2025 AlSiC IGBT Substrates Market Growth: USA, Japan, and Germany Leading the Way Worth $1.93 Billion

Explore the AlSiC IGBT substrates market trends, growth, and key applications in power electronics, electric vehicles, and renewable energy systems.

- Last Updated:

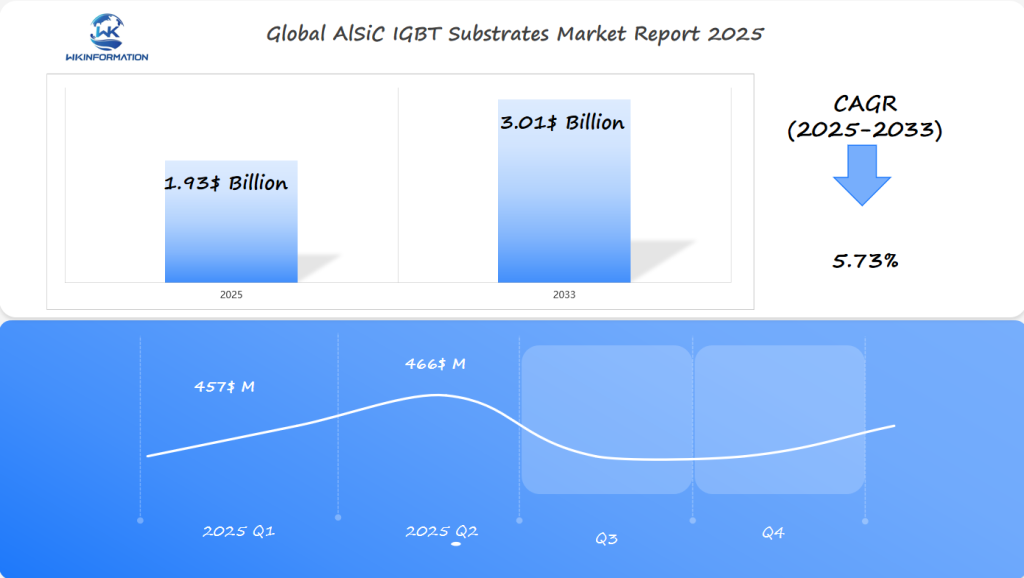

Market Forecast for AlSiC IGBT Substrates in 2025: Q1 and Q2 Predictions

The AlSiC IGBT Substrates market is forecast to reach $1.93 billion in 2025, with a CAGR of 5.73% from 2025 to 2033. In Q1, the market is expected to generate around $457 million, while Q2 is likely to see a slight increase to approximately $466 million. This growth is driven by rising demand in the electric vehicle (EV) sector, power electronics, and renewable energy industries. The USA, Japan, and Germany are expected to lead the charge in 2025, as these countries continue to make advancements in energy-efficient technologies and electric mobility solutions, significantly contributing to the overall market expansion.

With governments worldwide pushing for cleaner energy and emission reductions, the demand for high-performance substrates used in power modules for EVs and renewable energy solutions is expected to surge. Furthermore, technological advancements in silicon carbide (SiC) and AlSiC composite materials are anticipated to increase substrate efficiency, adding to the overall market growth in the coming years.

Key Takeaways

- Projected market value of $1.93 billion by 2025

- USA, Japan, and Germany driving technological innovation

- Significant growth in electric vehicle manufacturing

- Renewable energy sector expanding market potential

- Stringent emission regulations accelerating market development

- Strong focus on sustainable energy solutions

- Increasing investments in advanced power electronics

Exploring the Upstream and Downstream Dynamics of the AlSiC IGBT Substrates Market

AlSiC IGBT substrates play a key role in power electronics, particularly in sectors like electric vehicles and renewable energy. The upstream market is influenced by the availability and cost of raw materials like aluminum and silicon carbide, driving innovation in substrate production as demand for high-performance devices grows.

Downstream, the use of AlSiC IGBT substrates is expanding in industries that require efficient power electronics, such as automotive and industrial sectors. As demand for energy-efficient solutions increases, the need for these substrates rises, encouraging advancements in device design and boosting market opportunities.

Key Trends in the AlSiC IGBT Substrates Market in 2025

The AlSiC IGBT substrates market is changing fast. New technologies and more uses are driving these changes. This is making a big impact on power electronics and semiconductors.

Technological Advancements Driving Market Growth

New tech is pushing the AlSiC IGBT substrates market to grow fast. Companies are working on better ways to manage heat and improve electrical performance.

