2025 Elastomer Test Socket Market Dynamics: USA, Japan, and Germany Leading Innovation Worth $1.5 Billion

Explore the growth trends in the Elastomer Test Socket Market, driven by semiconductor advancements and rising consumer electronics demand.

- Last Updated:

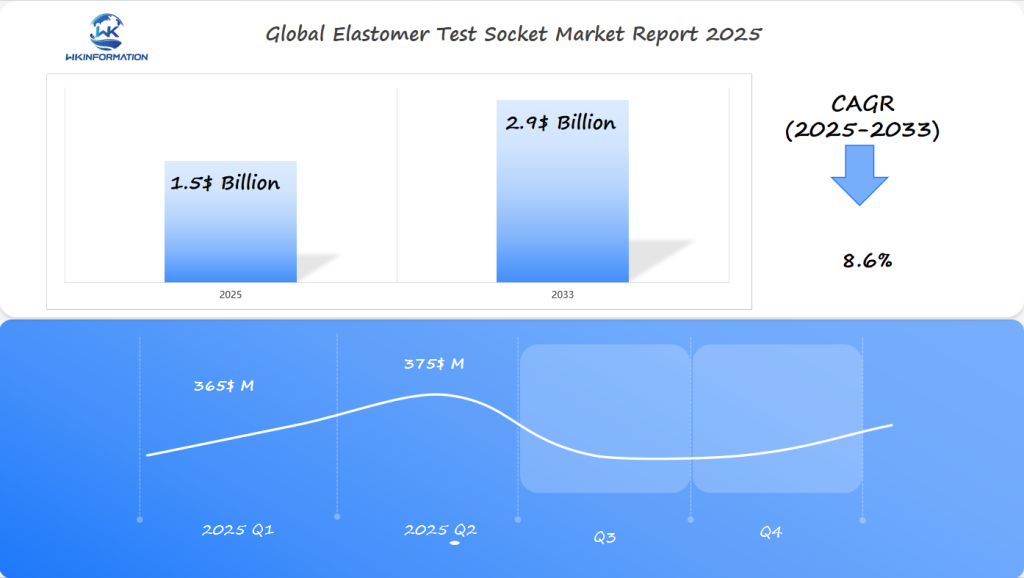

Market Forecast for Elastomer Test Socket in 2025: Q1 and Q2 Predictions

The Elastomer Test Socket market is projected to reach a total size of $1.5 billion in 2025, with a compound annual growth rate (CAGR) of 8.6% from 2025 to 2033. Q1 is expected to generate approximately $365 million, with Q2 showing a slight increase to around $375 million. The growth is largely driven by the increasing demand for reliable and efficient testing solutions in the semiconductor and electronics industries. The USA, Japan, and Germany are anticipated to be the leading countries in the market, owing to their advanced technological infrastructure and dominance in semiconductor manufacturing.

As the global electronics industry grows, especially with the rise of IoT, 5G, and automotive applications, the need for precise testing solutions to ensure product reliability is expected to grow significantly. Additionally, advancements in elastomeric materials and testing technologies are expected to contribute to market growth, offering faster, more cost-effective, and high-precision testing methods in 2025.

Key Takeaways

- Projected market value of $1.5 billion in 2025

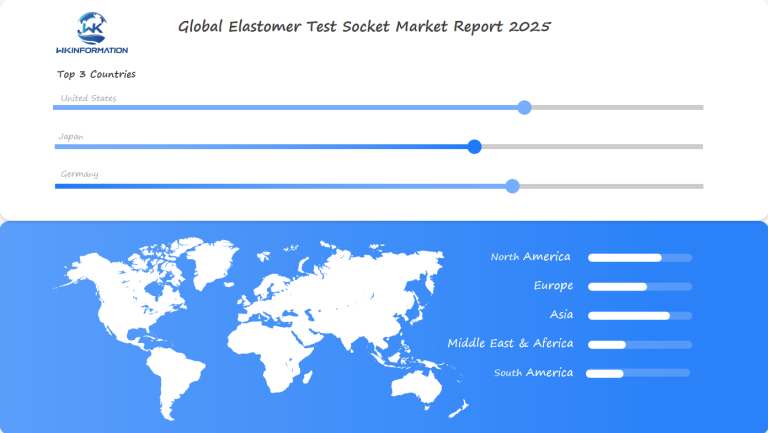

- USA, Japan, and Germany lead technological innovations

- Increasing global demand across multiple industries

- Advanced testing solutions driving market growth

- Semiconductor and automotive sectors show significant potential

Analyzing the Upstream and Downstream Dynamics in the Elastomer Test Socket Market

The elastomer test socket market is shaped by complex upstream and downstream dynamics. These interactions are key to understanding market performance and innovation.

