Electroplating Market Set to Reach $21.34 Billion by 2025: Key Growth Drivers in the U.S., China, and Germany

Explore the expanding electroplating market, projected to hit $21.34 billion by 2025. Discover growth drivers across the U.S., China and other key regions in this essential industrial sector.

- Last Updated:

Electroplating Market Forecast for Q1 and Q2 2025

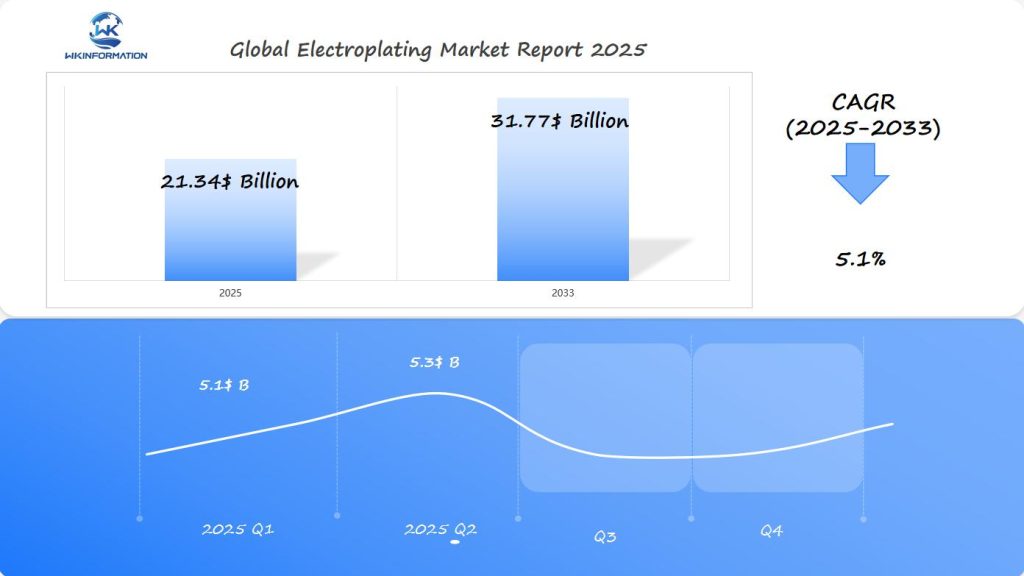

The global electroplating market is projected to reach $21.34 billion by 2025, growing at a CAGR of 5.1% from 2025 to 2033. In Q1 2025, the market size is expected to be around $5.1 billion, with Q2 seeing a slight increase to approximately $5.3 billion. Electroplating continues to be an essential process in industries such as automotive, electronics, aerospace, and jewelry, where high-quality finishes and corrosion resistance are critical.

The U.S., China, and India are major players in the electroplating market, with the U.S. leading in advanced electroplating technologies, especially for high-precision electronics. In China, the increasing demand for electroplated components in consumer electronics and automotive industries will drive market growth. India’s expanding manufacturing sector, particularly in automotive and consumer goods, will contribute to a growing need for electroplating services. The increasing demand for environmentally friendly electroplating techniques will also boost the market, as more industries adopt low-energy and non-toxic solutions. With the rise of electric vehicles, the electroplating of parts such as batteries and electric connectors will contribute significantly to market expansion.

Key Takeaways

- Projected market value of $21.34 billion by 2025

- Strong growth potential in U.S., China, and Germany

- Technological innovations driving industry expansion

- Increasing demand across multiple industrial sectors

- Strategic investments transforming manufacturing capabilities

Understanding the Upstream and Downstream Dynamics in Electroplating

The electroplating supply chain is a complex network. It drives innovation and market growth. Raw materials are key to the industry’s success and capabilities.

Key Components of the Electroplating Supply Chain

Key components of the electroplating supply chain include:

- Primary raw material suppliers

- Chemical processing facilities

- Specialized electroplating service providers

- End-user industries

Manufacturers in the electroplating ecosystem depend on a complex network of suppliers. Metal precursors, chemical solutions, and precision equipment are essential for production.

| Supply Chain Segment | Key Responsibilities | Impact on Industry |

| Raw Material Suppliers | Provide high-quality metals and chemical compounds | Determine product quality and performance |

| Electroplating Services | Design and execute surface treatment processes | Enable technological advancements |

| End-User Industries | Implement electroplated components | Drive market demand and innovation |

End-user industries like automotive, electronics, and aerospace shape electroplating technology. They need advanced surface treatments that push the limits of technology.

