$64.32 Million Vacuum Arc Remelting Market Thrives in 2025: Germany, Japan, and South Korea Advance Metallurgy

Discover comprehensive insights into the Vacuum Arc Remelting market, including growth projections from 2025 to 2033, technological advancements, and expanding applications in aerospace and defense. Learn about key market drivers, regional dynamics, and emerging opportunities in sustainable manufacturing processes across Germany, Japan and South Korea. Understand how VAR technology is shaping the future of high-quality material production and creating new investment possibilities in the global market.

- Last Updated:

Vacuum Arc Remelting Market Q1 and Q2 2025 Forecast

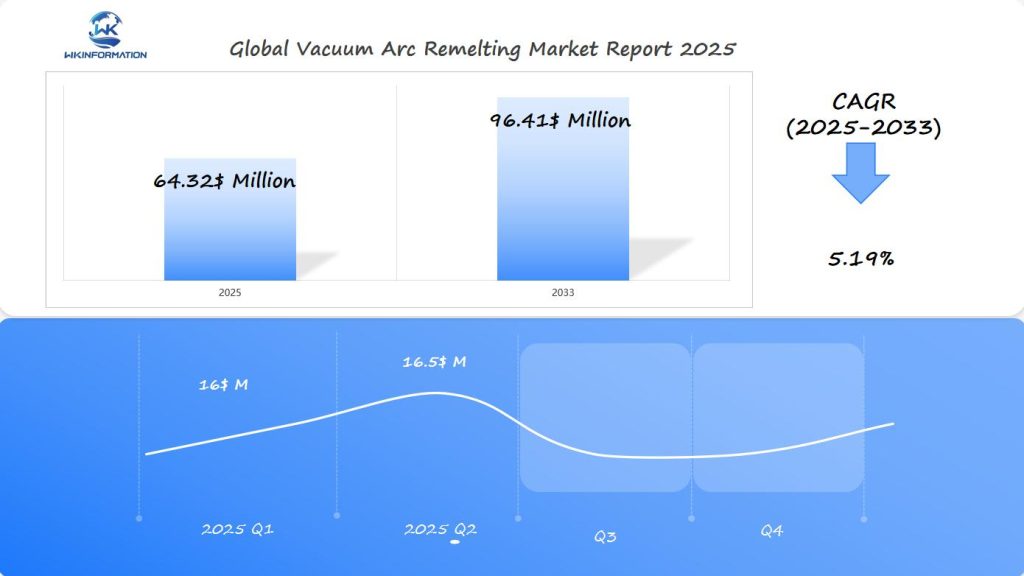

The Vacuum Arc Remelting market is projected to reach $64.32 million in 2025, with a CAGR of 5.19% from 2025 to 2033. In Q1 2025, the market is expected to generate approximately $16 million, driven by demand from the aerospace, automotive, and high-performance alloys industries in Germany, Japan, and South Korea.

VAR is used to produce high-quality materials, especially for aerospace and defense applications, where material purity is critical. The rising need for advanced materials in aerospace engineering and automotive manufacturing will be key contributors to market growth.

By Q2 2025, the market is expected to grow to $16.5 million, with Japan and South Korea seeing strong demand for vacuum arc remelting technology in the production of titanium and nickel-based alloys for use in high-performance aerospace components. Germany’s demand for high-quality steel and alloys in industrial applications will also support the market’s steady growth trajectory. As technology advancements in material science continue to evolve, the VAR process will play a significant role in producing next-generation materials for various industrial applications.

Key Takeaways

- Projected market value of $64.32 million by 2025

- Leading technological advancements in Germany, Japan, and South Korea

- Increasing demand across aerospace and industrial sectors

- Enhanced metal purity through advanced remelting techniques

- Significant investments in metallurgy research

Exploring the Upstream and Downstream Industry Chains for Vacuum Arc Remelting

The supply chain for Vacuum Arc Remelting is made up of many different industries working together. This complex system plays a crucial role in producing high-performance materials. VAR has a significant impact on metal manufacturing across various sectors, from sourcing raw materials to creating advanced products.

Upstream Industries: The Building Blocks of VAR

Upstream industries are essential players in the VAR ecosystem. They are responsible for providing the necessary resources and inputs for the VAR process. The key upstream industries involved in VAR include:

- High-purity metal ore extraction: This involves mining and extracting metal ores with a high level of purity, which is critical for producing high-quality metals through VAR.

- Specialized metal refining processes: These are specific methods used to refine metals and remove impurities, ensuring that the starting material for VAR is of the highest quality.

- Advanced alloy material preparation: This refers to the production and preparation of advanced alloys, which are combinations of different metals with unique properties, required for specific applications.

