Automotive Sliding Load Floor Market to Exceed $1.33 Billion by 2025: Insights from the U.S., Germany, and China

The Automotive Sliding Load Floor Market is projected to surpass $1.33 billion by 2025, driven by rising demand in commercial and passenger vehicles across key regions including the U.S., Germany, and China. Technological advancements and innovative vehicle designs are fueling growth, emphasizing efficient cargo handling solutions. Explore emerging trends, market challenges, and regional insights shaping the future of automotive sliding load floor technology.

- Last Updated:

Automotive Sliding Load Floor Market Expands With SUV and EV Adoption in Q1 and Q2 2025

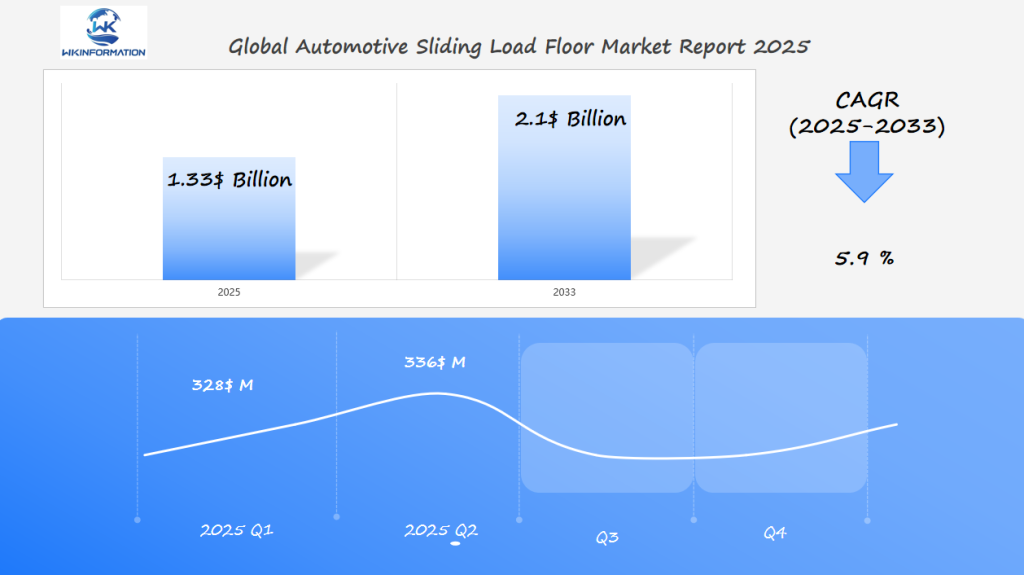

The global Automotive Sliding Load Floor market is forecast to achieve $1.33 billion in 2025, supported by a CAGR of 5.9% through 2033. Estimated revenue in Q1 2025 reached around $328 million, increasing to approximately $336 million in Q2, aided by growing consumer preference for convenience features in SUVs and electric vehicles.

In the U.S., the popularity of large SUVs and pickups contributed to steady sales of premium sliding floor systems. Germany showcased resilience in Q2, with automakers adopting modular cargo solutions for both utility and luxury models. Meanwhile, China saw growing OEM interest in value-added interior components, particularly in the mid-range EV segment.

Key Takeaways

- The global market is expected to exceed $1.33 billion by 2025.

- Growth is driven by demand in commercial and passenger vehicles.

- Regions like the U.S., Germany, and China are leading.

- Technological advancements are a key growth factor.

- Efficient cargo handling solutions are increasingly in demand.

Automotive Sliding Load Floor market upstream and downstream industry chain analysis

Upstream Industry Chain Analysis

- Raw Material Suppliers

- Providers of high-strength lightweight materials such as aluminum alloys, composites, and advanced polymers essential for manufacturing sliding load floors.

- Suppliers of mechanical components including rails, rollers, motors (for powered sliding floors), and electronic control units.

- Component Manufacturers

- Manufacturers specializing in precision engineering parts, such as sliding mechanisms, locking systems, and motor assemblies.

- Electronics suppliers providing sensors and automation components for powered sliding load floors.

- Technology Providers

- Firms developing Industry 4.0 technologies integrated into production processes for enhanced manufacturing efficiency and quality control.

- Software developers creating smart control systems for powered sliding load floors.

