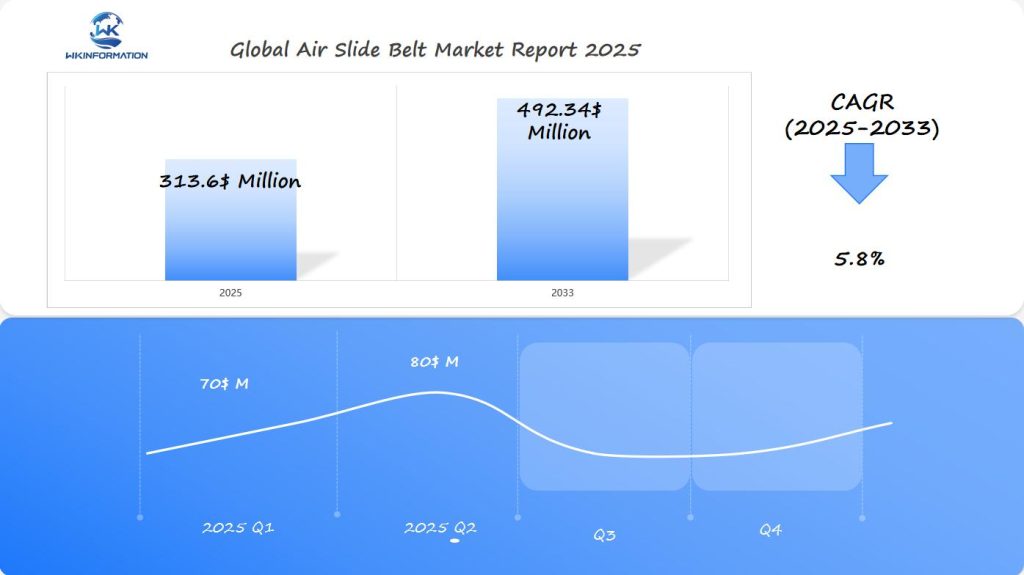

Air Slide Belt Market to Reach $313.6 Million by 2025: Industrial Handling and Material Transport Growth in the U.S., China, and India

Discover key trends driving the Air Slide Belt Market toward $313.6 million by 2025, fueled by innovations in industrial handling and material transport solutions across manufacturing sectors.

- Last Updated:

Air Slide Belt Market: Q1 and Q2 Forecast for 2025

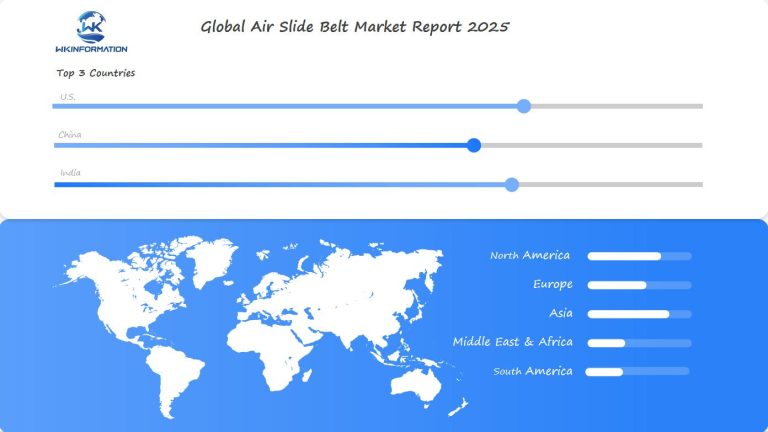

The Air Slide Belt market is projected to reach $313.6 million by the end of 2025, with a CAGR of 5.8% from 2025 to 2033. In Q1 2025, the market is estimated to reach approximately $70 million, driven by steady demand from industrial sectors such as bulk material handling and transportation. By Q2 2025, the market is expected to grow to around $80 million, with the continued expansion of automated systems in logistics and materials handling. This moderate growth pattern reflects the sector’s ongoing transition to more efficient, cost-effective solutions in industrial applications. The U.S., China, and India represent the most noteworthy regions for this product, given their large-scale manufacturing, logistics, and infrastructure development.

Key Takeaways

- Air Slide Belt Market expected to reach $313.6 million by 2025

- Significant growth in industrial handling technologies

- United States and China leading market expansion

- Increased focus on efficient material transport solutions

- Technological innovations driving market development

Air Slide Belt upstream and downstream industry chain analysis

The air slide belt manufacturing industry is a complex web of processes and players. Knowing the upstream and downstream sides helps us understand market trends and new tech.

Upstream Components

Upstream parts are vital for making air slide belts. They include:

- Raw material suppliers who focus on advanced fabrics

- Companies that make special manufacturing machines

- Engineering firms that create new design tech

Downstream Components

The downstream side is also key for growth. It includes distribution channels and end-user industries. Together, they form a strong supply chain for air slide belt tech.