Upstream dynamics affect the quality and price of elastomer test sockets. Suppliers of raw materials play a big role. They provide essential components that impact socket performance.

Key Upstream Considerations

- Material quality selection

- Elastomer compound innovations

- Supply chain resilience

- Manufacturing precision

Downstream dynamics focus on the demand from end-user industries. Sectors like semiconductor manufacturing, automotive electronics, and telecommunications need high-performance testing solutions.

Strategic Downstream Insights

- Semiconductor industry requirements

- Electronic device testing protocols

- Performance reliability standards

- Technological adaptation capabilities

The connection between suppliers and consumers is crucial. It creates a dynamic ecosystem. Here, innovation and market demands shape elastomer test socket technologies.

Successful market navigation requires understanding the intricate balance between material innovation and technological application.

Collaboration between material scientists, manufacturers, and end-users will drive future developments. This is key to the elastomer test socket market’s growth.

Current and Future Trends Driving the Elastomer Test Socket Market in 2025

The elastomer test socket market is changing fast. New technologies in many electronic fields are leading the way. These changes are making how we test and make devices more precise.

Important factors are pushing innovation in test socket technology. The growth of semiconductors and electronics is huge. This is thanks to several key advancements:

- Miniaturization of electronic devices demanding more compact test solutions

- Expansion of 5G network infrastructure creating new testing requirements

- Increasing complexity of integrated circuits requiring advanced testing methodologies

Digital Transformation Accelerating Market Growth

New technologies are changing the test socket world. The need for high-performance computing is driving better testing tools. These tools can handle complex electronic parts.

The rise of IoT devices is opening up big chances for test socket makers. Precision and reliability are key for the next big testing tech.

Emerging Market Opportunities

There’s a lot of potential in areas like car electronics, telecom, and gadgets. Companies are spending a lot on R&D. They want to make test sockets that can keep up with changing needs.

The future of elastomer test sockets lies in their ability to adapt to rapidly changing technological ecosystems.

Key Barriers and Challenges Facing the Elastomer Test Socket Industry

The elastomer test socket industry faces big challenges. These include technological limits and market barriers. These issues make it hard to grow and innovate.

Technological Constraints in Component Testing

Developing test sockets for tiny electronic parts is tough. The need for high precision in testing modern chips is huge. It requires advanced engineering skills.

- Miniaturization of electronic components

- Higher signal integrity requirements

- Complex material engineering

Economic Pressures and Market Barriers

Keeping costs down is a big problem for makers of elastomer test sockets. The cost of research and development is very high. This makes it hard for small companies to compete.

| Challenge Category | Impact Level | Primary Constraints |

| Technological Limitations | High | Component complexity |

| Economic Barriers | Medium | R&D investment costs |

| Regulatory Compliance | Medium-High | International standards |

Regulatory and Compliance Challenges

Global standards for electronics testing add to the complexity. Navigating international regulatory landscapes is tough. It needs a lot of knowledge and flexibility in design and quality control.

The ability to overcome technological limitations determines market leadership in the elastomer test socket industry.

Geopolitical Landscape Impacting the Elastomer Test Socket Market

The global elastomer test socket market is changing fast. This is due to complex geopolitical factors. Trade policies and global market dynamics are reshaping the competitive landscape across key technological regions.

Geopolitical tensions are creating unique challenges and opportunities for manufacturers in the elastomer test socket industry. Different regions are responding with strategic approaches to maintain technological competitiveness:

- North America’s strong industrial infrastructure enables rapid technological innovation

- European markets prioritize sustainable manufacturing processes

- Asia-Pacific regions demonstrate accelerated industrial growth

Regional Manufacturing Shifts

The elastomer test socket market is witnessing significant regional manufacturing shifts. Trade policies are compelling companies to reconsider their supply chain strategies. Key technological players like Siemens and Mitsubishi are adapting to these dynamic global market dynamics by developing more resilient production networks.

Intellectual Property Considerations

Protecting intellectual property has become crucial in maintaining competitive advantages. Companies are investing heavily in securing their technological innovations through strategic patent registrations and collaborative research agreements.

The future of the elastomer test socket market depends on navigating complex geopolitical landscapes with agility and strategic foresight.

Manufacturers must continuously assess geopolitical factors to remain competitive in this rapidly evolving technological ecosystem.

Understanding the Different Types of Elastomer Test Sockets and Their Role in Electronics

Elastomer test sockets are a big deal in checking out electronic parts. They offer flexible and dependable ways to test semiconductors. These sockets use special materials to work well in many testing situations.

