$313.25 Million Wafer Used Quartz Boat Market Expands in 2025: South Korea, Taiwan, and Germany Lead Semiconductor Growth

Discover the latest insights into the Wafer Used Quartz Boat Market for Q1-Q2 2025. As semiconductor manufacturing advances drive market growth to $313.25 million, explore key developments in South Korea, Taiwan, and Germany’s semiconductor industries. Learn about the crucial role of quartz boats in wafer processing, emerging technologies, and market opportunities in this comprehensive analysis of the semiconductor manufacturing ecosystem.

- Last Updated:

Wafer Used Quartz Boat Market Q1 and Q2 2025 Forecast

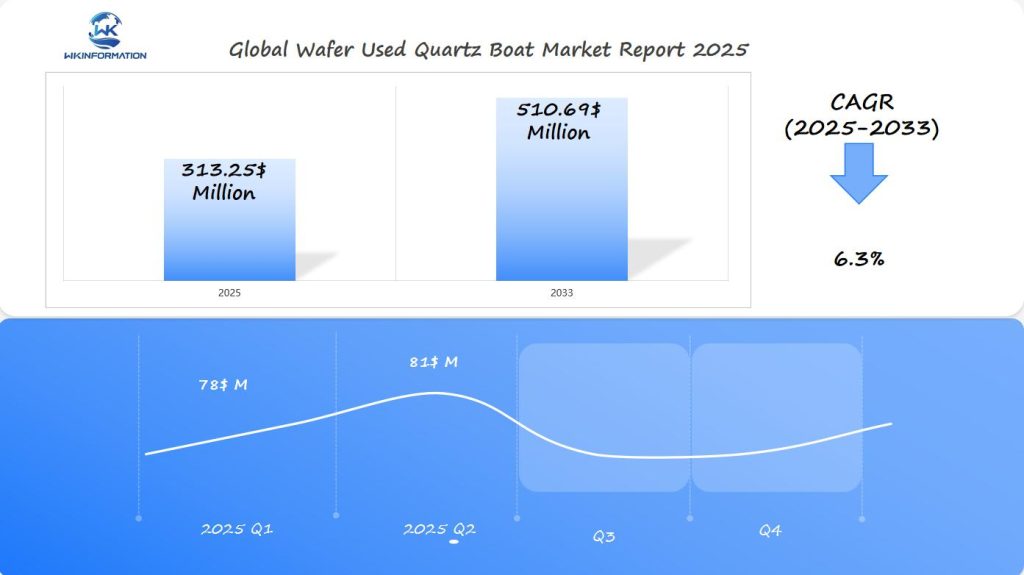

The Wafer Used Quartz Boat market is projected to reach $313.25 million in 2025, with a CAGR of 6.3% from 2025 to 2033.

In Q1 2025, the market is expected to generate approximately $78 million, driven by the increasing demand for semiconductor manufacturing and the growing adoption of silicon wafers in the U.S., Japan, and China. Quartz boats are essential for wafer processing in semiconductor and electronics applications, providing the stability required for high-temperature applications. As advanced technologies in the electronics and solar energy sectors continue to evolve, the demand for quartz boats is expected to rise.

By Q2 2025, the market is expected to grow to $81 million, as China and Japan continue to increase investments in semiconductor production. The U.S. will also see strong demand driven by electronic device manufacturing and solar panel production. The increasing need for precision in wafer handling and advanced semiconductor applications will remain key drivers of growth in the quartz boat market.

Key Takeaways

- Market projected to grow from $313.25 million in 2025 to $510.69 million by 2033

