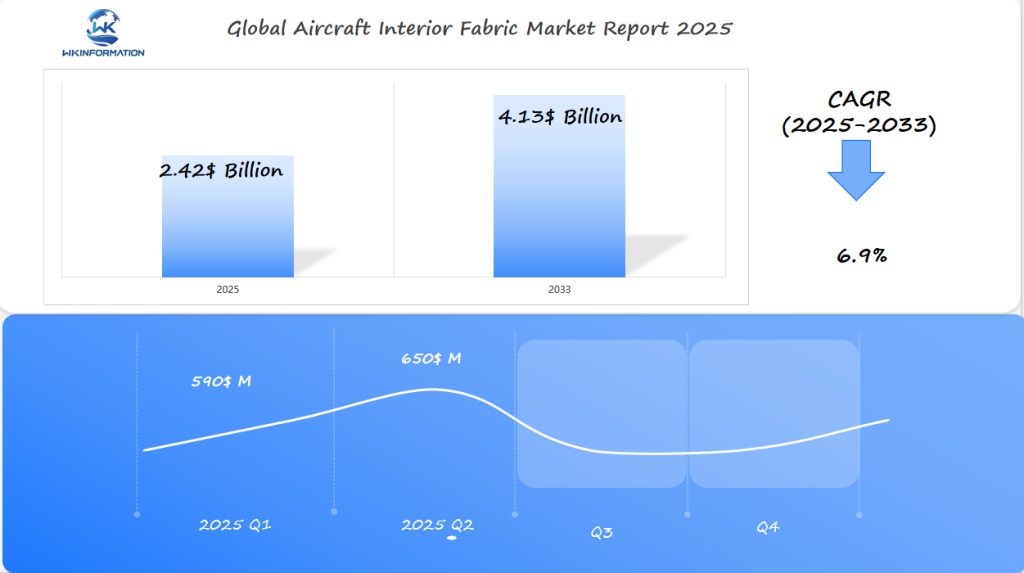

Aircraft Interior Fabric Market Forecasted at $2.42 Billion by 2025: Boosted by the U.S., UAE, and Singapore

The Aircraft Interior Fabric Market is forecasted to reach $2.42 Billion by 2025, boosted by demand in the U.S., UAE, and other major markets.

- Last Updated:

Aircraft Interior Fabric Market: Q1 and Q2 of 2025 Analysis

The Aircraft Interior Fabric market is projected to reach $2.42 billion by 2025, growing at a CAGR of 6.9% from 2025 to 2033.

Q1 and Q2 Projections for 2025

In Q1 of 2025, the market size is expected to be approximately $590 million, with further growth continuing into Q2, reaching $650 million.

Factors Driving Growth

The demand for high-quality, durable, and lightweight fabrics in aircraft interiors is increasing, driven by both aesthetics and functionality.

Key Markets

The U.S., UAE, and Singapore are major markets for aircraft interior fabric:

- The U.S. is seeing growth due to its strong aviation industry and demand for both commercial and private jets.

- The UAE is investing heavily in the aviation sector.

- Singapore’s strategic position as a hub for air travel and maintenance is boosting demand for interior fabric solutions.

As airlines focus on passenger comfort and cabin aesthetics, the aircraft interior fabric market is expected to expand.

Aircraft Interior Fabric Market Upstream and Downstream Industry Chain Analysis

The aircraft interior fabric market is closely connected to its upstream and downstream industry chains, which affect its overall growth and development. The upstream segment includes the supply of raw materials and manufacturing processes, while the downstream segment includes the demand from aircraft manufacturers and interior designers.

Supply Chain Dynamics are crucial in the aircraft interior fabric market. The industry depends heavily on a complex network of suppliers, manufacturers, and distributors to provide high-quality fabrics that meet strict aviation standards.

Supply Chain Dynamics

The supply chain for aircraft interior fabrics is complex, involving various players from raw material suppliers to finished goods manufacturers. Raw material suppliers are crucial in this chain, providing the basic materials used in fabric production.

Raw Material Suppliers

Raw material suppliers are the backbone of the aircraft interior fabric industry, providing essential materials such as wool, leather, synthetic fibers, and composite materials. These materials are sourced from various global suppliers and are processed into fabrics that meet the aviation industry’s strict standards for safety, durability, and appearance.

