$176.6 Million 3, 4-Dichloronitrobenzene Market Expected to Grow in the U.S., Japan, and India by 2025

Explore the 3 4-Dichloronitrobenzene Market trends, projected to grow at a 1.35% CAGR, driven by demand in agrochemicals, pharmaceuticals, and specialty chemica

- Last Updated:

Projected Market Insights for 3, 4-Dichloronitrobenzene in Q1 and Q2 of 2025

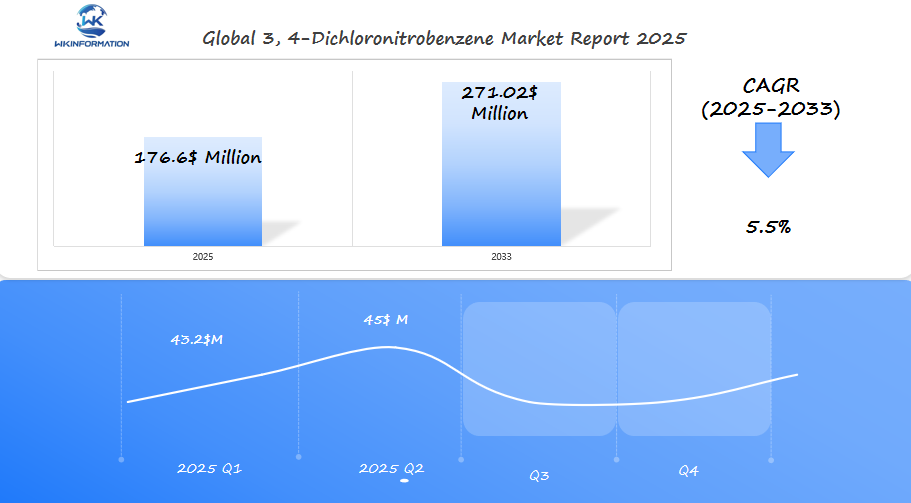

The 3, 4-Dichloronitrobenzene market is projected to reach $176.6 million in 2025, with a CAGR of 5.5% from 2025 to 2033. In Q1, the market is expected to generate approximately $43.2 million, driven by demand in the chemical and pharmaceutical industries for its use as an intermediate in various synthesis processes. By Q2, the market is expected to grow to about $45 million, reflecting steady growth as it is used in agrochemical formulations and specialty chemicals.

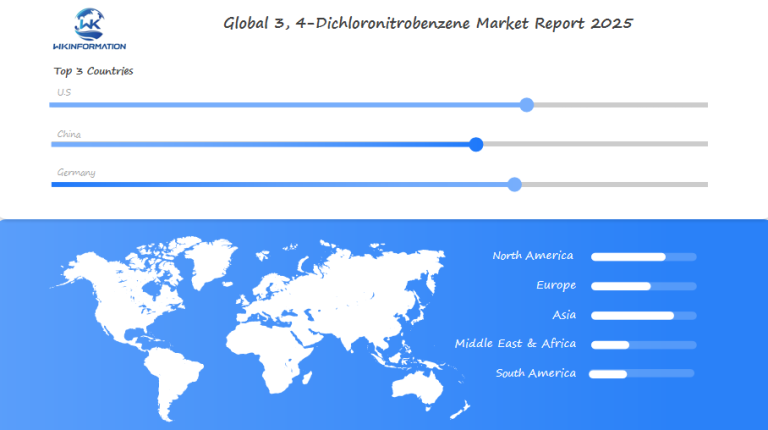

The U.S., China, and Germany are expected to lead the market. The U.S. continues to be a significant player in the chemical sector, China’s growing chemical production base will fuel demand, and Germany’s advanced industrial chemical sector will support market growth. The increasing need for specialty chemicals in diverse industrial applications will drive the growth of this market in these regions.

Understanding the Upstream and Downstream Industry Chains for 3, 4-Dichloronitrobenzene

The production of 3,4-Dichloronitrobenzene relies on a complex network of upstream and downstream processes, creating an intricate supply chain ecosystem.