The relationships between raw material suppliers, electroplating service providers, and end-user industries are complex. They create a dynamic ecosystem of continuous improvement and market adaptation.

Key Trends Driving the Electroplating Industry

The electroplating industry is changing fast. New technology and market solutions are leading the way. Companies are working hard to make electroplating more sustainable and efficient.

Several key industry innovations are reshaping the electroplating landscape:

- Advanced automated plating systems with precision control

- Eco-friendly chemical formulations reducing environmental impact

- Nanotechnology-enhanced surface treatment techniques

- Digitally integrated quality monitoring platforms

Market drivers are pushing the growth of electroplating technology trends. The automotive and electronics industries are leading the charge. They need coatings that last long and look great.

| Industry Sector | Key Electroplating Requirements | Technology Impact |

| Automotive | Corrosion resistance | Enhanced component longevity |

| Electronics | Precision conductivity | Improved electrical performance |

| Consumer Goods | Decorative finishes | Increased aesthetic value |

The focus on sustainable manufacturing is growing. Researchers are finding ways to make electroplating greener. They aim to use fewer toxic chemicals while keeping quality high.

These trends show the electroplating industry’s dedication to innovation, efficiency, and the environment.

Barriers to Growth in the Electroplating Market

The electroplating industry faces big challenges that slow its growth. These challenges come from many complex factors. They make it hard for manufacturers and service providers to grow.

Key barriers in the electroplating landscape include:

- Stringent environmental regulations limiting chemical processes

- Substantial initial capital investment requirements

- Persistent shortage of skilled technical workforce

- Increasing raw material procurement costs

Regulatory hurdles are a big problem for new electroplating businesses. Environmental agencies have strict rules. These rules require big investments in technology and compliance.

Small and medium-sized enterprises find it hard to meet these standards.

“The electroplating industry must balance technological innovation with environmental responsibility” – Industrial Manufacturing Review

Financial issues also make it hard to enter the market. Buying advanced electroplating equipment costs a lot. This creates big barriers for new players.

Getting the right technical skills is also a challenge. Companies need to invest in training and development. This is key for growing in this competitive field.

- Advanced training programs needed

- Continuous technology skill upgrades

- Collaborative industry-academic partnerships

Despite these challenges, innovative companies are finding ways to grow. They are adapting technology and making strategic investments.

Geopolitical Factors Affecting Electroplating Production and Distribution

The global electroplating trade is facing big challenges from politics. Rules and trade fights make it hard for makers all over. They have to deal with many rules and tensions.

Important things affecting the electroplating world include:

- Changes in trade rules between big countries

- Tariffs on materials and tools for electroplating

- Different rules in each market

Countries like the United States, China, and Germany are seeing big changes in their electroplating supply chains. Trade restrictions and international regulations are making makers change fast to keep up with the world.

Tariffs are really affecting the global electroplating trade. Makers have to find a balance between keeping costs down and following rules. They need to be smart and quick to stay ahead.

Local economic plans are key for making electroplating products. Makers need to be flexible and ready to change fast because of trade changes.

“Geopolitical dynamics are reshaping the global electroplating industry, demanding unprecedented levels of strategic planning and adaptability.” – Industry Analyst

Electroplating Market Segmentation by Type: Techniques, Materials, and Industries Served

The electroplating market is a complex world of new techniques and special uses in many industries. Knowing how electroplating is segmented helps makers and scientists improve their work and pick the right materials.