- Enhanced heat dissipation capabilities

- Improved electrical conductivity

- Miniaturization of substrate designs

- Advanced material composition techniques

Increasing Demand in Electric Vehicle Manufacturing

Electric cars are a big reason for the growth of AlSiC IGBT substrates. The car industry needs better power management to make cars more efficient.

Things to consider for electric cars include:

- Optimized thermal performance

- Compact substrate designs

- Higher power density requirements

- Improved reliability under extreme conditions

Expansion of Renewable Energy Sector

Renewable energy is also boosting the demand for AlSiC IGBT substrates. Solar and wind power need better materials to work more efficiently.

The use of AlSiC substrates in renewable energy is a big step forward in power electronics.

Restrictions and Challenges in the AlSiC IGBT Substrates Market

The AlSiC IGBT substrates market is facing big challenges. These challenges test the strength of manufacturers and tech developers. The production complexities are a big barrier to using these advanced parts widely.

Key challenges in the AlSiC IGBT substrates market include:

- Extremely high production costs that limit market penetration

- Technical difficulties in achieving precise thermal conductivity

- Complex manufacturing processes requiring specialized expertise

- Competitive pressures from alternative semiconductor technologies

Manufacturers must deal with tough technical issues while keeping costs down. They need to balance thermal performance with electrical insulation. Thermal management is a big challenge in substrate development, with engineers always looking for new ways to solve material problems.

There’s also competition from new technologies like silicon carbide and gallium nitride. These alternatives offer good performance at lower costs, making things harder for the market.

The true innovation in AlSiC IGBT substrates lies not just in overcoming technical challenges, but in creating economically viable solutions.

Research and development teams are working hard to solve these challenges. They aim to make AlSiC IGBT substrates more efficient and affordable. This will help them compete in the fast-changing power electronics industry.

Geopolitical Impact on the AlSiC IGBT Substrates Industry

The AlSiC IGBT substrates industry is changing fast because of global politics. The way goods move around the world is getting more complicated. Trade rules are changing the world of semiconductors. International conflicts are making companies rethink where they make and buy things.

Key geopolitical influences impacting the market include:

- Shifting trade regulations between major economic powers

- Regional market regulations affecting semiconductor production

- Strategic realignment of global supply chain networks

- Technological sovereignty initiatives

The COVID-19 pandemic showed how weak the semiconductor supply chains were. It made companies want to make things in more places. They’re trying to not rely on just one supplier.

Market rules are getting stricter. Governments are making laws to help their own semiconductor industries. Geopolitical strategies now directly influence technology development and market access for AlSiC IGBT substrate manufacturers.

The future of the AlSiC IGBT substrates industry will be defined by strategic adaptability and global collaboration.

Types of AlSiC IGBT Substrates and Their Technological Advances

The AlSiC IGBT substrates market is always changing. New material innovations are making power electronics better. Engineers and researchers are working hard to create advanced substrate technologies.

Modern substrate technologies are key in electronic component design. They offer better thermal management and electrical performance.

Thick Film AlSiC Substrates

Thick film substrates are great for high-power applications. They are strong and work well in:

- Industrial machinery power systems

- High-performance automotive electronics

- Extreme environment electrical components

“Thick film substrates provide unparalleled durability in challenging operational conditions,” says leading materials engineering expert Dr. Sarah Chen.

Thin Film AlSiC Substrates

Thin film substrates are a big step forward in miniaturization. Material innovations have made them very good for:

- Compact electronic devices

- Precision sensor technologies

- Advanced medical electronics

Emerging Hybrid Technologies

New hybrid technologies are mixing different materials. This is creating next-generation solutions with:

- Enhanced thermal conductivity

- Improved electrical insulation

- Superior mechanical strength

These new ideas are changing AlSiC IGBT substrate development. They promise more efficient and versatile electronic components.

Applications of AlSiC IGBT Substrates in Power Electronics and Electric Vehicles

AlSiC IGBT substrates are changing the game in power electronics. They are key in electric vehicle technology, offering top-notch thermal management and energy efficiency.

These substrates are used in many important areas:

- Electric vehicle powertrain systems

- High-performance industrial motor drives

- Renewable energy conversion equipment

- Advanced power electronics modules

In electric vehicles, they make a big difference. K. Hamada’s 2008 research shows how they boost energy efficiency with better semiconductor design.

| Application Area | Performance Benefit |

| Electric Vehicle Inverters | Improved Power Density |

| Traction Systems | Enhanced Thermal Management |

| Power Electronics Modules | Higher Energy Efficiency |

Companies like Littelfuse and Semikron show how these substrates work in real products. The SKiM429GD17E44F module is a top example of AlSiC’s power.

