Amorphous Motor Market to Hit $2.17 Million by 2025: Energy Efficiency in the U.S., China, and Japan

Discover insights into the amorphous motor market’s evolution through 2025, exploring innovations in energy-efficient motors for automotive and industrial applications. This comprehensive analysis covers market trends, technological advancements, and future projections in the rapidly growing sector of energy-efficient motor solutions.

- Last Updated:

Amorphous Motor Market Outlook for Q1 and Q2 2025

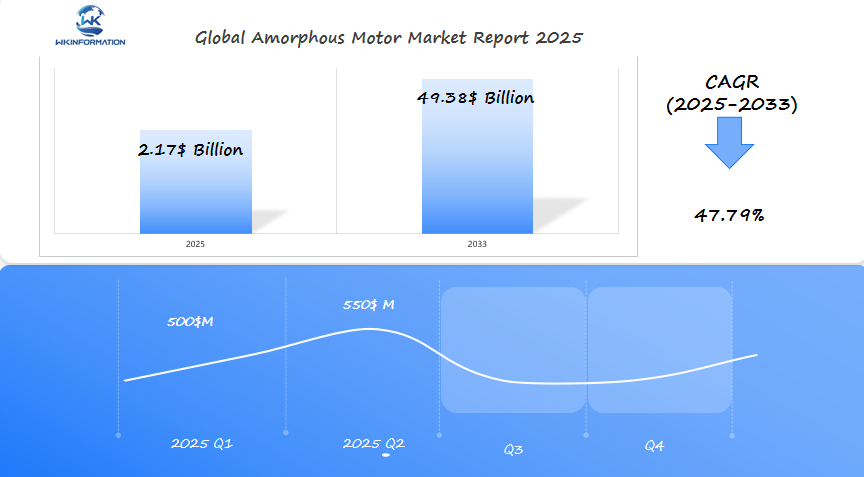

The Amorphous Motor market is expected to reach $2.17 billion in 2025, with an astonishing CAGR of 47.79% from 2025 to 2033. In Q1 2025, the market is expected to be valued at $500 million, as amorphous motors—characterized by their high energy efficiency and low power consumption—begin to gain traction in the U.S., China, and Japan. These motors are particularly attractive for applications in renewable energy and low-energy consumption industries.

By Q2 2025, the market is projected to grow to $550 million, with China and Japan leading the demand for energy-efficient technologies in industrial applications. The U.S. is also seeing a rise in interest from sectors focused on green energy solutions. The rapid growth in demand for advanced, energy-saving technologies will continue to propel this market forward.

Key Takeaways

- The amorphous motor industry is expected to grow significantly by 2025.

- Energy efficiency is a key driver of this growth.

- The U.S., China, and Japan are leading the way in adopting energy-efficient technologies.

- The market is driven by the increasing demand for sustainable solutions.

- The amorphous motor industry is projected to reach $2.17 million by 2025.

Amorphous Motor Upstream and Downstream Industry Chain Analysis

Understanding the upstream industry chain of amorphous motors is essential for analyzing the market’s dynamics and identifying key factors that influence its growth. The amorphous motor industry chain is a complex network that involves various stakeholders, including raw material suppliers, manufacturers, and distributors.

Upstream industry chain analysis

The upstream industry chain analysis of amorphous motors involves examining the raw material suppliers and other stakeholders that contribute to the production of these motors. Raw materials such as iron, copper, and other metals are crucial for the production of amorphous motors.

Raw material suppliers

Raw material suppliers play a vital role in the amorphous motor industry chain. The availability and cost of raw materials such as iron and copper can significantly impact the production costs and pricing of amorphous motors. Some of the key raw material suppliers for amorphous motors include:

- Iron and steel producers

- Copper manufacturers

- Other metal suppliers

The quality and pricing of raw materials can vary depending on several factors, including global demand, supply chain disruptions, and trade policies. Therefore, it is essential for amorphous motor manufacturers to establish strong relationships with reliable raw material suppliers to ensure a stable supply chain.

Furthermore, the upstream industry chain analysis also involves examining the manufacturing processes and technologies used by amorphous motor manufacturers. Advances in manufacturing technologies can lead to improved efficiency, reduced costs, and enhanced product quality.

Growing demand for energy-efficient motors in industrial applications

As industries work towards reducing their carbon footprint, energy-efficient motors are becoming more popular. The use of energy-efficient motors in industrial applications is becoming increasingly important, driven by the need to minimize energy consumption and reduce operating costs.