How we electroplate metals is key to their quality and how well they work. Experts use several main ways to get the right finish:

- Barrel plating for lots of small parts

- Rack plating for delicate or big parts

- Continuous plating for making lots of parts

Each plating material has special traits for certain uses. The most used materials are:

- Nickel: It’s good against corrosion and lasts longer

- Chrome: It makes surfaces harder and looks better

- Gold: It’s great for electrical work and doesn’t corrode

- Silver: It’s top for heat and electrical flow

Electroplating is used in many important areas:

| Industry | Primary Electroplating Applications |

| Automotive | Decorative and protective parts |

| Electronics | For making printed circuit boards |

| Aerospace | For precise engineering parts |

| Jewelry | For looks and surface treatment |

“Electroplating is not just a process, but a sophisticated art of transforming metal surfaces for enhanced performance and appearance.” – Manufacturing Engineering Journal

Choosing the right electroplating methods, materials, and uses helps makers get the best results in metal treatment and surface engineering.

The Role of Applications in Expanding Electroplating Demand

Electroplating is key in many industries, leading to big market growth. It makes products better by adding coatings that improve how they work, last, and look.

Every sector has its own needs for electroplating. Companies use special coatings to meet tough standards and make products better.

- Automotive sector requires corrosion-resistant protective layers

- Electronics industry needs precise conductive coatings

- Medical device manufacturers seek biocompatible surface treatments

- Aerospace applications demand high-performance metal finishes

New uses for electroplating are popping up in tech fields. It’s used in green energy, making semiconductors, and in advanced medical tech.

| Industry | Primary Electroplating Application | Key Performance Enhancement |

| Automotive | Corrosion Protection | Extended Component Lifespan |

| Electronics | Conductive Coating | Improved Signal Transmission |

| Medical Devices | Biocompatible Surfaces | Enhanced Patient Safety |

| Aerospace | Wear-Resistant Finishes | Increased Mechanical Durability |

Electroplating keeps getting better, helping makers create advanced coatings. These coatings meet the complex needs of each industry.

Regional Insights into the Global Electroplating Market

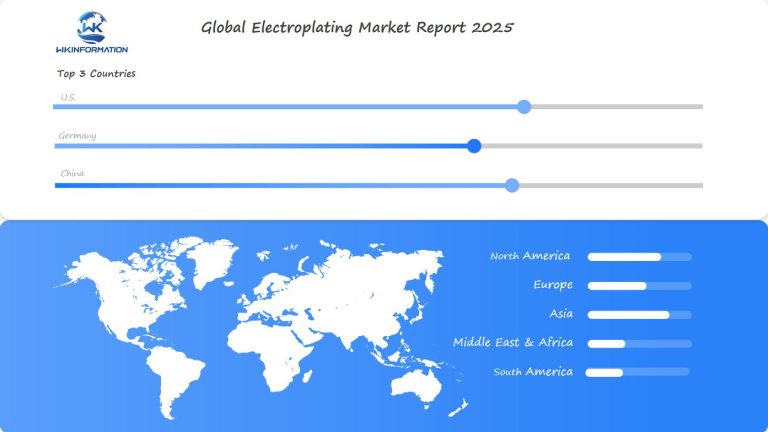

The global electroplating markets show different trends in each region. These trends highlight how each area has its own growth drivers and innovations.

Each continent has its own way of growing in electroplating. North America leads with its advanced tech. Asia-Pacific grows fast because of its big manufacturing base.

- North America: High-precision electroplating technologies

- Asia-Pacific: Massive industrial manufacturing capabilities

- Europe: Sustainable electroplating practices

- Latin America: Emerging market potential

Several factors shape the electroplating markets in each region. These include:

- Industrial infrastructure development

- Technological innovation capabilities

- Regulatory environmental standards

- Economic investment strategies

The market share by region shows a competitive scene. The U.S. and China are big players. Germany is a key spot for new electroplating tech.

Geographical trends suggest a transformative period for global electroplating industries, characterized by technological adaptation and strategic regional investments.

The U.S. Electroplating Market: Key Developments and Opportunities

The U.S. electroplating industry is changing fast. New technologies and shifting market trends are driving these changes. Domestic makers are now using advanced electroplating methods. These methods make products better and more eco-friendly.

Important changes in the American market include:

- More money going into green electroplating technologies

Domestic growth factors are changing the electroplating scene. The U.S. electroplating industry is seeing more local production. This opens up new chances for metal finishing companies in the U.S.

New technologies are giving companies an edge. They’re using innovative methods that are better for the environment. These methods also make coatings last longer and work better. This is especially true for electronics, medical devices, and advanced manufacturing.

