Rare Earth Magnet Market Projected to Hit $19.5 Billion by 2025: Strategic Growth Across the U.S., China, and Germany

Discover how the Rare Earth Magnet Market is expanding rapidly across the U.S. and China, driving innovation in electronics, automotive, and renewable energy sectors to reach $19.5 billion by 2025.

- Last Updated:

Rare Earth Magnet Market Forecast for Q1 and Q2 2025

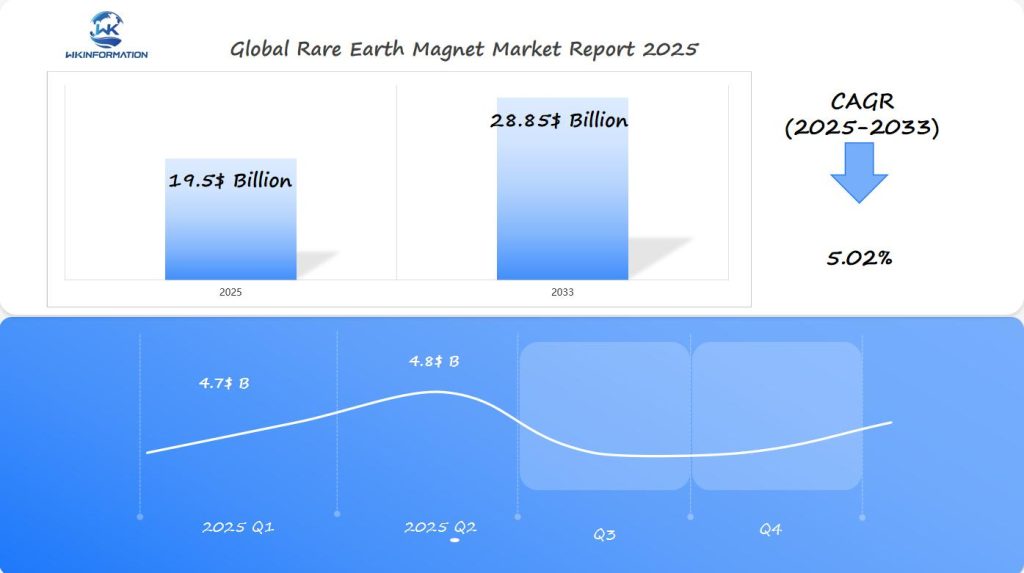

The rare earth magnet market is poised to reach $19.5 billion by 2025, growing at a CAGR of 5.02% through 2033. The U.S. remains the largest consumer of rare earth magnets, driven by its expanding electric vehicle (EV) market and clean energy initiatives. China, a key producer, continues to dominate in terms of both supply and demand, especially as the country increases production for high-tech industries, including consumer electronics and renewable energy. Germany’s automotive and industrial sectors are also significant contributors to demand.

The market is expected to grow steadily in Q1 2025, with projected sales of $4.7 billion, rising to $4.8 billion in Q2 due to increased investments in EVs, wind turbines, and advanced electronics.

Key Takeaways

- The rare earth magnet market is projected to reach $19.5 billion by 2025.

- Strategic growth is concentrated in the U.S., China, and Germany.

- Technological innovations are driving market expansion.

- Rare earth magnets play a critical role in the electronics, automotive, and renewable energy sectors.

- American Rare Earths is leading with innovative production strategies.

Upstream and Downstream Integration in the Rare Earth Supply Chain

The rare earth magnet industry is changing fast. Companies are now focusing on complete supply chain integration. They see it as key to staying ahead in a global market.

Supply chain integration is crucial for rare earth processing firms. By controlling production stages, they can:

- Lessen reliance on foreign suppliers

- Boost quality control

- Streamline raw material sourcing

- Enhance manufacturing skills

Strategic Vertical Integration Approaches

American Rare Earths is a prime example. They’re building a U.S. supply chain for rare earth oxides. Vertical integration helps companies avoid global supply chain problems and makes production smoother.

“Control of the entire supply chain is no longer a luxury, but a necessity in the rare earth magnet industry.” – Industry Expert

Places like the U.S., China, and Germany are leading the way. Each has its own strengths in rare earth processing. They are focusing on new technologies and environmentally friendly manufacturing practices.

Global Integration Strategies

For supply chain integration to work, companies need to invest in tech, infrastructure, and people. They’re setting up advanced facilities and training experts. This creates strong, reliable systems for making rare earth magnets.

Technology Trends Fueling Magnet Innovation

The rare earth magnet industry is undergoing a significant transformation due to new technologies. Advanced manufacturing and recycling technologies are at the forefront of this change. Researchers and companies are making concerted efforts to enhance magnet performance and sustainability.

