$15.54 Billion Carbon Fiber Autoclave Market to Expand by 2025: Key Insights from Germany, Japan, and South Korea

The $15.54 Billion Carbon Fiber Autoclave Market is set to grow by 2025. Get key insights from Germany, Japan, and more.

- Last Updated:

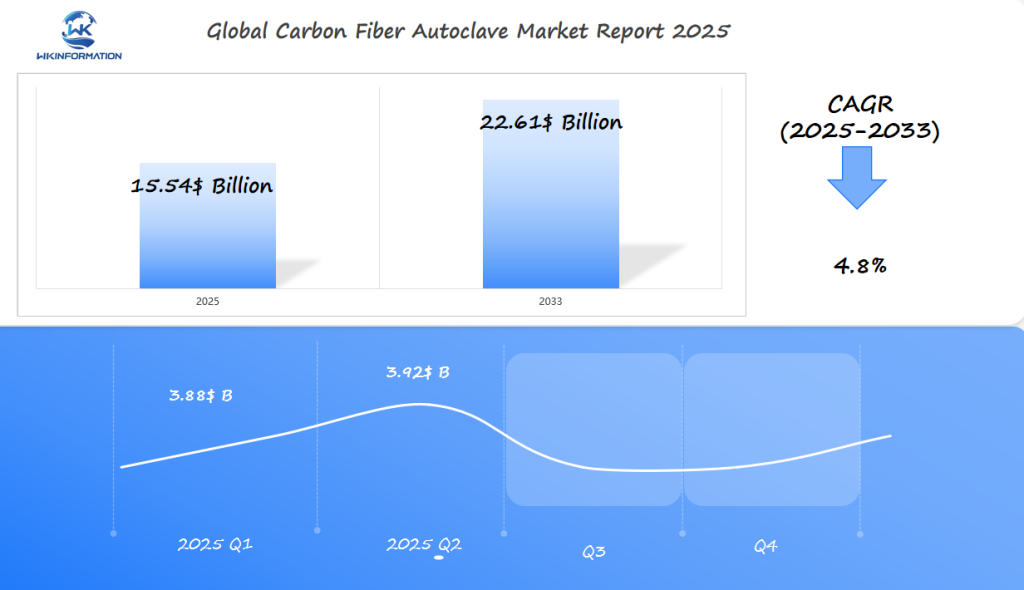

Carbon Fiber Autoclave Market Q1 and Q2 2025 Forecast

The Carbon Fiber Autoclave market is expected to reach $15.54 billion in 2025, with a CAGR of 4.8% from 2025 to 2033. In Q1 2025, the market is projected to generate approximately $3.88 billion, driven by advancements in aerospace, automotive, and industrial applications. Carbon fiber autoclaves, essential for the curing process of carbon fiber composites, are gaining traction in sectors like aviation, automotive manufacturing, and renewable energy. Key regions like Germany, Japan, and South Korea continue to invest heavily in high-performance manufacturing technologies, including carbon fiber components.

By Q2 2025, the market is expected to grow to $3.92 billion, driven by demand for lightweight, durable materials in the automotive and aerospace industries. Increasing regulatory pressures on emissions standards in the automotive industry are also accelerating the need for advanced composite materials in electric vehicles (EVs) and fuel-efficient aircraft. As the carbon fiber industry expands, carbon fiber autoclaves play an integral role in enhancing the quality and performance of high-end components.

Exploring the Upstream and Downstream Industry Chains for Carbon Fiber Autoclave

Upstream Industry Chain

Raw Material Supply

The operation of carbon fiber autoclaves relies heavily on advanced raw materials, particularly carbon fiber prepregs. These are pre-impregnated materials combining carbon fibers with resin systems such as epoxy, phenolic, or BMI resins. Key global suppliers include Toray, Hexcel, Mitsubishi Chemical, and Solvay. Additionally, autoclave construction requires high-strength steel or stainless steel to withstand extreme pressure, as well as insulation and sealing materials to maintain internal temperature and pressure stability during curing.

Equipment Manufacturing and Control Systems

Building a carbon fiber autoclave is a complex process involving the fabrication of large pressure vessels that must meet strict safety standards. This includes precision welding, quality testing (often to ASME or CE standards), and integration of sophisticated control systems. Autoclaves require programmable logic controllers (PLCs), temperature and pressure sensors, vacuum systems, and heating elements (either electric or gas-powered). Leading manufacturers in this field include ASC Process Systems, Italmatic, Scholz, and Bondtech.