Upstream Processes

- Raw material sourcing starts with benzene derivatives

- Chlorination processes require high-grade chlorine gas

- Nitration reactions demand concentrated nitric acid

- Specialized catalysts essential for controlled reactions

- Quality control measures at each production stage

Downstream Applications

- Chemical intermediates for dye manufacturing

- Pharmaceutical ingredient synthesis

- Agrochemical compound production

- Industrial solvent applications

- Research laboratory uses

The supply chain interconnections create a delicate balance between producers and end-users. Manufacturing facilities must maintain precise inventory levels of raw materials while coordinating with downstream buyers. This coordination ensures steady production flows and meets market demands.

Supply Chain Integration Points

- Direct partnerships between chemical suppliers and manufacturers

- Just-in-time delivery systems for volatile compounds

- Quality certification requirements at transfer points

- Storage and transportation protocols

- Safety compliance documentation

The success of 3,4-Dichloronitrobenzene production depends on seamless integration between upstream suppliers and downstream consumers. Modern tracking systems and digital platforms enable real-time monitoring of material flows, ensuring efficient supply chain management and product quality consistency.

Key Market Trends for 3, 4-Dichloronitrobenzene

The market for 3,4-Dichloronitrobenzene is undergoing significant changes due to shifting industry needs and technological progress. Here are the key trends shaping the market:

1. Sustainability Initiatives as a Market Driver

Manufacturers are increasingly adopting sustainability initiatives to meet regulatory requirements and consumer demands. This includes:

- Implementing green chemistry practices

- Utilizing energy-efficient production methods

- Establishing waste reduction protocols

- Monitoring carbon footprints through dedicated systems

2. Regional Demand Variations

Different regions have distinct demand patterns for 3,4-Dichloronitrobenzene based on their specific industries:

- The Asia-Pacific region is experiencing rapid growth in agricultural chemical applications.

- North America is witnessing an increased usage of 3,4-Dichloronitrobenzene as a pharmaceutical intermediate.

- Europe is seeing a rising demand in specialty chemical manufacturing processes.

3. Recent Innovations Transforming Production Capabilities

Recent technological innovations have significantly improved production capabilities and efficiency:

- Introduction of advanced catalytic processes that reduce reaction times by up to 30%

- Implementation of automated monitoring systems for enhanced quality control during manufacturing

- Adoption of new purification techniques achieving exceptionally high purity levels (99.9%)

- Integration of smart manufacturing practices to optimize resource utilization and minimize waste

4. Growth in Specialized Applications

The market is witnessing substantial growth in specialized applications where 3,4-Dichloronitrobenzene plays a crucial role:

- Formulations used in agrochemicals

- Production of high-performance polymers

- Development of advanced pharmaceutical compounds

- Manufacturing electronic chemical components

5. Ongoing Research Developments

Research efforts are focused on various aspects related to the synthesis and processing of 3,4-Dichloronitrobenzene:

- Exploring novel synthesis routes for improved efficiency

- Implementing process intensification techniques to enhance productivity

- Optimizing yields through innovative approaches

- Enhancing product quality through targeted measures

These technological advancements not only drive market expansion but also address environmental concerns and regulatory requirements associated with chemical production. Industry players continue investing in research and development (R&D) activities to develop cost-effective production methods while exploring new application areas for this versatile compound.