Key Technology Trends Driving Magnet Innovation

Here are some of the key technology trends that are driving innovation in the magnet industry:

- Breakthrough advanced manufacturing techniques improving magnetic material efficiency

- Cutting-edge recycling technologies enabling rare earth element recovery

- Novel magnet compositions reducing dependence on critical rare earth materials

Innovative Extraction and Recycling Strategies

CoTec Holdings Corp is leading in mineral extraction innovation. They’re investing in recycling tech to recover rare earth elements. This work aims to make the supply chain for magnetic materials more sustainable and strong.

Research and Development Frontiers

Research teams in the US, China, and Germany are working together. They’re creating new magnet technologies. Their goal is to make magnets stronger, lighter, and better for the environment.

This ongoing innovation could change many industries. It offers sustainable and efficient solutions for big tech challenges.

Challenges in Sourcing and Environmental Regulations

The rare earth magnet industry faces big challenges in finding rare earths and following environmental rules. Global supply chain issues are getting worse. Manufacturers need to find sustainable and reliable ways to get materials.

Extracting rare earths has many environmental and operational problems. Mining and processing these minerals need advanced methods to reduce harm to nature. At the same time, they must meet the increasing needs of industries.

Key Supply Chain Obstacles

- Limited geographic concentration of rare earth deposits

- High environmental compliance costs

- Complex extraction and processing techniques

- Geopolitical restrictions on material exports

Companies are finding new ways to tackle these supply chain issues. American Rare Earths’ Halleck Creek project shows how to manage land well. This helps speed up permits and development.

Environmental Regulation Landscape

| Region | Regulatory Complexity | Environmental Standards |

| United States | High | Strict emissions control |

| China | Moderate | Emerging environmental protocols |

| Germany | Very High | Stringent sustainable practices |

The future of rare earth sourcing depends on innovation, caring for the environment, and smart resource use. Sustainable practices are key to solving current problems in the industry.

Geopolitical Factors Reshaping Global Magnet Distribution

The global rare earth magnet market is changing fast because of complex geopolitical factors. Trade tensions between big countries have changed how rare earth exports work. This has made it hard for international makers and governments to plan.

Important geopolitical factors are affecting rare earth magnet distribution:

- More countries are worried about the safety of their mineral supplies.

- They are trying to not rely on just one supplier for these minerals.

- International groups are working together to find more mineral resources.

Supply Chain Resilience Strategies

CoTec Holdings Corp is a great example of managing resources well. They want to make sure the U.S. and its allies have a steady supply of important minerals. This shows how countries are trying to avoid risks in getting rare earth materials.

The U.S. and European countries are working hard to make more minerals at home. They want to avoid problems with trade rules. They’re trying to make new ways to get rare earth magnets that won’t be affected by world market changes.

Strategic International Collaborations

Both governments and private companies are teaming up to make rare earth exports stronger. They’re making deals with other countries to find and use more minerals. This way, they can avoid problems with trade and make sure they have the minerals they need.

Segmenting Rare Earth Magnets: Neodymium, Samarium Cobalt, and Others

The world of rare earth magnets is vast and varied. Each type has its own special traits and uses. Scientists and makers are always looking for new ways to make these magnets better for many fields.

NdFeB magnets are the most common, making up about 80% of all rare earth magnets. They are strong and affordable, making them great for many tech uses.

Comparative Analysis of Rare Earth Magnet Types

Each rare earth magnet type has its own special features. These features are important for different tech needs:

- NdFeB magnets: High magnetic strength, lower temperature resistance

- SmCo magnets: Excellent high-temperature performance, superior stability

- Ceramic magnets: Economical, moderate magnetic capabilities

| Magnet Type | Temperature Range | Primary Applications |

| NdFeB Magnets | -40°C to 150°C | Electronics, Wind Turbines |

| SmCo Magnets | -55°C to 350°C | Aerospace, Military Equipment |

| Ceramic Magnets | -40°C to 250°C | Consumer Electronics |

New recycling methods, like HyProMag’s HPMS, are changing how we make NdFeB magnets. They help us reuse materials from old products.

Innovative magnet technologies are reshaping industrial capabilities through enhanced magnetic performance and environmental consciousness.

Applications in Electronics, Automotive, and Renewable Energy

Rare earth magnets are essential in various high-tech industries. They contribute to improving new technologies, making them more advanced and efficient. These magnets possess unique magnetic properties that are crucial for numerous contemporary and environmentally friendly technologies.