Downstream Industry Chain

3. Composite Component Manufacturing

Once composite materials are cured in autoclaves, they are used to produce high-performance parts across several industries. These components are valued for their high strength-to-weight ratio, heat resistance, and structural integrity. Manufacturers use autoclaves to create fuselage sections, wing components, automotive body panels, sports equipment, wind turbine blades, and even medical devices. Precision and consistency during the curing process are critical, which is why autoclaves are essential in advanced composite production.

End-Use Industries

The primary consumers of autoclave-cured carbon fiber components include the aerospace, automotive, wind energy, sporting goods, and medical sectors. In aerospace, companies like Boeing, Airbus, Lockheed Martin, and Northrop Grumman rely heavily on autoclaved composites for aircraft and spacecraft parts. In the automotive industry, high-end manufacturers such as BMW and Lamborghini use them for lightweight, performance-enhancing designs. Wind energy companies, like Siemens Gamesa and Vestas, use them for blade reinforcement. Medical firms apply these materials in prosthetics and orthopedic devices.

Final Products and Market Value

The downstream output of the carbon fiber autoclave industry includes premium, lightweight, and durable components with complex geometries and precise specifications. These products contribute significantly to fuel efficiency, mechanical performance, and innovation in design. The use of autoclave technology remains crucial in sectors where material reliability under stress is non-negotiable, driving continued investment in both autoclave systems and advanced composite materials.

Key Trends Driving the Carbon Fiber Autoclave Market: Growth in Aerospace and Automotive Applications

Advances in aerospace applications carbon fiber autoclaves are changing industries. These autoclaves make high-performance composites for aircraft frames and engine parts. They reduce weight and increase durability.

In aerospace, companies like Boeing and Airbus use these tools. They build fuel-efficient jets like the 787 Dreamliner.

Automotive sectors also see a rise in demand. BMW and Tesla use carbon fiber autoclaves for EV batteries and body panels. This boosts performance and cuts emissions.

Key trends include:

- Lightweight materials for fuel efficiency

- Government regulations pushing emission cuts

- Rising demand for electric and hybrid vehicles

| Application Area | Trend | Impact |

| Aerospace | Autoclave-cured composites in wings and fuselages | 20% weight reduction in aircraft |

| Automotive | Autoclave-formed battery enclosures | 30% increase in EV range |

Automated manufacturing is speeding up adoption in both industries. New autoclave technology fits with the global move to sustainable, high-performance materials.

Challenges in Carbon Fiber Autoclave Production and High-Cost Manufacturing

Carbon fiber autoclave production is facing big problems due to high cost manufacturing challenges. The cost of raw materials, like carbon fiber and special resins, is very high. The energy needed for curing and the need for skilled workers also add to the expenses.

Key Challenges

- High-priced raw materials like aerospace-grade carbon fiber

- Complex curing cycles requiring precise temperature control

- Scarce technical expertise in composite material handling

New solutions are trying to solve these problems. Companies like Hexcel and Teijin Limited are working on recycling programs to reduce waste. Now, there are smaller, more affordable autoclave designs for smaller businesses. Also, partnerships between suppliers and manufacturers are making things easier and cheaper.

Despite these challenges, new ideas are helping. Companies are focusing on making autoclaves more energy-efficient and recycling composites. This way, they can make high-quality products without breaking the bank. Overcoming these challenges will help more industries use carbon fiber autoclaves.

Geopolitical Influence on the Carbon Fiber Autoclave Market

Global trade policies and international alliances shape the carbon fiber market in unexpected ways. For example, U.S.-China trade disputes have forced manufacturers like Boeing to rethink sourcing strategies for aerospace-grade materials. This shift highlights how geopolitical tensions directly impact production costs and supply chains.

