Solid Recovered Fuel (SRF) Market Set to Grow to $4.75 Billion by 2025: Trends and Insights from the U.S., Germany, and India

Discover comprehensive insights into the evolving Solid Recovered Fuel (SRF) market, exploring global trends, market dynamics, and industry analysis from 2025-2033. This in-depth analysis covers regulatory impacts, technological innovations, regional market variations, and key industry players shaping the future of sustainable waste management and energy production. Learn how environmental regulations, circular economy initiatives, and advancing technologies are transforming the SRF landscape while creating new opportunities for sustainable energy solutions.

- Last Updated:

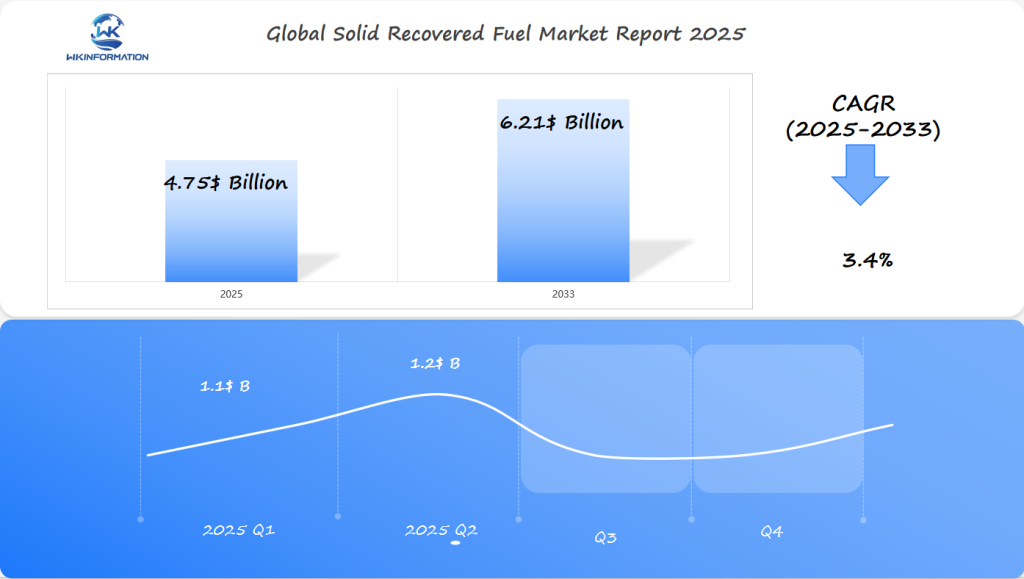

Solid Recovered Fuel Market Forecast for Q1 and Q2 2025

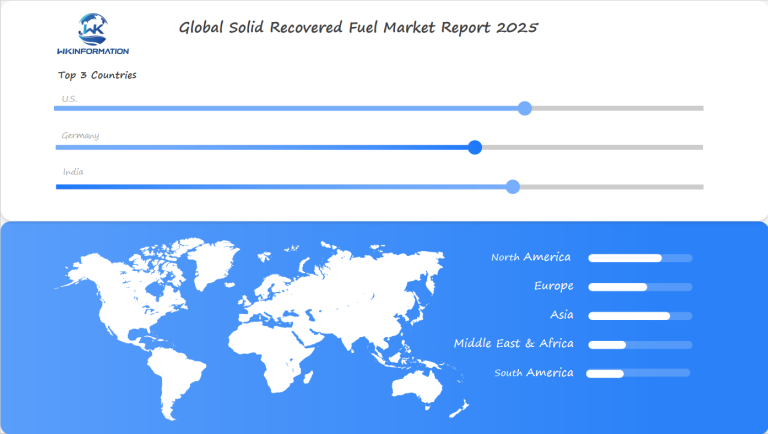

The solid recovered fuel (SRF) market is expected to reach $4.75 billion in 2025, with a modest CAGR of 3.4% through 2033. For the first half of 2025, Q1 is projected to generate around $1.1 billion, with Q2 seeing moderate growth to approximately $1.2 billion. The demand for SRF is increasing due to its role as an alternative fuel source for cement and energy production, driven by global sustainability and waste management trends. The U.S., Germany, and India are significant markets for SRF.

