2025 3D Nonwovens Market Growth: USA, China, and Germany Leading the Charge Worth $1.8 Billion

Explore 3D nonwovens market growth, trends, and innovations shaping industries like automotive and healthcare.

- Last Updated:

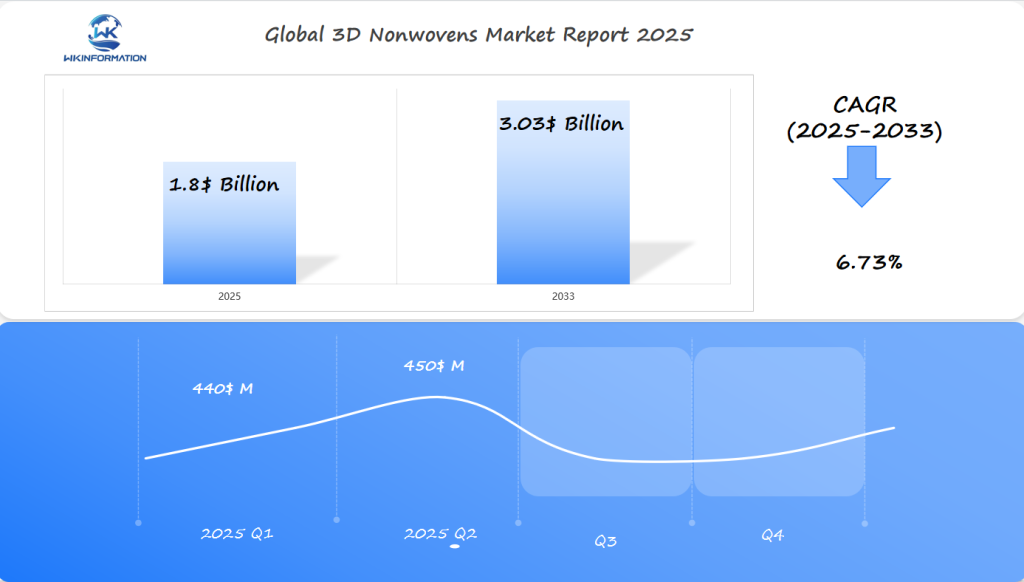

Market Forecast for 3D Nonwovens in 2025: Q1 and Q2 Predictions

The 3D Nonwovens market is projected to reach a total size of $1.8 billion in 2025, with a compound annual growth rate (CAGR) of 6.73% from 2025 to 2033. In Q1, the market is expected to generate approximately $440 million, with Q2 rising to about $450 million. This growth is primarily driven by the increasing demand for innovative materials in the textile, automotive, and healthcare industries.

The USA, China, and Germany are expected to be the key regions leading the market in 2025. The rapid industrialization in China, coupled with the strong manufacturing base in the USA and Germany’s leadership in advanced material technologies, positions these countries as the most significant contributors to market growth. The rising demand for lightweight, high-performance materials in sectors such as automotive and medical devices is anticipated to drive significant demand for 3D nonwoven fabrics, which offer superior properties such as strength, flexibility, and breathability. The market is also benefiting from the ongoing trend toward sustainable production methods, with 3D nonwovens being increasingly adopted in eco-friendly applications.

Key Takeaways

- Global 3D nonwovens market expected to reach $1.8 billion by 2025

- United States, China, and Germany emerge as market leaders

- Advanced manufacturing techniques driving market transformation

- Technological innovations creating new industry opportunities

- Significant investments supporting market growth and development

Understanding the Upstream and Downstream Impact in the 3D Nonwovens Market

The 3D nonwovens market is a complex system. Supply chain dynamics are key to product quality and market success. Raw materials are at the base, affecting everything from making to the final product.

Manufacturers in the 3D nonwovens field face a complex supply chain. They deal with many players. Important points include:

- Finding top-quality raw materials

- Keeping production standards high

- Using cost-effective ways to make products

- Keeping the supply chain strong

End-user industries push demand for 3D nonwovens in many fields. The automotive, healthcare, and construction sectors are big users. They use these materials for new and better products.

The way supply chain parts work together shapes the 3D nonwovens market’s future.

Upstream, things like material choice, tech, and making efficiency are key. Downstream, it’s about meeting industry needs, making custom solutions, and keeping up with new market demands.

Working together, raw material suppliers, makers, and end-users build a strong system. This system supports growth and innovation in the 3D nonwovens area.