Regional partnerships drive innovation too. The EU’s Clean Energy Initiative prioritizes carbon fiber for wind turbine production, creating opportunities for autoclave suppliers like Hexcel and Toray. Meanwhile, sanctions on Russian exports have accelerated alternative material research in NATO member countries.

| Region | Geopolitical Factor | Market Impact |

| North America | U.S.-Mexico-Canada Agreement (USMCA) | Streamlined component imports for automotive autoclaves |

| Asia-Pacific | U.S.-Japan technology pacts | Boosted R&D collaboration for aerospace composites |

| Europe | EU carbon neutrality goals | Increased demand for lightweight automotive parts |

Trade agreements like the Indo-Pacific Economic Framework (IPEF) are also fostering cross-border manufacturing hubs. These dynamics show that geopolitical decisions don’t just affect politics—they redefine who leads the carbon fiber market in the next decade.

Types of Carbon Fiber Autoclaves: Small, Medium, and Large-Scale Industrial Units

Autoclaves are key in manufacturing, coming in small, medium, and large sizes. Each type fits different needs, from making prototypes to producing lots of items.

- Small Autoclaves: Great for labs and new companies that need to test or make small amounts.

- Medium Autoclaves: A good middle ground, perfect for businesses growing and making more products.

- Large-Scale Industrial Units: Built for making lots of items, like airplane wings or turbine blades.

Big industrial autoclaves use special heating to cure big materials evenly. They’re found in places like Boeing or Airbus, where making things fast and right is crucial. It’s important for companies to pick the right size autoclave for their work. This ensures they’re efficient without spending too much.

Applications of Carbon Fiber Autoclaves in Aerospace, Automotive, and High-Performance Manufacturing

Automotive carbon fiber autoclaves are changing the game in many fields. They make parts that are both light and strong. In aerospace, they help make wings and body parts that use less fuel.

For cars, they create frames and engine parts that improve performance and reduce emissions. This is a big win for the environment.

Aerospace

Forms complex aircraft structures under high pressure and heat.

Automotive

Produces automotive carbon fiber autoclaves for luxury and electric vehicles.

High-Performance

Crafts racing car chassis and sports equipment like bicycles.

| Industry | Applications | Benefits |

| Aerospace | Wing spars, turbine blades | Strength-to-weight ratio improvement |

| Automotive | Body panels, drive shafts | Enhanced fuel efficiency |

| High-Performance | Racing car parts, skis | Customized material bonding |

Big names like Boeing and Tesla rely on autoclaves to meet high standards. For example, using these machines can reduce a car’s weight by up to 50%. This is a big step towards making vehicles more eco-friendly.

These machines help cure carbon fiber parts with great precision. This is crucial for parts that face a lot of stress. From Formula One cars to commercial jets, their impact is felt worldwide.

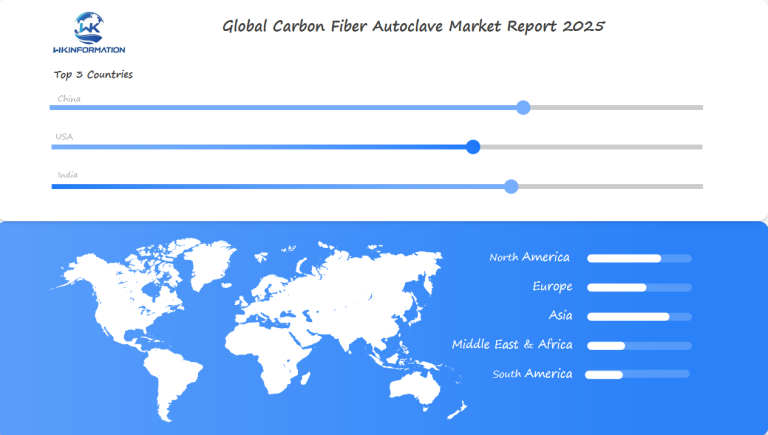

Global Insights into the Carbon Fiber Autoclave Market

The global carbon fiber market is changing fast. It’s influenced by demand in different parts of the world and new ideas. Asia-Pacific is leading, thanks to cars and planes. Europe and North America are close behind, focusing on saving energy and using technology.

There’s a steady increase in the market, with a 6.2% growth rate expected by 2030. Here’s how different areas are doing:

- Asia-Pacific: 45% market share (2023)

- Europe: 28% share, focusing on lightweighting in aviation

- North America: 22% growth from wind energy and EV adoption

| Region | Market Size (2023) | Growth Drivers |

| Asia-Pacific | $7.2B | Automotive composites |

| Europe | $4.1B | Aerospace partnerships |

| North America | $3.6B | Renewable energy demand |

Big names like Toray Industries and Hexcel Corp. are working hard to make things cheaper. They’re also focusing on being green and using technology. These efforts will shape the market in the future.

