$7.18 Billion Industrial Girth Gear Market Booms in 2025: India, Germany, and Mexico Lead Global Demand

Growing demand for industrial girth gears in mining, cement, and energy sectors drives the Industrial Girth Gear Market expansion, with robust growth in India, Germany, and Mexico

- Last Updated:

Industrial Girth Gear Market Q1 and Q2 2025 Forecast

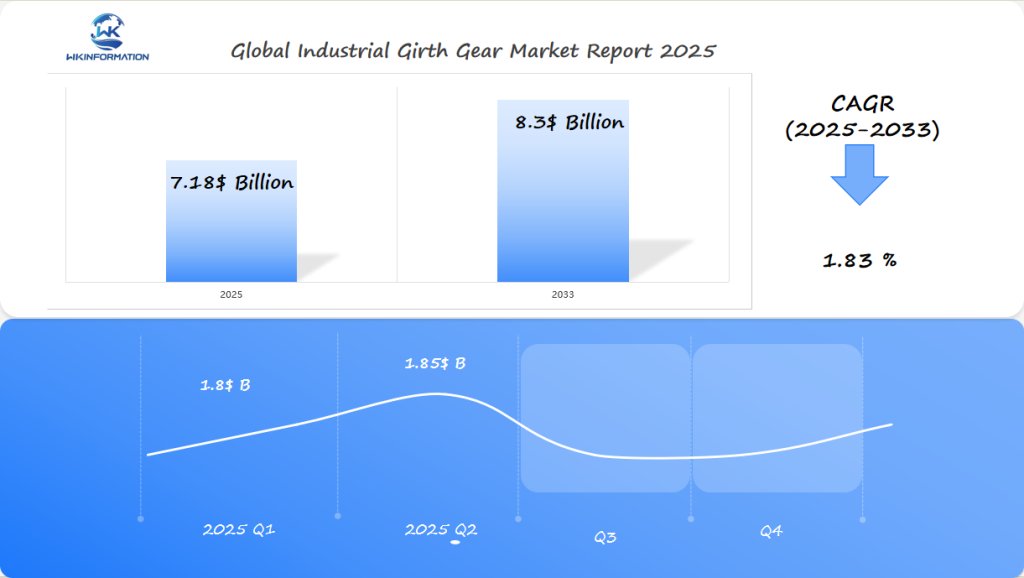

The Industrial Girth Gear market is expected to reach $7.18 billion in 2025, with a CAGR of 1.83% from 2025 to 2033. In Q1 2025, the market is projected to generate approximately $1.8 billion, largely driven by demand from the cement, mining, and steel industries in India, Germany, and Mexico. Girth gears are essential for large-scale industrial machinery used in kilns, mills, and grinders, and their demand is often linked to the production levels in these energy-intensive sectors. As industrial automation and energy efficiency improve, the demand for high-performance girth gears is expected to remain steady, even with a moderate growth rate.

By Q2 2025, the market is expected to grow to $1.85 billion, with industrial sectors in Germany and Mexico increasingly relying on advanced girth gear systems for their cement production and mining operations. The ongoing investments in machinery upgrades and maintenance contracts will sustain steady growth in the market, even though growth rates remain lower compared to other industrial sectors.

