2025 Carton Erector Machine Market Expanding with $1.99 Billion Demand in United States, China, and Germany

US, China and Germany witness Carton Erector Machine Market expansion amid shifting domestic production policies.

- Last Updated:

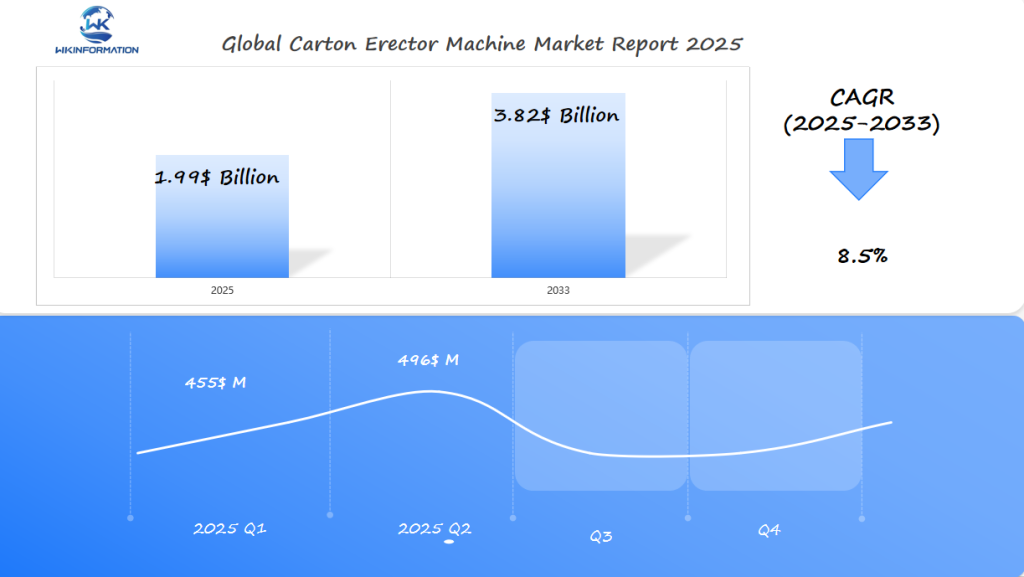

Market Forecast for Carton Erector Machine in Q1 and Q2 of 2025

The Carton Erector Machine market was valued at USD 1.99 billion in 2025, growing at a CAGR of 8.5% from 2025 to 2033. Based on this projection, the estimated market size for Q1 2025 is approximately USD 455 million, increasing to around USD 496 million in Q2 2025. Growth is being driven by the booming e-commerce industry, the demand for automation in packaging, and sustainability trends that encourage efficient material usage.

The United States, China, and Germany are key markets for carton erecting machinery. In the US, the surge in online retail and warehouse automation is fueling investments in high-speed packaging solutions. China, as a global manufacturing powerhouse, is adopting more automated systems to improve efficiency and reduce labor costs. Germany, with its strong emphasis on engineering excellence, continues to develop advanced and energy-efficient carton erecting technologies. Companies in this sector should focus on machine customization, eco-friendly packaging solutions, and integration with Industry 4.0 technologies to gain a competitive edge.

Carton Erector Machine Market Upstream and Downstream Industry Chain Analysis

To understand the carton erector machine world, we must follow the path of materials. This path goes from raw suppliers to the end-users. It shows the packaging machinery supply chain, from making parts to setting up machines in factories.

Raw Material Suppliers and Component Manufacturers

At the start, we have steel suppliers and electronics companies. ArcelorMittal gives steel for the machine frames. Meanwhile, makers of carton erector components like sensors and actuators are crucial. Big names like Bizerba and Krones depend on these partnerships to create strong systems.