- Companies that handle industrial materials

- The mining and mineral processing sectors

- Logistics and transport providers

How upstream suppliers and downstream buyers work together shapes the market. Technological innovation and cost-effective making are what set companies apart in this complex system.

Effective integration of upstream and downstream capabilities drives sustainable growth in air slide belt manufacturing.

Manufacturers need to keep up with changing needs. They must balance performance, durability, and cost across the whole supply chain.

Rising demand for efficient material handling systems in industries

The world of material handling is changing fast. Companies are using new automation to make their work better. Air slide belts are key in making things more efficient in many areas.

What’s driving these changes?

- More need for precise material transport

- Wants to cut down on work stoppages

- Looking for ways to grow automation

- Trying to make production smoother

Businesses see big wins with advanced material handling systems. Automation technologies help them work better and save money. Air slide belts move materials smoothly, with less chance of damage or contamination.

| Industry Sector | Material Handling System Impact | Efficiency Improvement |

| Manufacturing | Precision Material Transport | 25-40% Productivity Increase |

| Food Processing | Hygienic Bulk Material Movement | 30-45% Operational Efficiency |

| Chemical Processing | Controlled Material Transfer | 35-50% Workflow Optimization |

Technology and industry needs are coming together fast. Air slide belt use is growing. Companies are updating their systems to keep up with the fast-changing world.

Challenges in system maintenance, efficiency, and cost optimization

Air slide belt systems are complex and need careful maintenance and efficiency strategies. Industrial experts face many challenges when handling these systems. They must manage these systems well.

Common Challenges in Managing Air Slide Belt Systems

- Regular wear and tear of critical components

- Managing compressed air consumption

- Preventing material contamination

- Minimizing system downtime

Keeping the system efficient means watching several key areas closely. Managers need to track air slide belt performance with exact metrics. These metrics are crucial for cost-saving plans.

| Maintenance Aspect | Efficiency Impact | Cost Optimization Potential |

| Component Replacement | High | Moderate |

| Air Pressure Management | Critical | Significant |

| Material Flow Control | Essential | High |

Using predictive maintenance can greatly reduce problems. Advanced monitoring systems help track air slide belt performance in real-time. This allows for quick actions before big issues happen.

Investing in top-quality parts and regular checks can greatly boost efficiency and save costs over time. Industrial engineers need to create detailed maintenance plans. These plans should meet both immediate needs and long-term savings goals.

Geopolitical analysis of manufacturing and logistics industry dynamics

The global manufacturing and logistics sectors are undergoing big changes. These changes come from complex geopolitical factors. International trade is reshaping how we manage supply chains, offering both challenges and chances for technologies like air slide belt systems.

Important geopolitical factors affecting the manufacturing and trade include:

- Shifting trade agreements between major economic powers

- Regional economic integration efforts

- Technological innovation competition

- Emerging market economic policies

Recent tensions have made companies rethink their logistics strategies. Countries are now focusing more on making things at home and building strong supply chains.

| Geopolitical Factor | Impact on Manufacturing | Logistics Industry Response |

| Trade Policy Changes | Increased regional production | Diversified supply chain routes |

| Economic Sanctions | Alternative sourcing strategies | Enhanced logistics flexibility |

| Technological Decoupling | Localized manufacturing investments | Advanced material handling solutions |

Global trade’s complex nature calls for adaptable material handling technologies. Air slide belt systems show great promise in these complex times. They offer efficient, flexible solutions in many industrial settings.

Segmentation by material and design type

The air slide belt market is complex, driven by new materials and designs. Different products meet various needs in industries. Companies work hard to make air slide belts that can handle toughenvironments.

There are several main materials for air slide belts:

- Polyester-based fabrics

- Nylon composite materials

- High-performance synthetic blends

- Specialized industrial-grade textiles

Designs also matter a lot. Each design has its own strengths for different challenges in moving materials.

| Design Type | Primary Application | Performance Characteristics |

| Flat Belt Designs | Light-weight material transport | Smooth surface, minimal friction |

| Troughed Belt Configurations | Bulk material handling | Enhanced material containment |

| Custom Specialized Designs | Industry-specific requirements | Precision engineering |

The market shows that air slide belt materials keep getting better. They meet growing needs for better efficiency, durability, and performance in many fields.

Key applications in bulk material handling, mining, and logistics

Air slide belts have transformed the way we handle bulk materials across various industries. They play a crucial role in efficiently transporting powdery and granular substances with precision.