Key Takeaways

- Market projected to reach $7.18 billion by 2025

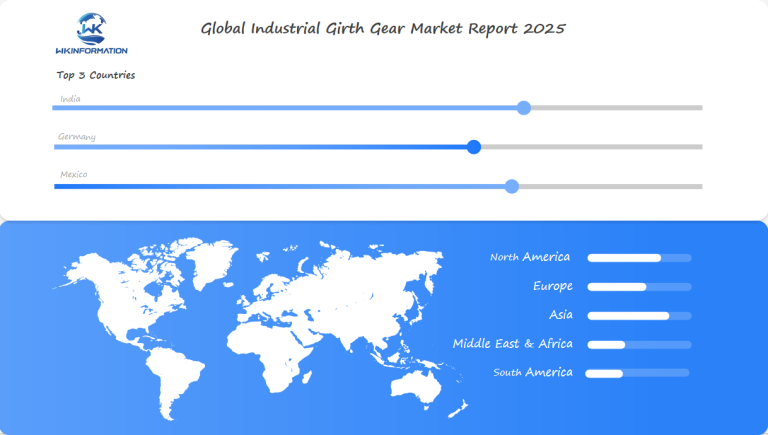

- India, Germany, and Mexico leading global market expansion

- Technological innovations driving gear manufacturing

- Increasing demand from infrastructure and heavy machinery sectors

- Strong growth in precision engineering capabilities

Understanding the Importance of Upstream and Downstream Industry Chains for Industrial Girth Gears

Industrial girth gears play a crucial role in intricate systems. They connect raw materials to final products across various sectors, making them essential in manufacturing and processing industries.

The realm of industrial girth gears is intricate, encompassing multiple stages from production to application. By understanding the supply chain, we can grasp their significance in modern factories.

Raw Material Suppliers and Manufacturing Processes

High-grade alloy steels and special metals are used for these gears. The making process is detailed:

- Material selection and quality testing

- Precision casting or forging techniques

- Advanced heat treatment processes

- Computer-guided machining and finishing

End-User Industries and Applications

Industrial girth gears are used in many industries. They work well in tough environments.

| Industry Primary Applications Typical Gear Requirements Mining | Large rotary kilns | High durability, wear resistance |

| Cement Production | Rotary kiln drives | Extreme temperature tolerance |

| Power Generation | Turbine and generator systems | Precision engineering |

| Construction | Heavy machinery drives | Load-bearing capacity |

The world of making industrial girth gears is always changing. New tech and global demand keep pushing it forward.

Key Trends Driving the Industrial Girth Gear Market: Growth in Heavy Machinery and Infrastructure

The industrial girth gear market is changing fast. This is thanks to big trends in heavy machinery and building projects. New tech is making manufacturing better and opening up chances in many industries worldwide.

Here are some key trends driving the growth of the industrial girth gear market:

- Advanced manufacturing technologies integrating automation and artificial intelligence

- Increasing demand from infrastructure development projects worldwide

- Sophisticated gear design improvements enhancing performance

- Growing investments in heavy machinery across emerging markets

Technological Advancements in Gear Design

Companies are investing heavily in new gear design technology. Precision engineering allows them to create more intricate and efficient gears capable of withstanding harsh conditions.

Tools such as digital simulations and advanced models are proving beneficial for engineers. These tools enable them to:

- Optimize the shape and structure of gear teeth

- Anticipate potential performance issues

- Minimize material waste during the manufacturing process

- Improve the overall durability of gears

Increasing Demand in Emerging Markets

Emerging markets are key for the growth of the industrial girth gear market. Countries like India, Brazil, and those in Southeast Asia are growing their buildings and factories. This means they need better gear tech.

Challenges in Industrial Girth Gear Manufacturing and Supply Chain Constraints

The industrial girth gear market faces big challenges. These test the limits of precision and efficiency. Manufacturers must deal with complex production while keeping quality high.

Creating large-scale girth gears is a complex task. It needs advanced technology and careful attention to detail.

Challenges in Precision Engineering

Precision engineering is a significant challenge in the production of industrial girth gears. The main issues include:

- Maintaining extremely precise measurements

- Handling intricate metal composition requirements

- Guaranteeing uniform strength and durability

- Reducing tiny surface flaws

Supply Chain Constraints and Material Dynamics

Supply chain issues have a significant impact on the industrial girth gear market. Shortages of raw materials make production unpredictable, forcing manufacturers to find new ways to source materials.

Some key supply chain problems include:

- Volatile pricing of specialized metal alloys

- Limited availability of high-grade manufacturing materials

- Extended procurement lead times

- Global logistics disruptions

Quality Control Strategies

Advanced quality control is crucial to overcome manufacturing challenges. Manufacturers use top-notch inspection technologies. This ensures industrial girth gears perform well and reliably.