- Steel: Structural frames and mechanical parts

- Electronics: Motion controllers and sensor arrays

- Plastics: Wear-resistant conveyor rollers and guides

Distribution Channels and End-User Industries

Machines get to customers through distributors or direct sales. Below is a table showing how end-user packaging applications drive demand:

| Industry | Key Applications | Top Distributors |

|---|---|---|

| Food & Beverage | Aseptic packaging for dairy products | Ball Corporation, Tetra Laval |

| E-commerce | Automated order fulfillment systems | FlexLink, Dematic |

Value Chain Integration Opportunities

Industrial automation suppliers like Siemens and Omron are connecting machines to smart factories. Working together, packaging equipment manufacturers and software providers create tools for predictive maintenance. This reduces downtime and makes systems more resilient against supply chain problems.

Latest Trends Shaping the Carton Erector Machine Market in 2025

The carton erector industry is changing fast. Smart packaging equipment and modular carton erection systems are key. Let’s explore the top trends.

Integration of IoT and Smart Technologies

IoT in carton erectors is changing how machines work. These systems use sensors and data to track performance and predict needs. This leads to:

- Real-time production analytics to cut downtime

- Remote diagnostics for faster issue resolution

- Integration with packaging automation trends 2025 for smarter workflows

Sustainability and Eco-Friendly Design Innovations

Now, manufacturers focus on sustainable packaging machinery to lessen environmental impact. Here’s how they’re improving:

| Traditional Machines | Sustainable Packaging Machinery |

|---|---|

| High energy use | Energy-efficient motors and solar options |

| Single-purpose designs | Reusable materials and waste reduction tech |

Customization and Modular Machine Configurations

Flexible modular carton erection systems allow companies to quickly meet new product demands. These systems:

- Enable easy reconfiguration for different carton sizes

- Reduce downtime during production changes

- Lower long-term costs via scalability

Innovation is making packaging faster, greener, and more adaptable than ever.

Market Restrictions and Challenges in the Carton Erector Machine Industry

Technology advances bring new chances, but also challenges. Companies face high costs, technical issues, and strict rules. These obstacles affect their choice to adopt new systems.

Cost Barriers and ROI Considerations

High initial costs act as carton erector investment barriers. Small businesses often wait to buy due to the high costs. They look at the packaging equipment ROI to see if it’s worth it. Many choose leasing to lower the upfront cost.

- Leasing options spread payments over time

- Retrofitting existing lines to extend lifespan

Technical Limitations and Integration Issues

Integrating with old systems is risky. Packaging automation challenges include setup downtime and compatibility issues. Industrial machinery integration needs careful planning to avoid workflow problems.

- Modular designs allow gradual upgrades

- Supplier support for system audits

Regulatory Compliance and Standards

Global manufacturing compliance issues require strict safety and quality standards. Different rules in each region make international work hard. Regular checks ensure companies follow OSHA and ISO rules.

- Third-party audits for certification

- Training programs for staff

Geopolitical Factors Impacting the Carton Erector Machine Market

Global trade tensions are changing how companies buy and make carton erector machines. International packaging equipment trade is facing challenges as tariffs and reshoring plans change the game.

Trade Policies and Tariff Implications

Tariffs on packaging machinery between big players like the U.S. and China have raised costs by up to 25%. This makes it harder for manufacturers to afford imports.

| Country Pair | Current Tariff Rate | Key Products Affected |

|---|---|---|

| US-China | 25% | Carton erector components |

| EU-India | 10-15% | Automation systems |

Regional Manufacturing Shifts and Reshoring Trends

Manufacturing reshoring impact is clear as companies like Sidel and Bosch move production closer to where it’s used. North America saw a 14% jump in local regional manufacturing trends in 2023.

- US: 30% of manufacturers plan to reshore by 2025

- Europe: 22% increase in local facility capacity

Global Supply Chain Resilience Strategies

Companies are turning to multi-sourcing to deal with global supply chain disruptions. They’re using:

- Localized supplier networks

- Inventory buffer stockpiling

These moves show how global politics are changing the carton erector market’s path forward.