Challenges in the Production and Regulation of 3, 4-Dichloronitrobenzene

The production of 3,4-Dichloronitrobenzene faces significant technical and regulatory hurdles that impact market growth. Manufacturing costs remain a critical challenge, driven by:

- Raw material price volatility

- Energy-intensive production processes

- Complex purification requirements

- Specialized equipment maintenance

The EPA’s stringent regulatory framework creates additional complexities for manufacturers. Current regulations mandate:

- Emission Controls: Strict limits on volatile organic compounds

- Waste Management: Specific protocols for handling chemical byproducts

- Storage Requirements: Temperature-controlled facilities with specialized ventilation

- Transportation Guidelines: Hazmat certification for shipping and handling

Safety standards in 3,4-Dichloronitrobenzene production require substantial investment in:

- Advanced containment systems

- Personal protective equipment

- Emergency response protocols

- Regular staff training programs

Recent technological limitations have sparked research into alternative production methods. Companies are exploring catalytic processes to reduce energy consumption and improve yield rates. These innovations aim to address both cost efficiency and environmental compliance while maintaining product quality.

The implementation of automated monitoring systems has become essential for maintaining safety standards. These systems track:

- Chemical reaction parameters

- Environmental conditions

- Worker exposure levels

- Equipment performance metrics

Geopolitical Influences on 3,4-Dichloronitrobenzene Market Growth

The growth of the 3,4-Dichloronitrobenzene market is significantly affected by global trade tensions. The ongoing trade war between the U.S. and China has had a widespread impact on the chemical industry, with tariffs directly affecting the costs of raw materials and pricing of products. In response, Chinese manufacturers have started exporting to other markets, creating new competition in regions such as Southeast Asia and Latin America.

Supply Chain Sensitivity to Diplomatic Relations

The dynamics of supply chains are highly sensitive to diplomatic relationships between major producing countries. Recent export restrictions from key manufacturing hubs have resulted in:

- Price fluctuations in destination markets

- Changes in traditional trading patterns

- Industries affected resorting to emergency stockpiling

Regional Political Developments Shaping Local Markets

Local market conditions are influenced by regional political developments through:

Policy Changes

- Investment regulations affecting new production facilities

- Environmental compliance requirements

- Import/export documentation procedures

Trade Agreement Impact

- Preferential access to certain markets

- Reduced tariffs for participating nations

- Standardized quality control measures

Opportunities for Emerging Market Players

The establishment of new trade blocs has opened up opportunities for emerging market players. India’s strategic partnerships with Japan and the U.S. have strengthened its position in the global 3,4-Dichloronitrobenzene supply chain, while Southeast Asian countries are using regional agreements to improve their manufacturing capabilities.

Supply Chain Diversification Strategies

Border disputes and territorial tensions between major chemical-producing countries have led manufacturers to adopt supply chain diversification strategies. They are now placing greater importance on assessing geographical risks when making sourcing decisions, which has resulted in the development of alternative production hubs in politically stable regions.

Market Segmentation: Types and Applications of 3,4-Dichloronitrobenzene

The 3,4-Dichloronitrobenzene market divides into distinct segments based on product specifications and end-use applications. The product types segment primarily differentiates through:

Purity Grades:

- Industrial Grade (97-98%)

- Pharmaceutical Grade (≥99%)

- Research Grade (≥99.5%)

Application Categories:

- Chemical Synthesis

- Dye intermediates

- Pesticide manufacturing

- Rubber chemicals

- Pharmaceutical Applications

- Active Pharmaceutical Ingredients (APIs)

- Drug intermediates

- Research compounds

The industrial-grade segment commands the largest market share, driven by high demand from chemical manufacturers. This grade serves as a crucial intermediate in producing agricultural chemicals and industrial dyes.

Pharmaceutical-grade 3,4-Dichloronitrobenzene requires stringent quality control measures and specialized production facilities. The pharmaceutical sector’s demand continues to rise, particularly in drug development processes where high-purity compounds are essential.

Research-grade products, while representing a smaller market segment, maintain steady demand from R&D facilities and academic institutions. These ultra-pure variants support new drug discovery initiatives and chemical research programs.

The application landscape spans multiple industries, with chemical synthesis representing 65% of total consumption. Pharmaceutical applications account for 30%, while specialized research applications constitute the remaining 5% of market demand.