- Precision equipment manufacturing: This involves the production of specialized equipment and machinery used in the VAR process, ensuring precise control over temperature, pressure, and other parameters.

Downstream Industries: Benefiting from VAR’s Superior Materials

Downstream industries are the end-users of VAR’s high-performance materials. These industries utilize the superior qualities achieved through VAR in their manufacturing processes. Some critical sectors that benefit from this advanced metallurgical technique include:

- Aerospace: The aerospace industry requires lightweight yet strong materials for aircraft components, where even the slightest structural defects can have catastrophic consequences.

- Medical devices: Precision-engineered medical devices demand materials with exceptional biocompatibility and mechanical properties to ensure patient safety and device functionality.

- Automotive engineering: The automotive sector relies on advanced materials to enhance fuel efficiency, reduce emissions, and improve overall vehicle performance.

- Energy infrastructure: Renewable energy systems such as wind turbines and solar panels require robust materials capable of withstanding harsh environmental conditions.

Advantages of VAR over Conventional Melting Methods

The supply chain associated with VAR offers distinct advantages that traditional melting methods cannot provide. These benefits are crucial for manufacturers seeking competitive edges in their respective industries:

- Enhanced material purity: VAR’s vacuum environment prevents contamination during melting, resulting in higher purity levels compared to conventional methods.

- Improved mechanical properties: The controlled cooling rates achieved through VAR lead to refined microstructures and enhanced mechanical characteristics like strength and toughness.

- Reduced structural defects: By minimizing thermal gradients during solidification, VAR reduces the likelihood of defects such as porosity or segregation commonly found in castings.

- Increased performance reliability: The combination of superior material properties obtained through VAR ensures consistent performance under demanding operating conditions.

The Role of Technology in Advancing VAR

Continuous technological advancements play a pivotal role in improving the efficiency and effectiveness of Vacuum Arc Remelting processes. These innovations benefit both suppliers within the supply chain as well as end-users across various industries:

- Enhanced supplier-user collaboration: Technology facilitates better communication and collaboration between suppliers providing raw materials or equipment used in VAR processes with end-users utilizing those materials.

- Development of new alloys/materials: Innovations driven by technology enable researchers/engineers to develop novel alloys or composite materials tailored for specific applications requiring unique combinations/properties not achievable through conventional means.

Such advancements ultimately contribute towards creating superior-quality products meeting ever-evolving industry standards/requirements globally!

Key Trends Driving the Vacuum Arc Remelting Market: Demand for High-Purity Alloys

The vacuum arc remelting market is growing fast. This is because of a big need for high-purity alloys in key industries. Companies are working hard to make new materials that meet tough standards.

High-purity alloys are playing a big role in changing how we make things. They help solve hard engineering problems. This makes them very important for new ideas in manufacturing.

Aerospace Industry Requirements

The aerospace industry requires materials that are both strong and lightweight. VAR produces alloys that are ideal for aircraft and spacecraft applications. Some of the recent advancements in this field include:

- Enhanced titanium alloy compositions

- Improved structural integrity

- Reduced material weight

Automotive Sector Advancements

VAR is changing cars and trucks too. It helps make them lighter and more fuel-efficient. Some of the benefits are:

- Lightweight component structures

- Improved fuel efficiency

- Enhanced durability

Energy Sector Innovations

Energy metals need to work well in very tough conditions. VAR helps make alloys that can handle high heat and stress.

“The future of industrial innovation lies in our ability to create materials that push the boundaries of performance and reliability.” – Advanced Materials Research Institute

| Industry Sector | Key VAR Material Requirements | Performance Characteristics |

| Aerospace | Titanium Alloys | High Strength-to-Weight Ratio |

| Automotive | Aluminum Composites | Enhanced Fuel Efficiency |

| Energy | Nickel-Based Superalloys | Extreme Temperature Resistance |

VAR is leading the way in material science. It’s making it possible to create materials that are more precise and perform better in many fields.

Challenges in Vacuum Arc Remelting Production and Energy Consumption

The Vacuum Arc Remelting (VAR) industry faces big challenges. These challenges affect manufacturers and how technology advances. VAR production hurdles come from complex technical and economic barriers that need new solutions.

1. Energy Efficiency Concerns

Energy efficiency is a big worry in VAR processing. Companies face big energy use problems that raise costs. The high-temperature processes need a lot of electricity, making it hard for companies to keep up.

2. High Costs of VAR Technology

Costs are a big deal in VAR technology. Small to medium-sized companies find it hard to afford the big money needed for VAR. Sophisticated metal processing demands a lot of money, making it hard for them to enter the market.

