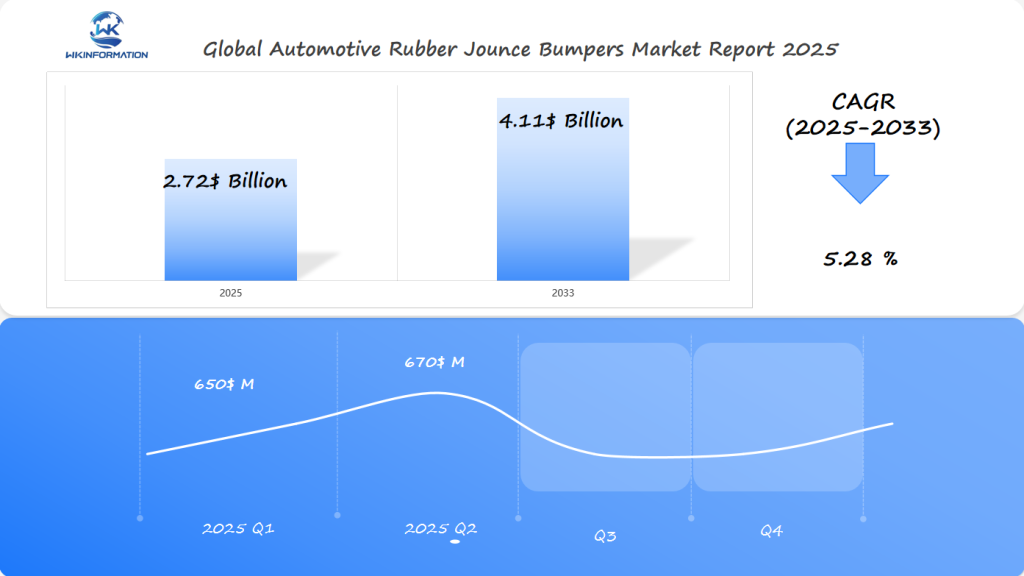

2025 Automotive Rubber Jounce Bumpers Market Growth: Reaching $2.72 Billion with Enhanced Vehicle Safety in US, Russia, and China

Get comprehensive insights into the 2025 Automotive Rubber Jounce Bumpers market trends, focusing on US, Russia, and China markets under Trump’s trade policies. Analysis covers market growth projections, regional dynamics, sustainability initiatives, and key player strategies in the evolving automotive components sector.

- Last Updated:

Automotive Rubber Jounce Bumpers Market Q1 and Q2 2025 Predictions

The Automotive Rubber Jounce Bumpers market is projected to reach USD 2.72 billion in 2025, growing at a CAGR of 5.28% from 2025 to 2033. In Q1 2025, the market is expected to generate around USD 650 million, driven by the increasing adoption of rubber jounce bumpers in the automotive industry to improve vehicle suspension systems and enhance comfort. The US, Russia, and China are expected to be the leading markets, with rising vehicle production and demand for enhanced ride quality. By Q2 2025, the market is projected to grow to approximately USD 670 million, supported by the expanding automotive manufacturing in these regions.

Understanding the Upstream and Downstream Dynamics of the Automotive Rubber Jounce Bumper Market

The supply chain for automotive rubber jounce bumpers is a complex network involving various stages of production and distribution. Key players in this chain include raw material suppliers, manufacturers, distributors, and automotive companies. Each player plays a crucial role in ensuring the quality and efficiency of the final product.

Key Players in the Supply Chain:

- Raw Material Suppliers: Provide essential materials like rubber and polyurethane which form the backbone of jounce bumper production.

- Manufacturers: Process these materials to create jounce bumpers, focusing on precision engineering to meet specific vehicle requirements.

- Distributors: Handle logistics and transport finished products to automotive manufacturers or aftermarket retailers.

- Automotive Companies: Integrate jounce bumpers into vehicles, often requiring customization to match suspension system specifications.

The influence of upstream suppliers on product quality cannot be understated. The choice of materials directly affects durability and performance, which are critical factors in automotive safety. High-quality raw materials lead to superior jounce bumpers that offer enhanced shock absorption capabilities.