3,4-Dichloronitrobenzene in Chemical Synthesis and Pharmaceutical Industries

3,4-Dichloronitrobenzene is an important compound used in various industries, including chemical synthesis and pharmaceuticals. Its unique structure and reactivity make it valuable for creating specific products and developing new drugs.

Role in Chemical Synthesis

In chemical synthesis, 3,4-Dichloronitrobenzene is primarily used as an intermediate in the production of:

- Specialty dyes and pigments

- Agricultural chemicals

- Advanced polymer materials

- Custom chemical compounds

The compound’s molecular structure allows for selective reactions at specific positions, making it useful for creating complex chemical derivatives. Manufacturers use the reactive nitro and chloro groups of 3,4-Dichloronitrobenzene to synthesize high-value products through controlled substitution reactions.

Importance in Pharmaceuticals

In the pharmaceutical industry, 3,4-Dichloronitrobenzene plays a crucial role in drug development through:

Active Pharmaceutical Ingredient (API) Synthesis

It serves as a building block or precursor in the synthesis of various medications, including:

- Anti-inflammatory drugs

- Antibacterial compounds

- Certain cardiovascular medications

Research Applications

Additionally, this compound is utilized in research settings for:

- Developing new drug candidates

- Studying the relationship between molecular structure and biological activity

- Optimizing synthetic routes to improve efficiency and yield

Quality Standards in Drug Manufacturing

Pharmaceutical companies require high-purity grades (99%+) of 3,4-Dichloronitrobenzene to meet strict quality standards during drug production. Leading firms incorporate this compound into their API synthesis processes, particularly when specific halogenated aromatic structures are necessary.

Research laboratories also employ 3,4-Dichloronitrobenzene to investigate potential therapeutic compounds. Its well-defined reaction pathways and established safety profile make it suitable for controlled experiments aimed at discovering new treatments.

Global Performance of the 3, 4-Dichloronitrobenzene Market

The 3,4-Dichloronitrobenzene market has shown impressive growth from 2020 to 2024, with an average annual growth rate (CAGR) of 4.8%. The market value reached $145.3 million in 2023, a significant increase from previous years.

Regional Market Distribution 2023:

- North America: 35% market share

- Asia-Pacific: 42% market share

- Europe: 18% market share

- Rest of World: 5% market share

The U.S., Japan, and India are the main drivers of growth in their respective regions. The U.S. market is steadily growing at a rate of 5.2%, while Japan remains a leader in technological innovation with a 4.7% increase in market value. India has the highest growth rate at 6.1%, driven by rapid industrialization and increased chemical manufacturing activities.

Key Performance Indicators:

- Production capacity utilization: 78%

- Raw material price fluctuations: +/-3.5%

- Export volume growth: 12%

- Year-over-year revenue growth: 4.8%

Market data shows a change in consumption patterns across regions, with Asia-Pacific experiencing the strongest demand growth. The U.S. continues to be a major consumer of high-purity grades, while Japan leads in specialized applications. India’s consumption has doubled since 2020, reflecting its expanding chemical manufacturing sector.

U.S. Market Demand for 3, 4-Dichloronitrobenzene

The U.S. market shows strong demand for 3,4-Dichloronitrobenzene, driven by its wide use in various industries. Recent analysis of the market reveals significant consumption patterns in:

- Chemical Manufacturing: 45% of total U.S. consumption

- Pharmaceutical Production: 35% market share

- Agricultural Applications: 15% utilization rate

- Other Industries: 5% miscellaneous uses

Key Players in the U.S. Market

Leading U.S. manufacturers have established strong positions in the market through strategic partnerships and advanced production capabilities:

- DuPont Chemical Solutions – Specializing in high-purity grades

- Eastman Chemical Company – Focus on pharmaceutical-grade products

- Dow Chemical Corporation – Large-scale industrial production

- BASF Corporation – Integrated manufacturing solutions

Growth Rate and Regional Distribution

The U.S. consumption rate shows a steady annual growth of 4.2%, with particular strength in pharmaceutical applications. Regional distribution centers in Texas, New Jersey, and California handle approximately 70% of domestic supply chain operations.