- High initial equipment investment

- Substantial electrical energy requirements

- Complex technological infrastructure

- Specialized technical expertise needed

3. Need for Research and Innovation

Research is working to make VAR systems use less energy. New technologies aim to cut down on electricity use while keeping metal quality high. Improving design and process could help solve current problems.

Technological innovation is the way to beat VAR production limits. It makes advanced metal processes more affordable.

Geopolitical Influence on the Vacuum Arc Remelting Market

The global Vacuum Arc Remelting market is facing tough challenges due to complex geopolitical factors. International trade policies greatly influence the use of vacuum arc remelting technologies. This leads to changes in how things are made and how the market works.

Important Geopolitical Factors Affecting the Global Vacuum Arc Remelting Market

- Diplomatic tensions between big manufacturing countries

- Strategic trade policies that affect access to raw materials

- International tariff rules

- Export control systems

Companies must deal with complex geopolitical situations. Countries like the United States, Germany, and Japan are finding ways to stay ahead in advanced metal technologies.

Geopolitical dynamics are reshaping the vacuum arc remelting industry’s global competitive environment.

It’s crucial for companies in the global Vacuum Arc Remelting market to adapt strategically. They are building strong supply chains. These can handle disruptions from trade talks and political changes.

New economies are putting money into advanced metal processing, opening up new chances. Technological innovation and partnerships will be essential for success in this changing market.

Vacuum Arc Remelting Market by Type: Titanium Alloys, Nickel Alloys, and Specialty Steel

The Vacuum Arc Remelting market deals with turning raw materials into high-performance alloys. These advanced materials are key in many industries. They drive innovation and improve technology.

- Titanium alloys for precision engineering

- Nickel alloys for extreme environment performance

- Specialty steel for critical infrastructure

Titanium Alloys in Advanced Manufacturing

Titanium alloys have transformed the aerospace and medical industries. They are both strong and lightweight. VAR produces parts for aircraft and medical equipment that can withstand greater pressure over time.

Nickel Alloys for Extreme Conditions

Nickel alloys are highly effective in high-temperature environments. They find applications in various industries such as gas turbines, chemical plants, and nuclear sectors. The VAR process ensures their resistance to corrosion and heat, thereby extending the lifespan of equipment.

Specialty Steel in Critical Sectors

Specialty steel made by VAR is essential in industries and defense. It’s designed to be durable and efficient in machinery, construction, and military equipment.

Applications of Vacuum Arc Remelting in Aerospace, Medical, and Industrial Sectors

Vacuum Arc Remelting (VAR) has transformed how we process materials in key areas. It’s crucial in aerospace, medical, and industrial fields. It produces high-purity alloys, addressing significant engineering challenges.

Aerospace Applications

In aerospace, VAR is a game-changer. It produces lightweight yet strong materials for aircraft and spacecraft, leading to advancements in components such as turbine blades and engine parts.

- Aerospace structural components with enhanced strength

- High-performance turbine blade manufacturing

- Lightweight yet durable spacecraft materials

Medical Applications

In the medical field, VAR plays a vital role in creating top-quality implants. It enables the production of body-safe and robust alloys, essential for surgical instruments and implants.

Industrial Applications

VAR is also critical in industries like power generation, oil, and gas. It facilitates the creation of materials capable of withstanding extreme temperatures and corrosive substances, supporting innovative industrial applications.

- Power generation equipment components

- Chemical processing machinery

- High-performance industrial alloys

Vacuum Arc Remelting continues to advance material science, unlocking new opportunities across various sectors.

Global Insights into the Vacuum Arc Remelting Market

The global Vacuum Arc Remeltingmarket is a fast-changing world of tech and strategy. Companies and researchers are keen to grasp the complex regional market shares. These shares are key to understanding international trade in vacuum arc remelting technologies.

Geographical areas have their own special traits in the global Vacuum Arc Remelting market. Each region has its own way of handling metal processing:

- North America is a leader in aerospace tech

- European countries are known for precision engineering

- Asian countries are growing fast in manufacturing

How industries use VAR technology varies worldwide. Technological capabilities and economic setup are key. They decide how well VAR systems do in different places.

“The future of metal processing depends on global market trends and new tech.” – Industry Expert

Trade patterns show how connected manufacturers, research, and industries are. Investing in VAR tech is changing the world of making things. It opens up new chances for tech progress and economic growth.

Germany’s Leadership in High-Precision Metallurgy and Specialty Alloy Production

Germany leads in German metallurgy, pushing the limits in precision alloys. It’s a top player in the European Vacuum Arc Remelting market. The country’s advanced manufacturing skills make it key in high-performance metals.