Core Manufacturing

- Automotive sliding load floor manufacturers who assemble raw materials and components into finished products.

- Adoption of smart manufacturing practices to improve productivity and product quality.

- Focus on innovation to meet demands for durability, efficiency, and lightweight solutions.

Downstream Industry Chain Analysis

- Vehicle Manufacturers (OEMs)

- Commercial vehicle manufacturers incorporating sliding load floors to improve cargo handling efficiency in delivery trucks, vans, and other transport vehicles.

- Passenger vehicle manufacturers integrating these systems for enhanced functionality in SUVs and multipurpose vehicles.

- Aftermarket Suppliers and Installers

- Businesses offering retrofitting services for existing vehicles with manual or powered sliding load floors.

- Maintenance providers ensuring operational reliability post-installation.

- Logistics and Transportation Companies

- End-users leveraging sliding load floor technology to optimize loading/unloading processes, reduce turnaround times, and increase overall efficiency.

- Distributors and Dealers

- Regional distributors that supply automotive sliding load floors to OEMs and aftermarket service providers across key markets such as the U.S., Germany, and China.

Industry Chain Dynamics

- The growth of e-commerce and logistics sectors is driving demand downstream for more efficient cargo handling solutions.

- Upstream innovations in materials science and smart manufacturing feed directly into downstream product enhancements.

- Geopolitical factors and trade policies impact the sourcing of raw materials upstream as well as regional market access downstream.

- Collaboration between component suppliers, manufacturers, OEMs, and end-users is critical to addressing design challenges like enhanced cargo handling capabilities.

- Regional market leaders are shaping the supply chain through strategic partnerships and technology investments to capitalize on growing demand.

Trends in Automotive Sliding Load Floors for Commercial and Passenger Vehicles in 2025

The automotive industry is experiencing a significant shift towards advanced sliding load floor technology in commercial and passenger vehicles by 2025. This shift is driven by the need for more efficient, durable, and lightweight solutions that enhance vehicle performance and reduce fuel consumption.

The trends in automotive sliding load floors are moving towards more sophisticated designs that integrate Industry 4.0 technologies. Manufacturers are adopting smart manufacturing practices to produce high-quality sliding load floors that meet the evolving demands of the automotive industry.

Emerging Trends in Sliding Load Floor Technology

One of the emerging trends in sliding load floor technology is the use of advanced materials that offer improved strength-to-weight ratios. These materials enable the production of lighter, yet stronger, sliding load floors that contribute to overall vehicle efficiency.

Another trend is the integration of smart technologies into sliding load floors. This includes the use of sensors and IoT devices to monitor and manage cargo handling, enhancing the overall user experience.

Impact of Industry 4.0 on Sliding Load Floor Manufacturing

The adoption of Industry 4.0 technologies is revolutionizing the manufacturing of sliding load floors. Smart manufacturing practices, such as automation and data analytics, are improving production efficiency and product quality.

Industry 4.0 is also enabling the development of customized sliding load floors that meet specific customer requirements. This is achieved through the use of advanced design tools and flexible manufacturing systems.

Challenges in the Design and Production of Automotive Sliding Load Floors

Designing and manufacturing automotive sliding load floors involves overcoming several hurdles, including durability, weight reduction, and enhanced cargo handling.

Design Challenges for Enhanced Cargo Handling

The design of automotive sliding load floors requires a balance between durability and weight reduction while ensuring enhanced cargo handling capabilities. Manufacturers must consider factors such as material selection, structural integrity, and ease of use.

Some of the key design challenges include:

- Optimizing load floor dimensions for various vehicle types

- Ensuring compatibility with different cargo handling systems

- Minimizing weight while maintaining structural strength

Production Challenges and Quality Control Measures

The production of automotive sliding load floors involves several challenges, including maintaining quality control and adhering to regulatory standards. Manufacturers must implement robust quality control measures to ensure that the load floors meet the required standards.

A comparison of production challenges and quality control measures is presented in the following table:

| Production Challenges | Quality Control Measures |

| Material sourcing and procurement | Supplier evaluation and auditing |

| Manufacturing process optimization | Regular inspection and testing |

| Cost management and efficiency | Continuous process improvement |

By understanding these challenges and implementing effective solutions, manufacturers can produce high-quality automotive sliding load floors that meet the needs of the industry.