Energy-efficient motors are being used in various industrial applications, such as manufacturing processes and equipment. These motors offer several benefits, including reduced energy consumption, lower operating costs, and increased reliability.

Industrial applications of energy-efficient motors

Energy-efficient motors are being used in a range of industrial applications, including:

- Pumps and fans

- Compressors and blowers

- Material handling equipment

- HVAC systems

These motors are designed to provide high efficiency and reliability, while minimizing energy consumption. By adopting energy-efficient motors, industries can reduce their energy costs, lower their carbon footprint, and improve their overall competitiveness.

The benefits of using energy-efficient motors in industrial applications are numerous. Some of the key advantages include:

- Reduced energy consumption

- Lower operating costs

- Increased reliability

- Improved competitiveness

By adopting energy-efficient motors, industries can achieve significant cost savings and reduce their environmental impact. As the demand for energy-efficient motors continues to grow, manufacturers are responding by developing innovative solutions that meet the needs of industrial applications.

Challenges in manufacturing costs, material availability, and performance optimization

As the demand for amorphous motors continues to grow, manufacturers are faced with the task of overcoming challenges related to production costs, material sourcing, and performance enhancement. The amorphous motor market is driven by the need for energy-efficient solutions, but several factors hinder its growth.

Manufacturing costs and material availability

The production of amorphous motors involves high manufacturing costs due to the complex process of creating amorphous magnetic materials. The cost of raw materials, such as iron and other metals, can fluctuate, affecting the overall production cost. Moreover, the availability of these materials can be limited, leading to supply chain disruptions.

Key factors contributing to high manufacturing costs include:

- Limited economies of scale due to relatively low production volumes

- High cost of raw materials and processing

- Complex manufacturing processes requiring specialized equipment

To mitigate these challenges, manufacturers are exploring alternative materials and production methods. For instance, some companies are developing new amorphous magnetic materials that are more cost-effective and easier to process.

Performance optimization techniques

Performance optimization is critical to the success of amorphous motors. Techniques such as design improvements and material advancements can significantly enhance the efficiency and reliability of these motors.

Some performance optimization techniques include:

- Optimizing motor design to minimize energy losses

- Using advanced materials with improved magnetic properties

- Implementing advanced manufacturing techniques to reduce defects

By adopting these techniques, manufacturers can improve the performance and efficiency of amorphous motors, making them more competitive in the market.

Geopolitical factors affecting the adoption of green technologies

Geopolitical factors, including government policies, have a profound impact on the development and adoption of green technologies. The interaction between geopolitics and green technologies is complex, involving various stakeholders, interests, and regulatory frameworks.

The adoption of green technologies, such as amorphous motors, is influenced by government policies and regulations that either promote or hinder their development and deployment. For instance, government incentives, tax credits, and subsidies can encourage the adoption of energy-efficient technologies, while stringent regulations and standards can drive innovation and compliance.

Government policies and regulations

Government policies and regulations play a crucial role in shaping the market for green technologies. In the United States, for example, government initiatives and policies aimed at reducing carbon emissions and promoting energy efficiency have led to increased demand for amorphous motors and other energy-efficient technologies.

Key government policies influencing green technologies include:

- Incentives and tax credits: Governments offer financial incentives to encourage the adoption of green technologies.

- Regulatory frameworks: Governments establish standards and regulations that govern the development and deployment of green technologies.

- Research and development funding: Governments invest in R&D to advance the development of green technologies.

The impact of geopolitical factors on the adoption of green technologies is multifaceted. Geopolitical tensions can disrupt supply chains, influence trade policies, and affect the global economy, all of which can have a ripple effect on the development and deployment of green technologies.

Understanding these factors is crucial for stakeholders, including businesses, policymakers, and consumers, to navigate the complex landscape of green technologies.

Segmentation by motor type and power rating

Motor type and power rating are key factors that segment the amorphous motor market, enabling manufacturers to cater to diverse customer needs. The amorphous motor market can be broadly classified into different segments based on these factors.

Motor Type Segmentation

The amorphous motor market is segmented into various motor types, including single-phase and three-phase motors.

Single-phase Motors

Single-phase motors are widely used in applications where the power supply is limited.

Three-phase Motors

Three-phase motors are used in industrial applications where high power is required.

The demand for single-phase motors is increasing due to their energy efficiency and cost-effectiveness. Three-phase motors, on the other hand, are preferred in applications where high torque and reliability are essential.

The amorphous motor market is also segmented based on power rating, which ranges from low to high power ratings.

