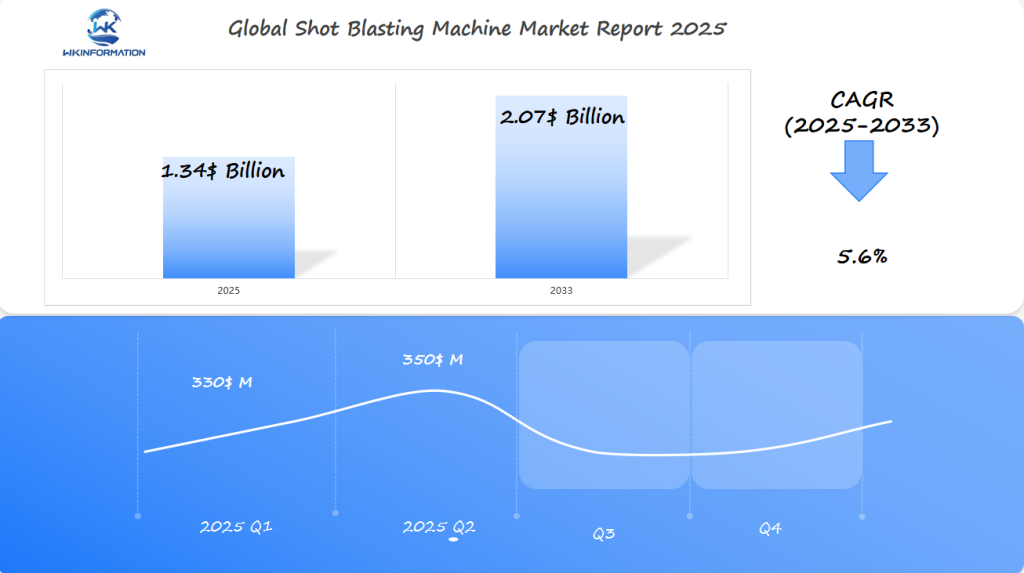

Shot Blasting Machine Market Set to Reach $1.34 Billion by 2025: Growth Opportunities in the U.S., Germany, and China

Explore comprehensive insights into the shot blasting machine market forecast for 2025, including key trends, technological advancements, regional analysis, and industry applications. Learn about market growth projections, emerging technologies, and leading manufacturers in this essential industrial equipment sector.

- Last Updated:

Shot Blasting Machine Market Forecast for Q1 and Q2 2025

The shot blasting machine market is projected to reach $1.34 billion by 2025, with a CAGR of 5.6% from 2025 to 2033. In Q1 2025, the market is expected to generate around $330 million, with Q2 seeing an increase to approximately $350 million.

Key Players and Drivers

The U.S., Germany, and China are key players in the market, driven by increasing demand in manufacturing, automotive, and metal industries.

- The U.S. market benefits from advanced industrial automation.

- Germany is a leader in precision engineering.

- China, with its vast manufacturing sector, will remain a critical market, supporting growth through the demand for efficient and sustainable surface preparation solutions.

Sustainability and Technological Advancements

Furthermore, the increasing focus on sustainability and eco-friendly manufacturing practices will push the demand for more energy-efficient shot blasting machines, particularly in the automotive and heavy machinery sectors. Technological advancements, such as automated shot blasting and the integration of robotics for precision work, will also fuel market expansion, providing manufacturers with cost-effective and high-quality surface finishing solutions.

Exploring the Upstream and Downstream Industry Chain in Shot Blasting Machines

Upstream Industry Chain (Supply Side)

This involves the raw materials, components, and technologies used in the manufacturing of shot blasting machines.

1. Raw Materials

-

Steel & Metal Alloys: Used in the construction of machine frames, blast chambers, and rotors.

-

Abrasive Media: Steel shot, grit, aluminum oxide, glass beads, etc., which are essential for the blasting process.

-

Electrical Components: Motors, control panels, sensors, and wiring for automation and power.

-

Protective Linings: Rubber or manganese steel linings to resist wear and prolong machine life.

2. Component Suppliers

-

Motors and Gearboxes: For driving the blast wheels or conveyors.

-

Blast Wheels and Turbines: The core components that propel abrasive media.

-

Dust Collection Systems: Filters, fans, and cyclones to manage debris and environmental compliance.

-

PLC/Automation Systems: For smart control and efficiency.

3. Manufacturing Equipment

-

CNC Machines: For precision cutting and machining of parts.

-

Welding and Fabrication Tools: For assembling the machine frames and components.