Geopolitical Influence on Automotive Sliding Load Floor Manufacturing and Trade

Geopolitical dynamics play a crucial role in shaping the global automotive sliding load floor manufacturing and trade landscape. The industry is heavily influenced by trade policies, regional agreements, and geopolitical tensions, which can either facilitate or hinder the growth of the market.

The automotive sliding load floor market is subject to various geopolitical factors that impact its manufacturing and trade. Understanding these influences is crucial for stakeholders to navigate the complexities of the global market.

Impact of Trade Policies on the Automotive Sliding Load Floor Market

Trade policies, including tariffs and quotas, significantly affect the automotive sliding load floor market. For instance, tariffs imposed on imported goods can increase the cost of raw materials, thereby affecting the profitability of manufacturers.

Key trade policies influencing the market include:

- Tariffs on imported steel and aluminum

- Quotas on exports to certain countries

- Trade agreements that reduce or eliminate tariffs

Regional Trade Agreements and Their Effects on the Industry

Regional trade agreements (RTAs) have a profound impact on the automotive sliding load floor industry. By reducing or eliminating tariffs among member countries, RTAs can increase trade volumes and encourage investment within the region.

Type Segmentation: Manual vs. Powered Automotive Sliding Load Floors

Automotive sliding load floors are broadly classified into manual and powered types, reflecting different user preferences and vehicle specifications. This segmentation is crucial as it influences the design, functionality, and user experience of vehicles equipped with sliding load floors.

Advantages and Disadvantages of Manual Sliding Load Floors

Manual sliding load floors are known for their cost-effectiveness and simplicity. They are generally less expensive to produce and maintain compared to their powered counterparts. However, they require manual effort to operate, which can be a drawback, especially for heavy or bulky loads.

The advantages of manual sliding load floors include:

- Cost-effectiveness: Lower production and maintenance costs make them an attractive option for budget-conscious buyers.

- Simplicity: With fewer mechanical components, manual sliding load floors are less prone to technical issues.

However, the disadvantages are:

- Manual Effort: Requires physical strength to operate, which can be challenging for some users.

- Limited Capacity: May not be suitable for heavy or bulky loads due to the manual operation.

Benefits and Challenges of Powered Sliding Load Floors

Powered sliding load floors, on the other hand, offer the convenience of automated operation, making it easier to handle cargo. They are particularly beneficial for heavy-duty applications or for users who prioritize ease of use.

The benefits of powered sliding load floors include:

- Convenience: Automated operation reduces the physical effort required to manage cargo.

- Enhanced Capacity: Suitable for heavy or bulky loads, making them ideal for commercial or heavy-duty applications.

Despite these benefits, powered sliding load floors also present some challenges:

- Higher Cost: More expensive to produce and maintain due to the complex mechanisms involved.

- Technical Issues: The automated system can be prone to technical faults, requiring more sophisticated maintenance.

A comparison of manual and powered sliding load floors is presented in the table below:

| Feature | Manual Sliding Load Floors | Powered Sliding Load Floors |

| Operation | Manual | Automated |

| Cost | Lower | Higher |

| Capacity | Limited | Higher |

| Maintenance | Simpler | More Complex |

Applications of Automotive Sliding Load Floors in Cargo Handling and Vehicle Design

The integration of automotive sliding load floors has transformed cargo handling and vehicle design. By improving the efficiency of loading and unloading cargo, these systems contribute to enhanced safety and lower labor costs.

Enhancing Cargo Handling Efficiency with Sliding Load Floors

Sliding load floors are designed to simplify the process of loading and unloading cargo, making it easier for users to manage their vehicle’s cargo space. This is particularly beneficial for commercial vehicles where time and efficiency are crucial.

The use of sliding load floors can significantly reduce the strain on workers, minimizing the risk of injury and improving overall productivity. Moreover, these systems can be customized to fit various vehicle types, making them versatile and widely applicable.

In terms of vehicle design, sliding load floors play a critical role in optimizing cargo space and ensuring that vehicles are used to their full potential. By integrating sliding load floors into vehicle design, manufacturers can create more efficient and user-friendly vehicles.