- Compound Annual Growth Rate (CAGR) estimated at 6.3%

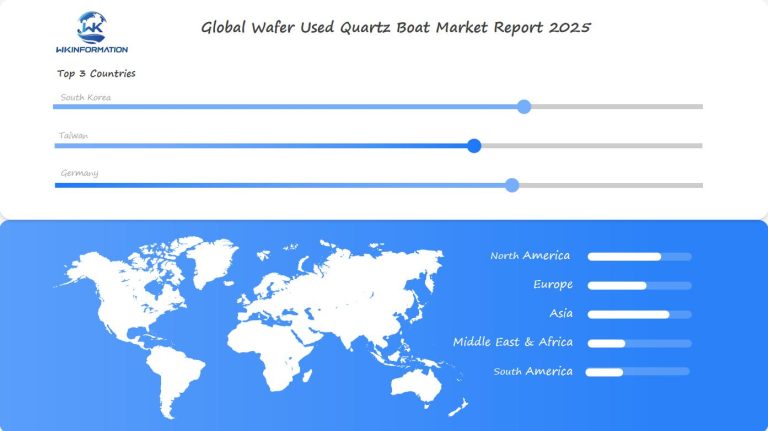

- South Korea, Taiwan, and Germany lead semiconductor manufacturing innovations

- Quartz boats critical for precision wafer processing

- Technological advancements driving market expansion

Exploring the Upstream and Downstream Industry Chains for Wafer Used Quartz Boats

The semiconductor manufacturing supply chain is complex. It relies heavily on quartz boat production. These ceramic vessels are key for high-temperature processing of semiconductors.

Importance of Quartz Boats in Semiconductor Fabrication

Quartz boats are vital in semiconductor fabrication. They are used in important processes like:

- Low-Pressure Chemical Vapor Deposition (LPCVD)

- Boron Diffusion

- High-Temperature Oxidation

- Thermal Treatment

Upstream Stakeholders: Who’s Involved in Making Quartz Boats?

The upstream chain involves many stakeholders. They focus on sourcing and making quartz boats. These include:

- Raw material suppliers of high-purity quartz

- Precision manufacturing facilities

- Quality control and testing labs

- Research and development centers

How Upstream Activities Impact Semiconductor Manufacturing

Here’s how the activities in the upstream supply chain impact semiconductor manufacturing:

| Supply Chain Stage | Key Activities | Impact on Semiconductor Manufacturing |

| Raw Material Sourcing | High-purity quartz extraction | Determines initial material quality |

| Manufacturing | Precision boat fabrication | Ensures consistent wafer processing |

| Quality Control | Rigorous testing and validation | Guarantees reliability in semiconductor production |

Downstream industries rely on the quality of quartz boats. The boats’ performance affects the efficiency and reliability of electronic devices.

Strategic collaboration across these supply chain segments is crucial for maintaining the high standards required in modern semiconductor manufacturing.

Key Trends Driving the Wafer Used Quartz Boat Market: Semiconductor Industry Growth

The semiconductor industry is growing fast, thanks to new tech and global demand for better electronics. Experts predict a big jump in semiconductor tech, changing many industries.

Several key trends are pushing the wafer used quartz boat market ahead. They’re driving up demand for semiconductors in many areas:

Rising Demand for Advanced Electronic Devices

People and companies want better electronic gadgets. Smartphones, laptops, tablets, and wearables are getting more complex. They need advanced semiconductors made with high precision.

- Smaller electronic parts

- More powerful computing

- Better energy efficiency

Expansion of 5G Technology and IoT

The introduction of 5G and IoT is opening new doors for chip makers. These technologies need chips that work well and are reliable, with few mistakes.

- Enhanced network connectivity

- Increased data transmission speeds

- Complex semiconductor design requirements

Automotive Sector’s Increasing Semiconductor Usage

Automotive semiconductors are growing fast, thanks to electric cars, self-driving tech, and safety systems. Modern cars have complex electronics that need precise semiconductors.

- Electric vehicle technology

- Advanced safety systems

- Complex vehicle electronics

These trends show how important wafer used quartz boats are for making advanced semiconductors.

Challenges in Wafer Used Quartz Boat Manufacturing and Material Sourcing

Semiconductor makers face big hurdles in making high-purity quartz boats. These boats are key for processing wafers. They need to be made with great precision and top-notch material quality.

Material Sourcing Challenges

Finding the right quartz material is a big challenge. Companies must get ultra-pure quartz that meets strict standards. They face several big obstacles in finding and using this material:

- Locating reliable sources of high-purity quartz

- Ensuring material consistency across production batches

- Minimizing impurities that could compromise semiconductor performance

Manufacturing Challenges

But it’s not just about finding the right material. Making quartz boats that can handle the harsh conditions of semiconductor making is also tough. This requires careful engineering.

“The semiconductor industry demands perfection in every micron of quartz boat production,” says leading industry expert Dr. Sarah Chen.

| Manufacturing Challenge | Impact on Semiconductor Production |

| Material Purity | Reduces potential contamination risks |

| Dimensional Accuracy | Ensures precise wafer positioning |

| Thermal Resistance | Maintains structural integrity during high-temperature processes |

New solutions are coming to tackle these challenges. Better purification methods and advanced manufacturing tech are improving quartz boat quality. This helps the semiconductor industry meet its high standards.