Strategic quality management helps reduce risks in complex manufacturing. It ensures products perform well in demanding industrial settings.

Geopolitical Influence on the Industrial Girth Gear Market

The global industrial girth gear market is changing due to complex geopolitical factors. These factors affect international trade. Now, the relationships between countries and their trade policies are key to market access and production plans.

Recent global events show the need for strong supply chains. Manufacturers are focusing on making products in strategic regions. This helps avoid disruptions.

Trade Policies Reshaping Market Dynamics

Global trade policies are bringing both new chances and challenges for industrial girth gear makers. Key points include:

- Increased focus on localized production

- Reduced dependency on single-source manufacturing

- Enhanced cross-border collaboration

Emerging Regional Manufacturing Hubs

Different regions are gaining specific advantages in producing industrial girth gears. Strategic geographic positioning has become increasingly important.

Countries such as India, Germany, and Mexico are becoming major manufacturing hubs. They leverage technology and effective trade policies to attract global investments.

Industrial Girth Gear Market by Type: Cast, Forged, and Fabricated Variants

The industrial girth gear market uses different ways to make these important parts. Knowing about each type helps engineers pick the best for their projects.

Girth gear types are made with special methods for different needs. Each one has its own benefits for solving mechanical problems.

Characteristics of Girth Gear Manufacturing Techniques

- Cast gears: Made cheaply and can have complex shapes

- Forged gears: Strong and durable for tough places

- Fabricated gears: Can be made to order with many material choices

Forged gears are growing fast, thanks to more use in big machines and precise engineering. Makers are working on new ways to make gears better for many uses.

Industrial Girth Gear Applications in Cement, Mining, and Power Generation

Girth gears are key in heavy industries like cement, mining, and power generation. They help machines work by transmitting power and rotating. This is crucial in tough environments.

These gears are used in many industries. Each one has its own needs and problems. But girth gears are very useful in these hard places.

Cement Industry Requirements

In the cement industry, girth gears are essential for kilns. They enable large machines to rotate at high temperatures, which is crucial for cement production.

Some specific applications of girth gears in the cement industry include:

- Rotary kiln rotation systems

- Material processing equipment

- Clinker production mechanisms

Mining Sector Implementations

The mining industry relies on girth gears for various tasks such as handling and processing materials. These gears play a crucial role in the operation of large grinding mills and the transportation of ore, ensuring that mining activities run efficiently.

Girth gears are used in the following areas of the mining sector:

- Large grinding mills

- Mineral processing machinery

- Ore transportation systems

Power Generation Challenges

Power plants require girth gears for turbines and generators. These gears ensure smooth power transmission. This is crucial for energy systems.

| Industry Primary Girth Gear Function Key Performance Requirement Cement | Kiln Rotation | High Temperature Resistance |

| Mining | Material Processing | Extreme Durability |

| Power Generation | Power Transmission | Precision Engineering |

There is an increasing demand for girth gears in power generation applications. These new applications hold the potential for improved efficiency and performance in critical machinery.

Global Insights into the Industrial Girth Gear Market

The industrial girth gear market is full of growth and new tech. Companies and experts watch how different areas of the world do in this market. They also look at how companies compete and grow.

Important changes in the global market show us a lot about the industrial girth gear industry:

- More companies are entering markets in new countries.

- New tech is changing how gears are made.

- Big companies are teaming up with others around the world.

Regional Market Dynamics

Looking at the global market, we see big differences in where gears are made and used. Each area has its own special traits in making and using industrial girth gears.

India's Growing Market for Industrial Girth Gears in Manufacturing and Construction

The India girth gear market is growing fast. This is thanks to quick industrial growth and smart infrastructure plans. India is becoming a big player in making industrial gears worldwide.

Government policies have helped the manufacturing and construction sectors grow a lot. The push for new infrastructure has made a big need for top-notch industrial girth gears in many areas.