Electronics and Consumer Devices

In electronics, rare earth magnets are changing how devices work. They make gadgets smaller and better. Here are some examples:

- Smartphones with better speakers

- Fast hard disk drives

- Top-notch audio gear

- Advanced medical imaging tools

Electric Vehicles and Transportation

Electric cars require a significant amount of rare earth magnets. The automotive industry relies on these magnets for powerful electric motors. Neodymium-based magnets play a crucial role in the functioning of electric car motors.

Renewable Energy Technologies

Renewable energy uses rare earth magnets too. Wind turbines use them to make electricity better. Solar tracking and grid storage also get a boost from these magnets.

The growing use of rare earth magnets in electronics, cars, and green energy looks bright. It shows a big future for these magnets, leading to big changes worldwide.

Regional Insights into the Rare Earth Magnet Industry

The global rare earth magnet market shows big differences in each region. Regional market analysis gives us important insights into the changing industry.

In the Asia-Pacific, China and countries like Japan and South Korea lead in production. North America is also growing, thanks to new investments and tech.

Market Dynamics by Region

- China continues to dominate rare earth magnet manufacturing

- United States accelerating domestic production capabilities

- European markets focusing on sustainable recycling technologies

Important updates show how key each region is. American Rare Earths is working on the Halleck Creek project in Wyoming. This shows a big push for using America’s own rare earth resources.

| Region | Key Strengths |

| Asia-Pacific | Manufacturing capacity |

| North America | Technological innovation |

| Europe | Recycling technologies |

“The future of rare earth magnets lies in strategic regional collaborations and sustainable production methods.” – Industry Expert

New investments in processing and supply chain are changing the rare earth magnet world. Each region is finding its own way to stand out.

The U.S. Focus on EV Expansion and Defense Tech

The United States is quickly changing its rare earth magnet strategy. This is to get the key tech needed for the future.

The U.S. rare earth policy focuses on two main areas: electric vehicles and advanced defense tech. Partnerships between the government and private sectors are making big investments in making rare earth magnets in the U.S.

Key Strategic Initiatives

- Establish domestic rare earth processing facilities

- Reduce dependency on international rare earth suppliers

- Support electric vehicle manufacturing infrastructure

- Enhance national defense technological capabilities

Defense tech needs high-performance rare earth magnets. Precision-engineered magnets are key for advanced aerospace, guidance, and communication systems.

Electric Vehicle Technology Advancements

The electric vehicle strategy needs new rare earth magnet solutions. Companies are putting a lot into magnet tech that boosts car performance, cuts weight, and saves energy.

Strategic domestic production of rare earth magnets represents a crucial national technological imperative.

China’s Dominance in Rare Earth Production and Exports

The global rare earth market is largely controlled by China. It holds 90% of the world’s refining capacity. This makes China the top player in rare earth production and exports.

China’s approach to rare earth production is complex. It involves several key areas:

- Consolidation of mining and processing operations

- Strategic environmental management

- Control of global supply chains

- Advanced technological investments

Global Market Impact and Strategic Positioning

China’s export policies have a big impact on the global market. By managing rare earth exports, China gains power in trade talks.

“China’s rare earth strategy is not just about minerals, but global economic influence” – Economic Research Institute

Other countries are trying to find new sources and improve recycling. The rare earth landscape continues to evolve. This is driven by politics and the need for strong supply chains.

Germany’s Push for Sustainable and High-Precision Manufacturing

The German rare earth industry is leading the way in sustainable innovation. It’s changing advanced manufacturing technologies for the better. Germany aims to be a top player in rare earth magnet development and recycling.

German makers are making big strides in rare earth recycling. They’re setting new standards worldwide. Their main strategies include:

- Creating advanced recycling tech for rare earth magnets

- Lowering reliance on imported raw materials

- Supporting circular economy solutions

- Working with European research groups

Automotive and Industrial Applications

The car industry is key in Germany’s rare earth plans. German engineers are making ultra-efficient electric vehicle parts using rare earth magnets. They team up with research centers to improve material recovery and new manufacturing methods.

International Partnerships and Innovation

Germany is collaborating with global tech leaders and research groups. These partnerships assist German companies in discovering sustainable methods to acquire essential materials. Additionally, they enhance advanced manufacturing techniques.

Innovation Outlook and Circular Economy Integration

The rare earth magnet industry is changing fast. It’s moving towards sustainable practices and better use of resources. Companies are now using circular economy ideas to change how they get, use, and recycle rare earth materials.

New technologies are leading the way in rare earth innovation. Important advancements include:

- Advanced recycling processes that get the most value from rare earth materials

- AI-driven sorting systems that help recover more materials

- Closed-loop supply chain strategies that cut down on waste

Emerging Technological Frontiers

Companies like CoTec Holdings Corp are leading in new technologies for mining and recycling rare earths. Their work shows how old ways of managing resources can change.

