$719 Million Overhead Hoist Transport Market Expected to Expand in the U.S., China, and Germany by 2025

Explore the 2025 growth trends in the overhead hoist transport market, driven by automation, sustainability, and emerging market expansion.

- Last Updated:

Projected Market Insights for Overhead Hoist Transport in Q1 and Q2 of 2025

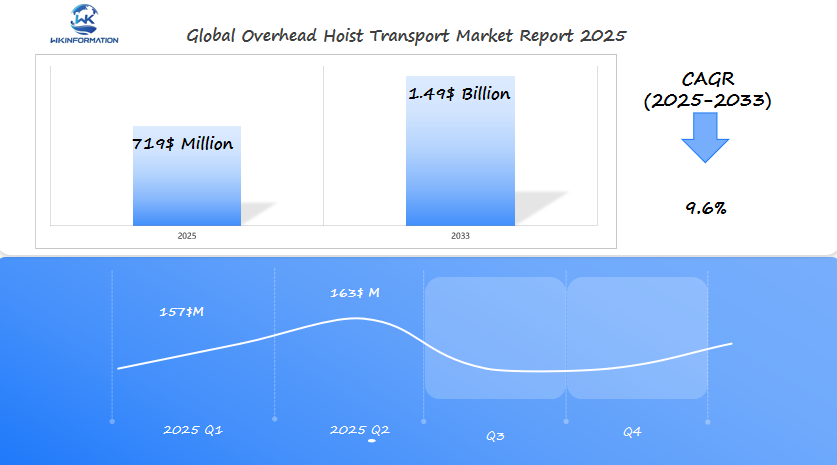

The Overhead Hoist Transport market is expected to reach $719 million in 2025, with a CAGR of 9.6% from 2025 to 2033. In Q1, the market is anticipated to generate around $157 million, driven by the growing industrialization in manufacturing and logistics sectors. By Q2, the market is forecasted to rise to approximately $163 million, as more industries adopt hoist transport systems to improve material handling efficiency and reduce operational costs.

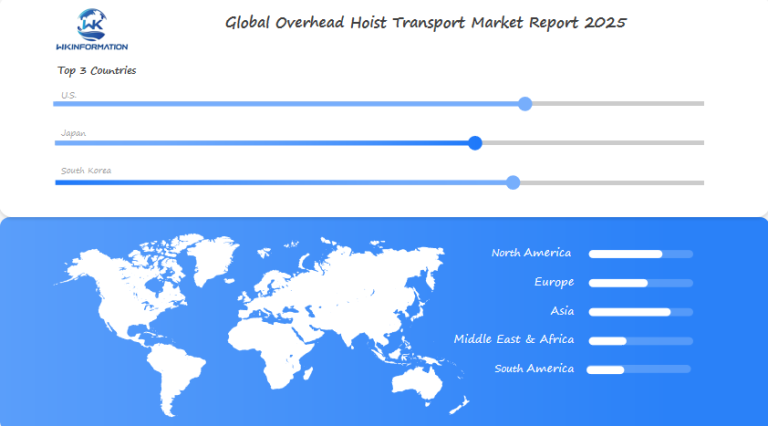

The U.S., China, and Germany are the key markets for this technology. The U.S. and Germany lead in advanced automation and heavy machinery applications, while China’s rapid industrial growth and infrastructure projects boost the demand for hoist transport systems. The ongoing trend towards automation and smart factories will continue to fuel the market’s growth throughout 2025.

Key Takeaways

- Market value expected to hit $719 million by 2025.

- U.S., China, and Germany are leading growth regions.

- Automation and infrastructure projects drive demand.

- Key applications include manufacturing, construction, and logistics.

- Innovation in safety and efficiency is reshaping industry standards.

Exploring the Upstream and Downstream Industry Chains for Overhead Hoist Transport

The overhead hoist transport sector depends on supply chains. These chains are crucial for delivering advanced systems. Let’s look at how upstream chains and downstream chains impact this industry.

Understanding Upstream Chains

Upstream chains start with raw material suppliers. Companies like Nucor and Siemens make key parts. Mitsubishi Electric’s electronics power control systems.