Mining

In the mining sector, air slide belts excel at transporting various minerals. They are particularly effective in managing:

- Coal and ore concentrates

- Mineral powders

- Fine geological materials

Logistics

Logistics operations utilize air slide belts to streamline material movement within warehouses and distribution centers. This technology offers significant advantages in material handling, such as:

- Reduced material damage

- Minimized friction during transport

- Enhanced overall efficiency

Manufacturing facilities greatly benefit from air slide belts’ ability to handle complex material requirements. These systems ensure smooth material flow in diverse environments.

Air slide belts represent a significant advancement in precise material transport for modern industries.

Crucial sectors like cement production, chemical processing, and food manufacturing rely on these systems to maintain uninterrupted material flow and seamless operations.

Regional demand trends in industrial automation and transport systems

The world of industrial automation and transport systems is changing fast. Different places have their own ways of handling materials. This affects how air slide belt technologyworks.

Looking at regional demand patterns, we see a few important points:

- North American markets focus on technological efficiency in transport systems

- European regions aim for sustainable industrial automation

- Asian markets quickly adopt new technologies

- Emerging economies invest in advanced material handling

Industrial automation is changing how markets work. Companies want better transport systems. They want to work more efficiently and need less human help.

Global demand patterns vary by region. This shows how different economies are at different stages. Developed areas have advanced tech, while growing ones offer new chances for material handling solutions.

The mix of new tech and regional economics is changing transport systems all over the world.

Investing in research helps make air slide belt technology better. It becomes more flexible and efficient for different needs.

U.S. demand for efficient material handling solutions in manufacturing

The U.S. manufacturing sector is going through big changes in material handling solutions. New technologies and economic needs are pushing companies to use better ways to make things. They are looking for ways to make production more efficient.

What’s Driving These Changes?

What’s driving these changes include:

- Reducing labor costs through automation

- Improving workplace safety and ergonomics

- Enhancing overall operational productivity

- Meeting stringent environmental sustainability goals

American market trends show a big need for better material handling systems. Precision engineering and intelligent design are key in picking the right equipment for moving and storing goods.

Rules and government plans are helping U.S. factories use the latest in material handling. Companies that jump on these new technologies are getting ahead in the fast-changing world market.

China’s industrial growth driving air slide belt demand in logistics

The Chinese logistics sector is undergoing significant transformations, with air slide belts playing a crucial role in its expansion. As China’s industrial growth accelerates, the need for advanced material handling technologies is skyrocketing.

Factors fueling this growth:

- Rapid development of infrastructure

- Expanding manufacturing capabilities

- Increased emphasis on efficient transportation of materials

- Government initiatives promoting technological modernization

Market dynamics in Asia are particularly favorable for manufacturers of air slide belts. The Chinese market presents opportunities for innovative material handling solutions that can streamline industrial processes and reduce costs.

New concepts in logistics are revolutionizing the way businesses manage bulk materials. State-of-the-art air slide belt technologies are enhancing the transportation of granular and powdered substances with greater precision, efficiency, and cost-effectiveness.

Technological advancements and investments in infrastructure within China bode well for the future of air slide belts. Companies recognize the significance of optimizing material handling operations to maintain a competitive edge.

India’s expanding infrastructure and manufacturing sectors driving market growth

India is changing fast, opening up big chances in the air slide belt market. The country is working hard on big projects to improve its infrastructure. This is making the manufacturing and logistics sectors grow a lot.

Emerging markets in South Asia are also seeing a big jump in industrial automation and material handling tech.

What’s driving this growth?

- Big investments from the government in infrastructure development

- Fast growth in manufacturing across many industries

- More need for advanced material handling systems

- Focus on making technology better

India’s manufacturing is really taking off in areas like cars, cement, mining, and chemicals. These industries are using advanced air slide belt tech to work better and make more.

There’s a big increase in demand for better material transport solutions in South Asia. Indian companies are putting a lot of money into new handling systems. These systems make production smoother and cut costs.

“India’s infrastructure development is transforming industrial capabilities and creating new market opportunities for advanced material handling technologies.”

New tech and government support are helping air slide belt systems get used more in different industries. The chance for growth in new markets is drawing a lot of international money and partnerships.

Innovations in air slide belt systems and materials for enhanced performance

The world of air slide belt technology is changing fast. New air slide belt innovations are making material handling systems better. They are improving how things move and work in many industries.

Key improvements in air slide belt technology

New materials and technologies are making big changes. They help air slide belts work better. Here are some key improvements:

- Advanced polymer composites with reduced friction

- Smart textile integration for real-time monitoring

- Nano-engineered surface treatments

- Self-cleaning mechanisms

The impact of digital technology on air slide belt systems

Digital tech is also changing air slide belt systems. IoT and AI help predict when things need fixing. This means less time stopped and better work done.

| Innovation Category | Key Technological Improvements | Performance Impact |

| Material Engineering | High-performance synthetic fibers | 50% increased durability |

| Digital Integration | IoT sensors and analytics | Reduced maintenance costs |

| Design Optimization | Advanced air distribution systems | 20% improved material flow |

“The future of air slide belt technology lies in intelligent, adaptive systems that can predict and prevent potential failures.” – Industrial Engineering Research Institute

These changes are more than just small updates. They are a big change in how material handling works. Now, manufacturers are making air slide belts that are smarter, more efficient, and better for the planet. These changes meet the needs of today’s industries.