The demand for sustainable and eco-friendly materials is driving innovation among raw material suppliers, who are increasingly focusing on developing fabrics that are not only compliant with aviation regulations but also environmentally friendly.

As the aircraft interior fabric market continues to change, understanding the dynamics of its upstream and downstream industry chains will be crucial for stakeholders to navigate the complexities of this specialized industry.

Trends in cabin comfort, aesthetics, and sustainable materials

The demand for premium cabin interiors is on the rise, driven by airlines aiming to enhance passenger experience. This trend is significantly influencing aircraft interior design trends, with a focus on comfort, aesthetics, and the incorporation of sustainable aviation fabrics.

Passenger Experience

Airlines are now more than ever focused on improving the passenger experience. This involves not just the comfort of the seats but also the overall ambiance of the cabin. Cabin interior fabrics play a crucial role in this aspect, with airlines opting for materials that are not only comfortable but also visually appealing.

As noted by industry experts, “The use of high-quality, sustainable materials in aircraft interiors is becoming a key differentiator for airlines.” This is reflected in the growing trend towards the use of sustainable materials that reduce environmental impact without compromising on aesthetics or comfort.

Sustainable Materials

The shift towards sustainable aviation fabrics is driven by both environmental concerns and passenger preferences. Materials such as recycled polyester and natural fibers are gaining popularity, offering a sustainable alternative to traditional materials.

- Recycled polyester reduces waste and conserves resources.

- Natural fibers provide a premium feel while being environmentally friendly.

- The use of sustainable materials is expected to grow, driven by passenger demand and regulatory pressures.

The incorporation of these materials into aircraft interiors not only enhances the passenger experience but also contributes to a more sustainable aviation industry. As the industry continues to evolve, the focus on cabin interior fabrics and sustainable materials is expected to remain a key trend.

Constraints in supply and compliance with fire safety standards

The aircraft interior fabric market faces significant challenges due to stringent fire safety regulations. These regulations are crucial for ensuring passenger safety, but they also complicate the manufacturing and supply process for aircraft interior fabrics.

Regulatory Compliance

Regulatory compliance is a critical aspect of the aircraft interior fabric market. Manufacturers must adhere to rigorous testing and certification processes to ensure their materials meet fire safety standards. This involves compliance with regulations set by aviation authorities such as the Federal Aviation Administration (FAA) in the United States.

Fire Safety Standards

Fire safety standards are paramount in the aviation industry. These standards dictate the materials used in aircraft interiors, including fabrics for seating, flooring, and paneling. The most critical standards include:

- Resistance to ignition

- Flame propagation

- Smoke toxicity

- Heat release rate

Meeting these standards requires significant investment in research and development, as well as rigorous testing protocols. Advanced materials that meet these standards are in high demand, driving innovation among suppliers.

The constraints imposed by fire safety regulations significantly impact the aircraft interior fabric market. Suppliers must balance the need for compliance with the demand for innovative, high-quality materials. As the aviation industry continues to evolve, the ability to meet these regulatory challenges will be crucial for success.

Geopolitical factors affecting aviation interior supply chains

The global aviation textile market is greatly affected by geopolitical factors that influence aviation interior supply chains. The complex network of trade policies, tariffs, and regional agreements can either help or obstruct the movement of materials and goods in the aviation industry.

Global Trade Impact

The aviation supply chain is a complex network that spans across multiple countries, making it vulnerable to geopolitical fluctuations. Trade policies, such as tariffs and quotas, can significantly impact the cost and availability of materials used in aircraft interiors.

For instance, the imposition of tariffs on imported textiles can increase the cost of production for aircraft interior fabric manufacturers, making it challenging for them to remain competitive in the market.

Regional Trade Agreements

Regional trade agreements, on the other hand, can provide a more favorable business environment for aviation interior fabric suppliers. Agreements such as the EU’s single market policy and the United States-Mexico-Canada Agreement (USMCA) facilitate the free movement of goods and services across borders, reducing costs and increasing efficiency.

These agreements can also promote cooperation and collaboration among countries, leading to the development of more robust and resilient supply chains.

