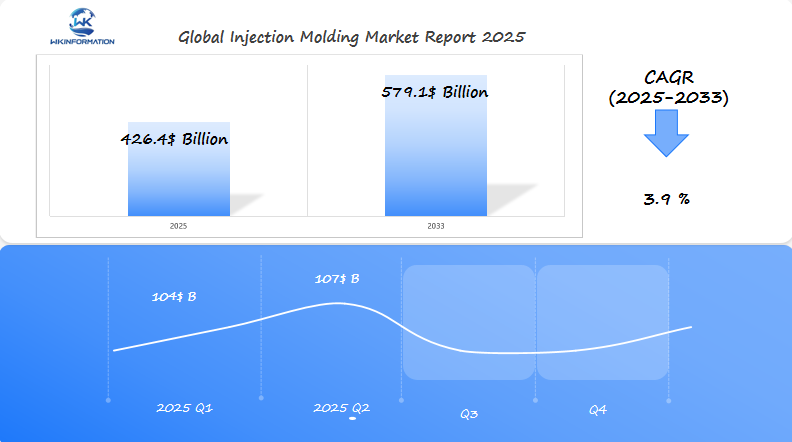

Injection Molding Market Set to Reach $426.4 Billion by 2025: Key Insights from the U.S., China, and Germany

Explore comprehensive insights into the Global Injection Molding Market from 2025-2033. This in-depth analysis covers market trends, regional dynamics, and industry growth projections, with a special focus on plastic, metal, and ceramic molding segments.

- Last Updated:

Injection Molding Market Forecast for Q1 and Q2 2025

The global injection molding market is expected to reach $426.4 billion in 2025, with a CAGR of 3.9% through 2033. In Q1 2025, the market is projected to generate approximately $104 billion, with Q2 reaching around $107 billion. The demand for injection molding is being driven by various industries such as automotive, electronics, medical devices, and consumer goods.

The U.S., China, and Germany are the key markets leading the growth of injection molding. The U.S. remains a strong player, driven by its diverse manufacturing sectors, while China and Germany’s manufacturing capabilities continue to provide substantial contributions to the market. These regions will be essential in understanding the evolution of injection molding over the next several years.

Upstream and Downstream Dynamics Shaping the Injection Molding Industry

The injection molding industry is a complex web of relationships. It connects raw material suppliers, manufacturers, and end-user industries. This creates a value chain that fuels innovation and growth.

Upstream dynamics are key in the injection molding market. Raw materials, like plastics and metals, are the base. They affect production costs and capabilities.

Raw Material Suppliers and Their Impact

Raw material suppliers have a big impact on the industry. They influence several important factors:

- Pricing volatility of base materials

- Quality and consistency of supply

- Technological advancements in material development

- Sustainability initiatives

| Raw Material Type | Market Share | Growth Potential |

| Thermoplastic Polymers | 62% | High |

| Engineering Plastics | 25% | Moderate |

| Metal Alloys | 13% | Emerging |

End-User Industries Driving Demand

End-user industries drive demand in the injection molding market. Key sectors include:

- Automotive manufacturing

- Consumer electronics

- Medical devices

- Packaging solutions

The relationship between suppliers and end-users pushes for new technologies. This drives innovation and efficiency in injection molding.

Major Trends Driving Growth in Injection Molding Manufacturing

The injection molding industry is going through big changes. These changes come from new technologies and a focus on being green. Companies are finding new ways to keep up with what the world needs.

Technological Advancements in Molding Processes

New technologies are changing how injection molding works. These changes help make products better and make the process more efficient.

- Gas-assisted injection molding enables complex part designs

- Thin-wall molding reduces material consumption

- Precision robotics improve manufacturing consistency

“Innovation drives the future of manufacturing growth in injection molding technologies.” – Manufacturing Insights Report

Sustainability Initiatives and Eco-friendly Materials

Now, making things in a way that’s good for the planet is key. The industry is moving fast to be more eco-friendly. This is happening through new materials and better ways to make things.

- Increased utilization of recycled plastic materials

- Development of biodegradable plastic alternatives

- Reduced carbon footprint in manufacturing processes

These changes show the industry’s dedication to getting better and being green. Companies are working hard to find ways to make things that are both good for the planet and work well.

The mix of new tech and green practices is changing the injection molding world. It’s opening up new chances for companies to meet needs and protect the environment.

Overcoming Supply Chain and Technological Barriers in Injection Molding

The injection molding industry faces big challenges. These need new solutions and smart plans. Supply chain issues and tech barriers test how well companies can adapt and stay strong in a global market.