What Makes Germany’s Metallurgy Stand Out?

Germany’s metallurgy is known for:

- Exceptional engineering precision

- Advanced research and development infrastructure

- Rigorous quality control standards

- Cutting-edge technological innovations

The European Vacuum Arc Remelting market gains a lot from Germany’s focus on metallurgy. German makers create special alloys for tough fields like aerospace, cars, and energy.

Key Contributions of German Metallurgy by Industry Sector

| Industry Sector | Key Metallurgical Contributions | Precision Alloy Applications |

| Aerospace | High-temperature resistant alloys | Turbine engine components |

| Automotive | Lightweight structural alloys | Performance engine parts |

| Energy | Corrosion-resistant materials | Power generation equipment |

How German Research and Labs Contribute to Metallurgy

German research places and labs keep improving in metallurgy. Their work together with industry leads to new alloy developments.

German engineering is the top in metallurgical excellence and precision.

Germany’s investments in research, development, and making things better keep it at the top in advanced metal tech.

Japan’s Innovation in High-Performance Metal Alloys for Aerospace and Medical Applications

Japan is at the forefront of advanced metallurgy, revolutionizing the aerospace and medical industries with cutting-edge technology. Their unwavering commitment to precision engineering has significantly enhanced the Vacuum Arc Remelting (VAR) processes, resulting in the production of high-performance alloys that are now globally recognized as industry leaders.

Breakthrough Materials for Space and Medicine

Japanese scientists have developed remarkable materials specifically designed for both space exploration and medical applications:

- Lightweight titanium alloys: These alloys boast exceptional strength-to-weight ratios, making them ideal for aerospace structures where minimizing weight without compromising strength is crucial.

- Corrosion-resistant medical alloys: Advanced implants require materials that can withstand bodily conditions over extended periods. Japan’s expertise in metallurgy has led to the creation of corrosion-resistant alloys specifically tailored for such applications.

- Special metal compositions: Extreme environments, whether in outer space or within the human body, demand unique material properties. Japanese researchers have formulated specialized metal compositions capable of enduring these harsh conditions.

Precision Metallurgy: The Key to Success

Japan’s innovation goes beyond conventional manufacturing techniques. The concept of precision metallurgy plays a pivotal role in both the aerospace and medical sectors. Through the use of VAR, Japanese manufacturers have successfully produced titanium and nickel alloys with unparalleled accuracy and consistency.

“Japanese metallurgical innovations represent the pinnacle of materials science, bridging advanced engineering with practical applications.” – Dr. Kenji Tanaka, Materials Research Institute

Collaborative Efforts for Advancements in Medical Alloys

Research institutions and private companies in Japan are actively collaborating to further enhance medical alloys. By combining their expertise and resources, they aim to develop materials that are not only biocompatible but also possess superior mechanical properties.

This collaborative approach reflects Japan’s ability to tackle complex scientific challenges head-on while simultaneously improving people’s lives through innovative solutions.

South Korea’s Expanding Market for Advanced Metallurgical Processing Technologies

South Korean metallurgy is a big deal worldwide. The country is leading in advanced metal tech. Big names like Samsung and LG are pushing the limits of innovation.

South Korea shines in several key areas:

- Advanced semiconductor manufacturing

- High-performance automotive components

- Precision engineering for electronic devices

The country’s focus on vacuum arc remelting (VAR) has opened new doors. Cutting-edge research facilities are making materials better for many industries.

South Korea’s metallurgy has some major strengths:

- Strong research and development setup

- Good teamwork between schools and factories

- Big support from the government for new tech

The Asian VAR market is growing fast, with South Korea at the forefront. The country is a top player in making high-quality materials and advanced tech.

The Future of Vacuum Arc Remelting: Sustainable Processing and Advanced Alloy Development

The vacuum arc remelting (VAR) industry is about to undergo significant changes. Companies are now prioritizing environmental sustainability in their VAR processes and actively pursuing the development of new materials.

The Impact of New Technologies

New technologies are reshaping the production methods of advanced alloys. The combination of eco-friendly manufacturing practices and cutting-edge metal science is creating new opportunities for growth in this field.

Eco-Friendly VAR Processes

More and more industries are adopting sustainable VAR methods. Some key improvements include:

- Less energy use

- Better ways to recycle metal

- Lower carbon footprint production

Next-Generation Alloy Innovations

New alloys are changing what we know about materials. Scientists are making materials that perform better through advanced VAR methods.

| Alloy Type | Key Performance Characteristics | Potential Applications |

| Titanium Composites | High strength-to-weight ratio | Aerospace, Medical Implants |

| Nickel Superalloys | Extreme temperature resistance | Jet Engines, Industrial Turbines |

Integration with Additive Manufacturing

VAR and additive manufacturing are coming together. This mix is creating new ways to make things. It lets us make complex shapes with amazing material properties.

