$632.2 Million Acrylic Polymer Market Booms in the U.S., Brazil, and China by 2025

The Acrylic Polymer Market expands rapidly across industrial sectors, driven by rising demand in coatings, adhesives, and textiles. Key growth regions include the U.S., Brazil, and China through 2025.

- Last Updated:

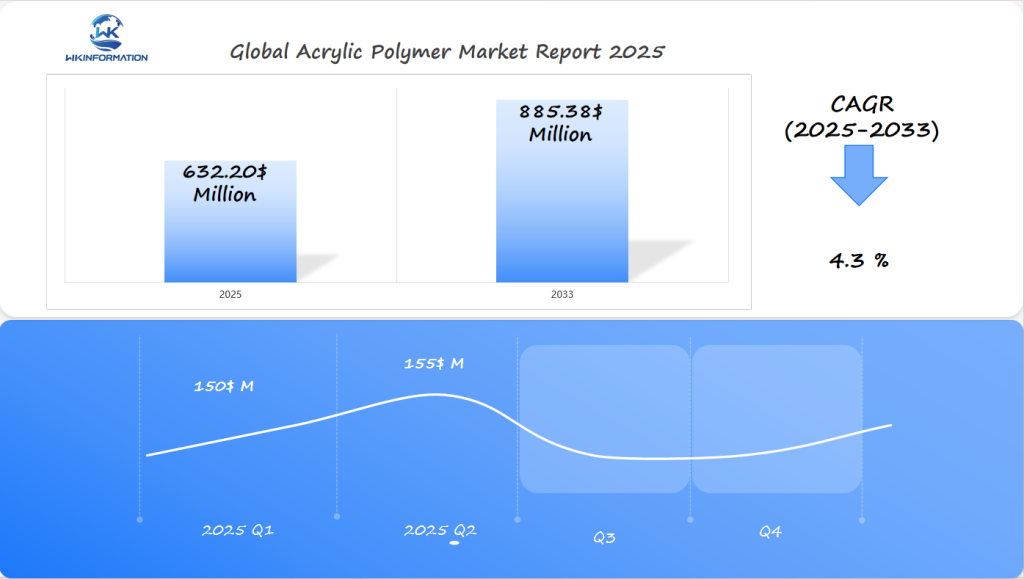

Projected Market Insights for Acrylic Polymer in Q1 and Q2 of 2025

The Acrylic Polymer market is expected to reach $632.2 million in 2025, growing at a CAGR of 4.3% from 2025 to 2033. In Q1, the market is projected to reach approximately $150 million, driven by the rising demand for acrylic polymers in coatings, adhesives, and construction materials. By Q2, the market is anticipated to expand to around $155 million, continuing its steady growth.

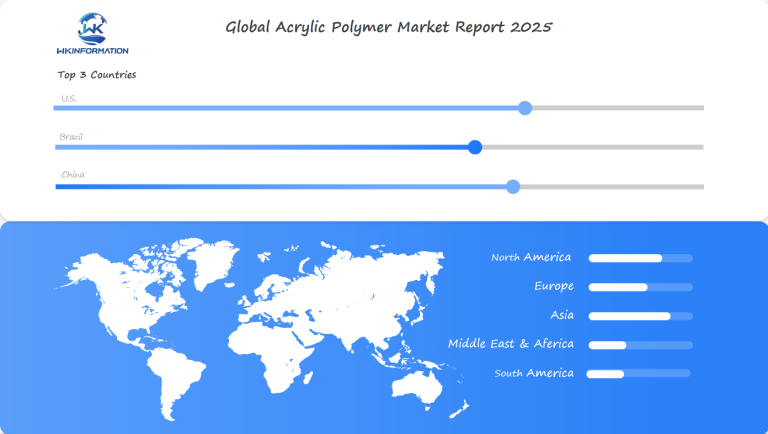

The USA, Brazil, and China are expected to be the most significant contributors to this market. In the U.S., increased demand for eco-friendly coatings and adhesives will fuel market growth. In Brazil, the booming construction sector and the adoption of sustainable building materials will drive demand for acrylic polymers. Meanwhile, China’s rapidly expanding industrial base will continue to support market growth through strong production capabilities in manufacturing and automotive applications. Technological innovations in polymer synthesis and environmental regulations favoring sustainable products will further boost the market.

Exploring Upstream and Downstream Industry Chains

The acrylic polymer industry is a complex web of raw materials and industries. It starts with important petrochemical by-products. These are the base for making acrylic polymers.