Downstream Industry Chain (Demand Side)

These are the industries and applications that use shot blasting machines, as well as services and support sectors.

1. End-User Industries

-

Automotive: Cleaning and preparing metal surfaces, deburring, and shot peening for fatigue resistance.

-

Foundry and Casting: Removing sand and scale from castings.

-

Construction and Shipbuilding: Surface preparation for coating and painting.

-

Aerospace: Peening and cleaning parts for structural integrity.

-

Steel Industry: Descaling and surface treatment of structural components.

2. Distribution Channels

-

Direct Sales: From manufacturers to industrial clients.

-

Distributors/Dealers: Who provide localized sales, installation, and service.

-

Online B2B Platforms: Like Alibaba, ThomasNet, or Made-in-China.

3. After-Sales Services

-

Maintenance and Repairs

-

Replacement Parts Supply

-

System Upgrades and Retrofitting

-

Training and Operation Support

Key Trends Driving the Shot Blasting Machine Industry

The Shot Blasting Machine industry is changing because of new technology and evolving market needs. Here are some important trends that are shaping the industry:

- Technological Advancements: New technologies are being developed to improve the efficiency and effectiveness of shot blasting machines.

- Increased Demand for Automation: Many industries are looking for ways to automate their processes, including shot blasting.

- Focus on Sustainability: There’s a growing emphasis on environmentally friendly practices in manufacturing, which is influencing the design and operation of shot blasting machines.

- Customization and Flexibility: Manufacturers are seeking machines that can be easily customized to meet their specific needs.

These trends are expected to have a significant impact on the Shot Blasting Machine industry in the coming years.

Technological Advancements in Shot Blasting

Technological advancements are playing a crucial role in shaping the Shot Blasting Machine industry. Innovations in machine design and functionality are enhancing the efficiency and effectiveness of shot blasting processes.

One of the significant technological advancements is the integration of advanced automation systems. These systems enable real-time monitoring and control, improving the overall quality of the blasting process.

Automation and Efficiency Improvements

The adoption of automation in Shot Blasting Machines is leading to significant efficiency improvements. Automated systems can operate continuously without human intervention, reducing downtime and increasing productivity.

- Improved surface finish quality

- Reduced labor costs

- Enhanced safety features

Furthermore, automation allows for precise control over the blasting process, resulting in consistent outcomes and reduced material waste.

Overcoming Barriers in Shot Blasting Machine Adoption and Production

Despite its benefits, the shot blasting machine market encounters significant obstacles in manufacturing and adoption. The industry faces numerous challenges that impact its growth and efficiency.

Challenges in Shot Blasting Machine Manufacturing

The manufacturing process of shot blasting machines is complex and involves several challenges. These include high production costs, the need for skilled labor, and the complexity of machine design.

High Production Costs

High production costs are a significant barrier, as they make it difficult for manufacturers to compete in a price-sensitive market.

Need for Skilled Labor

The need for skilled labor adds to the challenge, as it increases labor costs and makes it harder to find qualified personnel.

Complexity of Machine Design

The complexity of machine design can also pose challenges in terms of manufacturing efficiency and cost-effectiveness.

Strategies for Overcoming Production Challenges

To overcome these challenges, manufacturers can adopt several strategies. These include investing in automation technologies to reduce labor costs and improve efficiency.

- Implementing lean manufacturing techniques to streamline production processes.

- Investing in research and development to improve machine design and functionality.

- Providing training programs for employees to enhance their skills and productivity.

By adopting these strategies, manufacturers can overcome the challenges in shot blasting machine production and improve their competitiveness in the market.

Geopolitical Impact on Shot Blasting Machine Supply Chains

The Shot Blasting Machine Market is significantly influenced by geopolitical factors that affect global supply chains. Geopolitical tensions, trade wars, and changing government policies can disrupt the production and distribution of Shot Blasting Machines.

These disruptions can lead to increased costs, delayed shipments, and reduced availability of critical components. Companies in the Shot Blasting Machine industry must navigate these challenges to maintain a stable supply chain.

Global Trade Policies and Shot Blasting Machines

Global trade policies play a crucial role in the Shot Blasting Machine Market. Tariffs, quotas, and other trade barriers can impact the cost and availability of Shot Blasting Machines.

For instance, tariffs imposed on imported steel can increase the cost of producing Shot Blasting Machines, making them less competitive in the global market.