Now, we can make detailed parts that are strong and perform well. This was not possible before with old ways of making things.

Competitive Landscape in the Vacuum Arc Remelting Market

The Vacuum Arc Remelting market is very competitive. Market research insights show that global players are pushing for new technologies. They are trying to get a big share of the market.

Here are some of the key players in the Vacuum Arc Remelting market:

-

ALD Vacuum Technologies GmbH – Germany

-

INTECO Group – Austria

-

Inductotherm Group (Consarc) – United States

-

Seco/Warwick Group – Poland

-

Xinlanhai Furnace Co. – China

-

Suzhou Zhenwu Electric Furnace Co., Ltd. – China

-

Dingsheng Furnace Co. – China

-

Shenyang Jinyan Electric Furnace Co. – China

-

Hengjin Furnace Co. – China

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Vacuum Arc Remelting Market Report |

| Base Year | 2024 |

| Segment by Type | · Consumable Electrode

· Non-Consumable Electrode |

| Segment by Application | · Aerospace

· Energy Sector · Medical Devices |

| Geographies Covered | · North America (United States, Canada)

· Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The Vacuum Arc Remelting market is looking bright for investors and industry players. It’s expected to grow from USD 64.32 Million in 2025 to USD 96.41 Million by 2033. This growth is seen across various sectors, thanks to investments in advanced metallurgy.

Key Areas of Focus

Investors are eyeing opportunities in:

- Making specialized equipment

- Creating new alloys

The market is primarily focused on:

- Titanium

- Nickel

- Advanced steels

Technological Advancements

Companies and research groups are actively working on improving VAR technologies with the following goals:

- Saving energy

- Enhancing material quality

Leading Countries in Metallurgical Solutions

The following countries are at the forefront of developing new metallurgical solutions:

- United States

- Germany

- Japan

- South Korea

Future Growth Drivers

Sustainability and innovation are expected to drive the future growth of the Vacuum Arc Remelting market. Investors should keep an eye out for:

- Eco-friendly methods

- New alloys

- Additive manufacturing

Changing Landscape of Global Manufacturing

The Vacuum Arc Remelting market is poised for significant changes as global manufacturing needs become more complex. Companies that leverage advanced materials, precision techniques, and overcome challenging obstacles will discover the most promising investment opportunities.

Global Vacuum Arc Remelting Market Report (Can Read by Free sample) – Table of

Contents

Chapter 1: Vacuum Arc Remelting Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Vacuum Arc RemeltingMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Vacuum Arc Remelting players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Vacuum Arc Remelting Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Vacuum Arc Remelting Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Vacuum Arc Remelting Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofVacuum Arc Remelting Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is Vacuum Arc Remelting (VAR) technology?

Vacuum Arc Remelting is a high-tech process for making pure metal alloys. It melts and refines materials in a vacuum. This method is key for making special alloys for aerospace, cars, and energy fields.

Which countries are leading in Vacuum Arc Remelting technology?

Germany, Japan, and South Korea lead in VAR technology. They are making significant progress in precise metallurgy and advanced alloys.

What are the main challenges in Vacuum Arc Remelting production?

The main challenges in Vacuum Arc Remelting production are:

- High costs

- Significant energy consumption

- Complex processes

Companies are actively working to overcome these obstacles and make the production process more efficient and affordable.

How does Vacuum Arc Remelting improve material quality?

VAR removes impurities and makes materials more uniform. This leads to stronger, more reliable alloys.

What types of alloys are produced using VAR technology?

VAR makes:

- Titanium alloys for aerospace and medicine

- Nickel alloys for high heat applications

- Special steels for industry and defense purposes

What is the projected market growth for Vacuum Arc Remelting?

The Vacuum Arc Remelting market is expected to reach approximately $64.32 million by 2025. This growth is primarily driven by the demand for improved alloys and innovative manufacturing technologies.

How is Vacuum Arc Remelting becoming more sustainable?

Eco-friendly VAR processes are being developed. They aim to use less energy, reduce environmental harm, and use new tech like 3D printing.

What role do geopolitical factors play in the Vacuum Arc Remelting market?

Global trade policies, diplomatic ties, and tech rivalry affect the Vacuum Arc Remelting market. They influence the supply of raw materials and how equipment is made.

What future innovations are expected in Vacuum Arc Remelting?

New alloys with amazing properties, more energy-efficient processes, and combining with 3D printing are expected. These advancements will change the industry.