2025 Alsic Hermetic Packaging Market Boom: Unlocking a $1.96 billion Opportunity with Advanced Technologies in the China, U.S. and Japan

Explore the global AlSiC hermetic packaging market, including advanced thermal management solutions, key industry players, regional innovations, and future growth trends for electronics and aerospace applications. Learn about material properties, manufacturing breakthroughs, and emerging opportunities in this critical semiconductor packaging area.

- Last Updated:

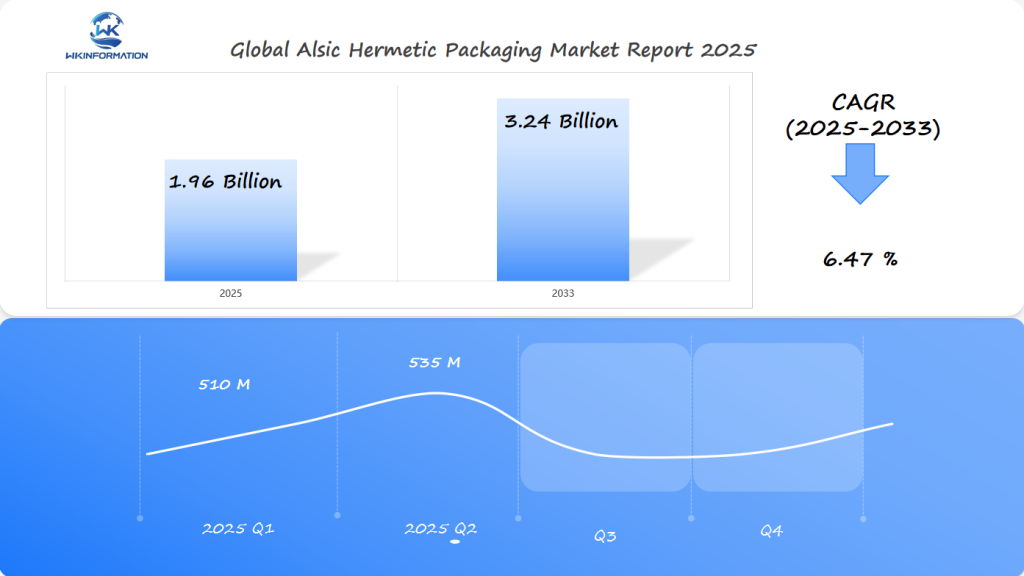

Global Alsic Hermetic Packaging Market 2025 Q1 & Q2 Data

The Alsic Hermetic Packaging market is expected to grow from USD 1.96 billion in 2025. The market is projected to exhibit a CAGR of 6.47% between 2025 and 2033.The Alsic Hermetic Packaging market is anticipated to witness steady growth in 2025, with Q1 and Q2 projected to reach USD 510 million and USD 535 million, respectively. This growth trajectory reflects a realistic, non-linear progression, driven by increasing demand in the electronics and semiconductor industries.

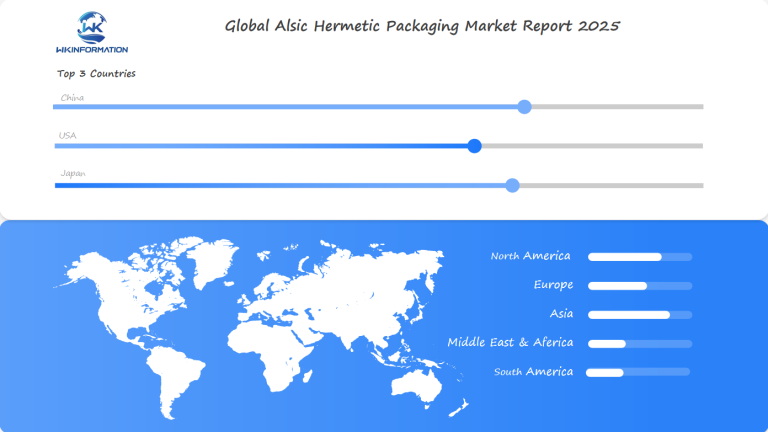

China, the United States, and Japan stand out as the most pivotal markets to study, with China leading in production volume, the U.S. excelling in technological advancements, and Japan maintaining a stronghold in high-quality manufacturing. Together, these three nations account for over 70% of the global market share, underscoring their strategic importance for industry stakeholders. For a detailed breakdown of market trends, regional dynamics, and future forecasts, access the Wkinformation Research sample and full report. Gain actionable insights to navigate this evolving landscape effectively and stay ahead of the competition.