The future of electroplating in the United States relies on continuous innovation and adaptive manufacturing strategies.

Following environmental rules and being eco-friendly is key now. Companies are spending on better waste treatment and greener electroplating. They aim to meet tough environmental standards.

- Less use of harmful chemicals

- Water recycling systems

- Creating eco-friendly metal finishing

The U.S. electroplating market is strong and growing. It’s a key part of the country’s advanced manufacturing world.

China’s Dominance in Electroplating Technology and Manufacturing

The Chinese electroplating industry has become a global leader in manufacturing. It shows amazing technological progress and smart market strategies. China’s growth has made it a top player in Asia-Pacific electroplating technologies.

Several factors make China stand out:

- Big investments in advanced manufacturing

- Strong government support for new technologies

- Big production capabilities

- Low costs in making things

Companies like ACM Research show the latest in Chinese electroplating tech. They use smart strategies in making semiconductors, showing the industry’s advanced tech skills.

The semiconductor supply chain benefits a lot from China’s electroplating skills. Precision electro-chemical plating techniques are key for top-notch electronic parts. This puts Chinese makers at the top of global tech.

China’s electroplating industry is changing advanced manufacturing. It links innovation with big-scale production.

China keeps investing in research and development. This pushes the electroplating industry to new tech heights. It keeps China ahead in the global market.

Germany’s Role in Electroplating Innovation

Germany leads in electroplating technology, pushing innovation in Europe. Their engineering skills have made electroplating better with new tech and precise methods.

German electroplating technology has made big strides in several areas:

- Advanced automation in surface treatment processes

- Precision engineering for complex electroplating applications

- Sustainable and eco-friendly plating solutions

- High-performance coating technologies

Research groups and big companies work together to break new ground. The Fraunhofer Institute and car makers have created new ways to be green and strong.

In Europe, Germany’s impact is clear. Their fresh ideas have set high standards for quality, efficiency, and being green in electroplating. Small and medium-sized businesses are key in making these advances.

“German engineering continues to redefine global electroplating standards through precision and innovation.”

Many areas benefit from German electroplating tech, like cars, planes, medical tools, and electronics. Their drive to keep improving keeps Germany at the top of innovation.

Future Developments in the Electroplating Industry

The electroplating industry is about to undergo significant changes. New technologies are reshaping our perspective on the future and creating new opportunities for manufacturers and researchers.

Impact of Nanotechnology

Nanotechnology is revolutionizing the field of electroplating by enabling us to operate at microscopic levels. Experts predict that we will witness significant advancements in materials science as a result of innovative electroplating techniques.

Some potential breakthroughs include:

- Precision nano-coating technologies

- Advanced alloy plating methods

- Smart manufacturing integration

Role of Artificial Intelligence and IoT

Artificial intelligence (AI) and the Internet of Things (IoT) are playing a crucial role in the evolution of electroplating. Intelligent sensors and machine learning algorithms are enhancing processes, minimizing waste, and maximizing efficiency.

| Technology | Potential Impact | Estimated Implementation |

| AI Process Control | Reduced Error Rates | 2-3 Years |

| Nano-Coating | Enhanced Surface Properties | 3-5 Years |

| IoT Monitoring | Real-time Quality Management | 1-2 Years |

Focus on Sustainability

Sustainability is a top priority for the electroplating industry. Researchers are actively exploring eco-friendly plating techniques that reduce chemical waste and lower carbon emissions.

The outlook for electroplating is promising, with upcoming advancements in materials, digital technologies, and sustainable manufacturing practices.

Competitive Landscape in the Electroplating Market

The electroplating market is full of life, with big names and new players. Companies are working hard to stand out. They want to keep their spot in the market.