D. Zheng et al. (2020) keep proving these substrates are reliable and perform well in high-current uses. This makes them even more important in today’s tech world.

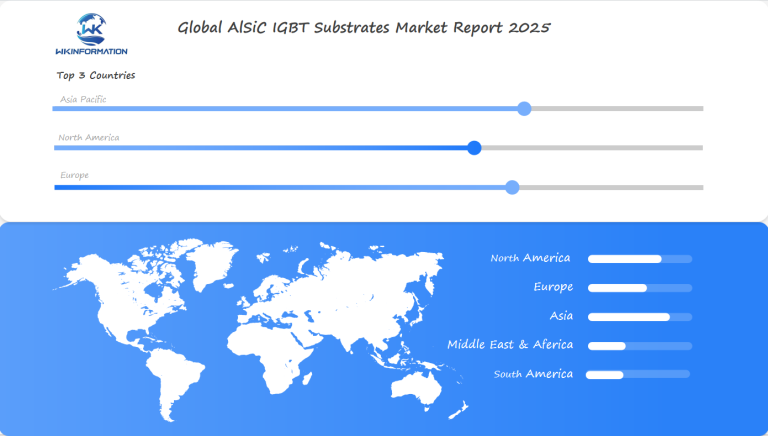

Global Market Insights: AlSiC IGBT Substrates Market Performance Worldwide

The global market for AlSiC IGBT substrates is changing a lot in 2025. An analysis shows a lively scene with big changes in who leads in different tech areas.

Asia Pacific is now the top player in the AlSiC IGBT substrates market. Its fast growth comes from strong car and industrial making scenes. Countries like China, Japan, and South Korea are key players.

- China: Leading electric vehicle production

- Japan: Advanced semiconductor technology development

- South Korea: High-tech industrial automation

But, other regions are growing too. North America and Europe are seeing steady growth, especially in power electronics and green energy. Technological innovation is driving this growth.

Investments in research and development are key to the AlSiC IGBT substrates market. Companies are working hard to make these products better. They want to meet the needs of today’s industries.

USA AlSiC IGBT Substrates Market: Trends, Opportunities, and Innovations

The United States is leading in AlSiC IGBT substrates technology. Companies like Wolfspeed, Infineon, and STmicro are pushing the limits with new semiconductor tech changing power electronics.

USA market trends show exciting changes in wide bandgap semiconductors. The market is growing fast, thanks to key sectors:

- Electric vehicle manufacturing

- Renewable energy systems

- High-performance data centers

New tech is changing power electronics. Companies are working on better semiconductor substrates. These offer:

- Improved thermal management

- Less energy loss

- Better reliability

US makers have a big edge with cutting-edge semiconductor solutions. Companies like Littelfuse and Semikron are tackling tough power electronics problems with new substrate tech.

Even with manufacturing emissions, AlSiC IGBT substrates are a smart choice for forward-thinking industries. They promise big carbon savings.

Japan AlSiC IGBT Substrates Market: Market Forecasts and Key Developments

The Japan market forecast for AlSiC IGBT substrates shows great promise. Japanese companies are at the forefront of innovation. They create new substrate designs that change how we use power in cars and factories.

Mitsubishi Electric is a major player in the automotive sector. They have made big strides in substrate technology:

- J3 series power modules with SiC-MOSFETs and RC-IGBT

- Compact design for 50kW to 300kW power range

- 16% smaller module size with new chip technologies

The advancements in Japan’s IGBT substrate market are truly remarkable. The SLIMDIP series is a great example. It’s 30% smaller than before but still performs well.

| Product Series | Key Features | Power Range |

| J3 Series | Compact design, multi-functional Si chip | 50-300 kW |

| SLIMDIP Series | 30% size reduction, 7th generation IGBT | Varied industrial applications |

The Japanese market is always looking to improve substrate technology. They focus on making things smaller, more efficient, and better performing. This makes Japan a key player in the global AlSiC IGBT substrates market.

Germany AlSiC IGBT Substrates Market: Key Trends and Innovations

The German market for AlSiC IGBT substrates is growing fast. This is thanks to new technologies and a strong focus on the automotive industry. Germany is leading the way in making advanced power electronics, thanks to its focus on renewable energy.

Several trends are shaping the Germany market trends:

- Accelerated electric vehicle production

- Increased investment in technological innovations

- Robust research and development infrastructure

- Sustainable energy transformation initiatives

The automotive industry has a big impact. German car makers are making high-performance AlSiC IGBT substrates. These substrates help electric vehicles use energy better and manage power well. Research institutions like Fraunhofer and technical universities are driving breakthrough developments in substrate technologies.