Companies are working hard to solve big problems in injection molding. Shortages of raw materials are a big worry. They’re using smart ways to manage risks.

Strategic Approaches to Raw Material Management

- Diversifying supplier networks to reduce dependency

- Establishing long-term procurement agreements

- Investing in alternative material research

- Implementing predictive inventory management systems

New technology is helping solve old problems in injection molding. Automation and smart manufacturing are changing how things are made. This helps companies overcome previous limitations.

Technological Innovations Driving Industry Transformation

- IoT-enabled monitoring systems

- Predictive maintenance technologies

- AI-driven process optimization

- Real-time quality control mechanisms

High costs of injection molding machines are a big issue. Companies are looking at modular and flexible solutions. These cut down on costs and make things more efficient.

Strategic adaptation is key to navigating complex manufacturing landscapes.

By using new ways to manage supply chains and tech, injection molding companies can face risks head-on. They can grow and thrive in a changing world.

Geopolitical Factors Influencing Injection Molding Production

The injection molding industry is changing a lot because of complex global politics. Global supply chains are being reorganized. This is because manufacturers are dealing with tough international trade rules.

Geopolitical factors are changing how we make things, leading to several important trends:

- Strategic shifts in regional manufacturing capabilities

- Evolving trade policies impacting global production networks

- Increased focus on localization strategies

Trade Policies Transforming Supply Networks

New trade policies are significantly altering global supply chains. Countries are implementing measures to safeguard their own manufacturing industries. The Asia-Pacific region, expected to account for more than 41.3% of the injection molding market in 2024, plays a crucial role in these transformations.

Regional Manufacturing Localization

Companies are moving towards regional manufacturing to avoid global risks. Important markets like the United States, China, and Germany are building strong local production. This is a smart move to deal with possible trade problems.

“The future of injection molding lies in adaptable, regionally-focused manufacturing strategies,” says an industry expert.

Global trade is very connected, so companies need to stay flexible. They must understand how global politics affects their production plans and how competitive they are in the market.

Exploring Injection Molding Market Segmentation by Industry and Product

The injection molding market is complex, with many industry sectors and product types. Market segmentation gives us key insights into the manufacturing world. It shows how different industries use this versatile method.

Understanding market segmentation is crucial for manufacturers and investors. It helps them find growth opportunities in various sectors. The injection molding market is divided into several strategic categories:

- Material types

- Manufacturing technologies

- Application domains

- End-user industries

Key Industry Sectors Driving Demand

Three main sectors lead the injection molding market:

- Automotive: Makes high-precision components and complex parts

- Packaging: The largest segment with 24.0% market share

- Healthcare: Essential for medical device manufacturing

Product Types and Market Shares

Product type analysis shows different market shares and growth potentials:

| Product Type | Market Share (%) | Growth Potential |

| Automotive Components | 22.5% | High |

| Packaging Solutions | 24.0% | Moderate |

| Medical Devices | 18.3% | Very High |

| Consumer Goods | 15.2% | Moderate |

These segments show the injection molding industry’s ability to adapt to various needs.

The Role of Applications in Boosting Injection Molding Demand

The injection molding industry is experiencing rapid growth, primarily due to the emergence of new applications in advanced sectors. Innovative technologies are transforming manufacturing processes, providing greater flexibility and accuracy.

Injection molding is now being utilized in ways that were previously unimaginable. Various industries are discovering fresh applications for this technique, enabling them to produce intricate and customized components.

Emerging Applications in Advanced Industries

Several cutting-edge sectors are driving injection molding innovation:

- Aerospace: Lightweight, high-performance components

- Medical Technology: Precision medical devices

- Renewable Energy: Specialized equipment parts

- Electronics: Intricate circuit board housings

Customization and Personalization Trends

Customization trends are changing injection molding. Now, manufacturers can make very special products with great precision and speed.

Some big changes in customization are:

- On-demand manufacturing

- Rapid prototyping

- Complex geometrical designs

- Patient-specific medical implants

The healthcare sector is a big area for injection molding. There’s a growing need for special medical parts. This is pushing for new materials and ways to make things.

Regional Insights into the Global Injection Molding Market

The injection molding market is diverse worldwide. Each region has its own growth path and unique features. Knowing these insights is key for companies and investors to succeed in this fast-changing field.

Across the globe, different areas show different growth patterns. Companies are now focusing on specific regions to use local chances and new tech.