Impact of Tariffs on Shot Blasting Machines:

- Increased production costs

- Reduced competitiveness

- Potential for supply chain disruptions

Regional Trade Agreements and Their Impact

Regional trade agreements can also affect the Shot Blasting Machine industry. Agreements such as NAFTA or the EU’s single market can reduce trade barriers and facilitate the exchange of goods and services.

However, changes to these agreements or the withdrawal of countries from them can create uncertainty and disrupt supply chains.

| Region | Trade Agreement | Impact on Shot Blasting Machine Market |

| North America | USMCA | Reduced tariffs, increased trade |

| Europe | EU Single Market | Barrier-free trade, increased competition |

| Asia | RCEP | Lowered tariffs, expanded market access |

To mitigate the geopolitical impact on their supply chains, companies in the Shot Blasting Machine industry can:

- Diversify their supplier base

- Invest in risk management strategies

- Stay informed about geopolitical developments

Shot Blasting Machine Market Segmentation: Types and Applications

To understand the Shot Blasting Machine market better, we need to examine its segmentation by type and application. This breakdown is essential for grasping the different requirements of various industries that depend on Shot Blasting Machines.

Types of Shot Blasting Machines

Shot Blasting Machines can be categorized into several types based on their design and functionality. The main types include:

- Tumble Belt Shot Blasting Machines: These machines are designed for blasting small parts and are highly efficient for cleaning and surface preparation.

- Spinner Hanger Shot Blasting Machines: Ideal for larger components, these machines offer a high level of automation and are used for heavy-duty applications.

- Air Blast Shot Blasting Machines: Utilizing compressed air to propel abrasive media, these machines are versatile and used for a variety of applications, including cleaning and surface finishing.

Applications of Shot Blasting Machines

Shot Blasting Machines have a wide range of applications across various industries, including:

- Automotive: For cleaning and preparing vehicle parts for further processing.

- Aerospace: To ensure high-quality surface finishes on aircraft components.

- Construction: For cleaning and refurbishing equipment and structural components.

Key applications include surface preparation, cleaning, and deburring, highlighting the versatility of Shot Blasting Machines.

The Role of Applications in Expanding Shot Blasting Demand

The growing demand for Shot Blasting Machines is greatly influenced by their wide range of uses in different industries. Shot Blasting Machines are essential for surface preparation, cleaning, and finishing tasks, making them invaluable in many sectors.

Emerging Applications of Shot Blasting Machines

The versatility of Shot Blasting Machines has led to their adoption in emerging applications. New industries are discovering the benefits of shot blasting, including its ability to improve surface finish and prepare surfaces for coating.

Growing Demand in Various Industries

The demand for Shot Blasting Machines is growing in various industries, including:

- Aerospace, where surface preparation is critical

- Automotive, for parts cleaning and surface finishing

- Construction, for cleaning and preparing surfaces for coating

The growing demand is also driven by the need for efficient and cost-effective surface treatment solutions.

The diverse applications of Shot Blasting Machines are driving their demand across various industries. As new applications emerge, the industry is expected to grow further.

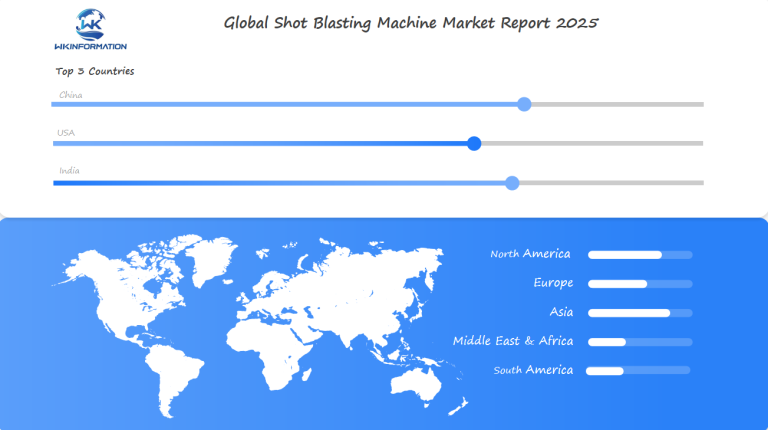

Regional Insights into the Global Shot Blasting Machine Market

Understanding regional market trends is essential for grasping the complexities of the global Shot Blasting Machine market. Different regions exhibit unique characteristics in terms of demand, supply, and technological adoption.

Regional Market Trends

The Shot Blasting Machine market is influenced by regional factors such as economic conditions, industrial growth, and regulatory environments. For instance, regions with significant manufacturing activities tend to have a higher demand for shot blasting machines.

Key regional trends include:

- Increased adoption of automated shot blasting machines in regions with high labor costs.