- Burn-in Test Sockets: Made for long tests to check how reliable parts are

- Functional Test Sockets: Help check how well parts work

- Custom-Designed Test Sockets: Made just for certain types of semiconductors

Advanced Elastomer Socket Technologies

Today’s elastomer test sockets have amazing features, like:

- They can handle high speeds up to 30GHz

- They use a special wire-in-elastomer contact

- They come in low-profile designs

- They keep signals clear and strong

Special sockets like ELTUNE and ELTUNE-coax show how good elastomers can be. They have top-notch electrical features, better signal protection, and last long in tough tests.

Key Performance Characteristics

Elastomer test sockets stand out in important areas, such as:

- They resist wear and tear well

- They make reliable electrical connections

- They fit with complex chip designs

- They can be used many times without losing quality

Applications of Elastomer Test Sockets Across Industries: Electronics, Automotive, and More

Elastomer test sockets have changed how we test semiconductors and other industrial parts. They are key in making sure electronic parts work well in many settings.

Semiconductor Testing Innovations

In the world of semiconductors, these test sockets help check microchips and circuits. New tech has made testing better, especially for fast computers and AI.

- Support fine-pitch testing below 0.25 mm

- Reduce contact resistance from 34.5 mΩ to 31 mΩ

- Enhance thermal management with advanced interface materials

Automotive Electronics Breakthroughs

The car industry uses these test sockets to check electronic systems in electric and self-driving cars. Extreme temperature testing is key to making sure these systems work well in tough conditions.

- Validate electronic control units (ECUs)

- Test high-voltage battery management systems

- Verify advanced driver-assistance systems (ADAS)

Telecommunications and 5G Infrastructure

Telecom companies use these test sockets to ensure 5G gear works right. They help keep quality high in fast-changing tech.

Advanced elastomer test socket technologies are driving innovation across multiple industry applications.

A Global View of the Elastomer Test Socket Market and Regional Variations

The elastomer test socket market is a fast-growing field. It shows a lot of innovation across the world. New markets are changing how the industry works.

How people use elastomer test sockets varies by region. Some areas stand out for their unique traits:

- North America leads in technological innovation

- Asia-Pacific shows rapid market expansion

- European markets focus on precision engineering

Market Segmentation by Region

The global market shows interesting patterns. Each area brings its own special touch to the field. This creates a complex web of innovation and growth.

New markets are becoming key players in the elastomer test socket world. They show a lot of promise for growth. This is thanks to their tech and industrial investments.

The future of elastomer test sockets lies in understanding and leveraging regional variations and technological capabilities.

Key Market Insights from the USA: Trends and Innovations

The United States is a leader in the elastomer test socket market. It drives big tech advances through strong R&D efforts. American makers are making advanced testing tools for the electronics and semiconductor fields.

- Increasing focus on miniaturization of test socket technologies

- Enhanced precision in semiconductor testing methodologies

- Development of high-performance elastomer materials

Leading Research and Development Efforts

Top American makers are spending a lot on new R&D projects. Companies in Silicon Valley and research groups are working together. They aim to make the next big thing in elastomer test sockets.

- Improved signal integrity

- Lower contact resistance

- Greater thermal stability

Technological Breakthroughs

The USA is all in on innovation. Advanced materials engineering and new making methods help American makers. They create better and more efficient test socket solutions for tough electronic parts.

The future of elastomer test sockets lies in continuous technological refinement and precision engineering.

New partnerships between chip makers, universities, and tech firms are speeding up test socket tech progress. These teams are making the USA a leader in elastomer test socket innovation worldwide.

Japan's Elastomer Test Socket Market: Growth Prospects and Technological Advances

Japanese companies are changing the game in elastomer test sockets. They are making big moves with their strategies:

- Advanced robotic integration in manufacturing processes

- Cutting-edge precision engineering techniques

- Sophisticated automation in testing methodologies

Driving Technological Breakthroughs

Japanese makers are breaking new ground in elastomer test socket design. Their focus on precision helps test electronic parts more accurately than ever before.

Some key advances include:

- Micro-precision socket designs

- Enhanced material durability

- Intelligent contact mechanism improvements

Market Expansion Strategy

The Japanese elastomer test socket market is strong thanks to smart investments in research. Automation in testing is key for Japanese electronics makers to compete worldwide.

Japan continues to set global standards in precision engineering and technological innovation.

Germany's Market Outlook: Opportunities in the Elastomer Test Socket Industry

The German elastomer test socket market is leading in tech innovation. This is thanks to the country’s top engineering skills and focus on Industry 4.0. German makers are changing the test socket tech world with great precision and planning.

- Advanced manufacturing skills

- Focus on green manufacturing

- Investments in new research and development

- Smart manufacturing techniques

Industry 4.0 and Technological Excellence

Germany’s way of making elastomer test sockets shows its tech strength. Using digital tech and automated making, they achieve unmatched precision and speed in design.