Low Power Rating Motors

Low power rating motors are used in applications such as HVAC systems and household appliances.

High Power Rating Motors

High power rating motors are used in industrial equipment and heavy machinery.

The demand for low power rating motors is increasing due to their energy efficiency and compact design. High power rating motors, on the other hand, are preferred in applications where high power and reliability are critical.

Key applications in industrial equipment, HVAC systems, and energy storage

Amorphous motors offer a promising solution for reducing energy consumption in HVAC systems and industrial applications. Their unique properties make them an attractive choice for various industries.

Industrial equipment applications

Amorphous motors are used in various industrial equipment, including pumps, fans, and conveyor systems. Their high efficiency and reliability make them ideal for applications where energy consumption is a significant concern.

The use of amorphous motors in industrial equipment can lead to significant energy savings, reduced maintenance costs, and increased productivity. For instance, a study found that using amorphous motors in industrial applications can result in energy savings of up to 30%.

| Industry | Application | Energy Savings |

| Manufacturing | Pumps and fans | 25% |

| Processing | Conveyor systems | 30% |

HVAC systems and energy storage applications

In addition to industrial equipment, amorphous motors are also used in HVAC systems and energy storage applications. Their high efficiency and reliability make them an attractive choice for these applications.

In HVAC systems, amorphous motors can help reduce energy consumption and improve overall system performance. In energy storage applications, amorphous motors can help improve the efficiency of energy storage systems, such as batteries and flywheels.

The growing demand for energy-efficient solutions is driving the adoption of amorphous motors in various industries. As technology continues to evolve, we can expect to see even more innovative applications of amorphous motors in the future.

Regional growth trends in energy efficiency adoption

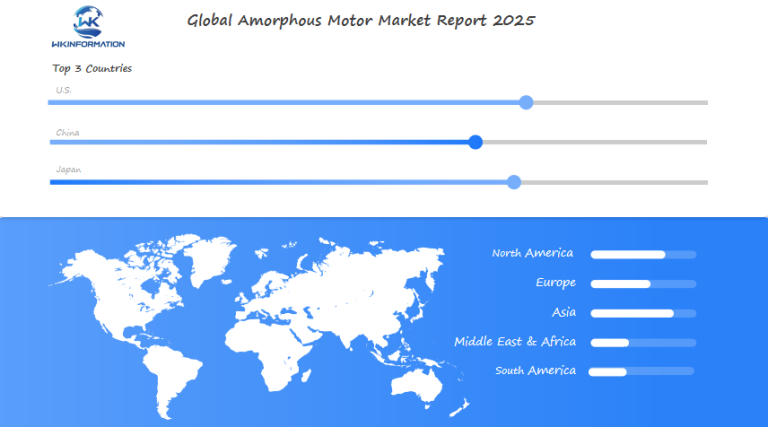

The amorphous motor market is driven by regional growth trends in energy efficiency adoption. As the world shifts towards more sustainable and energy-efficient technologies, different regions are showing distinct growth patterns.

North America

North America is currently experiencing significant growth in the adoption of energy-efficient motors. This can be attributed to government incentives and regulations that promote green technologies. The United States, in particular, is a key market for amorphous motors, with a rising demand in industrial applications.

Regional analysis of energy efficiency adoption

Europe

In Europe, the emphasis on reducing carbon emissions is driving the demand for energy-efficient motors. Countries like Germany and the UK are at the forefront of adopting green technologies, including amorphous motors, in their industrial sectors.

Asia-Pacific

The Asia-Pacific region is also experiencing rapid growth in energy efficiency adoption, with countries like China and Japan leading the charge. China’s focus on reducing energy consumption and promoting sustainable technologies is driving the demand for amorphous motors.

Other regions

In contrast, regions with less stringent environmental regulations are slower in adopting energy-efficient technologies. However, as global awareness about climate change and energy conservation grows, these regions are also expected to follow suit.

The regional differences in energy efficiency adoption are influenced by factors such as government policies, economic conditions, and technological advancements. Understanding these regional growth trends is crucial for manufacturers and suppliers of amorphous motors to tailor their strategies and capitalize on emerging opportunities.

U.S. Government Incentives for Energy-Efficient Technologies and Motor Systems

The U.S. government offers various incentives to encourage the development and use of energy-efficient motor systems. These incentives are designed to promote the adoption of energy-efficient technologies, reduce energy consumption, and mitigate environmental impacts.

