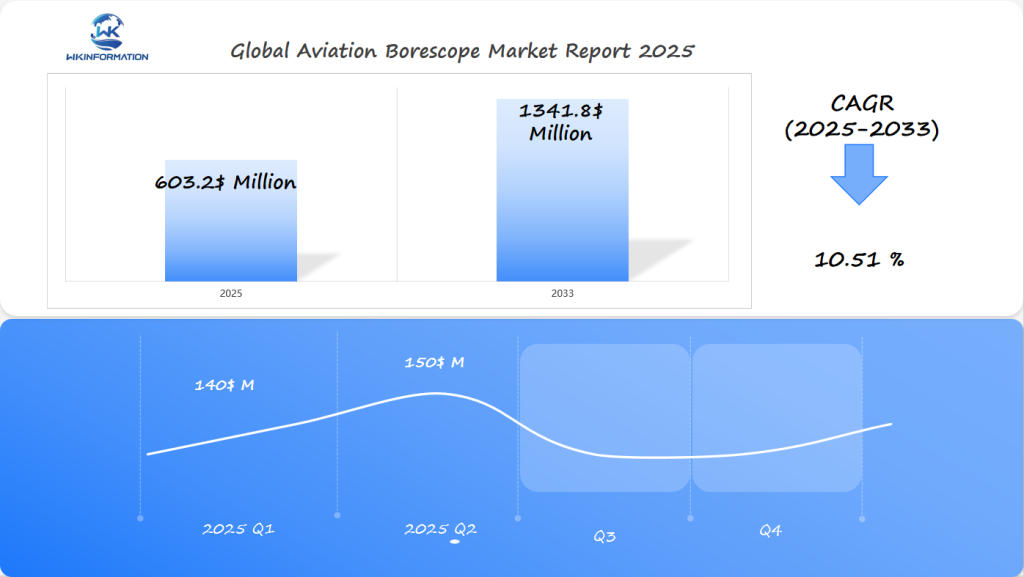

$603.2 Million Aviation Borescope Market to Expand in the U.S., France, and Japan by 2025

The Aviation Borescope Market is projected to reach $603.2M by 2025, driven by increasing aircraft inspections, maintenance demands, and technological innovations in aerospace manufacturing.

- Last Updated:

Projected Market Insights for Aviation Borescope in Q1 and Q2 of 2025

The Aviation Borescope market is projected to reach a market size of $603.2 million in 2025, with a CAGR of 10.51% from 2025 to 2033. In Q1, the market is expected to generate approximately $140 million, fueled by increasing demand for aviation maintenance and the need for advanced inspection technology.

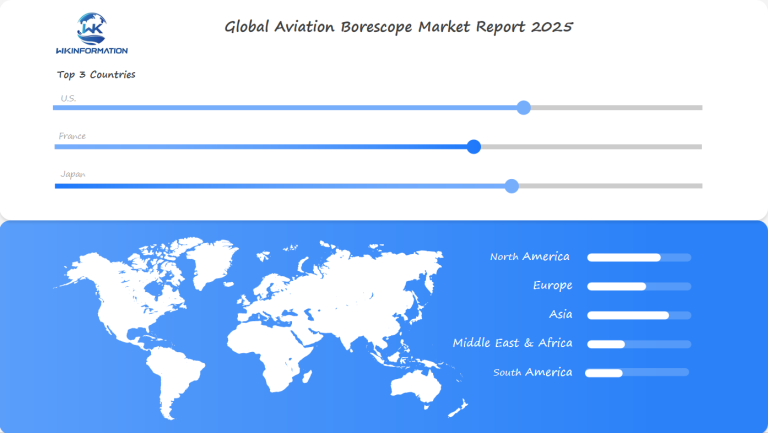

By Q2, the market is forecast to grow to around $150 million, driven by the expansion of the aerospace industry and the continuous advancements in borescope technologies. The U.S., France, and Japan are expected to dominate this market, with the U.S. leading in technological development and France and Japan focusing on high-precision applications for commercial and military aircraft.

Exploring the Upstream and Downstream Industry Chains for Aviation Borescopes

The aviation borescope market involves multiple industries, starting from the production of these tools to their practical use in various applications. By studying the supply chain, we can gain insights into how technological advancements and market trends drive innovation in aircraft inspections.