Market Segmentation of Carton Erector Machines by Type and Automation Level

Semi-Automatic vs. Fully Automatic Systems

| Feature | Semi-Automatic | Automatic |

|---|---|---|

| Automation Level | Operator loads cartons | Full automation |

| Cost | Lower upfront cost | Higher investment |

| Speed | 10–20/min | 30+ per minute |

Semi-automatic packaging equipment is great for smaller operations. On the other hand, automatic carton erectors are perfect for high-volume settings.

Applications of Carton Erector Machines in Packaging and Manufacturing Sectors

Carton erectors make packaging processes more efficient. They solve problems in food, online retail, and healthcare. This leads to faster workflows and lower costs.

Food and Beverage Industry Applications

Food packaging automation changes how food is made. High-speed carton erecting systems handle perishable items quickly and cleanly. They keep environments sterile, lowering the chance of contamination.

For instance, yogurt makers use these machines to pack thousands of containers every day. They meet FDA standards while doing so.

E-commerce and Retail Packaging Solutions

E-commerce needs flexible packaging solutions. Retail packaging machinery can handle different box sizes, especially during busy times. Key benefits include:

- Reduced labor time by 40% through automated box forming

- Integration with warehouse management software for real-time tracking

- Custom box sizes for fragile or oddly shaped items

Pharmaceutical and Medical Device Packaging

Pharmaceutical packaging systems focus on precision and safety. They handle small batches of medications, applying tamper-evident seals and child-resistant closures. Medical device makers use them for sterile packaging of surgical kits, meeting ISO 15378 standards.

Carton erectors play a big role in making operations smoother. They are crucial in the food, retail, and medical fields, helping in the quest for efficiency.

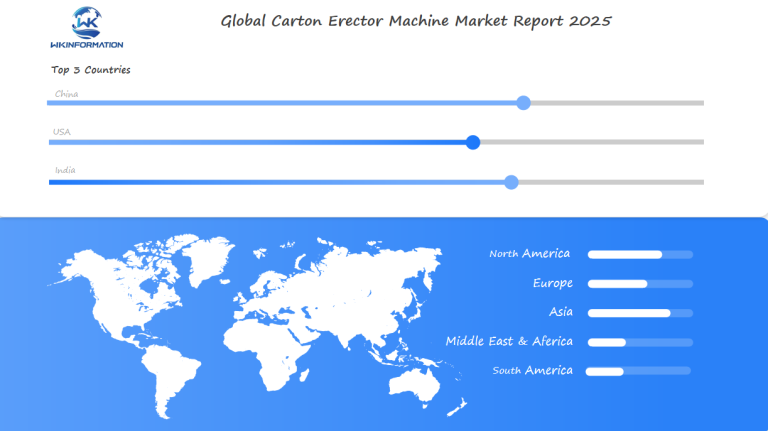

Global Carton Erector Machine Market Regional Demand and Forecast Analysis

The global packaging equipment market changes a lot from one region to another. Each area has its own needs and economic goals. This part looks at how demand changes in three main areas: North America, Europe, and Asia-Pacific.

North American Market Dynamics

In North America, the need for packaging machines is growing fast. This is because of a shortage of workers and more online shopping. The U.S. is leading with a $1.99 billion market share, thanks to fast automation in food and retail.

Companies are buying new machines to keep up with more online orders. They want machines that can work fast and efficiently.

European Market Growth Factors

In Europe, the need for carton erectors is going up because of green laws. Makers focus on machines that save energy and use recyclable stuff. German tech standards are high, which affects other countries too.

Automation in Europe matches EU green goals. This leads to new tech for saving energy and cutting down waste.

Asia-Pacific Expansion Opportunities

Asia-Pacific is seeing a big jump in packaging investment. Countries like China and India are growing their factories fast. This creates a big need for affordable carton erector machines.

More online shopping and food and consumer goods sales are driving this growth. Local companies are teaming up with big brands to meet these needs.

USA Carton Erector Machine Market Growth and Competitive Landscape

The US packaging automation market is a hub of innovation. It’s driven by the increasing United States packaging equipment demand. Companies across various sectors are adopting smart systems to improve efficiency. This section explores the trends shaping this sector.