The government initiatives include tax credits, grants, and loan programs that support manufacturers, consumers, and industries in adopting energy-efficient motor systems. For instance, the Energy Star program, launched by the U.S. Environmental Protection Agency (EPA), recognizes and promotes energy-efficient products, including motors and motor systems.

Some of the key government incentives and policies that support energy-efficient motor systems include:

- Tax credits for manufacturers and consumers who invest in energy-efficient motor systems

- Grants and funding opportunities for research and development of new energy-efficient motor technologies

- Loan programs that provide financial assistance to businesses and industries adopting energy-efficient motor systems

Government incentives and policies

Government incentives and policies have a significant impact on the market, driving the demand for energy-efficient motor systems. By providing financial support and recognition to manufacturers and consumers, the government encourages the development and adoption of energy-efficient technologies.

The benefits of these incentives are multifaceted:

- For manufacturers, government incentives can help offset the costs associated with developing and producing energy-efficient motor systems.

- For consumers, these incentives can make energy-efficient motor systems more affordable and accessible.

As the U.S. government continues to promote energy-efficient technologies, the demand for energy-efficient motor systems is expected to grow. This trend is likely to drive innovation, reduce energy consumption, and contribute to a more sustainable future.

China's push for energy efficiency in manufacturing and industrial growth

China is driving innovation in its industrial sectors with a strong commitment to reducing energy consumption. The country’s focus on energy efficiency is reshaping its manufacturing landscape, which has significant implications for the motor market.

China’s energy efficiency initiatives involve a range of policies, regulations, and technological innovations. The government has implemented various measures to promote energy-efficient practices, including incentives for industries that adopt green technologies.

China’s energy efficiency initiatives

One of the key initiatives is the development of energy-efficient motors, including amorphous motors. These motors offer significant energy savings and are being increasingly adopted in various industrial applications.

The Chinese government has also launched several programs to promote the use of energy-efficient technologies, including tax incentives, subsidies, and low-interest loans. These initiatives have encouraged industries to invest in energy-efficient solutions, driving growth in the amorphous motor market.

A key aspect of China’s energy efficiency drive is the focus on industrial applications. The country is promoting the use of energy-efficient motors in various industries, including manufacturing, textiles, and chemicals.

The growth prospects for the amorphous motor market in China are significant, driven by the government’s commitment to energy efficiency and the increasing demand for energy-efficient technologies.

Key benefits of China’s energy efficiency initiatives include:

- Increased adoption of energy-efficient technologies

- Improved energy savings

- Reduced greenhouse gas emissions

- Enhanced competitiveness of Chinese industries

As China’s energy efficiency initiatives continue to evolve, the amorphous motor market is likely to play an increasingly important role in the country’s industrial growth.

Japan’s Technological Advancements in Energy-Saving Motor Solutions

Japan’s commitment to reducing energy consumption has led to significant advancements in motor technology, particularly in amorphous motors. The country’s strong focus on innovation and technological development has enabled the creation of energy-efficient motor solutions that are crucial for various industrial applications.

Development of Amorphous Motors

One of the key areas where Japan has made significant contributions is in the development of amorphous motors. These motors use amorphous metal alloys in their cores, which significantly reduces energy losses due to their unique magnetic properties. The result is a more efficient motor that consumes less energy while maintaining or even improving performance.

Japan’s technological advancements

Japan’s technological advancements in energy-saving motor solutions are driven by a combination of government support, research and development investments, and collaboration between industry players. The government has implemented policies and regulations that encourage the development and adoption of energy-efficient technologies, including amorphous motors.

The advancements in motor technology have not only improved the efficiency of industrial equipment but also contributed to the development of more sustainable and environmentally friendly technologies. As the demand for energy-efficient solutions continues to grow, Japan’s technological advancements in this area are expected to play a crucial role in shaping the future of the motor industry.

Key benefits of Japan’s technological advancements include improved energy efficiency, reduced energy consumption, and enhanced performance of motor systems. These benefits are expected to drive the adoption of amorphous motors and other energy-efficient technologies in various industries, contributing to a more sustainable future.

Innovations in Amorphous Motor Design and Magnetic Materials

Amorphous motor design and magnetic materials are undergoing significant transformations, driving market growth. The amorphous motor market is driven by innovations in motor design and magnetic materials, leading to improved performance and efficiency.

Advances in Amorphous Motor Design

Recent advancements in amorphous motor design have led to the development of more efficient and compact motors. These advancements have been driven by the need for energy-efficient solutions in various industries, including industrial equipment, HVAC systems, and energy storage.