The impact of regional trade agreements on the aviation interior fabric market can be seen in the increased trade volumes and investment flows between signatory countries.

Segmentation by fabric type: Wool, Leather, Synthetic, Composite

There are several types of fabrics used in aircraft interiors, including wool, leather, synthetic fabrics, and composite materials. Each type of fabric has its own unique qualities. Choosing the right fabric type is important because it affects how the aircraft interior looks, how long it lasts, and how safe it is.

Fabric Types

The aircraft interior fabric market is characterized by a variety of fabric types, each catering to different needs and preferences. Wool is valued for its natural, luxurious feel and inherent fire-resistant properties, making it a popular choice for premium airline interiors.

Leather, on the other hand, is prized for its durability and aesthetic appeal. It is often used in high-end aircraft interiors to provide a luxurious ambiance.

Material Characteristics

The characteristics of aircraft interior fabrics play a significant role in their selection for various applications. The table below summarizes the key characteristics of different fabric types:

| Wool | Moderate | High | Natural, Luxurious |

| Leather | High | Moderate | Luxurious |

| Synthetic Fabrics | High | Variable | Versatile |

| Composite Materials | High | High | Customizable |

Understanding these characteristics is essential for selecting the appropriate fabric type for different aircraft interior applications, ensuring a balance between aesthetics, durability, and safety.

Application Segmentation: Seating, Flooring, Paneling, Curtains

Aircraft interior fabrics are essential for enhancing the passenger experience, covering everything from seating to decorative features. Each area has its own unique requirements, which is why it’s important to have a thorough understanding of the specific needs for each part.

Interior Components

Aircraft interior fabrics are used in various components, including seating fabrics, flooring materials, paneling, and curtains. Each of these components has unique requirements in terms of durability, aesthetics, and functionality.

For instance, seating fabrics need to be durable and easy to clean, while paneling and curtains may require more decorative and visually appealing materials. Here’s an example of a seating fabric that illustrates the durability and ease of maintenance required for such components.

Design Considerations

When designing aircraft interior components, several factors come into play. These include the type of fabric, its durability, and its aesthetic appeal. For example, synthetic fabrics are often used for seating due to their durability and ease of maintenance.

- The choice of fabric can significantly impact the overall passenger experience.

- Different fabrics offer varying levels of comfort, durability, and aesthetic appeal.

- Designers must balance these factors to create a cohesive and comfortable cabin environment.

To illustrate this further, consider this image which showcases a well-designed aircraft interior that successfully balances these design considerations.

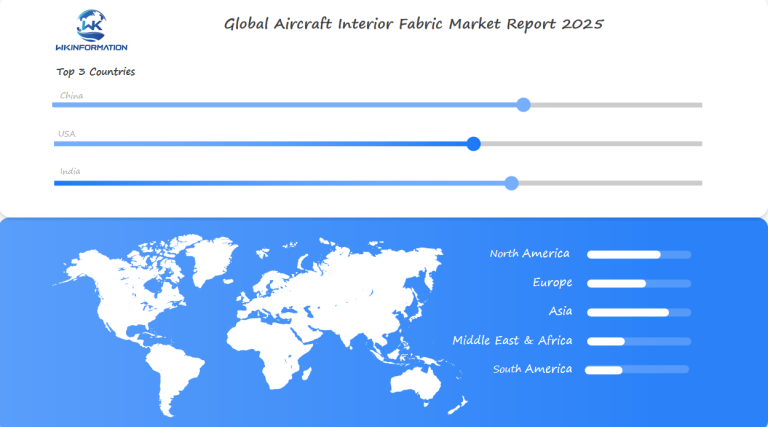

Demand for Aircraft Interior Fabric in Different Parts of the World

The demand for aircraft interior fabrics varies significantly around the world because different airlines have different preferences and passengers have different expectations. This variation is influenced by factors such as local market trends, regulatory requirements, and the overall growth of the aviation industry in each region.

It’s important for suppliers to understand these regional dynamics so they can customize their products and marketing strategies accordingly.

Regional Demand

Different regions have their own specific needs when it comes to aircraft interior fabrics. Here’s how various areas are shaping the demand:

- North America: With its large number of aircraft and focus on passenger comfort, this region has a strong need for top-notch, long-lasting fabrics.