Market Trends Shaping the Future of 3D Nonwovens in 2025

The 3D nonwovens market is going through a big change. This is thanks to new technologies and a focus on being green. Companies are working hard to make new nonwoven products that meet tough industry needs.

Some big trends are changing the 3D nonwovens world fast:

- Advanced manufacturing processes enable complex 3D textile structures

- More focus on sustainable and eco-friendly materials

- Custom nonwoven materials for specific uses

- Smart technologies in nonwoven making

Sustainability is a big deal in the 3D nonwovens field. Companies are using recyclable materials and making production more energy-efficient. Green manufacturing is now key for growth.

New tech is making it possible to create nonwovens with amazing precision. Scientists are looking into nanotechnology and new ways to make fibers. This is leading to materials that perform better in many industries.

Key Restrictions and Market Challenges in the 3D Nonwovens Industry

The 3D nonwovens industry faces big challenges that test its strength and creativity. Rules and regulations are major hurdles to growth and adoption.

Key market challenges include:

- Stringent safety and environmental compliance requirements

- High production costs for advanced materials

- Limited standardization across global markets

- Intense competition from traditional manufacturing techniques

Companies must deal with tough rules that require lots of testing and approval. The competition pushes for better technology but also makes it hard for new players to join.

| Challenge Category | Primary Impact | Potential Mitigation Strategy |

| Regulatory Compliance | Increased development costs | Proactive regulatory engagement |

| Technical Standardization | Market fragmentation | Industry collaboration |

| Material Innovation | Higher research investments | Strategic partnerships |

The best companies will use strategic innovation to beat these challenges. They will find ways to make solutions that are affordable, meet strict rules, and scale up.

How Geopolitics Are Shaping the 3D Nonwovens Market Landscape

The global 3D nonwovens market is changing fast because of complex geopolitical factors. International trade policies and global competition are making big changes in the industry. These changes bring both challenges and opportunities for makers and investors.

Key geopolitical factors affecting the 3D nonwovens market include:

- Shifting trade relationships between major economic powers

- Strategic manufacturing relocations

- Emerging regional investment strategies

- Technology transfer restrictions

China is a big player in this changing market. It’s the world’s largest exporter and second-largest importer. The country is open to foreign trade, with 37% of its GDP coming from international commerce in 2023. Geopolitical tensions between big economies can disrupt supply chains and slow market growth.

Trade policies are getting more complex. Governments are taking steps to protect their domestic industries. The 3D nonwovens sector must find a balance between innovation and geopolitical limits.

Manufacturers are coming up with plans to deal with global competition. They’re diversifying their supply chains, investing in local production, and building strong international partnerships.

The future of the 3D nonwovens market will be shaped by those who can handle geopolitical risks while staying ahead in technology.

Different Types of 3D Nonwovens and Their Role in Various Industries

3D nonwoven materials are a big step forward in textile making. They come in different types, each made for a specific use. This is because of their unique properties and how they’re made.

The main types of 3D nonwovens are:

- Meltblown Nonwovens: These have very fine fibers that filter well.

- Spunbond Nonwovens: They are strong and good for protection.

- Electrospun Nonwovens: These have tiny fibers with a lot of surface area.

Special methods make these 3D nonwovens. Meltblown uses air to make tiny fibers. Electrospinning uses electricity to create even smaller fibers. Each way makes materials with special properties for different uses.

3D nonwovens are used in many fields, like:

- Medical devices and protective gear

- Car filters

- Thermal insulation

- Sound dampening

These materials keep pushing the limits of what’s possible in making things. They offer new ways to solve tough engineering problems.

Applications of 3D Nonwovens in Medical, Automotive, and Consumer Goods

3D nonwovens have changed many industries with their unique features. They are making big impacts in medicine, cars, and everyday products. Their special structure makes them stand out.

In medicine, 3D nonwovens are key for new healthcare tech. They help make advanced medical textiles. These improve patient care and treatment results.

- Wound dressings with better healing

- Surgical gowns that protect better

- Advanced filters for medical gear

The car industry loves 3D nonwovens for their interior and performance parts. They make cars lighter, stronger, and more comfortable.

- Acoustic panels for quiet rides

- Light interior parts

- Top-notch air and cabin filters

Consumer products also get a boost from 3D nonwovens. They make cleaning tools and personal care items better. Users enjoy more functionality and a better experience.

- Advanced cleaning wipes

- New personal hygiene items

- Special home decor materials

As more industries use 3D nonwovens, we’ll see even more new uses. This will keep driving innovation in medicine, cars, and everyday products.