Key Raw Materials for Acrylic Polymers

Key raw materials for acrylic polymers include:

- Acrylonitrile

- Methyl methacrylate

- Ethylene

- Propylene derivatives

These raw materials help create versatile polymers. These polymers are used in many industries. The relationship between suppliers and manufacturers shapes the market and new products.

| Raw Material | Primary Source | Key Applications |

| Acrylonitrile | Petrochemical Refineries | Automotive Components |

| Methyl Methacrylate | Chemical Processing Plants | Construction Materials |

| Ethylene Derivatives | Oil and Gas Extraction | Consumer Goods Manufacturing |

Changes in raw material prices affect the acrylic polymer market. Manufacturers must keep up with economic changes and new technologies. This helps them stay competitive and keep product quality high.

Industries like automotive, construction, and consumer goods need these polymers. Their demand pushes for more research and development in acrylic polymer technology.

Shaping the Future: Trends to Watch in 2025

The acrylic polymer market is changing fast. This is thanks to new technologies and market trends. Experts say we will see big changes by 2025.

Technological Advancements

Technological advancements are changing the acrylic polymer world. Companies are working on new polymer formulas. These formulas will have better performance:

- Improved UV resistance for outdoor use

- Water repellency technologies

- Sustainable polymers that are better for the environment

Sustainability Focus

Sustainability is a big trend now. Companies are making eco-friendly acrylic polymers. Green chemistry principles are helping make biodegradable and recyclable polymers. These meet tough environmental rules.

Growth in Global Plastic Market

The global plastic market is expected to grow a lot. It will go from USD 712 billion in 2023 to USD 1,050 billion by 2033. This means big chances for new acrylic polymer ideas. Companies like BASF SE and Dow Inc are leading in these advancements.

“Innovation is the cornerstone of future market success in the acrylic polymer industry.” – Industry Expert

Problem-Solving with New Technologies

New technologies are solving big problems. They are making polymers better, cheaper, and more eco-friendly. These changes will help the market grow and open up new uses in many industries.

Overcoming Barriers in the Acrylic Polymer Market

The acrylic polymer industry faces big challenges. These challenges test the strength of manufacturers and supply chain managers. Shortages of raw materials and strict rules make it hard for businesses to grow and stay stable.

Key market challenges

These challenges come from several areas:

- Supply chain vulnerabilities exposed by global disruptions

- Volatile raw material pricing

- Sustainability requirements

- Technological adaptation needs

Geopolitical tensions and natural disasters affect raw material availability. The pandemic showed how weak supply chains are. Global inflation and rising fuel prices make things worse, increasing costs for making and moving products.

| Challenge Category | Primary Impact | Mitigation Strategy |

| Raw Material Shortages | Production Halts | Diversified Supplier Networks |

| Transportation Delays | Operational Inefficiencies | Advanced Logistics Technologies |

| Sustainability Demands | Higher Procurement Costs | Eco-friendly Material Sourcing |

Industry leaders are finding ways to overcome these challenges. They use advanced technologies like AI and ERP systems to see their supply chains better. They also manage their inventories well, keeping extra stock for important chemicals.

But, there are also strict rules to follow. Companies must spend on following rules, train their staff, and use strong screening tools. This helps them stay on top in a complex world.

Geopolitical Forces Reshaping the Acrylic Polymer Landscape

The acrylic polymer market is changing fast because of global politics. Changes in trade and markets are making the industry more competitive. Companies are facing tough economic and legal hurdles.

Strategic moves are happening in important markets:

- The U.S. leads with a 33.4% share in coating additives

- China’s growth is boosted by green tech support from the government

- Europe is focusing on sustainable polymers due to strict rules

Global politics are causing big problems in the market. Trade limits and price swings in raw materials are affecting costs and supply chains. Companies are turning to local production to deal with these issues.

- They’re investing a lot in green research and development

- They’re working together across borders

- They’re creating new, eco-friendly polymer technologies

The market is showing us how different regions are doing. North America is strong thanks to its industrial base. Asia-Pacific is growing fast because of new factories and cities.

These changes mirror the nine forces reshaping the global business landscape and highlight some of the five forces reshaping the global economy, as detailed in recent reports from various sources including the World Economic Forum’s Annual Report 2023-2024.

Market Segmentation Insights and Growth Drivers

The acrylic polymer market is changing fast. This is thanks to different market segments and new uses. As demand grows worldwide, it’s key for companies to understand this complex landscape.

Market segments show interesting trends in various polymer types and technologies. Polymethyl Methacrylate (PMMA) leads, with a 36% market share in 2023. Its wide use and versatility explain its success.

Water-Borne vs. Solvent-Borne Polymer Insights

Two main types of polymers are changing the market:

- Water-Borne Polymers: Expected to grow at a 5.4% CAGR by 2034

- Solvent-Borne Polymers: Still holds a big market share

Water-based polymers are becoming more popular. This is because of stricter environmental rules and a push for green products. Companies are moving towards products that reduce harmful emissions.