These parts are then put together by Konecranes and Cargotec. They create the finished hoist systems.

Examining Downstream Chains

On the downstream side, distributors like Grainger and Motion Industries sell equipment. Construction firms, automotive plants, and warehouses use these systems every day. For example, Amazon’s fulfillment centers use automated hoists to improve logistics.

“Balancing upstream and downstream needs ensures smoother operations,” states a 2023 report by Grand View Research. “Supplier delays or poor distribution can disrupt entire projects.”

The Role of Collaboration

Efficiency comes from working together between suppliers and manufacturers. Upstream delays, like steel shortages, can slow down projects. But, strong distribution networks help expand market reach. This teamwork drives innovation, like IoT-enabled hoists and modular designs.

Finding Opportunities for Growth

Understanding these chains shows ways to save costs and grow. As automation increases, linking upstream tech suppliers with downstream users will be crucial. This will help meet the growing demand.

Key Market Trends Driving the Overhead Hoist Transport Industry Forward

Market Trends in Hoist Systems are making industries smarter and safer. Automation and digital tools are changing how we handle heavy lifting. Three major changes are happening:

- IoT and AI integration for real-time system monitoring.

- Safety-focused upgrades like collision detection and load sensors.

- Custom designs for specialized sectors like automotive or aerospace.

| Trend | Impact | Leading Brands |

| Smart Technology | Reduces downtime through predictive maintenance. | Konecranes, Cargotec |

| Enhanced Safety | Cuts accident rates via automated alerts. | Demag, Hyster-Yale |

| Industry-Tailored Systems | Meets unique demands of factories and warehouses. | Terex, STS Cranes |

Companies like Konecranes are introducing AI-driven hoists that warn operators of risks. These trends focus on flexibility, fitting various work settings. As factories and warehouses seek better efficiency, these advancements are being adopted worldwide.

Challenges in Overhead Hoist Transport System Design and Efficiency

Creating efficient overhead hoist systems is tough. Engineers must tackle Hoist System Design Challenges that impact safety, cost, and how well they work. These systems need to carry heavy loads and fit into current industrial spaces.

1. Engineering Constraints

Structural limits in load capacity and space limit options.

2. Integration Costs

Updating older buildings costs more upfront.

3. Performance vs. Budget

Finding affordable, advanced features is hard.

| Challenge | Impact | Solution |

| Material Fatigue | Equipment failure risks | High-strength alloys and predictive maintenance |

| Complex Installations | Time delays | Modular components for easy assembly |

| Regulatory Compliance | Legal penalties | Automated safety sensors and AI monitoring |

Companies like Konecranes and Cargotec use smart software and lightweight materials to solve these problems. Innovations, like Demag’s IoT-enabled systems, make integration easier. While Hoist System Design Challenges still exist, new technologies and materials are making solutions more available. Focusing on safety and cost helps these systems meet today’s industrial needs without losing efficiency.

Geopolitical Factors Shaping the Overhead Hoist Transport Market

Global trade policies and international alliances shape the demand for overhead hoist transport. Trade tensions between big economies like the U.S. and China make supply chains uncertain. Geopolitical Factors like tariffs or sanctions can slow down imports, increasing costs for industries that need heavy lifting systems.

| Region | Key Geopolitical Factors | Market Impact |

| United States | Trade agreements with allies | Streamlined machinery exports |

| China | Belt and Road infrastructure projects | Increased demand for heavy lifting solutions |

| Germany | EU environmental regulations | Push for energy-efficient systems |

“Tariff fluctuations have become a critical consideration for manufacturers,” noted industry analysts. “Companies now prioritize local suppliers to avoid geopolitical disruptions.”

Regional conflicts also drive innovation. For example, European manufacturers are creating modular hoist systems to keep up with changing trade routes. Meanwhile, U.S. firms are working on cybersecurity for connected transport systems to fight off geopolitical risks. These Geopolitical Factors keep the market lively, with companies always looking at global partnerships and production spots.