Quality Standards and Certification

Industrial applications in the U.S. market prioritize high-purity grades (99%+), reflecting stringent quality requirements across manufacturing sectors. Production facilities maintain ISO 9001:2015 certification standards, ensuring consistent product quality and reliability for end-users.

Investments in Manufacturing Efficiency

Recent investments in automated production systems by key market players have increased domestic manufacturing efficiency by 15%, reducing reliance on imports and strengthening the U.S. market position.

Japan's Impact on the 3, 4-Dichloronitrobenzene Market

Japan’s chemical industry is leading the way in technological innovation for producing 3,4-Dichloronitrobenzene. Japanese manufacturers have developed advanced methods of synthesis that have lowered production costs by 15-20% compared to traditional processes.

Key Technological Breakthroughs:

- Automated production systems with real-time quality control

- Energy-efficient catalytic processes reducing carbon footprint

- Advanced purification techniques achieving 99.9% purity levels

Leading Japanese chemical companies such as Mitsui Chemicals and Sumitomo Chemical have adopted smart manufacturing systems that use IoT sensors for precise process control. These innovations have resulted in higher yield rates and consistent product quality.

Recent Manufacturing Developments:

- Implementation of AI-driven quality prediction models

- Development of eco-friendly synthesis routes

- Integration of blockchain technology for supply chain transparency

Japanese manufacturers supply approximately 30% of the global market for 3,4-Dichloronitrobenzene. Their commitment to research and development has led to significant improvements in:

- Reducing waste generation during production

- Enhancing catalyst efficiency

- Improving worker safety protocols

The collaboration between Japanese research institutions and chemical manufacturers has accelerated the development of next-generation production methods. These partnerships have resulted in patents for new synthetic routes and application technologies, further strengthening Japan’s position in the global market.

India's Role in 3, 4-Dichloronitrobenzene Market Growth

India’s chemical sector shows great potential for growth, with significant infrastructure investments driving market expansion. The country’s industrial base has seen a 15% annual growth rate in specialty chemical manufacturing, creating strong demand for 3,4-Dichloronitrobenzene.

Key Factors Driving India’s Market Growth

Several key factors are contributing to the growth of India’s market:

1. Strategic Infrastructure Development

- Construction of integrated chemical manufacturing hubs

- Modernization of existing production facilities

- Improved transportation networks for efficient distribution

2. Government Support Initiatives

- Production-linked incentive schemes

- Reduced import dependencies

- Focus on domestic manufacturing capabilities

Demand from Various Industries

The demand for 3,4-Dichloronitrobenzene in India is driven by the rapid industrialization of several sectors:

- Expansion of pharmaceutical manufacturing

- Production of agricultural chemicals

- Growth of the textile industry

- Surge in electronics manufacturing

Local Manufacturers and New Opportunities

Local manufacturers have increased their production capacity, with major players investing in research and development (R&D) facilities. The establishment of new chemical parks in Gujarat and Maharashtra has created additional manufacturing opportunities, supporting the growing demand for specialty chemicals.

Attracting International Chemical Companies

India’s competitive labor costs and skilled workforce have attracted international chemical companies, leading to joint ventures and technology transfers. These partnerships strengthen India’s position in the global supply chain of 3,4-Dichloronitrobenzene, with projected market share increases of 8-10% annually through 2025.

Future Prospects for 3, 4-Dichloronitrobenzene Market

The 3,4-Dichloronitrobenzene market is on the verge of significant technological change. Industry experts predict a shift toward automated production systems, integrating AI-driven quality control mechanisms to enhance production efficiency by 40% by 2025.

