbon fiber cloth in aerospace applications provides significant weight reduction, leading to improved fuel efficiency and reduced emissions. Additionally, its high resistance to fatigue and damage tolerance enhances the safety and reliability of aircraft.

The benefits of using pan-based carbon fiber cloth in aerospace are multifaceted. It not only contributes to the overall performance of the aircraft but also plays a crucial role in reducing maintenance costs over the aircraft’s lifespan.

Automotive Applications

In the automotive sector, carbon fiber cloth is increasingly being used to produce lightweight vehicle components, such as body panels, chassis parts, and interior trim. The reduction in vehicle weight achieved through the use of carbon fiber cloth can significantly improve fuel efficiency and reduce CO2 emissions. Moreover, its high strength and stiffness enhance vehicle performance and safety.

Several automotive manufacturers are now incorporating pan-based carbon fiber cloth into their production models, driven by the need to meet stringent emissions regulations and consumer demand for more efficient vehicles.

Construction Applications

The construction industry is also beginning to adopt pan-based carbon fiber cloth for various applications, including the strengthening and repair of structures. Its high tensile strength and durability make it an effective material for reinforcing concrete and masonry structures, extending their lifespan and reducing maintenance needs.

The use of carbon fiber cloth in construction can also contribute to the development of more sustainable and resilient infrastructure, capable of withstanding natural disasters and other external stresses.

Global Market Overview: Regional Insights into Pan-Based Carbon Fiber Cloth Demand

The global pan-based carbon fiber cloth market is evolving as the demand for lightweight and high-strength materials increases. Various regions are driving the market, each with its own characteristics and growth factors.

Regional Market Analysis

The global carbon fiber cloth market is divided into several regions: North America, Europe, Asia-Pacific, and the Rest of the World. Each region has its own factors affecting the market, such as industrial growth, technological advancements, and regulatory policies.

North America

North America is a significant market for pan-based carbon fiber cloth, driven by the aerospace and defense industries. The region is home to several major manufacturers and consumers of carbon fiber cloth.

Europe

Europe is another key market, with countries like Germany and France leading the way in the adoption of carbon fiber cloth in automotive and aerospace applications.

Asia-Pacific

Asia-Pacific is expected to experience the highest growth rate, driven by the expanding aerospace and automotive industries in countries like China, Japan, and South Korea.

The regional market analysis shows that different regions are experiencing growth at different rates. Companies operating in the pan-based carbon fiber cloth market need to understand these regional factors in order to take advantage of new opportunities.

U.S. Market Analysis: Growth in the Use of Pan-Based Carbon Fiber Cloth for Aviation

The U.S. aviation industry is increasingly using pan-based carbon fiber cloth due to the growing demand for lightweight and high-strength materials. This change is motivated by the desire for better fuel efficiency, lower emissions, and improved aircraft performance.

Aviation Applications in the U.S. Market

Pan-based carbon fiber cloth is increasingly being used in aviation due to its exceptional strength-to-weight ratio and resistance to fatigue. This material is becoming more popular among aircraft manufacturers as they strive for greater sustainability and efficiency in air travel.

Market Growth Potential

The market for pan-based carbon fiber cloth in the U.S. aviation sector is expected to grow significantly over the next few years. Key factors driving this growth include:

- Increasing demand for commercial aircraft

- Advancements in carbon fiber technology

- Government regulations promoting fuel efficiency and reduced emissions

The U.S. market for pan-based carbon fiber cloth in aviation is expected to grow significantly, driven by technological advancements and regulatory pressures. As the industry continues to evolve, the demand for high-performance materials like pan-based carbon fiber cloth is expected to rise.

Japan’s Leadership in Carbon Fiber Cloth Manufacturing and Innovation

Japan’s leadership in carbon fiber cloth manufacturing is a result of decades of innovation and investment. The country’s expertise in producing high-quality carbon fiber cloth has enabled it to become a significant player in the global market.

Japan carbon fiber cloth market

The Japanese carbon fiber cloth industry has been at the forefront of technological advancements, with companies investing heavily in research and development. This has led to the creation of innovative products that cater to various industries, including aerospace, automotive, and construction. These advancements are reflected in the increasing demand for carbon fiber cloth across these sectors.

Japan’s Carbon Fiber Cloth Industry

Japan’s carbon fiber cloth industry is known for its large production capacity and technological expertise. The country’s manufacturers have developed advanced production methods that allow them to create high-quality carbon fiber cloth with exact specifications.

Some of the key factors that contribute to Japan’s leadership in the carbon fiber cloth market include:

- Significant investment in research and development

- Advanced production technologies

- High-quality raw materials

- A skilled workforce with expertise in carbon fiber production

The pan-based carbon fiber cloth manufacturing process in Japan is highly sophisticated, involving the use of advanced machinery and strict quality control measures. This ensures that the final product meets the required standards for various applications.

As a result of its leadership in carbon fiber cloth manufacturing, Japan has become a key player in the global market, with its products being exported to various countries around the world.

Germany’s Role in High-Performance Pan-Based Carbon Fiber Cloth Production

Germany is well-positioned to lead the global high-performance Pan-Based Carbon Fiber Cloth market with its advanced manufacturing capabilities. The country’s strong focus on research and development, combined with its expertise in producing high-quality carbon fiber products, has enabled it to gain a significant share in the global market.

Germany’s high-performance carbon fiber cloth industry is driven by its robust automotive and aerospace sectors, which demand high-quality materials for various applications. The industry’s growth is further supported by the government’s initiatives to promote the use of advanced materials in manufacturing.

Germany’s High-Performance Carbon Fiber Cloth Industry

Germany’s high-performance carbon fiber cloth industry is known for its large production capacity and advanced technology. The country has several top manufacturers of carbon fiber cloth who are investing heavily in research and development to improve product quality and lower production costs.