Market Segmentation: Types and Applications of Overhead Hoist Transport Systems

Market Segmentation for overhead hoist systems divides the industry into different groups. These groups are based on design and use. This helps businesses find the right opportunities in specific areas. The main types include:

- Bridge cranes: Perfect for big factories and warehouses

- Gantry systems: Great for both indoor and outdoor use

- Monorails: Make assembly lines more efficient

These systems are used in many ways across different industries. For instance:

- Manufacturing: Car factories use electric overhead cranes for precise assembly

- Construction: Gantry systems move heavy materials at building sites

- Retail logistics: Monorails help organize storage in distribution centers

Big names like Konecranes and Cargotec create systems for these areas. Market Segmentation also shows new trends, like automation in warehouses. By matching products with sector needs, suppliers can increase adoption. This focus leads to better innovation and customer happiness.

Overhead Hoist Transport in Manufacturing, Construction, and Warehousing

Overhead hoist transport systems are key in today’s industries. They move heavy parts safely in manufacturing. Construction sites use them to lift steel beams or precast concrete. Warehouses use them to organize large inventories quickly.

Manufacturing plants, like car factories, rely on these systems. For example, Konecranes designs crane systems for assembling engines. In construction, Demag cranes lift materials to high floors during skyscraper builds. Warehouses use automated overhead hoists from Cargotec to speed up order fulfillment.

Applications of Overhead Hoist Transport

These systems find application in various sectors:

- Manufacturing: Used in assembly lines and material handling processes.

- Construction: Employed for site assembly and heavy equipment placement tasks.

- Warehousing: Utilized in storage rack systems and pallet stacking operations.

“Overhead hoists reduce workplace injuries by 40% through controlled material movement,” says a 2023 OSHA report.

Benefits of Overhead Hoist Transport

These systems make workplaces safer and more productive. They fit different industrial applications, from automotive plants to logistics centers. With automation, smart sensors now monitor load weights in real time, preventing overloading. Companies invest in these systems to stay competitive and meet efficiency demands.

Global Insights into the Overhead Hoist Transport Market

Global Market Insights show a world where different areas drive innovation and trade. Asia-Pacific is the top in making things, thanks to China and India’s big factories. Europe, especially Germany, is known for its precise engineering, sending top systems around the globe. In North America, the U.S. leads in making things better with new tech.

Regional Drivers of Demand

- Asia-Pacific: More building projects mean more cranes and hoists are needed.

- Europe: Focus on green tech leads to more energy-saving designs.

- North America: New rules push for safer, high-tech solutions.

“Collaboration between regions is key to solving logistical bottlenecks in global supply chains.”

Global Market Insights also look at partnerships across borders. For example, Chinese and European companies team up to create new tech. Countries like those in Latin America and the Middle East are looking for affordable options. At the same time, richer countries want the best systems.

There’s a big demand for different types of hoists, from mining to online shopping warehouses. This demand keeps companies working on new ideas. By keeping up with these trends, businesses can stay ahead in the global market.

U.S. Market Demand for Overhead Hoist Transport Systems in Industrial Sectors

The demand for overhead hoist transport systems in the U.S. is on the rise. This is because industries are focusing more on efficiency. The manufacturing, logistics, and energy sectors use these systems to move heavy materials safely.

Modern facilities are now using advanced hoists. This helps them streamline their operations and meet safety standards.

Factors Driving Demand

Several factors are driving the demand for overhead hoist transport systems in various industrial sectors:

- Government grants for infrastructure upgrades

- Rising automation in warehouses

- Renewable energy projects requiring heavy lifting

Key Players and Trends

Companies like Konecranes and Hyster-Yale are seeing more orders from U.S. manufacturers. Customized systems with IoT sensors are now the go-to for real-time monitoring. A 2023 industry report says:

“Investment in smart hoist tech will boost U.S. Industrial Demand by 8% annually through 2025.”

The automotive and aerospace industries use these systems to assemble big parts. This cuts down on downtime. With the U.S. investing $1 trillion in infrastructure, construction sites are turning to durable overhead solutions.

Future Outlook

This move aligns with efforts to modernize factories and lower workplace injuries. As industries keep evolving, the U.S. Industrial Demand is all about innovation and safety. This is shaping the sector’s future.