Government Initiatives Powering Industrial Growth

- Dedicated manufacturing policy supporting domestic gear production

- Infrastructure investment programs targeting industrial modernization

- Incentives for advanced manufacturing technologies

The construction industry is also driving the growth of the girth gear market. Big projects need gear systems that can handle tough work.

Domestic Production and Market Dynamics

Indian makers are getting better at making complex industrial girth gears. Made in India gears are now strong competitors in both local and global markets. This means less need for imported gears.

India’s good location and skilled workers make it a key place for making industrial girth gears. This opens up great chances in the global market.

Germany's Precision Engineering and Leadership in Industrial Girth Gear Production

Germany leads in making industrial girth gears, thanks to its top-notch precision engineering. The country’s factories are known for their cutting-edge gear designs and performance. This makes Germany a big player in the global market.

- Advanced design capabilities

- High-quality manufacturing processes

- Cutting-edge technological innovations

- Rigorous quality control standards

Technological Breakthroughs in Gear Manufacturing

Companies like SEW-Eurodrive in Germany have led in gear making tech. They use smart computer designs and advanced making methods. This makes their gears very precise and reliable.

| Technology Area Innovation Impact Global Market Significance Digital Design Tools | 95% Precision Accuracy | High Competitive Advantage |

| Material Engineering | Enhanced Durability | Expanded Industrial Applications |

| Smart Manufacturing | Real-time Quality Monitoring | Reduced Production Errors |

Export Markets and Global Competitiveness

Germany aims to sell more industrial girth gears to places like mining and energy. Its reputation for precision engineering helps it win big in other countries.

Germany keeps improving by spending on research and development. This keeps it ahead in making industrial girth gears.

Mexico's Rising Demand for Industrial Girth Gears in Heavy-Duty Industries

The Mexican industrial scene is changing fast. Demand for industrial girth gears is growing in heavy-duty industries. This is thanks to Mexico’s strong economic position, which supports growth in mining and energy.

Several factors are driving this growth:

- Increased investment in infrastructure projects

- Growing mining sector capabilities

- Enhanced technological capabilities in manufacturing

Growth in Mining and Energy Sectors

The mining sector is a major driver of demand for industrial girth gears in Mexico. Advanced gear technologies help make mining more efficient, supporting Mexico’s role as a leading mineral producer.

Energy projects are also increasing the need for specialized gears, including renewable energy initiatives and upgrades to power plants. This presents significant opportunities for high-performance gear systems.

Strategic Partnerships and Technology Transfer

International companies see Mexico’s potential and are teaming up. These partnerships help bring in new technology and local production. They are key for developing advanced gear capabilities.

Mexican firms are working with global gear makers to improve their tech skills. This helps them stay competitive in the fast-changing heavy-duty industries market.

The Future of Industrial Girth Gears: Advanced Materials and Smart Monitoring

The industrial girth gear market is changing fast. New technologies are being developed. These include advanced materials and smart monitoring systems that will change how gears work and last.

Advanced materials are leading this change. Engineers are looking into new alloys and composites. These materials make gears last longer and work better.

- Enhanced wear resistance

- Reduced weight

- Improved thermal stability

- Extended operational lifespan

Innovations in Gear Materials and Coatings

New surface coatings are also making a big difference. These coatings, made with nanotechnology, protect gears from wear and tear. They help gears last longer in tough environments.

| Material Type Performance Improvement Primary Applications Ceramic Composites | 90% Increased Wear Resistance | Heavy Mining Equipment |

| Titanium Alloys | 75% Weight Reduction | Aerospace and Precision Machinery |

| Polymer Nanocomposites | 85% Improved Thermal Stability | High-Temperature Industrial Processes |

Integration of IoT and Predictive Maintenance

Smart monitoring is changing how we manage gears. IoT sensors track gear performance in real-time. This lets us fix problems before they happen, saving time and improving efficiency.

The mix of advanced materials and smart monitoring is a big step forward. Companies that use these new technologies will stay ahead in the fast-changing world of industrial gears.