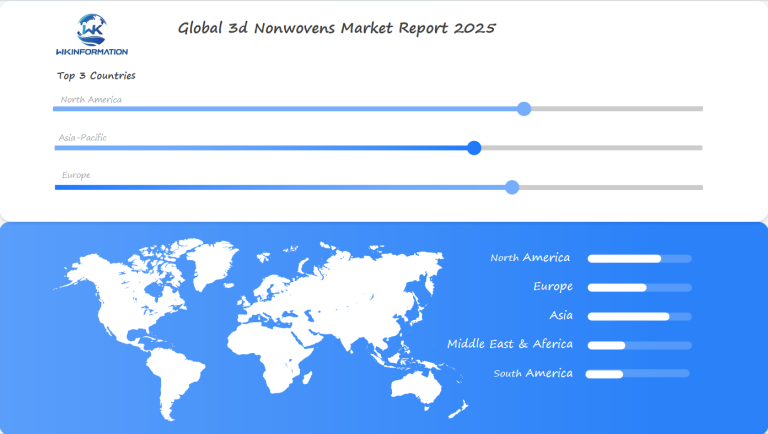

A Global Look at the 3D Nonwovens Market: Key Trends and Regional Dynamics

The 3D nonwovens market is changing fast around the world. New markets are leading the way in innovation and growth. Each region has its own path to follow, offering chances for makers and researchers.

Looking at the global 3D nonwovens market, we see a few key points:

- North America is at the forefront of tech innovation

- Asia-Pacific is growing fast

- Europe is all about green solutions

Working together is key in the global market. For example, HERMA Group from Germany and Wausau Coated Products from the USA teamed up. Their partnership shows how companies can reach new markets and improve their products by working across regions.

| Region | Market Characteristics | Growth Potential |

| North America | Advanced technological infrastructure | High |

| Asia-Pacific | Rapid industrialization | Very High |

| Europe | Sustainable innovation focus | Moderate |

New markets offer big chances for 3D nonwovens to grow. Companies are seeing the potential in places like Mexico. With the right distribution networks, they can find new ways to grow.

USA 3D Nonwovens Market: Developments and Market Insights

The United States is leading the way in 3D nonwovens market growth. It’s doing this through strategic research and development. Places like Massachusetts, California, and Texas are at the forefront of this innovation.

There have been big investments in the US 3D nonwovens market. Both private companies and government research institutions are putting in a lot of money. This is changing many industries, like medical tech, cars, and consumer goods.

- Emerging research centers focusing on advanced nonwoven materials

- Breakthrough technological advancements in material science

- Increased funding for sustainable nonwoven solutions

The rules and regulations in the US are also important. They make sure products are safe and good for the environment. This pushes companies to make better and greener products.

| Innovation Hub | Primary Research Focus | Key Technological Contribution |

| MIT Materials Research Laboratory | Advanced Textile Engineering | Nano-structured nonwoven materials |

| Stanford Nanomaterials Center | Sustainable Manufacturing | Eco-friendly nonwoven composites |

| Georgia Tech Polymer Research Center | Performance Material Development | High-strength nonwoven fabrics |

Protecting intellectual property is a big deal. There are many patents filed in new nonwoven technologies. The US market shows a lot of promise for more growth and innovation in 3D nonwovens.

China's Contribution to the 3D Nonwovens Market: Growth and Opportunities

The Chinese market is growing fast in 3D nonwovens, driving global growth. China’s strong manufacturing makes it a major player worldwide. The country’s focus on advanced textile tech opens doors for both local and international companies.

China’s exports of 3D nonwovens are reaching many parts of the world.

The 3D nonwovens market analysis shows China’s makers are innovating fast. They’re making special products for complex needs. Technological advancements and cost-effective production help them compete globally.

Foreign companies looking to enter the market find great partnership chances in China. The country’s advanced research, supportive policies, and big manufacturing base make it a top choice for 3D nonwoven tech investments.

Germany's Role in Advancing 3D Nonwovens and Innovation

German engineering leads in 3D nonwovens technology. The country’s focus on precision and innovation makes it a world leader. Strategic partnerships are key to Germany’s success in innovation.

Industry leaders are making big strides with Industry 4.0. Companies like Evonik Industries are exploring new materials. They aim to create advanced nonwoven solutions.