- Europe: Known for its high-end airline services, Europe also has a significant demand for luxurious and environmentally-friendly interior fabrics.

- Asia-Pacific: This region is home to a rapidly expanding aviation market, offering opportunities for suppliers to meet diverse airline preferences, including budget-friendly options and luxury services.

Market Trends

Market trends in the global aircraft interior fabric market are influenced by regional factors. Here’s how different areas are impacting the industry:

- Europe: The increasing demand for sustainable and eco-friendly materials is a major trend here, driven by both regulations and passenger preferences.

- North America: The focus in this region is on advanced materials that provide better durability and comfort.

- Asia-Pacific: There’s a rising interest in innovative materials and designs that can enhance the passenger experience.

The variations in demand for aircraft interior fabrics across regions highlight the significance of a customized approach for suppliers. By understanding and addressing these regional dynamics, suppliers can improve their positioning in the global aircraft interior fabric market, taking advantage of regional demand and keeping up with market trends.

U.S. aircraft fleet renewal influencing interior upgrades

The renewal of the U.S. aircraft fleet is creating new opportunities for interior upgrades. With a growing focus on passenger experience, airlines are continually seeking to modernize their fleets with newer, more efficient aircraft.

These modern aircraft often feature advanced interior designs and materials, driving the demand for high-quality, innovative interior fabrics. As a result, suppliers of aircraft interior fabrics have significant opportunities to provide materials that meet the evolving needs of airlines and passengers alike.

Fleet Renewal Trends

The trend of fleet renewal in the U.S. is driven by the need for airlines to improve efficiency, reduce operational costs, and enhance passenger comfort. Newer aircraft models are designed with advanced materials and technologies that not only improve fuel efficiency but also offer improved interior aesthetics and comfort.

Key trends in fleet renewal include:

- Increased adoption of lightweight materials to improve fuel efficiency

- Integration of advanced technology for improved passenger experience

- Focus on sustainability and eco-friendly materials

Interior Upgrade Opportunities

The renewal of aircraft fleets presents significant opportunities for interior upgrades. Airlines are looking to differentiate themselves by offering enhanced passenger experiences, which includes upgrading their aircraft interiors with high-quality fabrics and innovative designs.

Some of the key areas for interior upgrades include:

| Interior Component | Upgrade Opportunities | Benefits |

| Seating | Advanced ergonomic designs, premium materials | Improved passenger comfort, enhanced aesthetics |

| Flooring | Lightweight, durable materials, customizable designs | Reduced maintenance costs, improved safety |

| Paneling | Innovative materials, customizable patterns | Enhanced interior aesthetics, improved passenger experience |

The demand for high-quality interior fabrics is expected to grow as the U.S. aircraft fleet continues to modernize. Suppliers who can provide innovative, sustainable, and aesthetically pleasing materials will be well-positioned to capitalize on this trend.

UAE’s premium airline industry driving luxury fabric use

The UAE’s premium airline sector is characterized by its commitment to luxury, reflected in the use of high-end aircraft interior fabrics. With a strong focus on passenger experience and comfort, airlines like Emirates are setting new standards in air travel.

The demand for luxurious fabrics is on the rise, driven by the UAE’s aviation industry’s emphasis on premium products. Suppliers who can offer unique, high-quality materials are well-positioned to capitalize on this trend.

Luxury Trends in Aviation

The luxury airline industry in the UAE is driving innovation in aircraft interior design, with a focus on aesthetics, comfort, and sustainability. This trend is expected to continue, with airlines seeking to differentiate themselves through the use of premium materials.

Key Trends:

- Increased demand for sustainable luxury materials

- Focus on passenger comfort and well-being

- Use of advanced materials and technologies

High-End Materials

The use of high-end materials is a hallmark of the UAE’s luxury airline industry. From luxurious leathers to advanced synthetic materials, the focus is on creating a premium passenger experience.

“The use of premium fabrics in aircraft interiors is not just about aesthetics; it’s also about creating a comfortable and healthy environment for passengers.”

Suppliers are responding to this demand by developing innovative, high-quality materials that meet the exacting standards of the UAE’s airlines.