Key Takeaways

- AlSiC Hermetic Packaging enables advanced electronic component protection

- China, US, and Japan lead global technological innovations

- Market trends indicate significant growth in multiple high-tech sectors

- Technological advancements drive improved packaging performance

- Emerging applications span aerospace, automotive, and telecommunications industries

Upstream and Downstream Industry Chain Analysis: Understanding the Alsic Hermetic Packaging Supply Chain

The AlSiC hermetic packaging supply chain is a complex system. It connects many parts to drive innovation and growth. With a global market expected to hit USD 1.96 billion by 2025, knowing this chain is key for all involved.

Raw Material Suppliers: The Foundation of Innovation

Raw material suppliers are vital in the AlSiC hermetic packaging market. Their work affects product quality and how efficiently it’s made. Key traits of these suppliers include:

- Advanced material development capabilities

- Consistent quality control processes

- Technological innovation in material science

Key Manufacturers: Production and Technological Capabilities

Manufacturers in the AlSiC hermetic packaging field are pouring resources into research and development. About 70% of them are focusing on tech advancements. Meanwhile, 40% are working to better their manufacturing methods.

The production scene is marked by:

- Precision manufacturing techniques

- Advanced thermal management solutions

- Competitive cost optimization strategies

End-User Industries: Driving Market Demand

Many end-user industries are boosting the AlSiC hermetic packaging market. The segments show great promise:

- Aerospace Sector: Set to make up 35% of the market by 2025

- Automotive Electronics: Expected to contribute 25% to the total market

- Semiconductor Industry: About 60% of manufacturers are using AlSiC packaging

Using AlSiC hermetic packaging could extend electronic component lifespans by 30%. This makes it a great choice for many high-performance uses.

Trend Analysis: Emerging Trends in Alsic Hermetic Packaging Technology

The world of hermetic packaging is changing fast. New technologies and materials are leading the way. These changes are making a big impact on how we protect and use electronic parts in many fields.

There’s a big push for smaller packaging sizes. This means making things that are both tiny and work really well. This trend is especially true in areas like phones and car electronics.

Miniaturization and Packaging Design

Miniaturization is changing hermetic packaging in big ways:

- Components are getting smaller, almost to the micro level

- It’s easier to manage heat in these tiny packages

- These small systems can handle signals better

Advanced Materials and Performance Enhancements

Smart packaging uses special materials that offer great benefits:

| Material Property | Measurement | Significance |

|---|---|---|

| Thermal Expansion Coefficient | 13 × 10−6·K−1 | Exceptional dimensional stability |

| Thermal Conductivity | 126 W/(m·K) | Superior heat dissipation |

| Material Density | 2.53 g/cm³ | Lightweight yet robust |

Smart Features in Hermetic Packaging

Hermetic packaging is getting smarter. It’s moving from just protecting parts to actively managing them. Intelligent packaging solutions now have sensors, smart materials, and can monitor things in real-time.

These new trends show how fast hermetic packaging technology is evolving. They highlight the ongoing work in materials science and electronic design.

Restriction Analysis: Challenges in the Alsic Hermetic Packaging Market

The AlSiC hermetic packaging market faces tough challenges. These challenges test the strength of manufacturers and tech innovators. Market challenges are big obstacles in the global electronics packaging world.

Manufacturers face many critical restrictions. These restrictions affect market growth and tech progress:

- Regulatory compliance demands strict quality control standards

- Technical limitations constrain packaging design innovation

- Market competition intensifies pricing pressures

Regulatory Hurdles and Compliance Issues

The regulatory landscape is a big challenge for AlSiC hermetic packaging producers. Strict quality rules in aerospace, telecommunications, and defense sectors are needed. About 40% of manufacturers say high production costs are a big barrier to entering the market.

Technical Limitations and Manufacturing Challenges

Technical limits are a big problem in hermetic packaging development. Current research shows that 25% of existing packaging solutions are outdated. To solve this, manufacturers need to invest in new materials and precise manufacturing methods.

| Challenge Category | Impact Percentage | Primary Concern |

|---|---|---|

| Production Costs | 40% | Market Entry Barrier |

| Technological Obsolescence | 25% | Performance Limitations |

| Material Innovation | 35% | Design Constraints |

Market Competition and Pricing Pressures

Intense market competition pushes for constant innovation in AlSiC hermetic packaging. Companies must balance pricing and tech superiority.

To tackle these challenges, companies invest in R&D, form partnerships, and use new manufacturing methods. These steps help meet regulatory needs and overcome technical hurdles.