Market Dynamics in North America, Europe, and Asia-Pacific

Each region has its own way of doing injection molding:

- North America: Strong in cars and medical devices

- Europe: Known for precision and green tech

- Asia-Pacific: Fast growth and big factories

In 2024, Asia-Pacific will lead with over 41.3% of the market. It’s expected to grow fast, with a 5.4% annual growth rate.

Emerging Markets and Their Growth Potential

New markets offer big opportunities for injection molding growth. Areas such as Latin America and the Middle East are receiving more industrial investment. This creates new opportunities for technology and market entry.

What’s driving growth in these regions includes:

- More factories and equipment

- More technology adoption

- Higher demand for better products

Companies that expand into these regions can gain a competitive advantage in the global market.

The U.S. Injection Molding Market: Trends and Growth Opportunities

The U.S. injection molding market is a leader in manufacturing, showing strong growth and resilience. It has a solid base of new technologies and strategic investments. This makes the U.S. a key player in the global manufacturing world.

Looking at the U.S. market trends, we see important insights into the injection molding industry. The market is growing in many areas, with key sectors driving demand. New technologies are also changing how things are made.

Key Industries Driving Demand in the U.S.

Several key industries are pushing the U.S. injection molding market forward:

- Automotive manufacturing

- Medical devices and healthcare equipment

- Consumer electronics

- Packaging solutions

These areas are growing fast, using advanced injection molding to make detailed, precise parts. The injection molding market analysis shows big growth potential.

Technological Innovations and Investments

New technologies are changing the U.S. injection molding scene. Companies are spending a lot on automation, new materials, and green manufacturing.

| Innovation Category | Key Developments |

| Process Automation | Advanced robotic systems and AI-driven quality control |

| Materials Technology | High-performance polymers and recyclable composites |

| Sustainability Initiatives | Energy-efficient machinery and circular manufacturing processes |

The U.S. injection molding market is very adaptable. It’s becoming a global leader in manufacturing innovation and technology.

China’s Role in Injection Molding Market Expansion

The China injection molding market is a global leader, driving growth and innovation. China has turned its manufacturing into a strong global advantage through smart planning.

China leads in injection molding exports for several reasons:

- Extensive manufacturing infrastructure

- Competitive labor costs

- Advanced technological capabilities

- Robust supply chain networks

Manufacturing Capabilities: A Technological Revolution

Chinese manufacturers quickly adopted new technologies, changing their production. They invested in automation and Industry 4.0, making their manufacturing more precise and efficient.

“China’s injection molding sector represents a new era of technological innovation and industrial excellence.” – Manufacturing Insights Report

Export Dominance and Global Market Positioning

China’s injection molding industry is a global leader. It offers high-quality products at good prices, winning big in markets like automotive, electronics, and medical devices.

China’s injection molding market is strong because of:

- Rapid technological adaptation

- Cost-effective production strategies

- Scalable manufacturing capabilities

- Strong focus on research and development

China’s injection molding market is set for more growth, thanks to smart tech investments and market-focused innovations.

Germany’s Competitive Edge in Injection Molding Technologies

Germany is at the forefront of injection molding technologies, primarily due to its exceptional precision engineering. The country specializes in high-value manufacturing, establishing a worldwide benchmark for innovation and quality.

Precision Engineering Driving Industrial Performance

German manufacturers are known for their focus on detail in injection molding technologies. They have several key advantages:

- Exceptional product quality and dimensional accuracy

- Advanced material selection and processing techniques

- Sophisticated engineering capabilities

- Rigorous quality control processes

Industry 4.0 Integration in Manufacturing

Germany’s injection molding industry has been transformed by Industry 4.0. Smart factories now employ data analytics, the Internet of Things (IoT), and real-time monitoring to enhance efficiency and enable greater product customization.

“German engineering represents the gold standard in precision manufacturing and technological innovation.” – Manufacturing Technology Insights

Through digitalization, German manufacturers are establishing intelligent production environments. These environments optimize performance, minimize waste, and provide high-value applications across various sectors.

What’s Next for the Injection Molding Industry?

The injection molding industry is at a turning point. New technologies and green challenges are changing its future. It’s expected to grow to $426.4 billion by 2031, with big changes in how things are made and how we care for the planet.

Emerging Technologies Driving Transformation

New technologies are changing the game for injection molding. Companies are using advanced tools for better accuracy and speed:

- 3D-printed intelligent molds with real-time monitoring capabilities

- Micro-injection molding for intricate medical and electronics components

- Artificial intelligence-powered process optimization

- Advanced robotics for automated production workflows

Sustainability Challenges and Strategic Opportunities

Sustainability is a big deal for the injection molding industry. Companies are finding new ways to be green:

| Sustainability Initiative | Potential Impact |

| Biodegradable material development | Reduced plastic waste |

| Energy-efficient manufacturing processes | Lower carbon footprint |

| Circular economy integration | Enhanced resource recycling |

Companies that focus on new tech and being green will stand out. Adaptive manufacturers who invest in innovation and environmental responsibility will lead the next wave of injection molding advancements.