Key Market Drivers in the United States

Labor costs and e-commerce growth are pushing businesses to adopt domestic packaging machinery production. The US industrial automation growth makes smart systems like IoT-linked machines crucial. Food safety regulations also boost demand for precise packaging solutions.

Leading American Carton Erector Manufacturers

Companies like Intech Packaging and Klik-N-Lok lead in modular systems. These American carton erector manufacturers create machines with AI sensors and eco-friendly materials. They focus on customization to meet different industry standards.

Investment and Expansion Opportunities

Investors should look into e-commerce logistics and medical packaging. The domestic packaging machinery production sector has room for startups focused on affordability. Partnerships with tech firms could speed up the adoption of US packaging automation market solutions.

China Carton Erector Machine Market Expansion and Industry Performance

The Chinese packaging equipment industry is leading the way globally. It’s growing thanks to manufacturing expansion in China. The demand for China carton erector production is strong, driven by a booming manufacturing sector and the need for automation.

China’s Manufacturing Ecosystem and Domestic Demand

Local factories use China carton erector production to improve packaging. Cities like Guangzhou and Shenzhen are hubs for suppliers. They use advanced systems for food, e-commerce, and pharmaceuticals.

The use of Chinese automation technology in factories is on the rise. It reduces labor costs and increases production.

Chinese Equipment Manufacturers and Export Strategies

- Export hubs focus on Asian packaging machinery exports, targeting Southeast Asia and Africa.

- Brands like Shanghai Packaging Machinery Co. and Guangdong Automation refine pricing strategies to compete globally.

- Exports now account for 35% of total production volumes, per trade data.

Technology Transfer and Innovation Trends

Firms invest in AI-driven systems for reverse-engineering and R&D. Partnerships with German firms transfer automation expertise, improving quality. Local patents in robotics and sensor tech are now on par with international rivals.

Market data shows a 5.5% CAGR for the Chinese packaging equipment industry through 2032. The focus is on sustainable designs and IoT-linked machines for future exports.

Germany Carton Erector Machine Market Trends and Investment Potential

Germany is a leader in carton erector technology thanks to its focus on precision and innovation. The country’s German packaging engineering skills are key to global supply chains. Industrie 4.0 packaging solutions are making automation more common. Here’s why Germany is at the forefront:

German Engineering Excellence and Innovation Leadership

- Companies like Krones and Bizerba create high-precision packaging equipment with incredible accuracy.

- The use of European carton erector technology cuts downtime by 30% in food and e-commerce packaging.

- Investments in AI for quality control meet Industrie 4.0 standards.

Market Positioning of German Equipment Manufacturers

German brands focus on high-quality products, even if they cost more. They aim for durability. Key points include:

| Metric | 2025 Forecast |

|---|---|

| Global Market Share | 28% |

| Annual Export Growth | 5.2% |

| Automated Systems Adoption | 70% |

Export Performance and Global Market Share

German machinery exports hit $1.2B in 2024, thanks to European carton erector technology. Key markets are:

- North America (35% of exports)

- Asia-Pacific (28% growth in 2023-2025)

Exports grow from partnerships with U.S. food and e-commerce leaders. They need high-precision packaging equipment.

Future Innovations and Smart Automation in Carton Erector Machines

Smart technologies are changing how carton erectors work. They include self-learning systems and adaptive robotics. These changes aim to save money and increase productivity. Here’s how these innovations are changing the industry:

Artificial Intelligence and Machine Learning Applications

AI in packaging automation lets carton erectors learn from data. They can adjust speeds, find material flaws, and cut down on waste. For instance, machine learning tweaks settings based on sensor data in real time.