Furthermore, sliding load floors contribute to vehicle safety by reducing the risk of cargo shifting during transit, which can cause accidents or damage to the vehicle. A well-designed sliding load floor system can also enhance the overall structural integrity of the vehicle.

| Benefits | Description |

| Improved Efficiency | Simplifies loading and unloading of cargo |

| Enhanced Safety | Reduces the risk of injury and cargo shifting |

| Customization | Fits various vehicle types and needs |

Global Market Overview: Regional Demand and Growth for Automotive Sliding Load Floors

The global automotive sliding load floor market is experiencing diverse demand patterns across different regions. This variation is driven by factors such as regional market trends, industry analysis, and the specific needs of the automotive sector in each area.

Regional market trends play a crucial role in shaping the demand for automotive sliding load floors. Understanding these trends is essential for manufacturers to tailor their strategies effectively.

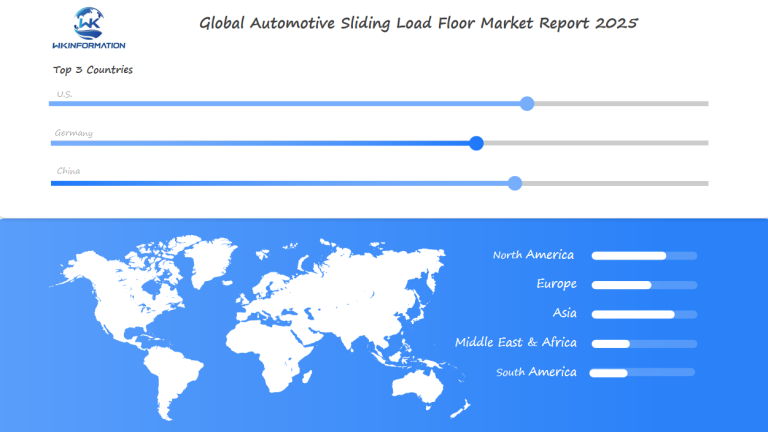

Regional Market Analysis: North America, Europe, Asia-Pacific

The demand for automotive sliding load floors varies significantly across North America, Europe, and Asia-Pacific.

North America

North America, with its large automotive market, shows a steady demand for sliding load floors, particularly in the commercial vehicle segment.

Europe

Europe, known for its advanced automotive technology, is witnessing a growing adoption of powered sliding load floors, driven by the need for enhanced cargo handling efficiency.

Asia-Pacific

Asia-Pacific, with countries like China and India, is emerging as a significant market due to the rapid growth of the automotive industry in these regions.

Regional Demand for Automotive Sliding Load Floors

Emerging markets, particularly in the Asia-Pacific region, offer substantial growth opportunities for the automotive sliding load floor market. Countries like India and Southeast Asian nations are expected to drive demand due to their expanding automotive industries.

Industry analysis indicates that these emerging markets are likely to adopt sliding load floor technology to enhance their logistics and transportation sectors, thereby driving market growth.

U.S. Market Insights: Increasing Adoption of Automotive Sliding Load Floors in Delivery Trucks

The growth of e-commerce and logistics requirements are driving the use of automotive sliding load floors in delivery trucks across the United States. The U.S. market is undergoing a major change in how products are moved, with a greater focus on being efficient and adaptable.

Market Drivers: E-commerce Growth and Logistics Demand

The rise of e-commerce has led to an increased demand for efficient logistics and transportation solutions. Automotive sliding load floors play a crucial role in enhancing the functionality of delivery trucks, allowing for easier loading and unloading of cargo.

Key drivers include:

- Increased e-commerce activities

- Growing demand for fast and reliable delivery services

- Need for improved cargo handling efficiency

Germany’s Automotive Industry and Demand for Sliding Load Floors in Commercial Vehicles

Germany, known for its rich automotive history, is leading the way in incorporating sliding load floors into commercial vehicles. The country’s automotive industry is famous for its innovation, quality, and engineering expertise, which fuels the need for advanced solutions like sliding load floors.

Key Features of the German Automotive Sector

The German automotive sector stands out due to its:

- Strong manufacturing base

- Cutting-edge technology

- Highly skilled workforce

This environment encourages the creation and use of complex automotive parts, such as sliding load floors, which aim to improve the efficiency and functionality of commercial vehicles.