Geopolitical Analysis: How Global Politics Influence Alsic Hermetic Packaging Production and Trade

The world of AlSiC hermetic packaging is changing fast. Global politics play a big role in this change. Countries like China, the United States, and Japan are leading the way.

Geopolitical tensions have made the AlSiC hermetic packaging market more complex. Production costs have gone up by about 15%. This is because of supply chain issues and trade pressures.

Trade Policies Reshaping Market Access

International trade policies are changing the game for AlSiC hermetic packaging. Key points to consider are:

- Tariff regulations affecting material imports

- Restrictions on technology transfer

- Compliance with international manufacturing standards

“The future of AlSiC hermetic packaging lies in strategic international collaborations that transcend geopolitical boundaries.” – Industry Expert

Technology Transfer and Intellectual Property Dynamics

Intellectual property is now a big deal in technology transfer. Countries are making rules to protect new packaging tech. This affects how companies share and develop new solutions.

Strategic Partnerships and International Collaborations

Global companies are teaming up to face geopolitical challenges. These partnerships aim to:

- Mitigate supply chain risks

- Share technological expertise

- Navigate complex regulatory environments

The global market for AlSiC hermetic packaging is expected to hit $1.96 billion by 2025. This shows how important it is to keep up with changing global politics.

Segmentation Type Market Analysis: Alsic Hermetic Packaging Market Segmentation by Application

The AlSiC hermetic packaging market is very diverse. It covers important areas like aerospace, automotive electronics, and telecommunications. This diversity drives innovation and growth in advanced packaging solutions.

In 2025, the global AlSiC hermetic packaging market was worth USD 1.96 Billion. It’s expected to grow to USD 3.24 Billion by 2033. This growth shows the increasing demand in high-performance sectors.

Aerospace and Defense Applications

Aerospace applications are a key part of the hermetic packaging market. These solutions protect sensitive electronics in harsh environments. They need:

- High thermal stability

- Electromagnetic interference shielding

- Resistance to mechanical stress

- Reliability in harsh temperature conditions

Automotive Electronics

The automotive electronics segment is also important. Modern cars use complex electronic systems. They need advanced hermetic packaging for:

- Enhanced durability

- Temperature resistance

- Compact design

- Protection against vibration and environmental factors

Telecommunications and 5G Infrastructure

Telecommunications is another key segment, especially with 5G. The demand for high-performance packaging in telecommunications focuses on:

- Signal integrity preservation

- Miniaturization of components

- Advanced thermal management

- EMI shielding capabilities

The market is expected to grow at 6.47% CAGR from 2025 to 2033. This shows AlSiC hermetic packaging’s vital role in these areas.

Application Market Analysis: The Role of Alsic Hermetic Packaging in Electronic Component Protection

AlSiC hermetic packaging is key for protecting electronic parts in many high-tech fields. These advanced packaging solutions are changing how we protect electronic components.

Protecting electronic parts is very important. Companies are looking for new ways to keep parts safe from the environment and improve their performance.

Thermal Management Solutions

Keeping parts cool is vital for their reliability. AlSiC composites are great at managing heat, with a thermal conductivity of up to 126 W/(m·K). They offer:

- Precise temperature control

- Less heat-related performance loss

- Longer-lasting components

Electromagnetic Interference (EMI) Shielding

Shielding against electromagnetic interference is now more important than ever. AlSiC hermetic packaging offers strong protection against EMI. This keeps signals clear and prevents performance issues.

Environmental Protection and Reliability Enhancement

Reliability is crucial in fields like aerospace and telecom. AlSiC hermetic packaging provides excellent protection, with failure rates under 1%. The automotive industry, for example, makes up 25% of the demand, showing its wide use.

Investing in advanced packaging technologies is a smart move for long-term electronic component performance and reliability.

Even though AlSiC hermetic packaging is about 30% pricier than traditional options, its long-term benefits are worth it for industries needing high reliability.

Global Alsic Hermetic Packaging Market Region Analysis: Regional Market Trends

The global AlSiC hermetic packaging market is full of new technologies and smart investments. Different regions have their own ways of approaching this market. They show different levels of technology and strategy.

Market Size and Growth Projections

The AlSiC hermetic packaging market is expected to grow a lot. It’s set to expand because of the need for new technologies in many fields.

- Estimated global market value by 2033: $3.24 billion

- Key growth drivers: Electronics, aerospace, telecommunications

Competitive Landscape

The AlSiC hermetic packaging market is very competitive. Companies are racing to be the best with new technologies. They also form partnerships to stay ahead.