China’s Growing Market for Overhead Hoist Transport Systems

China’s industrial sector is driving the growth of the overhead hoist transport market. This shows the country’s economic progress. The China Growth path is linked to modernizing manufacturing and infrastructure.

Key Industries Driving Growth

The automotive and logistics industries are key players in this growth. They rely on advanced hoist systems to improve their operations.

Leading Chinese Manufacturers

Top Chinese manufacturers such as Cargotec and Sany Heavy Industry are leveraging smart technology to meet the increasing demand for overhead hoist transport solutions. This aligns with the China Growth goals of promoting innovation through automation and IoT integration.

Factors Contributing to Market Expansion

Several factors are pushing this growth forward:

- Government subsidies for infrastructure development

- Rising automation needs in factories

- Export opportunities to neighboring Asian markets

Market Growth Projections

Since 2020, the overhead hoist transport market in China has experienced steady growth of 8-12% each year. By 2025, it is expected to be worth over $2.5 billion.

| Year Market Size (USD Billion) 2020 | 1.2 |

| 2023 | 1.8 |

| 2025 (Est.) | 2.6 |

Impact of Technology on Productivity

A report by Grand View Research found that 60% of China’s hoist systems now have smart sensors, resulting in a productivity increase of 30%. This demonstrates the positive impact of technology on operational efficiency within various industries.

Urbanization and E-commerce Influence

Urbanization and the growth of e-commerce also contribute to the rising demand for overhead hoist transport systems. Companies like ZPMC are incorporating AI into their crane systems, showcasing China’s advancement in tech-driven logistics.

China’s Position as a Global Leader

With its focus on innovative material-handling solutions, China is positioning itself as a world leader in this field. The combination of government support, industry collaboration, and technological advancements will continue to drive the growth of overhead hoist transport systems in the country.

Germany’s Expertise in Overhead Hoist Transport Technology

Germany’s engineering history influences today’s German Hoist Technology. Leaders like Konecranes and Terex Demag push the limits in crane systems. They focus on precision and safety, meeting EU’s high standards.

Efficiency through Research and Development

German R&D aims for efficiency. For instance, German Hoist Technology companies cut energy use by 20% in bridge cranes. They use lightweight materials, saving costs for factories and warehouses.

Key Features of German Hoist Technology

- Customizable systems for heavy industrial use

- Long-term durability under heavy loads

- Integration with smart factory systems

Innovations by Leading Companies

| Company Innovation Impact Konecranes | Wireless remote controls | Safer operation in hazardous zones |

| Terex Demag | AI-driven load monitoring | 25% faster maintenance planning |

German standards are a global benchmark for safety and performance. Their approach ensures solutions meet specific business needs. This makes German Hoist Technology a preferred choice worldwide.

The Future of Overhead Hoist Transport: Automation and Smart Solutions

Smart Automation is changing how we move materials in industries. New tech like IoT sensors and AI systems makes overhead hoists faster and safer. Now, factories and warehouses use these tools to reduce delays and increase productivity.

Key advancements include:

- IoT-connected cranes sharing real-time data

- AI algorithms optimizing lift paths

- Automated safety checks reducing human error

| Technology | Benefit | Example |

| IoT Sensors | Monitor equipment health | Data-driven maintenance schedules |

| AI Planning | Route optimization | 30% faster material handling |

| Automated Controls | Error reduction | Collision-avoidance systems |

Smart Automation saves businesses money while keeping them safe. Companies like Maximal Cranes already use these tools in their products. As more factories adopt Industry 4.0, expect to see smarter overhead systems everywhere.

Competitive Landscape in the Overhead Hoist Transport Market

- Murata Machinery, Ltd. – Kyoto, Japan

- SMCore Corporation – Seongnam, Gyeonggi-do, South Korea

- ZENIX Corporation – Seongnam, Gyeonggi-do, South Korea

- SYNUS Tech Corporation – Seongnam, Gyeonggi-do, South Korea

- Shinsung E&G Co., Ltd. – Gyeonggi-do, South Korea

- Siasun Robot & Automation Co., Ltd. – Shenyang, Liaoning, China

- Seen BnTek Co., Ltd. – Seongnam, Gyeonggi-do, South Korea

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Overhead Hoist Transport Market Report |

| Base Year | 2024 |

| Segment by Type | · Manual Hoists

· Electric Hoists · Hydraulic Hoists |

| Segment by Application | · Manufacturing

· Warehousing and Logistics · Construction |

| Geographies Covered | · North America (United States, Canada)

· Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The market for overhead hoist transport systems is growing steadily. This growth is driven by needs in manufacturing, construction, and warehousing. The U.S., China, and Germany are key players in this expansion, thanks to advances in automation and smart logistics.