Pricing strategies within the market are also shaped by upstream dynamics. Fluctuations in raw material costs can significantly impact manufacturing expenses, driving prices up or down accordingly. Manufacturers must navigate these variables carefully to maintain competitive pricing while ensuring product integrity.

Understanding these intricate supply chain dynamics provides valuable insights into how the automotive rubber jounce bumper market functions. This knowledge is essential for stakeholders aiming to enhance their operational strategies, optimize production processes, and ensure alignment with industry demands.

Key Trends Shaping the Automotive Rubber Jounce Bumper Industry

Innovations in Material Technology

Recent innovations in material technology have significantly enhanced the performance and durability of automotive rubber jounce bumpers. Manufacturers are increasingly leveraging advanced rubber and polyurethane compounds to improve shock absorption capabilities. These materials not only extend the life span of jounce bumpers but also ensure they perform efficiently under various temperature conditions and mechanical stresses.

The Impact of Electric Vehicles (EVs)

The surge in electric vehicles (EVs) presents unique challenges and opportunities for jounce bumper design. EVs often have different weight distributions compared to traditional combustion engine vehicles, necessitating tailored suspension solutions. This has led to a shift in design strategies, where jounce bumpers must accommodate these novel configurations while ensuring optimal vehicle handling and ride comfort.

Evolving Safety Features

Safety features are becoming a focal point in modern vehicle design, influencing the demand for more sophisticated jounce bumpers. The integration of advanced driver-assistance systems (ADAS) requires components that can seamlessly support these technologies. Jounce bumpers now play a crucial role in enhancing vehicle safety by providing improved impact resistance and minimizing damage risks during sudden stops or collisions.

These trends highlight the dynamic nature of the automotive rubber jounce bumper market, driven by technological advancements and evolving consumer preferences. As vehicles become more complex and safety-centric, the importance of high-quality, durable jounce bumpers is expected to grow, shaping future market developments.

Overcoming Challenges in Automotive Rubber Jounce Bumper Manufacturing

Manufacturing automotive rubber jounce bumpers involves a variety of production challenges that require meticulous attention to detail. One prevalent issue is achieving dimensional accuracy and surface finish quality. Variations in these aspects can significantly affect the performance of jounce bumpers, leading to potential failures in the suspension system.

To ensure high-quality outcomes, manufacturers implement several strategies:

1. Robust Inspection Protocols

Incorporating comprehensive inspection procedures throughout the production stages helps maintain precision and consistency. These protocols often include both manual checks and automated systems that quickly identify defects or deviations.

2. Advanced Testing Methods

Utilizing technologies such as Finite Element Analysis (FEA) allows producers to simulate real-world stress scenarios on their products. This predictive approach ensures that the jounce bumpers meet rigorous standards before they reach the market.

Cost management remains a critical concern in this segment of the automotive industry. Manufacturers strive to adopt cost-effective practices without compromising product integrity or performance:

1. Efficient Resource Utilization

By optimizing the use of raw materials and streamlining production processes, manufacturers can reduce waste and lower costs while maintaining high-quality standards.

2. Lean Manufacturing Techniques

Implementing lean methodologies helps minimize unnecessary steps in production, thereby reducing time and resource expenditure.

With these strategies, producers are well-positioned to tackle common manufacturing hurdles while upholding stringent quality control measures, ultimately supporting growth within the Automotive Rubber Jounce Bumpers Market.

Geopolitical Impact on the Automotive Rubber Jounce Bumper Market

Geopolitical tensions are increasingly shaping the landscape of global trade, affecting industries across the board, including automotive components like rubber jounce bumpers. These tensions often lead to changes in trade regulations, influencing how materials and products move across borders.

Influence of Geopolitical Tensions on Trade Regulations

- Trade regulations can change when countries have political disputes. This can directly affect the automotive sector by changing import/export rules for important parts like jounce bumpers.

- Countries may implement stricter regulations or modify existing ones, aiming to protect domestic industries or leverage political influence. Such adjustments can lead to increased compliance costs for manufacturers.

Tariffs and Their Implications

- In recent years, governments have been using tariffs as a way to control the economy. For example, tariffs on raw materials like rubber can increase production costs for jounce bumper manufacturers.