- High-performance material development

- Precision manufacturing techniques

- Sustainable production processes

The VoluMAX³ 3D embossing and aperturing line shows Germany’s tech strength. It was made by German and Italian engineers. This system can work at speeds of up to 600 meters per minute.

German makers are setting new benchmarks in the nonwovens market. They focus on quality, innovation, and being green. This drives progress in many fields, from hygiene to technical textiles.

The Future of 3D Nonwovens: What's on the Horizon in 2025?

The 3D nonwovens industry is on the verge of big changes. New technologies and market trends are leading the way. Researchers and makers are working on new ideas that will change many fields.

Some areas to watch include:

- Advanced material science with nano-engineered fibers

- Smart manufacturing powered by artificial intelligence

- Sustainable production techniques

- Enhanced performance characteristics

“The next generation of 3D nonwovens will redefine industrial capabilities,” says Dr. Sarah Rodriguez, materials innovation expert.

New technologies will change how we make things. Machine learning will make production better. And new ways of making will let us customize more than ever before. The market is expected to grow a lot in medical, car, and consumer goods.

Being green is also a big deal. Companies are finding ways to make products without harming the environment. These green steps will help the market grow and open up new chances worldwide.

- Projected market value expected to reach $1.8 billion by 2025

- Increased adoption in high-performance sectors

- Breakthrough in material flexibility and durability

The future of 3D nonwovens looks very exciting. It promises a lot of new ideas and growth in many areas.

Competitive Overview of the 3D Nonwovens Market: Key Players and Strategies

Big players:

1. Halyard Health, Inc. —— United States

2. DuPont de Nemours, Inc. —— United States

3. Freudenberg Group —— Germany

4. Johns Manville —— United States

5. Glatfelter Corporation —— United States

6. Asahi Kasei Corporation —— Japan

7. Kimberly-Clark Corporation —— United States

8. Toray Industries, Inc. —— Japan

9. Tredegar Corporation —— United States

10. 3M Company —— United States

Overall

| Report Metric | Details |

| Report Name | Global 3d Nonwovens Market Report |

| Base Year | 2024 |

| Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The 3D nonwovens market is growing fast, thanks to new technologies and smart strategies. It’s expected to hit $1.8 billion by 2025. This shows big chances in many fields, like medicine, cars, and everyday products.

Places like the United States, China, and Germany are leading the way. They invest in tech and make lots of products. This means the market will keep growing as more advanced materials are made and used.

Companies looking to invest in 3D nonwovens have great chances. New tech and more uses mean big profits. Big players are working hard to make new products that meet tough needs.

By 2025, the 3D nonwovens world will keep changing. New tech, world politics, and better making will shape it. Those who get the current trends and future challenges will do well in this fast-changing field.

Global 3d Nonwovens Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: 3d Nonwovens Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- 3d Nonwovens MarketSegmentation Overview

Chapter 2: Competitive Landscape

- Global 3d Nonwovensplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: 3d Nonwovens Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: 3d Nonwovens Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: 3d Nonwovens Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of 3d Nonwovens Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market value for 3D nonwovens by 2025?

The 3D nonwovens market is expected to hit $1.8 billion by 2025. This growth is fueled by new tech and rising demand in various sectors.

Which countries are leading the 3D nonwovens market?

The US, China, and Germany are at the forefront. They lead in innovation, production, and market expansion.

What are the key industries using 3D nonwovens?

Key sectors include the automotive, healthcare, construction, and medical fields. Also, filtration and consumer goods use 3D nonwovens.

What manufacturing techniques are used in 3D nonwovens production?

Main methods are meltblown, spunbond, and electrospinning. Each creates materials with distinct properties.

What challenges does the 3D nonwovens industry face?

Challenges include meeting regulations, environmental standards, and staying competitive. The industry must innovate continuously and protect its market share.

How are sustainability trends impacting the 3D nonwovens market?

Sustainability is becoming a focus. Companies are working on eco-friendly products and green manufacturing methods.

What role do geopolitical factors play in the 3D nonwovens market?

Global politics, trade policies, and economic changes affect the market. China’s role in trade and manufacturing is especially significant.

What are some specific applications of 3D nonwovens?

Applications include wound dressings, surgical gowns, and car interiors. They also cover filtration, insulation, cleaning products, and personal care items.

How is technology advancing the 3D nonwovens industry?

New tech improves fiber formation and material properties. AI and machine learning are being used in production. Advanced materials with special features are also being developed.

What makes the 3D nonwovens market attractive for investment?

The market is appealing for investment. It’s growing, with high demand, continuous innovation, and global expansion.