Germany’s Automotive Sector: Overview and Trends

Germany’s automotive industry is a significant contributor to the country’s economy, with a strong focus on producing high-quality vehicles that meet the evolving needs of the global market. The industry is driven by trends such as the increasing demand for electric vehicles, advancements in autonomous driving, and the integration of smart technologies.

Key Trends in Germany’s Automotive Industry:

- Increased adoption of electric and hybrid vehicles

- Advancements in autonomous driving technologies

- Integration of smart technologies and connectivity solutions

- Growing demand for lightweight and durable automotive components

Demand for Sliding Load Floors in German Commercial Vehicles

The demand for sliding load floors in German commercial vehicles is driven by the need for efficient, durable, and versatile cargo handling solutions. Sliding load floors offer numerous benefits, including enhanced cargo handling efficiency, improved vehicle versatility, and reduced loading times.

According to industry experts, the adoption of sliding load floors is expected to continue growing as manufacturers seek to improve vehicle functionality and meet the demands of the logistics and transportation sectors.

China’s Growing Market for Automotive Sliding Load Floors in the Transportation Sector

As China’s transportation industry continues to evolve, the demand for innovative solutions like automotive sliding load floors is on the rise. The country’s vast and growing logistics network requires efficient and cost-effective solutions to manage the increasing volume of goods being transported.

China’s Transportation Sector: Growth and Trends

China’s transportation sector has been experiencing rapid growth, driven by the country’s economic expansion and the rise of e-commerce. The sector is witnessing significant investments in infrastructure development, including highways, railways, and ports. This growth is creating a high demand for automotive sliding load floors, particularly in commercial vehicles.

Key trends shaping the transportation sector in China include:

- Increasing adoption of electric and hybrid vehicles

- Growing demand for logistics and transportation services

- Advancements in technology, such as automation and telematics

Opportunities for Sliding Load Floor Manufacturers in China

The growing demand for automotive sliding load floors in China’s transportation sector presents significant opportunities for manufacturers. To capitalize on this trend, manufacturers must focus on developing innovative, cost-effective solutions that meet the specific needs of the Chinese market.

According to industry experts, “The Chinese market is expected to drive growth in the global automotive sliding load floor market over the next few years.”

Future Outlook: Innovations in Automotive Sliding Load Floor Technology

The automotive industry is about to undergo a technological revolution, and sliding load floor innovations are gaining momentum. The future of automotive sliding load floors is expected to be influenced by new trends and technologies.

Emerging Technologies and Their Impact

The integration of electrification and autonomous vehicles is expected to bring about significant changes in the design and functionality of sliding load floors. These advancements will not only enhance the efficiency of cargo handling but also improve safety features.

“The shift towards electrification and autonomy will redefine the automotive sliding load floor market, enabling more efficient and safe transportation solutions.”

Some of the key trends expected to influence the market include:

- Increased adoption of powered sliding load floors for enhanced convenience and efficiency.

- Growing demand for customizable and modular designs to cater to diverse vehicle configurations.

- Integration of smart technologies for real-time monitoring and optimization of cargo handling.

Competitive Landscape: Leading Companies in the Automotive Sliding Load Floor Market

The automotive sliding load floor market is highly competitive, with several key players leading the industry. These companies are focusing on innovation, strategic partnerships, and expansion into new markets to stay ahead of the competition.

Key Players

- Decked LLC – United States

- TruckVault, Inc. – United States

- Cargo Glide – United States

- Bedslide (part of Takit Inc.) – United States

- Sortimo International GmbH – Germany

- EZ STAK – Canada

- Bott Ltd. – United Kingdom

- Tuff Drawer (by Highway Products Inc.) – United States

- Kersten Transportgeräte GmbH – Germany

- RHINO Products Ltd. – United Kingdom

Overall

| Report Metric | Details |

| Report Name | Global Automotive Sliding Load Floor Market Report |

| Base Year | 2024 |

| Segment by Type | ·Manual

·Powered |

| Segment by Application | ·Cargo Handling

·Vehicle Design |

| Geographies Covered | ·North America (United States, Canada)

·Europe (Germany, France, UK, Italy, Russia) ·Asia-Pacific (China, Japan, South Korea, Taiwan) ·Southeast Asia (India) ·Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The automotive sliding load floor market is set for significant growth, driven by technological advancements and increasing demand from the logistics and transportation sectors.