- When tariffs are imposed, it often creates a chain reaction throughout global supply chains. Manufacturers might have to pay more, which could result in higher prices for consumers.

Navigating Global Supply Chains

- Companies in this industry need to navigate complex global supply chains. Geopolitical actions that restrict the movement of goods or change pricing structures can disrupt these supply chains.

- To reduce risks associated with geopolitical instability, strategies such as diversifying supplier bases or setting up manufacturing facilities in multiple countries can be helpful.

The ability of manufacturers to adapt to these geopolitical challenges is crucial for maintaining competitiveness in a rapidly evolving market landscape.

Market Segmentation: Types of Automotive Rubber Jounce Bumpers and Their Applications

Product Types

Rubber jounce bumpers come in various designs, each tailored to specific vehicle needs and performance requirements. The most common types include:

- Traditional Cylindrical Designs: These are simple in structure, usually a single piece of rubber molded into a cylindrical shape. They offer reliable shock absorption and are cost-effective. However, their simplicity may limit customization options for specific vehicle requirements.

- Advanced Multi-Stage Configurations: These designs incorporate multiple layers or stages of rubber density, providing superior shock absorption and a smoother transition between compression phases. This results in enhanced ride comfort and reduced noise, vibration, and harshness (NVH) levels, making them ideal for high-performance applications.

Each type presents distinct advantages and potential drawbacks. Traditional designs excel in simplicity and affordability, while multi-stage configurations offer advanced performance at a higher production cost.

Applications in Vehicles

Jounce bumpers are integral to the suspension systems of various vehicle types, each with unique demands:

- Passenger Cars: These vehicles prioritize ride comfort and NVH reduction. Multi-stage bumpers are often preferred to optimize these aspects while maintaining cost-effectiveness.

- SUVs: With their heavier build and off-road capabilities, SUVs require jounce bumpers capable of handling greater weight capacity while ensuring ride stability over uneven terrains.

- Trucks: Given their significant load-bearing requirements, trucks benefit from robust jounce bumpers that provide maximum durability and support for heavy-duty usage.

Different applications demand tailored solutions, highlighting the importance of selecting appropriate bumper types based on vehicle-specific characteristics such as weight capacity requirements and ride comfort preferences.

The Role of Rubber Jounce Bumpers in Vehicle Suspension Systems

Rubber jounce bumpers are an important part of vehicle suspension systems. They are designed to absorb shock and impact when a vehicle goes over bumps or uneven surfaces, like potholes or speed bumps. By doing this, they help protect the suspension from damage and ensure a smoother ride for passengers.

How Rubber Jounce Bumpers Work

When the suspension system of a vehicle is compressed under pressure, the jounce bumper also compresses. This compression helps to dissipate energy and reduce the force that is transferred to the vehicle’s chassis. As a result, the suspension system can effectively manage impacts and provide a more comfortable ride experience.

Benefits of Rubber Jounce Bumpers

Rubber jounce bumpers offer several benefits:

- Improved Shock Absorption: The primary function of jounce bumpers is to absorb shock and impact forces. This helps to minimize the amount of energy that is transmitted to the vehicle’s body, resulting in a smoother ride.

- Enhanced Ride Comfort: In addition to absorbing shocks, jounce bumpers also reduce vibrations and harshness that can be felt inside the vehicle. This makes for a more pleasant driving experience, especially on rough or bumpy roads.

- Protection for Other Components: By acting as a buffer between the suspension system and the chassis, jounce bumpers help protect other important parts of the vehicle from potential damage. This can lead to lower maintenance costs and increased lifespan for these components.

Materials Used in Rubber Jounce Bumpers

Rubber jounce bumpers are typically made from durable materials like rubber or polyurethane. These materials are chosen for their ability to withstand repeated compression and provide long-lasting performance. The use of high-quality materials ensures that jounce bumpers can effectively absorb shocks and maintain their shape over time.