The growth of Germany’s high-performance carbon fiber cloth industry is expected to continue in the coming years, driven by increasing demand from various end-use industries. The industry’s focus on technological innovation and quality improvement will be key to its success in the global market.

Future Outlook: Technological Innovations and Sustainability in Pan-Based Carbon Fiber Cloth

The future of the Pan-Based Carbon Fiber Cloth market is expected to be shaped by groundbreaking technological innovations and a shift towards sustainability. The industry is on the verge of a significant transformation, driven by the need for materials that are not only high-performance but also environmentally friendly.

Advancements in Production Technology

The future of Pan-Based Carbon Fiber Cloth is closely tied to advancements in production technology. Innovations such as rapid manufacturing processes and the development of new precursor materials are expected to play a crucial role in shaping the market. These advancements will not only improve the quality and consistency of carbon fiber cloth but also reduce production costs, making it more accessible to a wider range of industries.

One of the key areas of focus for future technological innovations is the development of more efficient manufacturing processes. This includes the use of automated production lines and advanced quality control systems, which can significantly enhance productivity and reduce waste.

Sustainability Initiatives

Sustainability is becoming an increasingly important consideration in the Pan-Based Carbon Fiber Cloth market. Manufacturers are exploring new ways to reduce the environmental impact of their products, from developing recyclable carbon fiber materials to implementing more energy-efficient production processes.

- Development of recyclable carbon fiber materials

- Implementation of energy-efficient production processes

- Use of sustainable precursor materials

These sustainability initiatives are not only beneficial for the environment but also offer manufacturers a competitive edge in a market that is increasingly driven by environmental considerations.

Competitive Landscape: Key Market Players and Trends in Pan-Based Carbon Fiber Cloth

As the demand for Pan-Based Carbon Fiber Cloth continues to grow, the competitive landscape is becoming increasingly dynamic. This section will provide an in-depth analysis of the key market players and trends shaping the industry.

Key Market Players:

-

TORAY INDUSTRIES, INC – Japan

-

VARTEST LABORATORIES INC. – USA

-

SGL Carbon – Germany

-

Mitsubishi Chemical Corporation – Japan

-

AKSA – Turkey

-

Taekwang – South Korea

-

Montefibre – Italy

-

Teijin Limited – Japan

-

Hexcel Corporation – USA

-

Solvay S.A – Belgium

Overall

| Report Metric | Details |

|---|---|

| Report Name | Pan-Based Carbon Fiber Cloth Market |

| Base Year | 2024 |

|

Segment by Type |

· Prepreg Carbon Fiber Cloth · Woven Carbon Fiber Cloth |

| Segment by Application |

· Aerospace · Automotive · Construction |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

A pan-based carbon fiber cloth market summary highlights the key trends and insights that will shape the industry’s future. The market is expected to reach $1.43 billion by 2025, driven by the growing adoption of carbon fiber cloth in various applications.

A closer look at the carbon fiber cloth market overview reveals a competitive landscape dominated by key players from the U.S., Japan, and Germany. These countries are at the forefront of innovation and manufacturing, driving the market forward with their cutting-edge technologies and high-quality products.

As the market continues to evolve, market insights suggest that sustainability and technological advancements will play a crucial role in shaping the industry’s future. Companies that invest in research and development, adopt sustainable practices, and respond to changing consumer demands are likely to thrive in this dynamic market.

Global Pan-Based Carbon Fiber Cloth Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Pan-Based Carbon Fiber Cloth Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Pan-Based Carbon Fiber ClothMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Pan-Based Carbon Fiber ClothPlayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Pan-Based Carbon Fiber Cloth Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Pan-Based Carbon Fiber Cloth Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Pan-Based Carbon Fiber Cloth Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Pan-Based Carbon Fiber ClothMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the expected size of the Pan-Based Carbon Fiber Cloth market by 2025?

The Pan-Based Carbon Fiber Cloth market is expected to reach $1.43 billion by 2025.

What are the key industries driving the demand for Pan-Based Carbon Fiber Cloth?

The key industries driving the demand for Pan-Based Carbon Fiber Cloth include:

- Aerospace

- Automotive

- Construction

What are the major countries contributing to the growth of the Pan-Based Carbon Fiber Cloth market?

The U.S., Japan, and Germany are major countries contributing to the growth of the Pan-Based Carbon Fiber Cloth market.

What are the challenges faced in the production of Pan-Based Carbon Fiber Cloth?

The production challenges include high production costs, complex manufacturing processes, and quality control issues.

How do trade policies and tariffs impact the global supply of Pan-Based Carbon Fiber Cloth?

Trade policies and tariffs can significantly affect the global supply chain and market dynamics of Pan-Based Carbon Fiber Cloth.

What are the different types of Pan-Based Carbon Fiber Cloth?

The different types of Pan-Based Carbon Fiber Cloth include prepreg and woven carbon fiber cloth.

What are the applications of Pan-Based Carbon Fiber Cloth in the aerospace industry?

Pan-Based Carbon Fiber Cloth is used in various aerospace applications due to its high strength-to-weight ratio and resistance to fatigue.

How is Japan contributing to the global Pan-Based Carbon Fiber Cloth market?

Japan is a leader in carbon fiber cloth manufacturing and innovation, with significant production capacity and technological advancements.

What is Germany’s role in the production of high-performance Pan-Based Carbon Fiber Cloth?

Germany is known for its expertise in producing high-performance Pan-Based Carbon Fiber Cloth, with significant market share and production capacity.

What are the future trends expected in the Pan-Based Carbon Fiber Cloth market?

The future trends include technological innovations and sustainability initiatives, which are expected to shape the market and provide opportunities for growth.