Here are some key players in the electroplating market:

-

Atotech Limited – Germany

-

Bajaj Electroplaters – India

-

Allied Finishing Inc. – United States

-

Peninsula Metal Finishing Inc. – United States

-

Kuntz Electroplating Inc. – Canada

-

Sharretts Plating Company Inc. – United States

-

Jing Mei Industrial Ltd. (JMI) – Taiwan

-

Precision Plating Co. – United States

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Electroplating Market Report |

| Base Year | 2024 |

| Segment by Type | · Mass Plating (Barrel Plating)

· Rack Plating · Continuous Plating · Others |

| Segment by Application | · Automotive Industry

· Electronics Manufacturing · Jewelry and Decorative Items · Others |

| Geographies Covered | · North America (United States, Canada)

· Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The electroplating market is growing fast and full of chances for investors and experts. It’s expected to hit $31.77 billion by 2033. The electroplating market forecast shows big growth in many areas. Copper electroplating and use in electronics are leading this growth, with a 5.1% annual increase expected.

Technological advancements and global trends will shape the market’s future. North America is leading with a big share, showing strong investment chances in new tech. The demand for precise engineering and green surface treatments is rising in cars, planes, and electronics.

Investment chances are growing in the U.S., China, and Germany. These places have the tech and factories for advanced electroplating. Research is all about making it more efficient, eco-friendly, and meeting tough industrial needs.

The electroplating sector is ready for big changes as global making evolves. Those who get the market and invest in new ideas will grab the best chances in this fast-changing tech world.

Global Electroplating Market Report(Can Read by Free sample)–Table of Contents

Chapter 1:Electroplating Market Analysis Overview

- Competitive Forces Analysis(Porter’s Five Forces)

- Strategic Growth Assessment(Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Electroplating Market Segmentation Overview

Chapter 2:Competitive Landscape

- GlobalElectroplating Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3:Electroplating Market Segmentation Analysis

- Key Data and Visual Insights

- Trends,Growth Rates,and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4:Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic,Demographic,and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5:Electroplating Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends,Challenges,and Opportunities

Chapter 6:Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7:Electroplating Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8:Key Findings and Recommendations

- Summary of Electroplating Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is electroplating and how does it work?

Electroplating is a method used to apply a thin layer of metal onto another material. This process involves the use of electricity to transfer metal ions from one location to another, resulting in the formation of a durable and uniform coating on the object.

What are the primary industries that use electroplating?

Many industries use electroplating, including:

- Automotive

- Electronics

- Aerospace

- Medical devices

- Jewelry

These industries utilize electroplating for various purposes such as protection against corrosion, improved performance, and enhanced aesthetics.

What metals are commonly used in electroplating?

Metals like nickel, chrome, gold, silver, zinc, copper, and palladium are often used. Each metal has special qualities like protection or shine.

What are the environmental challenges in electroplating?

The industry faces significant environmental challenges such as:

- Managing chemical waste

- Pollution caused by metals

- Energy consumption

However, companies are actively seeking eco-friendly solutions and improving waste management practices.

How is technology transforming the electroplating industry?

New technology is changing electroplating. It includes automated systems, nanotechnology, AI, and IoT. These advancements help improve coatings, reduce waste, and increase efficiency.

What factors are driving growth in the global electroplating market?

Several things are making the market grow. These include:

- more demand

- new technology

- the need for protective coatings

- growth in electronics and cars

Additionally, new areas such as renewable energy and medicine are increasingly adopting electroplating techniques.

What are the major regional markets for electroplating?

The main markets for electroplating are:

- North America

- Asia-Pacific, with a focus on China

- Europe, particularly Germany

- Emerging regions in Latin America and Southeast Asia

Each of these areas has its own strengths, such as China’s manufacturing capabilities and Germany’s technological expertise.

What are the primary challenges in the electroplating industry?

The electroplating industry faces several challenges, including:

- Tough environmental regulations

- High operational costs

- The need for skilled workers

- Managing waste effectively

- Keeping up with rapidly changing technology

- Competing with other surface treatment methods

How is the electroplating market expected to grow by 2025?

The electroplating market is expected to experience significant growth by 2025, reaching a value of $21.34 billion. This growth can be attributed to several factors, including:

- Increased applications of electroplating in various industries

- Advancements in technology related to electroplating processes

- Rising demand from major sectors such as automotive, electronics, and others

What future developments are anticipated in electroplating?

The future looks bright for electroplating. We can expect better nanotechnology coatings, greener processes, more automation, AI, and IoT. There will also be new alloy plating and uses in new tech like green energy and advanced medicine.