As the renewable energy sector grows, so does the need for advanced substrates. German companies are making special AlSiC IGBT substrates. These substrates can handle tough conditions and keep things cool.

“Germany’s innovative approach to power electronics is reshaping global substrate technology,” says a leading industry analyst.

Investments and government support are helping the AlSiC IGBT substrate market grow. The market is expected to see a lot of growth. This will happen thanks to focused research and partnerships between industries.

What's Next for the AlSiC IGBT Substrates Market in 2025?

The AlSiC IGBT substrates market is on the verge of big changes. Experts say we will see huge growth thanks to new tech in power electronics and renewable energy.

Experts predict big leaps in how these substrates work and where they’re used. We can expect:

- Better heat management

- Use with new semiconductor tech

- More use in electric cars

- New uses in power electronics

Experts say new tech will be key to the market’s growth. They expect big steps forward in materials, heat handling, and how semiconductors work together.

“The AlSiC IGBT substrates market represents a pivotal technology with transformative potential across multiple industries,” notes Dr. Elena Rodriguez, leading research analyst in advanced materials.

Competitive Landscape of the AlSiC IGBT Substrates Market

Key players:

-

CPS Technologies —— USA

-

Denka —— Japan

-

Japan Fine Ceramic —— Japan

-

MC-21, Inc. —— USA

-

BYD —— China

-

Xi’an Jingyi Technology —— China

-

SITRI Material Tech —— China

-

Xi’an Chuangzheng New Materials —— China

-

Xi’an Fadi Composite Materials —— China

-

Hunan Harvest Technology Development —— China

Overall

| Report Metric | Details |

| Report Name | Global AlSiC IGBT Substrates Market Report |

| Base Year | 2024 |

| Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

AlSiC IGBT substrates have changed the game in power electronics. They offer top-notch performance in many fields. These materials are a big step forward, making systems more efficient and powerful.

They help manage power and heat better than before. This is thanks to wide-bandgap semiconductor tech. It’s a game-changer for electronic systems.

AlSiC IGBT substrates do more than just improve power electronics. They make systems smaller and more efficient. This leads to less need for cooling and fewer parts.

Studies show they cut down on carbon emissions a lot. In the U.S., they help reduce emissions by tens of millions of tonnes each year.

These substrates are especially good for renewable energy, cars, and factories. They let systems switch faster and work better. This leads to greener, more efficient tech.

Using AlSiC IGBT substrates is a big deal for semiconductors. They push the limits of what’s possible in power electronics. This means better performance, efficiency, and care for the planet in tech.

Global AlSiC IGBT Substrates Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: AlSiC IGBT Substrates Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- AlSiC IGBT Substrates MarketSegmentation Overview

Chapter 2: Competitive Landscape

- Global AlSiC IGBT Substrates players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: AlSiC IGBT Substrates Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: AlSiC IGBT Substrates Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: AlSiC IGBT Substrates Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofAlSiC IGBT Substrates Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are AlSiC IGBT substrates?

AlSiC IGBT substrates are advanced parts in power electronics. They mix aluminum and silicon carbide. This mix helps manage heat well and works better with electricity for high-power uses.

What is the projected market value for AlSiC IGBT substrates by 2025?

The market is expected to hit $1.93 billion by 2025. Growth will come from the U.S., Japan, and Germany.

Which industries are primarily using AlSiC IGBT substrates?

Main users are the automotive, renewable energy, and industrial automation sectors. Also, electric vehicle makers and power electronics use them.

What are the key advantages of AlSiC IGBT substrates?

They have better heat management, electrical performance, and strength. They also use less energy than older materials.

How are AlSiC substrates impacting electric vehicle technology?

They help manage heat and improve power use in electric vehicles. This is especially true for inverters and power modules, boosting vehicle performance.

What challenges exist in AlSiC IGBT substrate production?

Challenges include handling production complexity and balancing heat and electricity. Keeping costs down and competing with SiC and GaN are also hurdles.

What types of AlSiC substrates are currently available?

The market has thick and thin film substrates. New hybrid technologies are emerging. They mix material benefits for better components.

How are geopolitical factors influencing the AlSiC IGBT substrates market?

Trade policies, regulations, and global events like COVID-19 are shaping the market. They push for local production and supplier diversity.

What regions are leading in AlSiC IGBT substrate innovation?

The U.S., Japan, and Germany lead. They have strong automotive sectors, tech innovation, and R&D investments.

What future developments are expected in AlSiC IGBT substrates?

Future advancements include better heat management and working with wide bandgap semiconductors. New uses and focus on energy and sustainability are also expected.