Future Developments in Rubber Jounce Bumpers

As technology continues to advance, there is potential for further improvements in rubber jounce bumpers. Manufacturers may explore new materials or manufacturing processes that can enhance the performance of these components even further. Additionally, as the automotive industry evolves and new demands arise, jounce bumpers may be adapted to meet specific requirements such as electric vehicles or off-road applications.

Overall, rubber jounce bumpers play a vital role in maintaining ride comfort and protecting suspension systems. Their ability to absorb shocks and reduce vibrations makes them an essential part of modern automotive design.

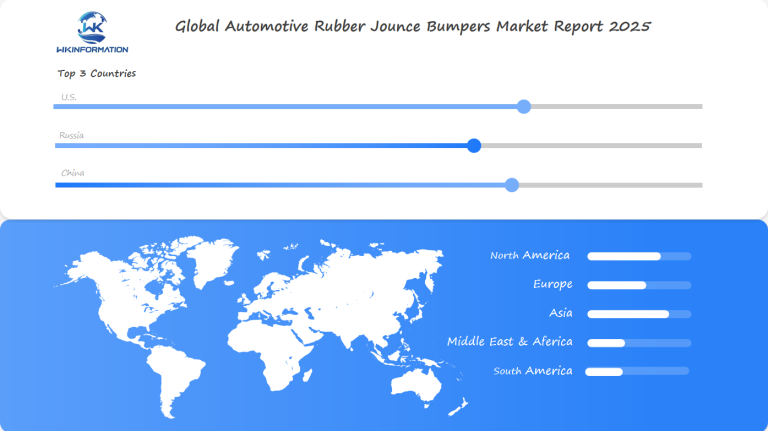

Regional Insights: Automotive Rubber Jounce Bumper Market Growth Globally

The Automotive Rubber Jounce Bumpers Market is experiencing significant growth across various regional markets, each contributing uniquely to the industry’s expansion. This section provides a snapshot of the global landscape, setting the stage for deeper exploration of key markets.

Key Regions Driving Market Growth

Here are some of the key regions driving the growth of the automotive rubber jounce bumper market:

- United States: A major player in the automotive sector, driven by continuous advancements in vehicle safety and performance, which fuels demand for high-quality jounce bumpers.

- Russia: Known for its contribution to advanced suspension technologies, influencing local and international markets with innovative solutions and robust engineering capabilities.

- China: The rapid urbanization and increase in vehicle production have made China a pivotal market. Its growing domestic production capacity significantly boosts the demand for jounce bumpers.

The US Market for Automotive Rubber Jounce Bumpers in the Automotive Sector

The United States is a major player in the global automotive rubber jounce bumpers market. The demand for these products is driven by the country’s strong automotive industry, which places a high priority on improving vehicle safety and performance standards.

Key Factors Driving Market Growth

Several key factors are contributing to the growth of this market:

- Increased Vehicle Production: The US continues to see substantial vehicle production volumes, necessitating the ongoing manufacture of high-quality suspension components like jounce bumpers.

- Advanced Safety Regulations: Stringent safety standards encourage manufacturers to innovate in suspension technologies, including the development of superior jounce bumpers that enhance vehicle stability and occupant protection.

- Rising Consumer Expectations: As consumers become more aware of vehicle safety and comfort, there is a growing demand for vehicles equipped with advanced suspension systems that incorporate effective shock absorption solutions.

- Technological Advancements: American manufacturers are increasingly integrating cutting-edge material technologies into their products, focusing on both rubber and polyurethane options to improve durability and performance.

Collaborations Between Manufacturers and Producers

The US market also benefits from strong collaborations between automotive manufacturers and jounce bumper producers. These partnerships focus on customizing solutions tailored to specific vehicle models, ensuring that performance and safety expectations are met or exceeded.

This combination of regulatory pressure, consumer demand, and technological innovation positions the US as a key player in the continued expansion of the global automotive rubber jounce bumpers market.

Russia’s Contribution to Advanced Suspension Technologies for Vehicles

Russia plays a crucial role in advancing suspension technologies, especially with the innovation and development of automotive rubber jounce bumpers. The country’s strong automotive industry places a high priority on research and development, which drives improvements in vehicle safety and performance.