Sustainable Manufacturing Strategies

German firms are at the forefront of green test socket solutions. Their dedication to eco-friendly making shows a global shift towards green electronics.

| Market Segment | Growth Potential | Key Drivers |

| Automotive Electronics | High | Electric Vehicle Innovation |

| Consumer Electronics | Medium | Advanced Testing Requirements |

| Industrial Manufacturing | High | Industry 4.0 Implementation |

The German market for elastomer test sockets looks strong. It has big chances for growth and tech progress in the future.

The Road Ahead: What's Next for the Elastomer Test Socket Market in 2025?

The elastomer test socket market is on the verge of big changes. These changes come from new technologies and predictions. By 2025, we will see major updates in how test sockets are made and work.

Several important trends are expected:

- Artificial intelligence for better testing

- New materials for better performance

- Smaller test socket designs

- Compatibility with quantum computing

Technological Convergence in Test Socket Development

New technologies are changing the test socket world. Machine learning algorithms will be key in making test sockets better. They will help in testing electronic parts more accurately and efficiently.

“The future of test sockets lies in smart, adaptive technologies that can anticipate and respond to complex testing requirements,” says Dr. Elena Rodriguez, leading electronics research analyst.

Market Dynamics and Growth Potential

Experts predict the market will grow a lot. This growth will come from different areas:

- Testing for car electronics

- Research on advanced semiconductors

- Testing for aerospace and defense

- Medical device technology

As the market grows, companies that focus on research and new technologies will lead. They will drive innovation and meet the needs of future electronic systems.

Competitive Landscape and Key Players in the Elastomer Test Socket Market

Top companies:

-

Smiths Interconnect —— USA

-

WinWay Technology —— Taiwan

-

Ironwood Electronics —— USA

-

LEENO —— South Korea

-

TwinSolution Technology —— China

-

Shenzhen Jixiangniao Technology —— China

-

TESPRO Co.,Ltd. —— Taiwan

-

SUNGSIM Semiconductor —— South Korea

-

Micronics Japan Co., Ltd. —— Japan

-

United Precision Technologies —— USA

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Elastomer Test Socket Market Report |

| Base Year | 2024 |

| Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The elastomer test socket market is at a key point in 2025. It’s expected to hit $1.5 billion, thanks to new tech in electronics making. Big players like the United States, Japan, and Germany are investing heavily. This sets the stage for big growth and change.

Investors looking for the latest tech have a chance to shine. Elastomer test sockets are key in testing semiconductors, car electronics, and advanced computers. The market is ripe for investment, with many chances to get in early.

Right now, the focus is on making these sockets better. Companies are working hard on precision and new materials. Those making top-notch test sockets will likely lead the market, especially in areas needing high accuracy and reliability.

The future looks bright for the elastomer test socket market. It’s where tech meets economic growth. Expect more growth as research keeps going, and electronic needs get more complex. This will benefit industries worldwide.

Global Elastomer Test Socket Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Elastomer Test Socket Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Elastomer Test Socket MarketSegmentation Overview

Chapter 2: Competitive Landscape

- Global Elastomer Test Socketplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Elastomer Test Socket Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Elastomer Test Socket Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Elastomer Test Socket Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofElastomer Test Socket Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market value for elastomer test sockets in 2025?

The market for elastomer test sockets is expected to hit $1.5 billion by 2025. This growth comes from major players in the USA, Japan, and Germany.

What industries primarily use elastomer test sockets?

Industries like semiconductor manufacturing, automotive electronics, and telecommunications use them a lot. They also play a key role in high-performance computing. These sectors need them for precise testing and quality checks.

How are 5G networks impacting the elastomer test socket market?

The rise of 5G and IoT devices is opening up new chances for makers of elastomer test sockets. It’s driving innovation and boosting demand for better testing tech.

What technological challenges do elastomer test socket manufacturers face?

Makers face challenges like making test sockets for smaller, more complex parts. They also deal with cost issues and keeping up with global rules.

What makes elastomer materials unique for test sockets?

Elastomer materials offer solid electrical connections and can handle lots of use. They’re also very flexible, making them great for testing different parts in various fields.

How do geopolitical factors affect the elastomer test socket market?

Things like trade wars, tariffs, and rules on intellectual property affect the market a lot. This is especially true in the USA, Japan, and Germany.

What types of test sockets are commonly used in the electronics industry?

The main types are burn-in, functional, and custom test sockets. Each one is designed for specific testing needs in the electronics world.

How are emerging technologies like AI influencing test socket development?

New tech like AI and machine learning are set to change test socket design. They could bring big improvements in testing abilities soon.

Which countries are leading the elastomer test socket market?

The USA, Japan, and Germany are leading the way. They’re known for their tech advancements, strong manufacturing, and big investments in research.

What role do elastomer test sockets play in automotive electronics?

Elastomer test sockets are key for the growth of electric and self-driving cars. They help make sure the complex electronics work well.