- Automated calibration for mixed-product lines

- Defect detection reducing rejects by up to 40%

Robotics Integration and Collaborative Systems

Factories are using collaborative packaging robots that work with humans. These robots handle delicate items. Meanwhile, robotic carton erectors handle large volumes:

| Type | Features | Use Cases |

|---|---|---|

| Collaborative Packaging Robots | Force-sensing grippers, intuitive programming | Small-batch customization |

| Autonomous Systems | Full-speed operation, zero human input | 24/7 beverage bottling lines |

Predictive Maintenance and Self-Optimizing Equipment

Industry 4.0 packaging equipment tracks data to predict when parts need to be replaced. This reduces unplanned stoppages by up to 50%. It also makes machines last longer.

Early users have seen 25% faster setup times and 15% less energy use. These trends suggest a future where carton erectors are smarter, safer, and more eco-friendly than ever.

Competitive Landscape and Key Players in the Carton Erector Machine Market

The carton erector machine market is all about innovation and competition. Leading brands are racing to meet growing demand. This section looks at key players driving growth and shaping the future.

-

Bosch Packaging Technology – Germany

-

Smurfit Kappa – Ireland

-

Fischbein – United States

-

KHS GmbH – Germany

-

A-B-C Packaging Machine Corporation – United States

-

Wexxar Packaging – Canada

-

Duravant – United States

-

Star Packaging – United States

-

FANUC Corporation – Japan

-

ProMach, Inc. – United States

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Carton Erector Machine Market Report |

| Base Year | 2024 |

| Segment by Type |

· Automatic · Semi-Automatic |

| Segment by Application |

· Food and Beverage Industry Applications · E-commerce and Retail Packaging Solutions · Pharmaceutical and Medical Device Packaging |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The global Carton Erector Machine market is on an upward trajectory, with analysts predicting steady growth. This expansion is expected to be substantial between 2025 and 2033. The rise in demand for automated packaging and a growing focus on sustainability are driving innovation and investment.

Geographically, the market is set to experience significant growth in the United States, China, and Germany. These regions benefit from favorable domestic production policies and advanced engineering capabilities. Companies and investors should keep a close eye on these markets, as they offer promising opportunities.

The future of the Carton Erector Machine market looks promising, with technological advancements and environmental considerations playing key roles. Consumer preferences are also evolving, contributing to the market’s growth. As the industry evolves, adaptability and a deep understanding of market dynamics will be crucial for businesses aiming to succeed.

Global Carton Erector Machine Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Carton Erector Machine Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Vacuum Arc RemeltingMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Carton Erector Machineplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Carton Erector Machine Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Carton Erector Machine Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Carton Erector Machine Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofCarton Erector Machine Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is a carton erector machine?

A carton erector machine turns flat cardboard into boxes automatically. It’s key in making packaging faster and more efficient. This is important for food, e-commerce, and pharmaceuticals.

How does a carton erector machine improve efficiency?

These machines make box-making faster and cheaper. They save time and money by doing the work for you. This helps companies grow and meet demand.

What are the different types of carton erector machines available?

There are semi-automatic and fully automatic machines. Semi-automatic ones need some help, while fully automatic ones work alone. They fit different needs and speeds.

What industries benefit the most from carton erector machines?

Many industries like food, pharmaceuticals, e-commerce, and consumer goods gain a lot. These machines make packaging better by being fast, consistent, and meeting standards.

How do I choose the right carton erector machine for my business?

Think about how much you produce, the box sizes, and how much automation you need. It’s important to match your needs with the right machine. Talking to providers can help.

What are the current trends in the carton erector machine market?

Now, there’s a focus on IoT, being green, and making machines flexible. These changes help companies meet new needs and work better.

Are there any regulatory compliance standards for carton erector machines?

Yes, machines must follow safety and operation rules. Knowing these rules is key to making sure your equipment is safe and meets quality standards.

What is the expected growth for the carton erector machine market in the coming years?

The market is growing fast, with big demand in the U.S. and China by 2025. This growth comes from more automation, e-commerce, and green efforts.

How can I ensure the longevity of my carton erector machine?

Keep it maintained, train your team, and use smart maintenance tools. This way, your machine will last longer and work better.

What roles do geopolitical factors play in the carton erector machine market?

Global politics can really affect the market