Key benefits of advanced amorphous motor design include:

- Increased efficiency

- Reduced energy consumption

- Improved reliability

Developments in Magnetic Materials

The development of new magnetic materials is a key factor in the growth of the amorphous motor market. These materials have improved magnetic properties, leading to more efficient motor operation.

Some of the key developments in magnetic materials include:

- Advanced soft magnetic materials

- Nanocrystalline magnetic materials

- Amorphous magnetic materials

| Magnetic Material | Properties | Applications |

| Soft Magnetic Materials | High magnetic permeability, low coercivity | Industrial equipment, HVAC systems |

| Nanocrystalline Magnetic Materials | High magnetic saturation, low losses | Energy storage, power electronics |

| Amorphous Magnetic Materials | Low core losses, high efficiency | Amorphous motors, high-frequency applications |

The innovations in amorphous motor design and magnetic materials are expected to drive the market forward, leading to more efficient and compact motors. As the demand for energy-efficient solutions continues to grow, the amorphous motor market is poised for significant growth.

Key competitors in the amorphous motor market

- Hitachi Metals — Tokyo, Japan

- Advanced Technology & Materials (ATM) — Beijing, China

- Qingdao Yunlu — Qingdao, China

- VACUUMSCHMELZE (VAC) — Hanau, Germany

- Henan Zhongyue — Zhengzhou, China

- Liquidmetal Technologies — Rancho Santa Margarita, USA

- Eontec — Gyeonggi, South Korea

- Changzhou Stream — Changzhou, China

- Dongguan PrometalTech — Dongguan, China

- Zhongyan Amorphous Technology — Zhengzhou, China

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Amorphous Motor Market Report |

| Base Year | 2024 |

| Segment by Type | · Permanent Magnet

· Induction |

| Segment by Application | · Electric Vehicles

· Electric Aircraft |

| Geographies Covered | · North America (United States, Canada)

· Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The motor market is expected to grow significantly, driven by the increasing demand for energy-efficient technologies. As the world moves towards sustainable practices, the market is projected to reach $2.17 million by 2025.

Market Outlook

The future prospects of the amorphous motor market look promising, with key applications in industrial equipment, HVAC systems, and energy storage. Government incentives and policies in the U.S., China, and Japan are further driving the adoption of energy-efficient technologies.

As the market continues to evolve, manufacturers and investors must be aware of the challenges and limitations, including manufacturing costs, material availability, and performance optimization. Innovations in amorphous motor design and magnetic materials will play a crucial role in shaping the market’s future.

With a growing demand for energy-efficient motors, the amorphous motor market is expected to witness significant growth opportunities. As the market continues to expand, it is essential to monitor regional growth trends, key competitors, and technological advancements to stay ahead in this competitive landscape.

Global Amorphous Motor Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Amorphous Motor Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Amorphous MotorMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Amorphous Motorplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Amorphous Motor Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Amorphous Motor Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Amorphous Motor Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofAmorphous MotorMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is an amorphous motor?

An amorphous motor is a type of electric motor that uses amorphous metal alloys in its construction, which provides improved energy efficiency and reduced energy losses.

What are the benefits of using amorphous motors?

The benefits of using amorphous motors include:

- Improved energy efficiency

- Reduced energy consumption

- Lower operating costs

- More environmentally friendly

- Help reduce greenhouse gas emissions

What are the key applications of amorphous motors?

Amorphous motors have various applications in industrial equipment, HVAC systems, and energy storage. They are used in manufacturing processes, equipment, and other industrial applications where energy efficiency is crucial.

How do government policies and regulations impact the amorphous motor market?

Government policies and regulations are crucial in encouraging the use of energy-efficient technologies, such as amorphous motors. These incentives and policies can stimulate market growth and motivate manufacturers to create more energy-efficient products.

What is the outlook for the amorphous motor market?

The amorphous motor market is expected to grow significantly, driven by the increasing demand for energy-efficient solutions in various industries. The market is expected to reach $2.17 million by 2025, driven by the growing demand in the U.S., China, and Japan.

What are the challenges facing the amorphous motor market?

The amorphous motor market faces challenges related to manufacturing costs, material availability, and performance optimization. However, ongoing research and development are helping to address these challenges and improve the efficiency and performance of amorphous motors.

How do amorphous motors contribute to energy efficiency?

Amorphous motors contribute to energy efficiency by reducing energy losses and improving the overall efficiency of the motor. This leads to lower energy consumption and reduced operating costs, making them an attractive option for industries looking to reduce their energy footprint.