Technology is changing the game in these industries. Companies using automated systems and IoT are tackling efficiency issues. This move towards smarter systems is in line with the global push for digitized operations.

Companies are putting a lot of effort into research and development to stay competitive. By focusing on precision engineering and sustainable designs, they turn challenges into growth opportunities. This ensures the industry meets changing market needs while keeping safety and reliability top priorities.

The future looks bright with technology and traditional industries working together. Businesses that invest in these solutions will have a competitive edge. By exploring these innovations now, stakeholders can prepare for the next steps in material handling and logistics.

Global Overhead Hoist Transport Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Overhead Hoist Transport Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Overhead Hoist TransportMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Overhead Hoist Transportplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Overhead Hoist Transport Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Overhead Hoist Transport Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Overhead Hoist Transport Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofOverhead Hoist Transport Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected value of the Overhead Hoist Transport Market by 2025?

The Overhead Hoist Transport Market is expected to reach an estimated value of $719 million by 2025. This shows significant growth in the U.S., China, and Germany.

What factors are driving the expansion of the overhead hoist transport industry?

Key drivers include advancements in technology and rising industrial activities. Also, increased investments in transportation solutions that enhance efficiency and safety across various sectors.

How does the supply chain work for overhead hoist transport systems?

The supply chain includes both upstream and downstream processes:

- Upstream focuses on manufacturing components.

- Downstream focuses on distribution and end-user applications, contributing to better market efficiencies.

What are some common challenges in overhead hoist transport system design?

Some of the main challenges in designing overhead hoist transport systems include:

- Engineering constraints: These are limitations imposed by factors such as available space, weight capacity, and structural requirements.

- Integration complexities: Overhead hoist systems often need to work seamlessly with other equipment or processes, which can introduce additional complexities in design and implementation.

- Balancing performance and cost: It’s important to achieve optimal system performance while also keeping costs within budget.

All these challenges require innovative solutions to address effectively.

How do geopolitical events impact the overhead hoist transport market?

Geopolitical factors like trade policies and international relations can significantly affect market dynamics. They influence supply chains, investment flows, and overall market strategies.

What are the different types of overhead hoist transport systems available?

Overhead hoist transport systems can be categorized by functionality and machinery types. They are also specific to various industries, offering tailored solutions for different operational needs.

In which industries are overhead hoist transport systems most commonly utilized?

These systems are crucial in:

- Manufacturing

- Construction

- Warehousing

They enhance operational efficiency and contribute to improved safety and productivity.

How does the overhead hoist transport market differ globally?

The global market has different trends. Emerging economies have the potential for rapid growth compared to established regions. This is due to various investment patterns and technological advancements.

What is the U.S. market demand for overhead hoist transport systems?

The demand in the U.S. is influenced by industrial innovation and infrastructure developments. Government incentives also support growth in the sector.

What are the key trends in China’s overhead hoist transport market?

China is experiencing growth due to increased industrialization and significant investments in modern transport solutions. These improvements enhance efficiency across various sectors.

How does Germany lead in overhead hoist transport technology?

Germany is known for its high engineering standards and research and development efforts. These factors contribute to the creation of dependable and cutting-edge overhead hoist transport solutions that establish global standards.

What future technologies are expected to impact overhead hoist transport?

Automation and smart technologies, including IoT integration and AI-driven systems, are expected to revolutionize the industry. They will optimize efficiency and reduce downtime significantly.

What does the competitive landscape look like in the overhead hoist transport market?

The competitive dynamics in the overhead hoist transport market include major players focusing on innovation and customer service. Strategic moves like mergers and acquisitions also help enhance their market position.