The U.S. continues to lead with a growing shift toward alternative energy sources and sustainable waste management practices in industrial sectors. Germany follows closely due to its commitment to reducing landfill waste and embracing circular economy initiatives. India, with its large industrial base and focus on reducing dependency on traditional fossil fuels, also presents a growing market for SRF. These countries are pivotal in understanding the future trajectory of the solid recovered fuel market.

Understanding the Upstream and Downstream Dynamics of the SRF Market

The Solid Recovered Fuel (SRF) market is a complex system that involves waste recycling and industrial energy needs. Understanding how this system works is key to knowing how waste can be transformed into valuable energy.

Upstream: The Process of SRF Production

SRF production begins with the sorting and processing of waste. These initial steps are critical in determining the quality and usability of the fuel:

- Thorough separation of waste from both municipal and industrial sources

- Utilization of advanced mechanical processing technologies

- Implementation of quality control measures and standardization processes for recovered fuel materials

Raw Material Sourcing Strategies

Waste recycling is vital for SRF. Countries aim to use less material and make the most of what they have.

Downstream Utilization Landscape

The downstream part of SRF deals with how industries use these fuels:

- Cement manufacturing facilities

- Power generation plants

- Industrial boiler systems

- Specialized industrial heating processes

These industries turn waste into sustainable energy. This approach helps the environment and meets energy needs.

Key Trends Driving Growth in the Solid Recovered Fuel Industry

The Solid Recovered Fuel (SRF) industry is changing fast. This is thanks to new waste management policies and the circular economy. Global trends are changing how we recover resources and find sustainable energy.

Several key factors are pushing the SRF industry forward:

- Environmental regulations are getting stricter

- There’s a big demand for alternative fuels

- Energy costs in traditional manufacturing are going up

- More companies are focusing on circular economy strategies

Waste Management Policy Innovations

Governments around the world are implementing new regulations for waste management. The United Kingdom’s experience with waste reduction demonstrates this trend.

“Transforming waste into a valuable resource is no longer an option—it’s a necessity,” says environmental policy expert Dr. Rachel Green.

Circular Economy Integration

The circular economy is a major factor contributing to the growth of SRF (Solid Recovered Fuel). It involves converting waste into fuel, which allows industries to reduce their environmental impact while also creating new economic opportunities.

Industries such as cement, power generation, and industrial processing are increasingly adopting SRF. This signifies a significant shift in our approach to resource management.

Addressing the Challenges in Solid Recovered Fuel Development

The Solid Recovered Fuel (SRF) industry has many complex challenges. It needs smart solutions and new ideas. Making waste-to-energy technologies sustainable means understanding the environment and following strict quality rules.

- Maintaining consistent SRF quality standards across production facilities

- Mitigating potential environmental impact of SRF processing

- Addressing technological limitations in waste conversion

- Improving public perception of waste-to-energy technologies

Quality Control and Standardization

Good SRF production needs strong quality control. Companies must use precise sorting and strict screening to keep materials consistent. Advanced sensor technologies help find and remove impurities, making the fuel better.

Environmental Considerations

It’s important to reduce the environmental impact of SRF. New methods for processing waste aim to lower emissions and generate more energy. Scientists are continuously searching for cleaner ways to incinerate waste and improve energy technology.

The future of SRF depends on balancing technological innovation with environmental responsibility.

Everyone needs to collaborate in order to address these issues. We must allocate resources towards research and discover solutions to enhance waste management practices.

Geopolitical Factors Shaping the SRF Market Landscape

The global solid recovered fuel (SRF) market is changing fast. This is due to complex global politics. Policies on waste trade and energy security are changing how countries manage waste and make renewable energy.

- Shifting international waste trade regulations

- National energy security strategies

- Cross-border waste management cooperation

- Technological innovation in waste-to-energy sectors

International Waste Trade Challenges

Changes in international waste trade have greatly affected SRF production. For example, China’s rules on waste imports have led to more local waste solutions. The UK has spent over £900 million since 2011 on exporting waste.

“The future of waste management lies in creating sustainable, domestic energy solutions,” says energy policy expert Dr. Rachel Henderson.