Singapore’s regional aviation growth supporting fabric suppliers

As a key aviation hub in Southeast Asia, Singapore is experiencing a surge in air travel, benefiting the local aviation industry. This growth is not only reflected in the increasing number of passengers but also in the expansion of airline fleets and the upgrading of aircraft interiors.

Regional Aviation Growth

Singapore’s strategic location and top-notch aviation facilities make it a perfect hub for airlines in the region. The growth of regional aviation is primarily driven by the rising demand for air travel, both for passengers and cargo services. This expansion is boosting the need for high-quality aircraft interior fabrics.

Opportunities for Suppliers

The growth in Singapore’s aviation industry presents opportunities for suppliers of aircraft interior fabrics. Airlines looking to upgrade their fleets and enhance passenger experience are seeking high-quality, durable, and aesthetically pleasing fabrics. Suppliers who can meet these demands are well-positioned to benefit from the growth in the regional aviation sector.

Key Factors Driving Growth

- Increasing disposable income and middle-class population in Southeast Asia

- Expansion of low-cost carriers (LCCs) offering affordable travel options

- Growth in e-commerce leading to higher demand for air cargo services

Understanding Market Trends

To effectively cater to the needs of airlines operating in Singapore, suppliers must stay updated on market trends such as:

- Shift towards sustainable materials in aircraft interiors

- Increasing focus on passenger comfort and wellness features

- Adoption of technology-driven solutions for cabin design

By aligning their product offerings with these trends, suppliers can enhance their competitive advantage and capture a larger share of the growing regional aviation market.

The growth of Singapore’s aviation industry is a positive indicator for aircraft fabric suppliers. By understanding the trends and demands of this growing market, suppliers can tailor their products and services to meet the needs of airlines operating in and through Singapore.

Future outlook for next-gen aircraft interior fabrics

The future of next-generation aircraft interior fabrics will be influenced by the combination of technology, sustainability, and passenger experience. Airlines are working hard to improve passenger comfort while also minimizing their impact on the environment. As a result, there is a growing need for new and creative materials.

Emerging Trends

The future of aircraft interior fabrics is characterized by several emerging trends. Sustainability is becoming a key driver, with suppliers exploring eco-friendly materials and production processes. For instance, the use of recycled polyester and natural fibers is gaining traction.

Another significant trend is the focus on passenger comfort. Airlines are investing in fabrics that not only meet stringent safety standards but also provide enhanced comfort and aesthetic appeal. This includes the development of fabrics with antimicrobial properties and advanced texture designs.

Innovative Materials

The incorporation of cutting-edge materials is set to revolutionize aircraft interior fabrics. Technologies such as nanotechnology and advanced composites are being leveraged to create fabrics that are not only durable but also lightweight and sustainable.

A comparative analysis of traditional and next-gen materials highlights the advancements in the industry:

| Material Type | Characteristics | Benefits |

| Traditional Fabrics | Durable, fire-resistant | Proven safety record |

| Next-Gen Fabrics | Lightweight, sustainable, antimicrobial | Enhanced passenger comfort, reduced environmental impact |

As the industry continues to evolve, suppliers who invest in research and development are poised to lead the market. The integration of innovative materials and sustainable practices will be crucial in shaping the future of aircraft interior fabrics.

The future outlook for next-gen aircraft interior fabrics is promising, with emerging trends and innovative materials set to transform the industry. As airlines and suppliers collaborate to meet the demands of sustainability and passenger comfort, the market is expected to witness significant growth.

Competitive landscape in aviation textile supply

The aviation textile supply industry is a highly competitive and specialized sector, driven by the need for high-performance materials in aircraft interiors, safety equipment, and overall cabin design. The competitive landscape includes a variety of companies offering different types of textiles and fabrics such as seat covers, carpets, curtains, insulation materials, and safety equipment (e.g., life vests and airbag fabrics).