1. Technological Innovation

Russian manufacturers are focused on integrating cutting-edge materials such as high-performance rubbers and polyurethanes into jounce bumpers. These materials enhance durability and shock absorption capabilities, which are essential for the difficult driving conditions often faced in Russia. This effort aligns with the top trends in the automotive suspension mount rubber market, where the focus is on improving performance and longevity.

2. Collaborative Efforts

Collaboration with global automotive giants, as well as local automakers, has resulted in the creation of customized solutions designed for various types of vehicles. This partnership promotes the development of jounce bumpers that not only meet but exceed international safety standards.

3. Focus on Electric Vehicles (EVs)

With a growing interest in EVs, Russian engineers are making adjustments to suspension systems in order to accommodate different weight distributions. This modification is crucial in ensuring that EVs maintain optimal ride comfort and handling, despite their unique design requirements.

Russia’s commitment to improving suspension technologies demonstrates its dedication to vehicle safety and reliability. By utilizing its knowledge in material science and engineering, Russia remains an important player in the global advancement of automotive components such as rubber jounce bumpers.

China’s Growing Demand for Automotive Rubber Jounce Bumpers

China’s automotive industry is experiencing unprecedented growth, leading to a higher demand for automotive rubber jounce bumpers. This expansion is largely driven by an increase in domestic vehicle production. China is not only one of the largest markets for passenger vehicles but also a major producer, impacting global supply chains.

Key Factors Driving Demand:

- Urbanization and Infrastructure Development: Rapid urbanization results in more people owning vehicles, which requires strong suspension systems with top-notch jounce bumpers.

- Growth of Electric Vehicles (EVs): The Chinese government’s initiative to promote EVs brings about specific needs for suspension systems. There is a rising demand for jounce bumpers that can accommodate varying weight distributions and dynamic loading conditions.

- Emphasis on Vehicle Safety: As consumers become more aware of safety features, automakers are prioritizing components such as jounce bumpers that improve ride comfort and protect against suspension damage.

Industry Innovations:

- Material Advancements: New developments in rubber and polyurethane materials enhance durability and performance, which are essential for meeting the requirements of China’s diverse weather conditions.

- Collaborative Developments: Partnerships between local manufacturers and international automotive companies encourage the creation of customized jounce bumper solutions designed specifically for the market.

This increasing demand highlights China’s crucial role in shaping future trends in the global automotive rubber jounce bumper market.

Innovations in Rubber Jounce Bumpers for Improved Safety and Comfort

Recent advancements in the automotive industry have led to significant innovations in rubber jounce bumpers, enhancing both safety and comfort for vehicle occupants. These developments are primarily focused on material technology and design improvements.

1. Material Innovations

Modern jounce bumpers often use advanced rubber compounds and polyurethane materials. These materials offer superior durability and resilience, which are essential for effectively absorbing impacts. Improved material formulations contribute to a longer lifespan and consistent performance under various driving conditions.

2. Design Enhancements

Engineers are exploring multi-stage configurations that provide progressive resistance during compression. This design allows for smoother transitions when the suspension system is under stress, resulting in a more comfortable ride experience.

3. Safety Integration

With a growing emphasis on safety, jounce bumpers are being integrated with sensor technologies to monitor suspension dynamics in real-time. This innovation supports advanced driver-assistance systems (ADAS) by providing critical data that can enhance vehicle stability and control.

These innovations not only improve the basic function of jounce bumpers but also align them with evolving automotive technologies, ensuring they meet the needs of modern vehicles. By focusing on both materials and design, manufacturers are setting new standards for suspension components that prioritize both safety and passenger comfort.

Key Competitors in the Automotive Rubber Jounce Bumper Market

Identifying leading players in the automotive rubber jounce bumper market provides insights into the competitive landscape. These companies are often at the forefront of innovation, driving advancements in material technology and product design.