Key Application Segments

Many areas are driving the market’s growth:

- Paints and Coatings

- Adhesives and Sealants

- Electronics

- Automotive Components

The global acrylic resin market is set to hit USD 40.0 billion by 2034. It will grow at a 5.6% CAGR. New trends like 3D printing are opening up new chances in these areas.

The Power of Applications in Acrylic Polymer Industries

Acrylic polymers have transformed various industries by introducing innovative products. They have improved manufacturing processes across multiple sectors, leading to significant outcomes and reliability.

Industries are increasingly turning to acrylic polymers for their unique capabilities. These materials address major challenges in numerous fields, demonstrating their versatility and sophistication.

Coatings and Paints

Acrylic polymers are great for making coatings. They have:

- Superior weather resistance

- Enhanced chemical durability

- Excellent adhesion properties

- Long-lasting protection

Adhesives and Sealants

The market for spray adhesives is growing fast. It’s expected to go from $3.42 billion in 2024 to $3.61 billion in 2025. They are used in:

- Automotive and transportation

- Building and construction

- Paper and packaging

- Woodworking and joinery

Textiles and Fibers

Textile makers use acrylic polymers to make better materials. These innovations help create stronger, more flexible, and eco-friendly textiles.

| Industry Sector | Market Contribution | Growth Rate |

| Packaging | $42.9 billion | 15.3% |

| Spray Adhesives | $3.42 billion | 5.7% CAGR |

The ongoing improvement of acrylic polymer technology opens up new chances worldwide.

Global Market Insights and Regional Performance

The global acrylic polymer market is experiencing significant growth, with expectations of substantial expansion in various sectors. This growth can be attributed to emerging opportunities and strategic advancements within the industry.

Key Trends in the Global Market

Some key trends in the global market include:

- The market size is expected to reach USD 632.2 million in 2025.

- An anticipated compound annual growth rate (CAGR) of 4.3% through 2033.

- A projected market valuation of USD 885.38 million by 2033.

Regional Growth and Opportunities

Different regions are growing at their own pace, with each area having its own prospects for growth:

| Region | Projected Growth | Market Characteristics |

| North America | Largest market segment | Strong adhesives and coatings sector |

| Asia-Pacific | Fastest-growing region | Emerging manufacturing capabilities |

| Korea | 7.9% CAGR through 2034 | Expanding technological innovations |

Water-based segments are showing strong growth, with a CAGR of 4.3% through 2033. The market’s strength is also seen in related areas like spray adhesives.

U.S. Growth Drivers in the Acrylic Polymer Market

The United States is leading in acrylic polymer innovation. Demand is growing fast in many industries. The market is expected to grow by 5.8% each year from 2023 to 2033.

By 2025, the market size is predicted to hit a huge $632.2 million.

Several factors are driving this growth:

- Advanced manufacturing technologies

- Expanding electronics sector

- Innovative composite material development

- Sustainable production techniques

The electronics industry is a big driver of demand. Electrical insulation properties of acrylic resins are key for consumer electronics and advanced components. These polymers are used in 3D printing and precision engineering.

Aerospace and automotive sectors are also changing fast. They use resin infusion techniques. This shows how important acrylic resins are for making lightweight, high-performance materials in U.S. manufacturing.

China’s Dominance in the Acrylic Polymer Market

China has become a major force in the global acrylic polymer market. It’s leading growth and innovation in the Asia-Pacific region. The country’s large manufacturing capacity makes it a key player in the acrylic polymer industry. It has made big strides in production and technology.

The Chinese market is growing fast for several reasons:

- It has a lot of production in acrylic acid and its derivatives.

- It invests a lot in downstream applications.

- It’s building its industrial infrastructure quickly.

- It has strong demand both at home and abroad.

Big companies are growing their production to meet the demand. Companies like BASF, Nippon Shokubai, and LG Chem have invested a lot in China. They see the region’s huge potential.

| Market Segment | Growth Projection | Key Drivers |

| Glycidyl Methacrylate (GMA) | 5.38% CAGR (2025-2034) | Technological innovations |

| 2-Ethylhexyl Acrylate (2-EHA) | 45% Market Share in Asia-Pacific | Coatings and adhesives demand |

China’s focus on manufacturing capacity has made it a key center for acrylic polymer production. Top Chinese companies like Lianyungang Ningkang Chemical and Wuhan Sincere Star Chemical are leading the way. They’re pushing innovation and growing their market through partnerships and new technologies.

Brazil’s Role in Acrylic Polymer Market Development

Brazil is leading the way in the Latin American market, pushing the acrylic polymer industry forward. Its strategic location makes it a major player in polymer development. The country has a lot of room to grow in many sectors.

What’s driving Brazil’s acrylic polymer market includes:

- Expanding automotive manufacturing capabilities

- Increasing construction industry investments

- Growing consumer goods production

- Advanced manufacturing infrastructure

The South American region, with Brazil at its core, is seeing fast growth in polymers. Experts say there will be steady growth, showing Brazil’s big role in global polymers.