Leading players in the air slide belt market

The global air slide belt market is full of life, with top players leading the way. Companies like Dollfus & Muller and Zonel Filtech are at the forefront. They are known for their air slide belt manufacturing skills and constant innovation.

Key players in the market include:

-

Dollfus & Muller – France

-

Zonel Filtech – China

-

Tiptopfilters – Bangladesh

-

CSM Machinery – Italy

-

Konus Konex – Slovenia

-

Testori USA – Italy

-

Filquip – Australia

-

Pearl Filtration – Australia

-

W.G. Benjey – United States

-

IFF Group – India and South Africa

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Air Slide Belt Market Report |

| Base Year | 2024 |

| Segment by Type | · Thickness Less than 4mm

· Thickness 4-8mm · Thickness More than 8mm |

| Segment by Application | · Mining

· Cement · Food Processing · Chemical · Others |

| Geographies Covered | · North America (United States, Canada)

· Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The air slide belt market is set to grow a lot, reaching $313.6 Million by 2025. This growth is due to the rising need for better material handling solutions in many industries. New technologies and smart investments are making the industry more efficient and green.

Looking ahead, makers will work on creating air slide belts that are lighter but still strong. Industries like mining, logistics, and manufacturing will lead the way in growth. Also, green rules and the need for energy-saving gear will shape the market’s future.

Those in the air slide belt market should get ready for big changes. Digital automation and new materials will be key. Companies that keep improving and making things better will likely lead the market. The market’s success depends on constant innovation and keeping up with new needs.

For those in the industry, it’s wise to focus on new tech, green materials, and flexible designs. The air slide belt market is full of chances for growth and new tech in handling materials.

Global Air Slide Belt Market Report(Can Read by Free sample)–Table of Contents

Chapter 1:Air Slide Belt Market Analysis Overview

- Competitive Forces Analysis(Porter’s Five Forces)

- Strategic Growth Assessment(Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Air Slide Belt Market Segmentation Overview

Chapter 2:Competitive Landscape

- GlobalAir Slide Belt Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3:Air Slide Belt Market Segmentation Analysis

- Key Data and Visual Insights

- Trends,Growth Rates,and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4:Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic,Demographic,and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5:Air Slide Belt Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends,Challenges,and Opportunities

Chapter 6:Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7:Air Slide Belt Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8:Key Findings and Recommendations

- Summary of Air Slide Belt Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are air slide belts and how do they work?

Air slide belts are special conveyor systems. They use compressed air to create a cushion between the belt and the material. This makes moving powders, grains, and other materials smooth and efficient.

In which industries are air slide belts most commonly used?

You can find air slide belts in many places. They’re used in bulk material handling, mining, and cement production. They’re also used in food processing, chemical manufacturing, and logistics. They’re great for moving fine or powdery materials without damaging them.

What are the key advantages of using air slide belt systems?

Air slide belts offer several benefits, including:

- Reduced material damage

- Low friction

- Minimal maintenance requirements

- Energy efficiency

- Ability to transport materials over long distances without causing harm

How do air slide belts contribute to industrial efficiency?

Air slide belts make industries more efficient. They allow for continuous transport, reduce manual handling, and prevent product loss. They also make material handling cleaner and more controlled, saving costs and boosting productivity.

What materials are typically used in manufacturing air slide belts?

Air slide belts are made from polyester, nylon, aramid fibers, and heat-resistant materials. The choice depends on the application, temperature, and material being moved.

How do air slide belts differ from traditional conveyor systems?

Air slide belts use an air cushion to move materials. This is different from traditional systems. It means gentler handling, less wear, and more efficient transport of fragile materials.

What factors influence the performance of air slide belt systems?

Several things affect air slide belt performance. Air pressure, belt material, design, material type, environment, and maintenance are all important. Proper design and regular upkeep are key for best results.

What are the emerging trends in air slide belt technology?

New trends include:

- IoT sensors

- advanced materials

- better air systems

- digital monitoring

- energy-saving designs

These developments aim to make systems more reliable, cut costs, and boost efficiency.

How do air slide belts support sustainability in industrial operations?

Air slide belts help the environment by reducing waste and energy use. They make transport more efficient and use less power. This lowers the environmental impact of material handling.

Which regions are experiencing the highest growth in air slide belt adoption?

The US, China, and India are seeing significant growth in air slide belt use. This surge is attributed to industrial growth, infrastructure development, and the need for better material handling.