- Growing demand for shot blasting machines in emerging economies with expanding industrial sectors.

- Technological advancements in shot blasting technology, driven by regions with strong R&D capabilities.

Regional Shot Blasting Machine Market Trends

A closer look at country-specific data reveals varied market conditions. For example, countries with significant automotive and aerospace industries tend to have a higher demand for shot blasting machines due to their need for surface preparation and cleaning.

Some key countries to watch include:

- The United States, with its large aerospace and automotive sectors.

- Germany, known for its engineering and manufacturing prowess.

- China, a major manufacturing hub with a growing demand for shot blasting machines.

The regional insights into the global Shot Blasting Machine market highlight the importance of understanding local market dynamics. By analyzing regional trends and country-specific data, businesses can better navigate the complexities of this market.

The U.S. Shot Blasting Machine Market: Key Developments and Insights

Key developments in the U.S. shot blasting machine market are driven by technological advancements and changing industrial needs. The market is experiencing significant growth due to the increasing demand for efficient surface preparation and cleaning solutions across various industries.

Market Trends in the U.S.

The U.S. shot blasting machine market is witnessing a shift towards more advanced and automated systems. This trend is driven by the need for higher productivity and reduced labor costs. Some of the key trends include:

- Increased adoption of automated shot blasting machines

- Growing demand for environmentally friendly shot blasting solutions

- Rising use of shot blasting machines in the aerospace and automotive industries

These companies are driving market growth through their innovative products and solutions.

Germany’s Role in Shot Blasting Technology and Innovation

Germany is known for its engineering excellence and has a long history of innovation in various industries. When it comes to Shot Blasting technology, Germany is no exception. German companies have been leading the way in developing Shot Blasting Machines that are:

- More efficient

- Safer

- Environmentally friendly

These innovations in Shot Blasting Machines from Germany are not only benefiting the local industry but also transforming the global market.

German Innovations in Shot Blasting

German innovations have focused on improving the efficiency and reducing the environmental impact of Shot Blasting Machines. Companies like AGF Maschinen GmbH and Rösler Oberflächentechnik GmbH have developed machines that not only improve surface finishing but also reduce energy consumption and noise pollution.

As noted by industry experts, “German technology has set a new standard in the Shot Blasting industry.”

Impact of German Technology on the Global Market

The influence of German technology on the global Shot Blasting Machine market is multifaceted. Not only have German innovations raised the bar for quality and efficiency, but they have also driven competition, pushing manufacturers worldwide to adopt more advanced technologies.

| Feature | Traditional Shot Blasting Machines | German Shot Blasting Machines |

| Energy Efficiency | High Energy Consumption | Optimized for Low Energy Use |

| Noise Pollution | Significant Noise Levels | Designed for Reduced Noise |

| Surface Finish | Variable Quality | Consistently High Quality |

China’s Dominance in Shot Blasting Machine Manufacturing

With its strong manufacturing infrastructure, China has become the top producer of Shot Blasting Machines globally. This dominance is not just due to its large production capacity, but also because of China’s advanced manufacturing skills and its ability to innovate and adjust to evolving market needs.

Manufacturing Capabilities

China’s manufacturing capabilities in the Shot Blasting Machine sector are multifaceted. The country has invested heavily in technological advancements, enabling the production of high-quality Shot Blasting Machines that meet international standards. Furthermore, Chinese manufacturers have optimized production processes, reducing costs and enhancing efficiency.

China Shot Blasting Machine Manufacturing

The impact of China’s dominance in Shot Blasting Machine manufacturing on the global market is significant. It has led to a surge in global supply, which in turn has driven down prices and made Shot Blasting Machines more accessible to a wider range of industries. Moreover, the competitive pricing has pushed manufacturers from other regions to innovate and improve their offerings.

As a result, the global Shot Blasting Machine Market has become more competitive, with China at the helm. This competitiveness is expected to drive further innovations and improvements in the industry, ultimately benefiting end-users worldwide.

The dominance of China in Shot Blasting Machine manufacturing is a key trend that is expected to continue in the foreseeable future. As the global demand for surface preparation and cleaning solutions continues to evolve, China’s manufacturing capabilities are poised to play a pivotal role in shaping the industry’s future.

Future Growth and Innovations in Shot Blasting Machines

Emerging technologies are set to redefine the shot blasting machine landscape. As industries continue to evolve, the demand for more efficient, automated, and environmentally friendly shot blasting solutions is on the rise.