Energy Security Considerations

Countries view SRF as crucial for improved energy security. Utilizing waste as fuel helps decrease dependence on fossil fuels, leading to more stable energy systems.

| Country | SRF Production Potential | Energy Security Impact |

| United States | High | Significant reduction in fossil fuel dependency |

| Germany | Medium-High | Advanced waste-to-energy technologies |

| United Kingdom | Medium | Domestic waste management strategies |

The evolving landscape of waste trade and energy security is driving the need for innovative approaches in the SRF market, presenting both challenges and opportunities for all stakeholders involved.

Exploring SRF Market Segmentation: Types and Their Impact

The solid recovered fuel (SRF) market is full of different fuel options. These options are changing how industries use energy. Each SRF type has special qualities that make it useful in various sectors.

SRF types fall into several main categories. These categories are based on what they’re made of and how much energy they hold:

- High-grade SRF with superior energy content

- Low-grade biomass-derived fuel for certain uses

- Specialized industrial recovery fuels

Composition and Energy Characteristics

The energy efficiency of SRF types varies a lot. High-grade solid recovered fuel is made from preprocessed waste. It has a high calorific value, making it great for energy-hungry industries like cement making.

Biomass-derived fuel is also a big part of the SRF market. These fuels are good for the environment and give steady energy for industrial needs.

Industrial Applications

SRF types are chosen based on what industries need. Cement plants, power plants, and special manufacturing places use these fuels a lot.

The recycling world is key in making top-notch SRF. Cities that recycle well help make better and more efficient SRF.

How Applications Are Shaping Solid Recovered Fuel Demand

The demand for Solid Recovered Fuel (SRF) is growing fast. This is thanks to new uses in many industries. As people worry more about the environment, businesses are looking for green alternatives to old fuels.

The cement industry is a big user of SRF. It’s changing how fuel is used in this field. By using SRF, cement plants cut down on carbon emissions and need less fossil fuel.

Key Industrial Applications of SRF

1. Cement kilns as primary waste-to-energy plants

Waste-to-energy plants are key for handling waste. They turn waste into energy, helping create a closed-loop system for managing waste.

2. Industrial boiler systems

Industrial boiler systems are used in various industries to generate steam or hot water for processes such as heating, power generation, and manufacturing. These systems can utilize SRF as a fuel source, replacing traditional fossil fuels and reducing greenhouse gas emissions.

3. District heating infrastructures

District heating infrastructures provide centralized heating to multiple buildings or areas through a network of insulated pipes. By incorporating SRF into the fuel mix, these systems can achieve higher energy efficiency and lower carbon emissions compared to conventional heating methods.

4. Process heat generation in manufacturing

Process heat generation in manufacturing involves using heat for various industrial processes such as drying, melting, or chemical reactions. By substituting fossil fuels with SRF in these applications, manufacturers can reduce their carbon footprint and contribute to a more sustainable production system.

The construction and demolition sector is also playing a big role. It has managed to recycle and recover 90% of its waste. This helps a lot in getting materials for SRF, especially for cement plants.

| SRF Application | Energy Efficiency | CO2 Reduction Potential |

| Cement Industry | 75-80% | 30-40% |

| Industrial Boilers | 65-70% | 25-35% |

| Waste-to-Energy Plants | 80-85% | 35-45% |

“SRF represents a transformative solution in sustainable energy production, bridging waste management and industrial fuel requirements.” – Environmental Research Institute

Regional Insights into the Solid Recovered Fuel Market

The global Solid Recovered Fuel (SRF) market is changing fast in different parts of the world. Each region has its own way of handling waste and making energy. This shows how diverse and promising the SRF market is.

In North America, the way we deal with waste is changing quickly. There’s more money going into green waste management tech. The U.S. is seeing a big jump in SRF making, thanks to green rules and money perks.

Key Regional Market Characteristics

- European SRF rules are making waste management greener

- North America is getting into new waste tech

- Asia-Pacific is growing fast in SRF

In Europe, especially in Germany, SRF making is a big deal. Their strict waste rules have cut down on landfills a lot. For example, in England, landfill use went from 80% in 2000 to under 20% by 2015. This shows how good alternative waste plans can be.

Market Development Trends

New opportunities in SRF markets are arising from technology, environmental regulations, and an increasing awareness about waste. Countries are beginning to view waste as a potential source of energy rather than just something to be discarded.