The world is moving towards a circular economy in rare earth magnet production. Investing in green technologies is opening up new chances for better resource use. It also helps reduce environmental harm and makes supply chains stronger.

Global Innovation Landscape

Research centers in the U.S., China, and Germany are collaborating to develop new recycling technology. Their aim is to reduce primary mining activities and promote sustainability in rare earth material systems.

Competitive Landscape Among Global Magnet Producers

The rare earth magnet market is seeing a lot of competition. New players are changing the game with fresh ways to make rare earth magnets.

Some big names in rare earth magnets are leading the way with smart moves:

• Hitachi Metals Group – Japan

• Shin-Etsu – Japan

• TDK – Japan

• VAC (Vacuumschmelze GmbH & Co. KG) – Germany

• Arnold Magnetic Technologies – United States

• ADAMS Magnetic Products Co. – United States

• Bunting Magnetics Co. – United States

• Lynas Corporation – Australia

• Neo Performance Materials – Canada

• Ningbo Tongchuang Magnetic Materials Co., Ltd. – China

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Rare Earth Magnet Market Report |

| Base Year | 2024 |

| Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The rare earth magnet market is at a turning point. It’s influenced by new technologies and changes in the global economy. Experts predict the market will reach $19.5 billion by 2025, thanks to new tech and green energy growth.

Factors Driving Change

New ways of making magnets and green tech are changing the market. Car makers, green energy firms, and tech companies are all looking at better magnets. These magnets will work better and be kinder to the planet. Investing in new research is key for staying ahead.

Political and Economic Influences

Politics and supply chains will shape the future of rare earth magnets. The US, China, and Germany are leading the way with their own factories and new ways to get magnets. The market will grow as it finds a balance between new tech and green, stable production.

The Importance of Adaptability

Everyone in the rare earth magnet world needs to stay flexible and look ahead. New tech, rules, and world trends will shape the market. Companies that can keep up with these changes will grab the biggest chances in this important field.

Global Rare Earth Magnet Market Report(Can Read by Free sample)–Table of Contents

Chapter 1:Rare Earth Magnet Market Analysis Overview

- Competitive Forces Analysis(Porter’s Five Forces)

- Strategic Growth Assessment(Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Rare Earth Magnet Market Segmentation Overview

Chapter 2:Competitive Landscape

- GlobalRare Earth Magnet Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3:Rare Earth Magnet Market Segmentation Analysis

- Key Data and Visual Insights

- Trends,Growth Rates,and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4:Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic,Demographic,and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5:Rare Earth Magnet Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends,Challenges,and Opportunities

Chapter 6:Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7:Rare Earth Magnet Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8:Key Findings and Recommendations

- Summary of Rare Earth Magnet Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are rare earth magnets and why are they important?

Rare earth magnets are made from elements like neodymium and samarium. They are key in many advanced technologies. This includes electric vehicles, renewable energy, electronics, and defense.

How large is the global rare earth magnet market?

The market is expected to hit $19.5 billion by 2025. This growth is driven by demand in automotive, electronics, and renewable energy.

Which countries are the leading producers of rare earth magnets?

China leads the market, but the U.S. and Germany are catching up. They aim to reduce their reliance on Chinese exports.

What are the main types of rare earth magnets?

There are two main types:

- Neodymium Iron Boron (NdFeB) magnets: These are common and versatile.

- Samarium Cobalt (SmCo) magnets: These are used in high-temperature applications.

What challenges does the rare earth magnet industry face?

The rare earth magnet industry faces several challenges, including:

- Sourcing raw materials

- Navigating environmental regulations

- Reliance on Chinese exports

Additionally, mining and processing activities in this industry have environmental impacts that need to be addressed.

How are companies addressing sustainability in rare earth magnet production?

Companies are adopting circular economy practices. They’re working on recycling, exploring new materials, and improving mining and processing methods.

Which industries use rare earth magnets the most?

The main industries that heavily rely on rare earth magnets are:

- Electronics

- Automotive

- Renewable energy

- Defense

These industries are the primary drivers of demand for rare earth magnets.

What technological innovations are emerging in the rare earth magnet sector?

New manufacturing methods and research on alternative materials are emerging. Recycling and reprocessing technologies are also being improved.

How are geopolitical tensions affecting the rare earth magnet market?

Trade tensions, especially between the U.S. and China, are pushing for diversification. This includes developing domestic production and reducing reliance on Chinese supplies.

What role do rare earth magnets play in electric vehicles?

They are essential for electric vehicles. They power electric motors and regenerative braking systems. Their compact size and strength are crucial.