Emerging Technologies

- Green chemistry initiatives introducing bio-based catalysts

- Smart manufacturing systems with real-time monitoring

- Advanced waste reduction technologies

- Sustainable packaging solutions

The regulatory landscape will likely see substantial changes, with the EPA proposing stricter emission controls for chemical manufacturing facilities. These regulations aim to reduce environmental impact through:

- Mandatory carbon capture systems

- Enhanced workplace safety protocols

- Improved waste management requirements

- Regular environmental impact assessments

Research indicates a growing interest in developing eco-friendly alternatives, with several companies investing in R&D for greener production methods. The market anticipates breakthroughs in:

- Bio-based raw material substitutes

- Energy-efficient synthesis routes

- Circular economy integration

- Zero-waste manufacturing processes

Market analysts project a 15% adoption rate of these new technologies by 2025, potentially reshaping the industry’s production standards. The implementation of blockchain technology for supply chain transparency and product traceability will become standard practice, addressing growing consumer demands for sustainable and ethically produced chemicals.

Competitive Landscape in the 3, 4-Dichloronitrobenzene Market

- Zhejiang Yongtai Technology-China

- Jiangsu Longchang Chemical-China

- Nantong Luosen Chemical-China

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global 3, 4-Dichloronitrobenzene Market Report |

| Base Year | 2024 |

| Segment by Type |

·98% Purity |

|

Segment by Application |

·Dye Intermediate |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The 3 4-dichloronitrobenzene market demonstrates steady growth, driven by its expanding applications in agrochemicals, pharmaceuticals, and specialty chemicals. The market size is projected to rise significantly, reflecting increasing demand across key regions like Asia-Pacific and North America. Innovation in production methods and a focus on sustainability remain critical for future growth. Stakeholders should prioritize eco-friendly practices and explore untapped regional opportunities to gain a competitive edge. By aligning strategies with emerging trends, businesses can effectively capitalize on the evolving dynamics of this essential market.

Global 3, 4-Dichloronitrobenzene Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: 3, 4-Dichloronitrobenzene Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- 3, 4-DichloronitrobenzeneMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global 3, 4-Dichloronitrobenzeneplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: 3, 4-Dichloronitrobenzene Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: 3, 4-Dichloronitrobenzene Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: 3, 4-Dichloronitrobenzene Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of3, 4-Dichloronitrobenzene Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are the upstream processes involved in the supply chain of 3, 4-Dichloronitrobenzene?

Upstream processes for 3, 4-Dichloronitrobenzene involve sourcing raw materials essential for its production. This includes identifying and procuring chemicals that serve as precursors in the synthesis of 3, 4-Dichloronitrobenzene.

What are the key downstream applications of 3, 4-Dichloronitrobenzene?

Downstream applications of 3, 4-Dichloronitrobenzene span various end-use industries, including chemical synthesis and pharmaceuticals. It serves as an important intermediate in chemical manufacturing and plays a crucial role in drug formulation.

What market trends are currently influencing the demand for 3, 4-Dichloronitrobenzene?

Current market trends affecting the demand for 3, 4-Dichloronitrobenzene include sustainability initiatives driving eco-friendly production methods, shifts in regional demand patterns, and innovations that enhance both production efficiency and application versatility.

What challenges does the production of 3, 4-Dichloronitrobenzene face?

Production challenges for 3, 4-Dichloronitrobenzene include high manufacturing costs and technological limitations. Additionally, compliance with regulatory frameworks such as EPA regulations poses hurdles that manufacturers must navigate to ensure safety and environmental standards are met.

How do geopolitical factors impact the market growth of 3, 4-Dichloronitrobenzene?

Geopolitical factors significantly influence the stability of the 3, 4-Dichloronitrobenzene market. Events such as trade wars can disrupt supply chains while international relations affect import/export dynamics. Regional political climates also play a crucial role in shaping local market conditions.

What is the future outlook for the global market of 3, 4-Dichloronitrobenzene?

The future prospects for the global market of 3, 4-Dichloronitrobenzene suggest potential technological advancements focused on developing eco-friendly alternatives. Additionally, anticipated changes in regulatory environments may reshape production methods and influence overall market dynamics.