- Freudenberg Group – Germany

- Trelleborg AB – Sweden

- Sumitomo Rubber Industries, Ltd. – Japan

- Cooper Standard Automotive, Inc. – USA

- Hutchinson – France

- ZF Friedrichshafen AG – Germany

- ThyssenKrupp AG – Germany

- Continental AG – Germany

- Pirelli & C. S.p.A. – Italy

- Parker Hannifin Corporation – USA

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Automotive Rubber Jounce Bumpers Market Report |

| Base Year | 2024 |

|

Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The automotive rubber jounce bumpers market is growing rapidly and is expected to reach a value of $2.72 billion by 2025. This growth is primarily driven by the increasing importance of vehicle safety and performance features in the automotive industry. The main factors contributing to this growth are:

- Advancements in Material Technology: Continuous innovations in rubber and polyurethane materials have enabled manufacturers to produce jounce bumpers that offer superior durability and shock absorption, essential for modern suspension systems.

- Rise of Electric Vehicles (EVs): The shift towards EVs necessitates specialized suspension solutions due to their unique weight distribution and handling requirements, thereby increasing the demand for sophisticated jounce bumper designs.

- Growing Emphasis on Safety Features: With the integration of advanced driver-assistance systems (ADAS), there is a heightened demand for high-quality jounce bumpers that complement these safety technologies.

- Regional Market Growth: Key regions such as the United States, Russia, and China are contributing significantly to market expansion due to rapid urbanization, increased vehicle production, and heightened consumer awareness about vehicle safety.

Manufacturers are responding to these trends by incorporating cutting-edge technologies into their products and forming strategic collaborations within the automotive sector. As a result, the market for automotive rubber jounce bumpers is well-positioned to continue flourishing in the years ahead.

Global Automotive Rubber Jounce Bumpers Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Automotive Rubber Jounce Bumpers Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Automotive Rubber Jounce Bumpers Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Automotive Rubber Jounce Bumpers Players and Regional Insights

-

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

-

- Key Differentiators and Strategic Moves

Chapter 3: Automotive Rubber Jounce Bumpers Market Segmentation Analysis

- Key Data and Visual Insights

-

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

-

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

-

- Historical Data and Growth Forecasts

- Regional Growth Factors

-

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Automotive Rubber Jounce Bumpers Emerging and Untapped Markets

- Growth Potential in Secondary Regions

-

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Automotive Rubber Jounce Bumpers Consumer Insights

- Demographics and Buying Behaviors

-

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Automotive Rubber Jounce Bumpers Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are the key players in the supply chain of the automotive rubber jounce bumper market?

The supply chain for automotive rubber jounce bumpers includes upstream suppliers of raw materials, manufacturers who produce the bumpers, and distributors who handle their delivery to vehicle manufacturers. Key players typically involve material suppliers, manufacturing firms specializing in rubber components, and logistics companies that manage distribution channels.

How do upstream suppliers affect the quality and pricing of jounce bumpers?

Upstream suppliers play a crucial role in determining the quality and pricing strategies of jounce bumpers. High-quality raw materials lead to better product performance and durability, while fluctuations in material prices can directly impact overall production costs and market pricing strategies.

What recent trends are influencing the design of automotive rubber jounce bumpers?

Recent trends shaping the automotive rubber jounce bumper industry include advancements in rubber and polyurethane materials that enhance performance, the rise of electric vehicles necessitating different design considerations for weight distribution, and an increasing focus on integrating safety features such as advanced driver-assistance systems (ADAS) into bumper designs.

What are some common manufacturing challenges faced by producers of jounce bumpers?

Manufacturers of automotive rubber jounce bumpers encounter challenges such as maintaining dimensional accuracy, achieving high surface finish quality, and managing production costs. Implementing strict quality control measures and advanced testing methods like finite element analysis (FEA) can help address these issues.

How do geopolitical tensions impact the automotive rubber jounce bumper market?

Geopolitical tensions can significantly influence trade regulations and tariffs applicable to automotive components like jounce bumpers. These factors can affect global supply chains, leading to increased costs for manufacturers and potential disruptions in sourcing raw materials or distributing finished products across borders.

What types of vehicles commonly utilize automotive rubber jounce bumpers?

Automotive rubber jounce bumpers are utilized in various vehicle types including passenger cars, SUVs, and trucks. Each type requires specific bumper designs tailored to their weight capacity needs and ride comfort preferences, with options ranging from traditional cylindrical designs to advanced multi-stage configurations.