- Aircraft Cabin Modification GmbH – Germany

- Belgrave B.V. – Netherlands

- Botany Weaving – United States

- Lantal Textiles AG – Switzerland

- INDUSTRIAL NEOTEX SA – Greece

- Zodiac Aerospace (Safran) – France

- Rockwell Collins (Collins Aerospace) – United States

- Panasonic Avionics Corporation – United States

- Diehl – Germany

- Thales Group – France

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Aircraft Interior Fabric Market Report |

| Base Year | 2024 |

| Segment by Type |

· Wool · Leather · Synthetic · Composite |

| Segment by Application |

· Seating · Flooring · Paneling · Curtains |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The aircraft interior fabric market is growing due to the increasing demand for comfort, aesthetics, and sustainability in aviation. As airlines update their fleets and improve their interiors, suppliers who can innovate and meet strict regulatory requirements are likely to succeed.

Market Summary and Future Directions

A comprehensive understanding of the aircraft interior fabric market summary reveals a complex interplay between supply chain dynamics, regulatory compliance, and evolving passenger preferences. The aviation textile industry outlook remains positive, with opportunities emerging in regions like the U.S., UAE, and Singapore.

As the industry continues to evolve, staying abreast of trends in cabin comfort, luxury fabric use, and sustainable materials will be crucial for suppliers looking to capitalize on the growing demand for high-quality aircraft interior fabrics.

Global Aircraft Interior Fabric Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Aircraft Interior Fabric Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Aircraft Interior FabricMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Aircraft Interior Fabricplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Aircraft Interior Fabric Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Aircraft Interior Fabric Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Aircraft Interior Fabric Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofAircraft Interior FabricMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is driving the growth of the aircraft interior fabric market?

The aircraft interior fabric market is growing because more people want comfortable and visually appealing cabin interiors. It’s predicted that the global market will reach $2.42 billion by 2025.

What role do raw material suppliers play in the aircraft interior fabric market?

Raw material suppliers, including fabric manufacturers and dyeing and finishing services, play a crucial role in the upstream segment of the aircraft interior fabric market, providing the necessary materials for aircraft interior designers and manufacturers.

What trends are shaping the aircraft interior fabric market?

Trends in sustainability, comfort, and aesthetics are shaping the aircraft interior fabric market, with a focus on lightweight, durable, and environmentally friendly materials, such as recycled polyester and natural fibers.

How do fire safety standards impact the aircraft interior fabric market?

Fire safety standards have a significant impact on the aircraft interior fabric market. Manufacturers are required to follow strict testing and certification processes to ensure their materials comply with these standards.

How do geopolitical dynamics affect the aviation interior supply chains?

Geopolitical dynamics, including trade policies, tariffs, and regional trade agreements, play a crucial role in shaping the aviation interior supply chains, affecting the sourcing of materials and the competitiveness of suppliers.

What are the different types of fabrics used in aircraft interiors?

The aircraft interior fabric market can be divided into several types of fabrics, including wool, leather, synthetic, and composite materials. Each of these fabric types has its own distinct qualities, benefits, and uses.

What are the various applications of aircraft interior fabrics?

Aircraft interior fabrics are used in various applications, including seating, flooring, paneling, and curtains, each with specific requirements in terms of durability, aesthetics, and functionality.

How does regional demand impact the aircraft interior fabric market?

Regional demand varies across global regions, influenced by factors such as airline preferences, passenger expectations, and regulatory requirements. This results in different market trends in regions like North America, Europe, and Asia-Pacific.

What is the impact of the U.S. aircraft fleet renewal on the interior fabric market?

The renewal of the U.S. aircraft fleet is driving demand for advanced interior fabrics, as airlines look to upgrade their fleets with newer, more efficient aircraft featuring advanced interior designs and materials.

How is the UAE’s premium airline industry influencing the demand for luxury fabrics?

The UAE’s premium airline industry, with carriers like Emirates, is driving the demand for high-end, luxurious fabrics. Suppliers who can offer unique, high-quality fabrics are well-positioned to capitalize on this trend.

What opportunities exist for suppliers in Singapore’s growing aviation industry?

Singapore’s growing aviation industry presents opportunities for suppliers who can meet the needs of airlines based in Singapore and operating through its airports, in terms of quality, reliability, and innovation.

What is the future outlook for the aircraft interior fabric market?

The future of the aircraft interior fabric market is expected to be shaped by emerging trends such as sustainability, comfort, and advanced materials. Next-generation fabrics, like those shown in this image , will incorporate cutting-edge technologies to achieve improved performance, durability, and environmental sustainability.