Competitive Landscape in the Injection Molding Market

The injection molding market is highly competitive, with several key players leading the industry. Companies such as C&J Industries, Biomerics, and HTI Plastics are at the forefront, driving the market with their emphasis on innovative technologies and business expansion.

- ARBURG GmbH + Co KG – Germany

- Engel – Austria

- KraussMaffei – Germany

- Haitian International – China

- Sumitomo (SHI) Demag – Germany/Japan (joint venture)

- Husky Technologies – Canada

- Negri Bossi S.P.A. – Italy

- Niigata Machine – Japan

- Nissei Plastic Industrial Co., Ltd. – Japan

- Yizumi Holdings Co., Ltd. – China

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Injection Molding Market Report |

| Base Year | 2024 |

| Segment by Type |

· Plastic · Metal |

| Segment by Application |

· Aerospace · Medical · Energy · Electronics |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The injection molding industry continues to evolve rapidly, driven by technological advancements, sustainability initiatives, and changing market demands. Success in this competitive landscape requires companies to focus on innovation, environmental responsibility, and strategic partnerships. Those who can adapt to these changing dynamics while maintaining operational excellence will be well-positioned for future growth and market leadership.

Global Injection Molding Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Injection Molding Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Vacuum Arc RemeltingMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Injection Moldingplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Injection Molding Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Injection Molding Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Injection Molding Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofInjection Molding Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

Which industries are the primary drivers of injection molding demand?

The main industries driving the demand for injection molding are:

- Packaging

- Automotive

- Consumer electronics

Healthcare and aerospace also play a significant role in this demand.

What are the major technological advancements in injection molding?

Recent advancements include:

- Gas-assisted injection molding

- Thin-wall molding

- 3D-printed molds

- Micro-injection molding

- AI for process optimization

How is sustainability impacting the injection molding industry?

Sustainability is becoming increasingly important in the injection molding industry. Here are some ways it is making an impact:

- Using recycled materials: Manufacturers are incorporating recycled plastics into their production processes, reducing the need for virgin materials and minimizing waste.

- Developing biodegradable plastics: There is a growing demand for environmentally friendly alternatives to traditional plastics. Companies are investing in research and development to create biodegradable plastics that can break down naturally after use.

- Implementing energy-efficient processes: Energy consumption is a significant factor in the carbon footprint of injection molding operations. Manufacturers are adopting energy-efficient technologies and practices to reduce their energy usage and lower greenhouse gas emissions.

By embracing sustainability initiatives, the injection molding industry can contribute to a more circular economy and address environmental challenges.

What challenges are facing the injection molding market?

The injection molding market is currently facing several challenges, including:

- Raw material shortages: There is a scarcity of certain raw materials used in the injection molding process, which can disrupt production and lead to delays.

- Price changes: Fluctuations in the prices of raw materials and other inputs can impact the overall cost of production and profitability for manufacturers.

- High equipment costs: The initial investment required for purchasing injection molding machines and equipment can be significant, posing a barrier for new entrants or smaller businesses.

- Adapting to new technologies: With the rapid advancement of technology, injection molding companies need to continuously upgrade their machinery and processes to stay competitive. This can be challenging, especially for those with limited resources.

- Environmental needs: Increasing regulations and demands for sustainable practices in manufacturing require injection molding companies to find environmentally friendly solutions, which may involve additional costs and investments.

Which regions are dominant in the injection molding market?

The Asia-Pacific region, especially China, leads the market. North America and Europe, particularly the United States and Germany, are also seeing growth.

What are emerging applications for injection molding?

New applications include:

- Aerospace

- Renewable energy

- Medical technology

- Customized consumer products

How are companies addressing supply chain issues?

Companies are tackling supply chain issues through partnerships and supplier diversification. They’re also localizing production and using automation and IoT.

What role does technology play in modern injection molding?

Technology is essential in modern injection molding. It includes Industry 4.0, smart factories, data analytics, and automation, driving efficiency and innovation.

How is the injection molding industry adapting to environmental concerns?

The industry is addressing environmental concerns by developing eco-friendly materials and recycling technologies. It’s also reducing energy use and making manufacturing more sustainable.