“Innovation distinguishes between a leader and a follower in the hermetic packaging market.” – Industry Expert

Investment and R&D Trends

R&D is key in the AlSiC hermetic packaging market. Companies are working hard to make better materials. They want materials that can handle heat and block electromagnetic waves well.

The market is changing fast because of new technologies and smart investments. This will keep making the AlSiC hermetic packaging market grow and change.

China Alsic Hermetic Packaging Market Analysis

The Chinese AlSiC hermetic packaging market is growing fast. This growth is thanks to government support and new technologies. China is becoming a top player in electronic packaging.

China’s AlSiC hermetic packaging sector is seeing big changes. The market is showing off its tech skills and is focusing on exports.

Government Policies and Industry Support

The Chinese government is backing the AlSiC hermetic packaging industry a lot. They have put in place several key policies, including:

- Big investments in research and development for new materials

- Tax breaks for companies making high-tech products

- Investments in the latest semiconductor packaging tech

Technological Innovations and Patent Landscape

China is leading in AlSiC hermetic packaging research thanks to new tech. The market is seeing big leaps in material science and packaging tech.

| Technology Metric | Performance Indicator |

|---|---|

| Thermal Conductivity | 200 W/mK |

| Market Penetration | 30% in Semiconductor Industry by 2025 |

| Manufacturing Adoption | 60% of Manufacturers Using AlSiC Packaging |

Export Strategies and Global Market Penetration

China’s plan for exporting AlSiC hermetic packaging is to use its tech edge and low costs. They’re aiming at the automotive and electronics sectors, which make up 75% of the market.

With its competitive prices and advanced tech, China is ready to grow its share in the global hermetic packaging market.

US Alsic Hermetic Packaging Market Analysis

The United States leads in advanced manufacturing in AlSiC hermetic packaging. It drives innovation with top technology and smart market strategies. The US has a strong system of research, development, and use in industry. This system sets high standards for precision engineering worldwide.

Advanced Manufacturing Capabilities and Industry 4.0 Integration

The US is known for its advanced technology in hermetic packaging production. Key advancements include:

- Precision manufacturing techniques with micron-level accuracy

- Implementation of smart manufacturing technologies

- Real-time monitoring and quality control systems

- Advanced material processing capabilities

Defense and Aerospace Market Drivers

The defense market is a key area for growth in AlSiC hermetic packaging. It includes:

- Aerospace electronic component protection

- Military-grade sensor packaging

- High-reliability communication systems

| Technology Parameter | Performance Metric |

|---|---|

| Thermal Conductivity | 126 W/(m·K) |

| Coefficient of Thermal Expansion | 13 × 10−6·K−1 |

| Composite Density | 2.53 g/cm³ |

Collaboration between Industry and Academia

The US thrives on industry-academia collaboration. This creates a strong innovation pipeline. Schools like MIT, Stanford, and CalTech team up with top manufacturers. Together, they develop new materials and processes for better hermetic packaging.

The synergy between academic research and industrial application defines the US approach to advanced manufacturing in hermetic packaging.

Japan Alsic Hermetic Packaging Market Analysis

Japan leads in advanced manufacturing, especially in AlSiC hermetic packaging. Its focus on quality and innovation makes it a top player worldwide. It excels in protecting electronic components and developing new materials.

The Japan market analysis shows great success in hermetic packaging tech. Sumitomo Electric Corporation has made an Al-40 wt.% Si composite. It has impressive technical specs:

- Coefficient of Thermal Expansion: 13 × 10−6·K−1

- Thermal Conductivity: 126 W/(m·K)

- Density: 2.53 g/cm³

High-Quality Manufacturing and Quality Control Processes

Japanese makers are top in precision engineering. They follow strict quality control, setting global standards. Attention to microscopic details is key to their success. Techniques like ball milling help optimize materials.

“Precision is not just a method, it’s a cultural commitment in Japanese manufacturing.” – Industry Expert

Automotive and Consumer Electronics Applications

Automotive uses are a big growth area for AlSiC in Japan. It helps with advanced car electronics, managing heat and shielding from electromagnetic interference.

Sustainability Initiatives and Green Manufacturing

Japan is serious about being green in manufacturing. It’s working to reduce environmental harm through new, eco-friendly methods. These methods cut down on waste and energy use.

Research shows ball milling can boost material quality while being eco-friendly. It shows how to balance performance with caring for the planet.

Future Development Analysis: The Future of Alsic Hermetic Packaging in Advanced Electronics

The world of advanced electronics is changing fast. AlSiC hermetic packaging is leading the way in new tech. It’s becoming key for new technologies.