Geopolitical Influence on the Wafer Used Quartz Boat Market

The global semiconductor supply chain is now a key area for tech and economic power. Geopolitical tensions are changing market dynamics in big ways. This is especially true for special parts like wafer used quartz boats.

The Role of Trade Policies

Trade policies are playing a big role in changing the semiconductor industry. Countries are trying to control key manufacturing tech. This is causing big changes in the global market.

“Control of semiconductor supply chains represents the new economic warfare of the 21st century.” – Tech Industry Analyst

- United States has implemented strict export controls on advanced semiconductor technologies

- China’s semiconductor ambitions face significant international restrictions

- European Union developing independent semiconductor manufacturing capabilities

Challenges for Manufacturers

Manufacturers of wafer used quartz boats face complex geopolitical landscapes. They must make strategic decisions based on trade, tech transfer rules, and local manufacturing.

They need to adapt fast to changing global politics. They must focus on investment, supply chain strength, and innovation. These are all linked to success in the international market.

Emerging market dynamics suggest that semiconductor component manufacturers will need unprecedented levels of strategic flexibility to succeed in the current global environment.

Wafer Used Quartz Boat Market by Type: Standard and Customized Variants

The world of semiconductor manufacturing is always changing. Different types of quartz boats are needed for various tasks. These boats are key for making advanced semiconductors.

Today, makers want boats that can handle wafers better. There are three main types of quartz boats for different needs:

- Right Angle Quartz Boats

- U-shaped Quartz Boats

- V-shaped Quartz Boats

Right Angle Quartz Boats

Right angle boats are the most commonly used type, accounting for approximately 40% of the market. They are highly effective in ensuring that wafers remain stable and properly aligned, which is essential for critical processes involved in semiconductor manufacturing.

U-shaped Quartz Boats

U-shaped boats are used in about 30% of the market. They are good for managing heat and aligning wafers in complex tasks. This makes them valuable in certain processes.

V-shaped Quartz Boats

V-shaped boats are designed for specific requirements in semiconductor manufacturing. They provide greater flexibility in handling wafers during intricate processes.

There is a significant demand for customized solutions in quartz boat design. Manufacturers are actively working to develop boats that cater to specific needs. This ensures optimal outcomes and efficiency in semiconductor production.

Applications of Wafer Used Quartz Boats in Semiconductor Fabrication and Processing

Quartz boats are key in making semiconductors. They help process wafers through various thermal steps. These tools support delicate wafers, ensuring they work well and are of high quality.

The semiconductor world needs quartz boats for many steps. They turn raw silicon into advanced electronic parts. Their special features are vital in high-tech wafer processing.

Chemical Vapor Deposition (CVD)

CVD is a crucial process in semiconductor manufacturing. Quartz boats are highly effective in this application due to their ability to:

- Stably hold multiple wafers

- Withstand high temperatures

- Ensure uniform gas distribution

- Minimize contamination

Diffusion Processes

Diffusion requires precise temperature control and minimal material interaction. Quartz boats are ideal for this purpose. They offer several advantages:

- Maintain proper positioning of wafers

- Remain inert and do not react with chemicals

- Facilitate uniform distribution of dopants

- Ensure efficient heat transfer

Oxidation and Etching

In 2023, oxidation was a big part of using quartz boats, making up about 35% of uses. These boats help change wafer surfaces by:

- Handling materials with high purity

- Reducing contamination risk

Quartz boats keep getting better. They meet the growing needs of semiconductor making with new materials and designs.

Global Insights into the Wafer Used Quartz Boat Market

The global wafer used quartz boat market is full of innovation and growth. Asia Pacific leads, making up about 45% of the market in 2023. This shows the region’s strong manufacturing and investment in new tech.

There’s a big change in global market demand. The growth is especially high in areas with strong tech scenes.

| Region | Market Share | Key Drivers |

| Asia Pacific | 45% | Electronics Manufacturing |

| North America | 25% | Technological Innovation |

| Europe | 20% | Research & Development |

| China | 10% | Industrial Expansion |

Demand for wafer used quartz boats varies by region. Semiconductor makers are focusing on precise tools to stay ahead.