The U.S. SRF Market: Key Growth Drivers and Trends

The U.S. SRF market is changing fast. This is thanks to new waste management rules and energy partnerships. Solid recovered fuel (SRF) is becoming key for turning waste into energy.

Key Growth Drivers

- Stringent waste management regulations encouraging alternative fuel development

- Increasing industrial demand for sustainable energy solutions

- Technological advancements in waste processing techniques

- Growing environmental consciousness among corporations

Regulatory Landscape and Market Dynamics

U.S. waste management rules are helping SRF grow. Federal and state policies are making it easier for waste-to-energy projects. This is pushing companies to use new recycling tech.

Energy Partnerships Driving Innovation

Partnerships between waste firms and power producers are boosting SRF. These teams are turning waste into green energy. This cuts down on pollution and brings in profits.

| Market Segment | Growth Potential | Key Drivers |

| Industrial Sector | High | Cost-effective energy alternatives |

| Manufacturing | Medium | Sustainability goals |

| Utilities | Very High | Renewable energy mandates |

The U.S. SRF market is set to grow even more. We can look forward to more money going into it, new tech, and better waste handling.

Germany's Role in SRF Production and Innovation

Germany leads in waste management innovation, creating advanced strategies for solid recovered fuel (SRF) production. It’s a global leader in cutting-edge SRF technologies.

The German SRF production scene is a technological marvel. It sets global standards. Their methods include:

- Rigorous SRF quality standards for top efficiency

- Advanced sorting and processing tech

- Complete waste-to-energy systems

- Strict environmental rules

Leading the Way in Waste Management Technology

Germany’s production of Solid Recovered Fuel (SRF) is a prime example of how innovation can drive sustainable waste management practices. The facilities responsible for producing SRF in Germany are equipped with state-of-the-art technology, including advanced near-infrared systems and highly accurate sorting processes. These technological advancements enable the creation of high-quality fuel alternatives from waste materials.

“Germany’s SRF production represents the gold standard in sustainable waste management globally.” – Environmental Research Institute

One of the key advantages of Germany’s waste management system is its ability to achieve high conversion rates. This means that a significant portion of waste materials, including those that are typically considered difficult to recycle or dispose of, can be transformed into valuable energy sources through the SRF production process.

Germany continues to lead the way in SRF production by constantly pushing the boundaries of what is possible. The country is actively exploring new ways to integrate technology into its waste management practices while also prioritizing environmental sustainability. This commitment to innovation and eco-friendliness sets Germany apart as a global leader in sustainable waste management solutions.

India's Emerging Position in the SRF Industry

The Indian SRF industry is going through a big change. It’s becoming key for managing urban waste and making sustainable energy. Fast growth in cities and more environmental problems have made India look for new ways to use waste.

Several factors are contributing to this shift:

- Significant government support for waste-to-energy initiatives

- Growing interest from cement industry fuel alternatives

- Increased focus on sustainable waste management practices

- Technological advancements in SRF processing

Waste Management Transformation

Managing urban waste is now a big deal for Indian leaders. The cement industry is starting to use SRF instead of old fossil fuels. This is making the market grow a lot. Municipalities see the good things about turning waste into energy.

Investment and Innovation

International partnerships are helping the Indian SRF industry grow fast. Money going into new tech is making it better to turn waste into fuel.

The potential for SRF in India represents a significant opportunity for sustainable waste management and energy production.

Working together, local governments, industries, and tech companies are building a strong SRF system. India is set to lead in new ways to turn waste into energy.

What's Next for the Solid Recovered Fuel Market?

The future of the SRF market is bright. New waste-to-energy technologies are changing how we manage waste. These innovations will help make sustainable fuel production and environmental protection easier.

- Advanced sorting and processing technologies

- Enhanced waste-to-energy conversion methods

- Increased focus on reducing carbon emissions

Technological Breakthroughs in SRF Production

New technologies are opening up growth opportunities in the market. These advancements are making solid recovered fuel production more efficient and green.

| Innovation Area | Potential Impact |

| Thermal Processing | Increased fuel quality |

| Chemical Separation | Improved material recovery |

| AI-Driven Sorting | Enhanced waste classification |

Market Consolidation Trends

The industry is seeing big changes with market consolidation. Large waste management companies are buying up SRF producers. This is making waste-to-energy systems more integrated and efficient.