“Brazil’s polymer market represents a critical emerging opportunity in Latin American industrial development” – Industry Research Report

Strategic moves like mergers and acquisitions are making Brazil stronger in acrylic polymers. These steps point to a bright future for Brazil’s factories, drawing in global money and new tech.

Brazil is using its advanced factories and good location to grow its acrylic polymer market. This is adding a lot of value to the Latin American market.

Innovation and Future Outlook for Acrylic Polymer

The acrylic polymer industry is on the verge of big changes. Research and development are leading to new breakthroughs.

Many new areas of innovation are popping up in different fields:

- Digital technology integration in production processes

- Advanced 3D printing applications

- Lightweight composite material development

- Enhanced performance characteristics

The future looks bright for specific areas. Technological breakthroughs are opening up new chances in electronics, aerospace, and cars. Big companies are working together to bring new ideas to life.

| Innovation Area | Key Developments | Projected Impact |

| Coating Technologies | UV Resistance | 5.1% CAGR by 2034 |

| Electronic Components | Advanced Protective Coatings | Expanding Electronics Sector |

| Sustainable Solutions | Low VOC Formulations | Environmental Compliance |

Companies are now making acrylic polymers that are better for the planet. They’re working on making products that are good for the environment. This focus on sustainability is changing how the industry will look in the future.

Competitive Landscape: Who’s Leading the Market

The acrylic polymer market is very competitive. Key players like BASF SE, Dow Chemical Company, and Arkema are leading the way. They use strong strategies to stay ahead.

- Dow – USA

- BASF SE – Germany

- Toagosei Co., Ltd. – Japan

- Sumitomo Seika Chemicals Co., Ltd. – Japan

- Arkema – France

- Nippon Shokubai Co., Ltd. – Japan

- Ashland – USA

- Lubrizol Corporation – USA

- Chemipol – Spain

- MCTRON Inc. – South Korea

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Acrylic Polymer Market Report |

| Base Year | 2024 |

| Segment by Type |

· Water-Borne Polymer · Solvent-Borne Polymer |

| Segment by Application |

· Paints and Coatings · Adhesives and Sealants · Textiles and Fibers |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The acrylic polymer market demonstrates significant growth potential, driven by technological innovations and sustainability initiatives. Key insights reveal the market’s expansion across various sectors, including construction, automotive, and textiles. The shift towards eco-friendly and bio-based acrylic polymers aligns with regulatory requirements and consumer preferences. Stakeholders should leverage these opportunities to capitalize on emerging trends and enhance their market presence. By investing in research and development, companies can stay ahead of the competition and contribute to a sustainable future.

Global Acrylic Polymer Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Acrylic Polymer Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Vacuum Arc RemeltingMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Acrylic Polymerplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Acrylic Polymer Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Acrylic Polymer Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Acrylic Polymer Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofAcrylic Polymer Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

Which industries primarily use acrylic polymers?

Acrylic polymers are used in various industries, including:

- Automotive

- Construction

- Consumer goods

They are also utilized in:

- Coatings

- Adhesives

- Textiles

- Specialized manufacturing

What are the key technological innovations in acrylic polymers?

Recent advancements in acrylic polymers include:

- Improved UV resistance

- Enhanced water repellency

- Development of bio-based formulas

- Introduction of smart coatings

These innovations prioritize eco-friendliness and sustainability.

How are geopolitical factors affecting the acrylic polymer market?

Geopolitical factors such as global trade, international relations, and economic changes have a significant impact on the acrylic polymer market. Trade policies implemented by major countries like the U.S., Brazil, and China can also influence the market dynamics.

What are the main challenges in the acrylic polymer market?

The acrylic polymer market faces several challenges, including:

- Fluctuations in raw material prices

- Regulatory pressures

- Competition from alternative materials

- The need for new technology to remain competitive

What is the difference between water-borne and solvent-borne acrylic polymers?

Water-borne polymers are better for the environment and have less VOCs. Solvent-borne polymers have different properties and are used in specific areas.

Which companies are leading the acrylic polymer market?

Leaders include BASF, Dow Chemical Company, and Arkema. They are driving innovation, developing new technologies, and expanding globally.

Which emerging markets are most promising for acrylic polymers?

Brazil and China are showing a lot of promise. Their fast industrial growth, infrastructure, and manufacturing capabilities are driving demand.

Are there sustainable alternatives in the acrylic polymer industry?

Yes, the focus is on bio-based polymers and eco-friendly processes. These efforts aim to reduce environmental harm while keeping performance high.

How are acrylic polymers used in different applications?

Acrylic polymers are used in many ways, including:

- Coatings

- Adhesives

- Textiles

- Automotive parts

- Construction

- Consumer goods