A comprehensive market overview reveals that regional demand, industry trends, and innovations in sliding load floor technology are key factors influencing the market’s trajectory. Industry insights suggest that stakeholders must navigate these factors effectively to capitalize on emerging opportunities.

As the market continues to evolve, industry stakeholders must stay informed about the latest developments in automotive sliding load floor technology. By doing so, they can make informed decisions and remain competitive in a rapidly changing market landscape.

Global Automotive Sliding Load Floor Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Automotive Sliding Load Floor Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Automotive Sliding Load Floor Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Automotive Sliding Load Floor Players and Regional Insights

-

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

-

- Key Differentiators and Strategic Moves

Chapter 3: Automotive Sliding Load Floor Market Segmentation Analysis

- Key Data and Visual Insights

-

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

-

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

-

- Historical Data and Growth Forecasts

- Regional Growth Factors

-

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Automotive Sliding Load Floor Emerging and Untapped Markets

- Growth Potential in Secondary Regions

-

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Automotive Sliding Load Floor Consumer Insights

- Demographics and Buying Behaviors

-

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Automotive Sliding Load Floor Market Insights

Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is driving the growth of the Automotive Sliding Load Floor Market?

The growth is driven by increasing demand in commercial and passenger vehicles, particularly in regions like the U.S., Germany, and China, due to advancements in sliding load floor technology and innovations in vehicle design.

What are the emerging trends in Sliding Load Floor Technology?

The trends are shifting towards more advanced and efficient solutions, with the integration of Industry 4.0 technologies, and the use of more durable and lightweight materials to enhance vehicle performance and reduce fuel consumption.

What are the challenges in designing and producing Automotive Sliding Load Floors?

The challenges include ensuring durability, reducing weight, and enhancing cargo handling capabilities while maintaining cost-effectiveness and adhering to regulatory standards.

How do geopolitical factors influence the Automotive Sliding Load Floor Market?

Geopolitical factors, such as trade policies and regional agreements, significantly influence the market, affecting manufacturing and trade. The industry must navigate these complexities to maintain a competitive edge.

What is the difference between Manual and Powered Automotive Sliding Load Floors?

Manual sliding load floors are cost-effective but require more effort, while powered sliding load floors offer convenience but at a higher cost. The choice between them depends on vehicle specifications, user preferences, and market trends.

What is the role of Automotive Sliding Load Floors in cargo handling and vehicle design?

Automotive Sliding Load Floors play a crucial role in cargo handling and vehicle design. Here’s how:

- Efficiency: They enhance the efficiency of loading and unloading cargo.

- Safety: Their design contributes to improved safety during cargo operations.

- Cost Reduction: By streamlining the process, they help reduce labor costs.

- Integration: The design of Sliding Load Floors must be integrated with the overall vehicle design to ensure optimal performance.

Which regions are key markets for Automotive Sliding Load Floors?

North America, Europe, and Asia-Pacific are key markets for Automotive Sliding Load Floors. Emerging economies in these regions also show potential for growth. It is essential for manufacturers to understand regional trends and demand in order to tailor their strategies effectively.

What is the outlook for the U.S. market for Automotive Sliding Load Floors?

The U.S. market is experiencing a surge in demand driven by the growth of e-commerce and logistics, with delivery trucks equipped with sliding load floors becoming more prevalent, enhancing operational efficiency.

What is the demand for Sliding Load Floors in Germany’s commercial vehicles?

The demand is significant, driven by the need for efficient and durable solutions, and German manufacturers are leading the way in adopting advanced technologies.

What opportunities exist for Sliding Load Floor manufacturers in China?

China’s transportation sector is expanding rapidly, creating a growing demand for automotive sliding load floors. This presents significant opportunities for manufacturers who can meet the local need for efficient and cost-effective solutions.

What are the future trends and projections for Automotive Sliding Load Floor Technology?

The future is set for significant innovations, driven by advancements in technology and changing market demands. Emerging trends such as electrification and autonomous vehicles are influencing the development of sliding load floors.

Who are the leading companies in the Automotive Sliding Load Floor Market?

The market is competitive, with several leading companies vying for market share. These companies are adopting various strategies, including innovation, partnerships, and expansion into new markets, to maintain their competitive edge.