The future of solid recovered fuel lies in technological innovation and sustainable practices.

Investors and industry leaders are seeing the value in SRF technologies. With ongoing research and development, the market is set to grow. This growth will be driven by environmental rules and the need for sustainable energy.

Competitive Forces in the SRF Market

The Solid Recovered Fuel (SRF) market is seeing a lot of competition. This is thanks to new waste management companies and partnerships with the energy sector. These players are changing the game with new tech and teamwork.

Main players:

-

Estre Ambiental – Brazil

-

Biffa – UK

-

Ecomondis – France

-

Countrystyle Recycling – UK

-

Renewi – Netherlands

-

SUEZ Recycling and Recovery – France

-

Veolia – France

-

Carey Group – Ireland

-

FCC Austria Abfall Service AG – Austria

-

EcoUrja Renewable Energy – India

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Solid Recovered Fuel Market Report |

| Base Year | 2024 |

| Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The Solid Recovered Fuel (SRF) market is ripe for smart investments in the waste-to-energy field. It’s expected to grow a lot, thanks to stricter environmental laws and a push for cleaner energy worldwide. Investors see big chances in the SRF value chain, especially in new waste handling tech.

Key Areas of Investment

Investors should look at:

- Waste collection systems

- Processing plants

- Energy uses

Countries like the U.S., Germany, and India are leading in green energy. Studies show that energy-from-waste plants work well, meeting emission rules and offering a solid alternative to oil and gas.

Risk Mitigation Strategies

It’s important for investors to think about how to avoid risks. They need to focus on:

- Following environmental rules

- Staying up-to-date with tech

- Being flexible in their business plans

The SRF market is strong because of more trash, higher energy needs, and a growing green mindset among businesses and governments.

Potential for High Returns

Smart investors can make a lot of money by focusing on:

- The latest recycling tech

- Efficient systems

- Big waste-to-energy projects

The market looks bright, with growth showing the world’s move towards sustainable and circular energy models.

Global Solid Recovered Fuel Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Solid Recovered Fuel Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Solid Recovered FuelMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Solid Recovered Fuel players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Solid Recovered Fuel Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Solid Recovered Fuel Emerging and Untapped Markets

- Growth Potential in Secondary Regions

-

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Solid Recovered Fuel Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofSolid Recovered Fuel Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is Solid Recovered Fuel (SRF)?

Solid Recovered Fuel (SRF) is made from processed waste. It includes waste from cities, industries, and businesses. It’s made to high standards and used in places like cement kilns and power plants.

How large is the SRF market expected to grow?

The SRF market is expected to reach $4.75 billion by 2025. This growth is due to stricter waste rules, the circular economy, and the need for new energy sources.

Which countries are leading in SRF production?

Germany, the United States, and India are leading in SRF production.

- Germany has a strong waste management system.

- The U.S. is creating policies to support it.

- India is using SRF to tackle urban waste.

What are the environmental benefits of SRF?

SRF offers several environmental benefits, including:

- Reducing landfill waste

- Cutting down on fossil fuel use

- Lowering CO2 emissions

By turning waste into energy, SRF helps the environment and provides a green alternative.

What challenges does the SRF industry face?

The SRF industry faces challenges like keeping quality high and dealing with emissions. It also needs to improve technology and change public views on using waste for fuel.

What industries primarily use Solid Recovered Fuel?

Cement, power, district heating, and industrial boilers mainly use SRF. These sectors benefit from SRF’s green energy source.

How is SRF different from traditional waste-to-energy methods?

SRF is processed to remove harmful substances and standardize its energy content. This makes it a cleaner and more efficient fuel than burning waste directly.

What role do government regulations play in SRF development?

Government rules, like the EU’s Waste Framework Directive, help SRF grow. They encourage less waste, more recycling, and support for green fuel technologies.

Are there different types of Solid Recovered Fuel?

Yes, there are high-grade and low-grade SRF. They vary in what they’re made of, their energy content, and where they can be used. Biomass-based SRF is also becoming more popular as a green energy option.

What is the future outlook for the SRF market?

The SRF market has a bright future. It will see new technologies, market growth, and more use. This is thanks to growing environmental worries, energy needs, and the circular economy.