AlSiC hermetic packaging is linked to many new technologies. These include:

Emerging Applications in Internet of Things (IoT) Devices

IoT devices are growing fast. AlSiC hermetic packaging helps them work better. By 2026, 40% of devices will use this tech.

- Enhanced reliability with failure rates below 1%

- Superior thermal management capabilities

- Extended component lifespan of approximately 15 years

Advancements in 5G and 6G Technologies

5G is changing what we need from electronics. AlSiC packaging is great for it. It’s 50% better at handling heat than old ceramic.

Integration with Artificial Intelligence and Machine Learning Systems

AI needs special packaging. AlSiC materials are perfect. They handle heat and stress well.

As tech gets better, AlSiC packaging will keep helping. It’s important for many areas like aerospace and cars.

Competitor Analysis: Key Players in the Alsic Hermetic Packaging Market

The AlSiC hermetic packaging market is always changing. It’s filled with new technologies and fierce competition. Companies from China, the US, and Japan are leading the way with smart strategies and new tech.

- AVX Corporation – United States

- Murata Manufacturing – Japan

- Bourns – United States

- Kyocera – Japan

- Rohm Semiconductor – Japan

- TAIYO YUDEN – Japan

- TDK – Japan

- NIC Components – United States

- Vishay Intertechnology – United States

- Samsung Electro-Mechanics – South Korea

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global AlSiC Hermetic Packaging Market Report |

| Base Year | 2024 |

| Segment by Type |

· SiC: 5%-30% · SiC: 35%-50% · SiC: 55%-70% |

| Segment by Application |

· Power Electronics · Communication Base Station |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The AlSiC hermetic packaging market is growing fast, with big chances in the global electronics world. It’s expected to grow by 15% every year from 2025 to 2035. This growth is driven by more use in semiconductor packaging.

Technological progress in aerospace, automotive, and telecom is key. China leads with 40% of the market, followed by the United States with 30%, and Japan with 20%.

Companies need to watch out for risks in tech and global politics. The use of AlSiC in semiconductors is set to jump from 25% to 40% by 2026. This shows a lot of promise.

Investing in R&D, especially in 5G and IoT, is advised. AlSiC packages perform well in hot conditions, with a reliability rate over 95%. To succeed, companies should team up, innovate, and stay flexible.

Global Alsic Hermetic Packaging Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Alsic Hermetic Packaging Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Alsic Hermetic PackagingMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Alsic Hermetic Packaging players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Alsic Hermetic Packaging Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Alsic Hermetic Packaging Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Alsic Hermetic Packaging Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofAlsic Hermetic Packaging Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is AlSiC Hermetic Packaging?

AlSiC Hermetic Packaging is a top-notch way to protect sensitive electronics. It uses sealed containers to keep out moisture, gases, and dirt. This keeps the electronics safe and working well.

Why is AlSiC Hermetic Packaging important in different industries?

It’s key in aerospace, defense, cars, and phones. It helps manage heat, block bad signals, and protect against the environment. This is crucial for electronics that need to work reliably.

How are China, the US, and Japan leading in AlSiC Hermetic Packaging technology?

China supports innovation with the government. The US uses advanced manufacturing and defense knowledge. Japan is known for quality and car electronics.

What are the key challenges in AlSiC Hermetic Packaging production?

Making it is hard due to rules, size limits, new materials, and keeping costs down. It’s also tough to manage global supply chains.

How do geopolitical factors impact the AlSiC Hermetic Packaging market?

Trade rules, patents, and tech sharing affect the market. Partnerships and rules shape who can sell and innovate in the global market.

What emerging technologies are driving AlSiC Hermetic Packaging innovation?

New tech like IoT, 5G, AI, and machine learning push packaging to new levels. They need better, more reliable packaging to work well.

What makes AlSiC Hermetic Packaging different from traditional packaging methods?

It’s better at handling heat, shielding signals, and withstanding tough conditions. It’s stronger and more reliable than old methods.

How is sustainability affecting the AlSiC Hermetic Packaging industry?

Countries like Japan are going green. They’re making production more eco-friendly and using sustainable materials. This cuts down on pollution.

What industries benefit most from AlSiC Hermetic Packaging?

Aerospace, defense, cars, phones, medical devices, and industrial systems all benefit. They need protection for their electronics.

What future applications are anticipated for AlSiC Hermetic Packaging?

It will be used in IoT, 5G, AI, self-driving cars, and medical implants. These need top-notch protection against the environment.