Emerging Technologies in Shot Blasting

The integration of automation and robotics in shot blasting machines is a significant trend. Automated systems can enhance precision, reduce labor costs, and improve safety. According to industry experts, “the future of shot blasting lies in its ability to adapt to Industry 4.0 standards.”

Another emerging technology is the use of advanced materials for shot blasting, such as ceramic shots or eco-friendly abrasives, which offer better durability and environmental benefits. These innovations not only improve the efficiency of the shot blasting process but also reduce the environmental footprint.

The market for shot blasting machines is expected to grow, driven by the increasing demand from the automotive and aerospace industries. Future market trends indicate a shift towards more sustainable and energy-efficient solutions.

Key trends include:

- Adoption of IoT technologies for real-time monitoring and predictive maintenance

- Development of shot blasting machines that can handle complex geometries and larger workpieces

- Increased adoption of automation

- Growing demand for eco-friendly abrasives

- Integration of IoT for smart manufacturing

As the industry moves forward, companies that invest in research and development and embrace emerging technologies are likely to lead the market.

Competitive Dynamics in the Shot Blasting Machine Market

The market is characterized by several key players who are constantly working to improve their products and services. This competition drives innovation and leads to better quality products.

Here are some of the major companies operating in the Shot Blasting Machine market:

- Viking Corporation – United States

- Graco Inc. – United States

- Wheelabrator Technologies Inc. – United States

- SINTOKOGIO LTD. – Japan

- Stem Inc. – United States

- Shandong Kaitai Shot-blasting Machinery Co. Ltd. – China

- General Engineering – Australia

- Pangborn – United States

- Qinggong Machine – China

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Shot Blasting Machine Market Report |

| Base Year | 2024 |

| Segment by Type |

· Tumble Belt Shot Blasting Machines · Spinner Hanger Shot Blasting Machines · Air Blast Shot Blasting Machines |

| Segment by Application |

· Automotive · Aerospace · Construction |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The Shot Blasting Machine market has been analyzed in-depth, covering its upstream and downstream industry chain, key trends, challenges, and regional insights. The industry overview highlights the significance of technological advancements, geopolitical factors, and market segmentation in shaping the market’s future.

The Shot Blasting Machine Market is expected to witness significant growth, driven by emerging applications and innovations in shot blasting technology. Regional insights from the U.S., Germany, and China demonstrate the global nature of the market, with each region contributing to its growth.

In conclusion, the Shot Blasting Machine Market is poised for continued expansion, driven by advancements in technology and increasing demand from various industries. As the market evolves, key players will need to adapt to changing trends and consumer needs to remain competitive.

Global Shot Blasting Machine Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Shot Blasting Machine Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Shot Blasting Machine Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Shot Blasting Machine Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Shot Blasting Machine Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Shot Blasting Machine Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Shot Blasting Machine Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Shot Blasting Machine Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is a Shot Blasting Machine?

A Shot Blasting Machine is a device used to clean, strengthen, or polish metal surfaces by propelling abrasive materials, such as steel shot or grit, at high velocities.

They serve purposes such as surface preparation, cleaning, and finishing.

How do Shot Blasting Machines work?

Shot Blasting Machines work by using a centrifugal wheel or pneumatic system to propel abrasive materials at high velocities, removing surface contaminants, rust, or scale from metal surfaces.

What are the benefits of using Shot Blasting Machines?

Using Shot Blasting Machines offers several advantages, including:

- Improved surface finish

- Increased surface area for coating adhesion

- Reduced surface roughness

- Enhanced fatigue life

Each type is designed for specific applications and production requirements.

How do I choose the right Shot Blasting Machine for my application?

To choose the right Shot Blasting Machine, consider factors such as:

- The type of material being blasted

- Production volume

- Surface finish requirements

- Available space and power supply

What are the key trends driving the Shot Blasting Machine industry?

Key trends driving the Shot Blasting Machine industry include:

- Technological advancements

- Automation and efficiency improvements

- Growing demand from emerging applications and industries

What is the role of automation in Shot Blasting Machines?

Automation in Shot Blasting Machines improves efficiency, reduces labor costs, and enhances consistency, allowing for increased productivity and better surface finish.

How do global trade policies affect the Shot Blasting Machine industry?

Global trade policies can impact the Shot Blasting Machine industry by influencing the availability and cost of raw materials, components, and finished machines, as well as affecting market demand and competition.

What are the emerging technologies in Shot Blasting?

Emerging technologies in Shot Blasting include advanced automation, robotics, and data analytics, which are expected to drive future growth and innovation in the industry.