Germany’s Role in Carbon Fiber Autoclave Production for European Aviation and Automotive Sectors

Germany is a key player in European manufacturing, especially in carbon fiber autoclave production. Companies like Saueressig and LPF Composites create advanced systems. These systems make lightweight, strong parts for Airbus wings and BMW sports cars.

German engineers focus on making things better and more efficient. They design autoclaves that use 30% less energy but still meet high quality standards. This helps Germany meet EU emissions goals.

Car and plane makers count on these machines. They make vehicles lighter, which saves fuel and keeps them safe.

German companies team up with European manufacturers to grow the industry. Innovations from German labs help supply chains. For example, Hennecke’s resin infusion tech works with autoclaves for luxury cars. This teamwork keeps Germany at the forefront of making advanced materials.

Japan’s Leadership in Carbon Fiber Autoclave Innovation for High-Precision Manufacturing

Japan is leading the way in carbon fiber technology, with companies like Toray Industries, Mitsubishi Chemical, and Teijin at the forefront. These industry leaders are setting new standards with their groundbreaking innovations.

Meeting the Demands of Aerospace and Automotive Industries

These companies specialize in precision engineering, catering to the stringent requirements of the aerospace and automotive sectors. Their expertise results in the creation of lightweight yet robust composites that deliver exceptional performance.

Key Innovations in Carbon Fiber Autoclave Technology

Here are some key innovations in carbon fiber autoclave technology that these companies have introduced:

- High-temperature stability: This feature ensures consistent material bonding even in extreme conditions, making it ideal for applications where temperature fluctuations are common.

- Automated quality checks: By implementing automated systems for quality inspection, these companies can significantly reduce defects in complex part production processes. This not only improves efficiency but also enhances overall product quality.

- Energy-efficient systems: The introduction of energy-efficient solutions in autoclave operations helps lower operational costs while maintaining precise manufacturing standards.

| Company | Innovation | Key Application |

| Toray Industries | Nano-scale fiber alignment tech | Aircraft wings and fuselage |

| Mitsubishi Chemical | Real-time pressure monitoring systems | Automotive racing components |

| Teijin | AI-driven temperature calibration | Satellite and medical device parts |

Japan’s expertise in carbon fiber technology ensures the production of top-notch products. This skill set positions Japan as a key player in advanced industries worldwide.

South Korea’s Expansion in Carbon Fiber Autoclaves for Advanced Composites and Electronics

South Korea is leading the way in advanced composites autoclave technology. Companies like Samsung and Hyundai are using these systems to make lightweight, durable materials for electronics and electric vehicles.

Applications of Advanced Composites in South Korea

- Electronics: Thinner smartphone components

- Automotive: Battery enclosures for EVs

- Aerospace: Collaborations with Boeing and Airbus

Key Players in South Korea’s Advanced Composites Industry

| Company | Focus Area |

| LG Chem | Autoclave-cured battery materials |

| Doosan Heavy Industries | Large-scale autoclave systems |

South Korea aims to make autoclave processes more energy-efficient. The government gives grants to startups like Hanwha and Kolon Industries, who work on eco-friendly manufacturing, matching global trends towards sustainable tech.

The Future of Carbon Fiber Autoclaves: Automation and Energy-Efficient Processing

Automation is changing how we make carbon fiber composites. Smart systems use AI to watch over curing cycles, making sure everything is just right while using less energy. Companies like MTorres and Hexcel use robots for handling materials, cutting down on mistakes by up to 35%. This makes production quicker and more consistent.

Energy Savings in Autoclave Design

Energy savings are a big deal. New autoclave designs can reuse 80% of waste heat, saving it for preheating. Boeing, for example, works with equipment makers to install these systems, cutting energy costs by 25%. These changes help meet global sustainability goals and increase profits.

Benefits of Automation and Energy Efficiency

- Automated systems reduce downtime via predictive maintenance alerts.

- Energy-efficient models cut emissions by optimizing heat retention.

Future Trends in Autoclave Technology

By 2025, more than half of new autoclaves might have IoT sensors for tracking data in real-time. Startups like A&D Technologies are testing solar-powered autoclaves, combining green energy with automation. These steps help move manufacturing towards net-zero goals without losing quality.