The future of semiconductor manufacturing is in smart investments and tech excellence.

- Asia Pacific leads in manufacturing capabilities

- North American firms drive technological innovation

- European markets emphasize research development

The global market for wafer used quartz boats looks bright. It’s expected to grow in new tech areas.

South Korea’s Dominance in Semiconductor Manufacturing and Quartz Boat Demand

The South Korean semiconductor industry is leading the world in technology. It drives a huge demand for wafer used quartz boats. Samsung and SK Hynix make South Korea key in advanced semiconductors, thanks to their research and big investments.

Being top in semiconductor production, South Korea has a strong system for quartz boat equipment. The country’s manufacturing has grown fast. It supports tech growth and keeps it competitive globally.

- Samsung Electronics leads global memory chip production

- SK Hynix ranks second in semiconductor manufacturing worldwide

- Continuous investment in research and development

South Korea’s tech progress in semiconductors boosts quartz boat demand. The need for precise manufacturing pushes innovation. This leads to new equipment for complex semiconductor making.

South Korean makers are dedicated to staying ahead in semiconductors. Their ongoing investment in advanced tech ensures they keep leading in quartz boat technology.

Taiwan’s Growing Market for High-Precision Wafer Processing Equipment

The Taiwanese semiconductor industry is a leader in global tech innovation. TSMC is at the forefront with its advanced manufacturing. Taiwan is key in the global market for wafer used quartz boats.

Taiwan’s semiconductor ecosystem has several strengths:

- Exceptional precision in high-performance manufacturing

- Significant investment in research and development

- Strategic partnerships with global technology leaders

TSMC’s leadership in semiconductors drives demand for advanced wafer processing equipment. The company’s focus on innovation boosts the market for high-precision quartz boats in semiconductor fabrication.

Taiwan’s semiconductor industry represents a critical nexus of technological innovation and manufacturing excellence.

The market for wafer used quartz boats in Taiwan is growing. This growth is due to the increasing need for smaller electronic devices and advanced semiconductor technologies. Manufacturers are now creating specialized quartz boats to meet the needs of next-generation semiconductor production.

Germany’s Role in Advanced Quartz Boat Development for Semiconductor Applications

The European semiconductor industry has grown a lot. German engineering is key to this growth. Germany leads in making advanced quartz boats, improving how semiconductors are made.

Innovations Driven by German Expertise

German experts have pushed the limits of wafer processing technologies. Their skill in precision engineering makes high-performance quartz boats. These boats meet the toughest needs in semiconductor manufacturing.

- Cutting-edge material research

- Advanced manufacturing techniques

- Precision engineering solutions

Collaborative Efforts Shaping the Future

Germany’s semiconductor world is strong because of teamwork. Important German groups and tech companies work together. They aim to make new quartz boat tech that makes making semiconductors better.

| Innovation Area | Key Contributions | Impact on Semiconductor Industry |

| Material Engineering | High-purity quartz boat development | Improved wafer processing precision |

| Manufacturing Techniques | Advanced fabrication methods | Enhanced semiconductor production quality |

| Research Collaboration | Cross-industry technology partnerships | Accelerated technological innovation |

German technological innovation keeps pushing the European semiconductor industry ahead. This makes Germany a vital part of making semiconductor equipment worldwide.

The Future of Wafer Used Quartz Boats: High-Purity Materials and Smart Fabrication

The semiconductor industry is about to undergo a significant transformation. This shift is driven by the introduction of innovative materials and intelligent manufacturing processes. Wafer used quartz boats are set to receive a substantial upgrade, thanks to these fresh concepts and advancements in technology.

1. High-Purity Materials: The Key to Enhanced Performance

Industry 4.0 is making quartz boat making smarter and better. Companies are looking into new materials that will make things work better and last longer.

- Silicon Carbide (SiC) boats offer superior thermal stability

- Advanced material compositions reduce maintenance requirements

- Precision engineering enables higher semiconductor processing standards

New trends in making semiconductors show how important pure materials are. Moving to Silicon Carbide is a big step up. It gives makers a chance to make wafer processing even better.

The future of semiconductor manufacturing lies in intelligent design and advanced material technologies.

2. Smart Fabrication Techniques: Redefining Production Methods

Smart ways of making things are changing how quartz boats are made. These new methods make making quartz boats more precise, efficient, and flexible. They promise to make semiconductors work better and last longer.