Competitive Landscape in the Industrial Girth Gear Market

The industrial girth gear market is highly competitive, with numerous global players vying for the top position. These companies employ innovative strategies and creative approaches to differentiate themselves, resulting in a complex and dynamic market.

Key Players:

- David Brown Santasalo — UK

- SEW-Eurodrive — Germany

- Groupe CIF — France

- FLSmidth MAAG Gear — Switzerland

- Dingwell’s — Australia

- CHAENG — China

- NIPPON CHUZO — Japan

- PWT Van Der Wegen — Netherlands

- UEDA HEAVY GEAR WORKS — Japan

- Galbiati Group — Italy

Key Strategies Used by Major Players

Leading companies in the industry have their own methods for maintaining a competitive edge:

- Investing in Research and Development: Big players are constantly working on developing new technologies to improve their products and stay ahead of the competition.

- Forming Strategic Partnerships: Collaborating with other businesses or organizations allows major players to leverage each other’s strengths and expand their reach.

- Expanding Internationally: Global growth is a key focus for many leading companies as they seek to tap into new markets and increase their market share.

These strategies enable major players to strengthen their position in the industrial girth gear market and effectively compete with other global contenders.

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Industrial Girth Gear Market Report |

| Base Year | 2024 |

| Segment by Type | · Cast Gears

· Forged Gears · Fabricated Gears |

| Segment by Application | · Cement

· Mining · Power Generation |

| Geographies Covered | · North America (United States, Canada)

· Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The industrial girth gear market is growing steadily. Business Research Insights says it will grow from USD 7.18 billion in 2025 to USD 8.3 billion by 2033. This shows a steady growth rate of 1.83% each year.

There are big opportunities in manufacturing, mining, and power generation. New technologies and more investments in infrastructure will shape the market. Countries in Asia and Latin America are expected to play a big role in the growth of industrial girth gears.

Several factors will influence the market’s growth. These include digital changes, better engineering, and green manufacturing. Companies that invest in new materials, smart tech, and predictive maintenance will have an edge.

But, there are challenges too. Prices of raw materials can change, and there are global uncertainties. Companies need to be quick to adapt and use the latest technologies to succeed in this growing market.

Global Industrial Girth Gear Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Industrial Girth Gear Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Industrial Girth GearMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Industrial Girth GearPlayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Industrial Girth Gear Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Industrial Girth Gear Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Industrial Girth Gear Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Industrial Girth Gear Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market value for industrial girth gears by 2025?

The market for industrial girth gears is expected to hit $7.18 billion by 2025. This growth is mainly driven by countries like India, Germany, and Mexico.

Which industries primarily use industrial girth gears?

Girth gears are key in:

- Cement production

- Mining

- Power generation

- Heavy machinery

They are vital for efficiency and power transmission.

What are the main types of industrial girth gears?

There are mainly three types: cast, forged, and fabricated. Each type has its own making process and use.

How are technological advancements impacting industrial girth gears?

New technology is changing the game with advanced materials and IoT. Predictive maintenance and better design are also improving performance and lifespan.

What challenges do manufacturers face in industrial girth gear production?

Making girth gears is tough due to precision, quality control, and material shortages. Price changes also affect costs and market trends.

Which countries are leading in industrial girth gear manufacturing?

India, Germany, and Mexico are leading the way in industrial girth gear manufacturing. These countries have strong capabilities in manufacturing, technology, and infrastructure.

What factors are driving growth in the industrial girth gear market?

Growth is driven by increased heavy machinery usage, infrastructure development, technological advancements, and demand from emerging markets.

How do geopolitical factors influence the industrial girth gear market?

Trade policies, international relations, and regional hubs affect market access, material sourcing, and distribution.

What role does IoT play in industrial girth gear technology?

IoT brings smart monitoring, predictive maintenance, and better performance tracking. This leads to more efficient and proactive management.

Are there emerging applications for industrial girth gears?

Yes, new uses are popping up in renewable energy, advanced manufacturing, and complex machinery. This expands girth gear’s traditional uses.