Automation in autoclave processing is more than just making things faster. It’s about creating a sustainable future. As technology gets better, industries from aerospace to wind energy will get parts that are lighter, stronger, and made in a smarter, cleaner way.

The advancements in autoclave technology aren’t limited to carbon fiber production alone. For instance, the autoclave tank in laminated glass production also showcases the versatility and efficiency of modern autoclaves across different industries.

Competitive Landscape in the Carbon Fiber Autoclave Market

The competitive carbon fiber market analysis shows a fast-changing industry. Top players like Toray Industries, Hexcel, and SGL Carbon lead the way. They work together to improve global supply chains. New companies are coming in, using smart autoclave tech to compete.

Key Players

Here are some of the key players in the carbon fiber autoclave market:

- ASC Process Systems – United States

- Boeing – United States

- GKN Aerospace – United Kingdom

- Northrop Grumman – United States

- Lockheed Martin – United States

- ATK (Northrop Grumman Innovation Systems) – United States

- Vought Aircraft Industries – United States

- Hexcel Corporation – United States

- Spirit AeroSystems – United States

- Cytec Solvay Group – Belgium

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Carbon Fiber Autoclave Market Report |

| Base Year | 2024 |

| Segment by Type |

· Small · Medium · Large-Scale Industrial Units |

| Segment by Application |

· Aerospace · Automotive · High-Performance Manufacturing |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Carbon fiber autoclaves have revolutionized manufacturing across aerospace, automotive, and high-performance sectors. Their ability to produce lightweight yet durable components has made them indispensable in modern manufacturing. In aerospace, these systems enable the production of fuel-efficient aircraft components. For automotive applications, they facilitate the creation of high-strength, lightweight vehicles that meet increasing demands for performance and sustainability. In high-performance manufacturing, these autoclaves continue to push the boundaries of what’s possible in materials processing.

As technology advances and environmental concerns grow, carbon fiber autoclaves will remain crucial in shaping the future of industrial manufacturing, offering solutions that combine strength, efficiency, and sustainability.

Global Carbon Fiber Autoclave Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Carbon Fiber Autoclave Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Carbon Fiber Autoclave Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Carbon Fiber Autoclave Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Carbon Fiber Autoclave Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Carbon Fiber Autoclave Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Carbon Fiber Autoclave Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Carbon Fiber Autoclave Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the carbon fiber autoclave market size expected to reach by 2025?

The carbon fiber autoclave market is expected to grow to $15.54 billion by 2025. This growth is driven by demand in aerospace and automotive sectors.

What are the main drivers of growth in the carbon fiber autoclave market?

Growth is driven by technological innovations and the need for lightweight materials. The aerospace and automotive industries are key drivers.

What challenges does the carbon fiber autoclave production face?

Production faces challenges like high costs and expensive raw materials. Complex methods also pose challenges for companies.

How do geopolitical factors impact the carbon fiber autoclave market?

Geopolitical factors such as trade policies and international collaborations play a significant role in shaping the carbon fiber autoclave market. These factors can either create opportunities for growth or act as barriers to expansion.

What types of carbon fiber autoclaves are available in the market?

The market offers small, medium, and large-scale autoclaves. Each type meets different production needs, offering flexibility.

In which sectors are carbon fiber autoclaves most commonly used?

They are used in:

- Aerospace

- Automotive

- High-performance manufacturing

They help produce lightweight, durable materials.

How does Germany contribute to the carbon fiber autoclave market?

Germany plays a significant role in Europe’s aviation and automotive industries. It is renowned for its exceptional engineering skills and top-notch manufacturing capabilities.

What advancements is Japan making in carbon fiber autoclave technology?

Japan is at the forefront of innovation, with a strong emphasis on precision manufacturing. This approach guarantees top-notch quality standards for industries with strict requirements.

What is South Korea’s role in the carbon fiber autoclave market?

South Korea is expanding its influence, especially in advanced composites and electronics. It invests heavily in new technologies.

What future trends should we expect in carbon fiber autoclave processing?

Future trends will include automation and energy-efficient processing. These aim to reduce costs and enhance sustainability.

Who are the major players in the carbon fiber autoclave market?

The market includes established leaders and emerging players, as depicted in this image. They use strategies like mergers and innovations to stay competitive.