Competitive Landscape in the Wafer Used Quartz Boat Market

The wafer used quartz boat market is very competitive. Market leaders are always trying to stay ahead with new technology. Companies like Ferrotec, Momentive Technologies, and QSIL AG lead with their research and development.

Key Players in the Industry

Here are some of the key players in the wafer used quartz boat market:

-

Ferrotec Holdings Corporation – Japan

-

Momentive Technologies –United States

-

QSIL AG – Germany

-

Heraeus – Germany

-

Techno Quartz Inc. – Japan

-

Tosoh Quartz – Japan

-

Shin-Etsu Quartz Products Co. – Japan

-

Japan Super Quartz Co. – Japan

-

Hubei Feilihua Quartz Glass Co., Ltd. – China

-

Hanntak – China

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Wafer Used Quartz Boat Market Report |

| Base Year | 2024 |

| Segment by Type | · Single Crystal Quartz Boats

· Polycrystalline Quartz Boats |

| Segment by Application | · Low-Pressure Chemical Vapor Deposition (LPCVD)

· Boron Diffusion Processes · Versatility in Semiconductor Manufacturing |

| Geographies Covered | · North America (United States, Canada)

· Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The wafer used quartz boat market is a promising place for investment. It’s expected to grow from $313.25 million in 2025 to $510.69 million by 2033. This growth shows a strong CAGR of 6.3%. Tech investors and semiconductor makers are watching this market closely for big opportunities.

Key Drivers of Growth

- Advanced Semiconductor Manufacturing: Companies making high-purity quartz boats for 5G, car tech, and IoT are leading the way.

- Investment in R&D: Investing in research and development is vital for staying ahead and innovating.

Regional Trends to Watch

It’s important to look at regional trends, especially in South Korea, Taiwan, and Germany. These places are at the heart of tech progress and offer unique investment chances.

The Future of Semiconductors

The ongoing change in semiconductors means a bright future for those investing in precision and new materials.

The outlook for this market is bright, with lots of growth and tech changes. Those who get the complex world of semiconductors and know where to invest will do well. With more demand for advanced electronics, the chance for smart investments is huge.

Global Wafer Used Quartz Boat Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Wafer Used Quartz Boat Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Wafer Used Quartz BoatMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Wafer Used Quartz Boatplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Wafer Used Quartz Boat Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Wafer Used Quartz Boat Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Wafer Used Quartz Boat Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofWafer Used Quartz BoatMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are wafer used quartz boats and why are they important in semiconductor manufacturing?

Wafer used quartz boats are special containers for semiconductor wafers. They help keep wafers safe and in the right place during making. This is key for steps like chemical vapor deposition and etching.

Which countries are leading the wafer used quartz boat market?

The leading countries in the wafer used quartz boat market are South Korea, Taiwan, and Germany. These countries are known for their excellence in semiconductor manufacturing and technological innovation.

What are the main types of quartz boats available in the market?

The main types of quartz boats available in the market are:

- Right angle quartz boats

- U-shaped quartz boats

- V-shaped quartz boats

Each type of quartz boat serves a specific purpose in the semiconductor manufacturing process. Additionally, manufacturers now provide custom solutions to cater to specific requirements.

How are emerging technologies driving demand for wafer used quartz boats?

New technologies such as 5G and IoT are increasing the demand for quartz boats. These technologies require improved semiconductor manufacturing processes, which in turn drives the need for quartz boats.

What challenges do manufacturers face in producing wafer used quartz boats?

Making these boats is tough. It involves finding pure quartz and keeping manufacturing precise. Research is ongoing to solve these problems.

How do geopolitical factors impact the wafer used quartz boat market?

Global events and trade policies affect the market. They change how prices are set and strategies are made.

What are the key applications of wafer used quartz boats in semiconductor manufacturing?

They are vital in processes like chemical vapor deposition and etching. They protect wafers, ensuring quality and performance.

What future trends are expected in the wafer used quartz boat market?

Expect advancements in materials and the use of Industry 4.0. These aim to boost performance and efficiency.

How large is the current wafer used quartz boat market?

The market is expected to reach $313.25 million by 2025. This growth is driven by the increasing demand for semiconductors and technological advancements.

How are semiconductor manufacturers addressing the need for more specialized quartz boats?

Makers are creating custom boats for specific needs. They focus on better thermal stability and material purity. This supports complex fabrication processes.