Upstream Industry Components

The upstream part of the aviation borescope world includes several important areas:

- Makers of optical components

- Creators of electronics and sensors

- Designers of high-precision lenses

- Suppliers of advanced materials

Downstream Industry Landscape

The downstream areas are key in setting market needs and tech standards. The main users are:

- Commercial aviation maintenance teams

- Military aircraft inspectors

- Aerospace research and development teams

- Maintenance, repair, and overhaul (MRO) centers

The link between upstream suppliers and downstream users drives constant improvement in borescope tech. Precision engineering and strict safety rules make a space where new tech boosts plane upkeep and flying efficiency.

Technological innovation in the aviation borescope supply chain is changing how planes are checked all over the world.

Nowadays, makers are working on making borescopes smaller but with better images. They aim to reach hard-to-get spots in planes, meeting the changing needs of users in aviation.

Key Trends in the Aviation Borescope Market

The aviation borescope market is changing fast. New technologies and ways to inspect are making aircraft maintenance better. These changes are happening all over the world.

Here are some key trends in the aviation borescope market:

- Advanced video borescopes with high-resolution imaging capabilities

- Flexible borescope designs with better movement

- AI integration for smarter inspections

- Real-time video streaming

Technological Breakthroughs in Non-Destructive Testing

Non-destructive testing is getting smarter with digital borescopes. Companies are using AI to make inspections more accurate and quick. This means finding tiny problems before they become big issues.

Digital Transformation in Aircraft Maintenance

The market is expected to grow to USD 1,030.2 Million by 2030, with a 4.2% CAGR. Leaders like Olympus Corporation and Baker Hughes are making new inspection tools. These tools use advanced optics and AI.

New tech is making borescopes better. They are more accurate and efficient. This will change how we keep aircraft safe and in good shape.

Challenges in the Manufacturing and Maintenance of Aviation Borescopes

The aviation borescope market has complex challenges. It needs precision engineering and advanced tech. Manufacturers must ensure these tools are reliable and accurate.

Borescope makers face big hurdles in meeting aviation standards. The industry requires strict rules that test tech and engineering skills.

Critical Inspection Challenges

- Engine inspection complexity requires specialized optical adaptors

- Potential financial risks from extended aircraft grounding

- Precise image categorization during maintenance inspections

Maintenance issues can hit the wallet hard. Borescope inspections may lead to aircraft being grounded for up to six months. This could cost sellers up to $1 million.

Technological innovation becomes crucial in overcoming these intricate manufacturing and maintenance challenges.

Technological Solutions in Borescope Manufacturing

New technology is emerging to address these issues. Tools such as OTT Engine Turning Tools and InHelp Inspection Assist Software are making inspections more convenient. They reduce the amount of manual labor required and improve precision.

Key Features of the New Tools

- Automated engine shaft rotation

- Standardized image categorization

- Enhanced post-inspection reporting

Manufacturers must continue to invest in research and development (R&D). It is crucial for them to stay updated with the evolving aircraft maintenance and safety requirements.

Geopolitical Influence on the Aviation Borescope Market

The aviation borescope market is changing a lot because of complex global politics and regional market trends. Global events and trade policies are making big changes in how we inspect and maintain aircraft.

Some key factors influencing the market include:

- Increasing defense spending across NATO and allied nations

- Strategic investments in AI-powered inspection technologies

- Supply chain resilience initiatives

- Technological modernization efforts

Regional Market Dynamics and Strategic Investments

The defense and aerospace sectors are going through big changes. Rolls-Royce is a great example. They’re using AI-powered borescopes for better engine checks. This shows how new tech is answering global market needs.

Global events really shape how companies plan their strategies. For example, CAE’s Defense segment hit a record adjusted backlog of $11.5 billion. This shows how strong demand is for advanced training and inspection solutions. It also shows how important global politics are in shaping aviation tech markets.

Supply Chain and Technological Adaptation

Geopolitical tensions are pushing companies to invest more in AI and making their supply chains stronger. They’re working on better strategies to deal with possible disruptions. They’re focusing on being able to adapt quickly and forming strong partnerships in different areas.

The aviation borescope market continues to evolve, driven by complex global interactions and technological advancements.

Types of Aviation Borescopes: Rigid, Flexible, and Digital Models

Aviation maintenance uses advanced inspection tools to check aircraft parts closely. Different borescope types are key to keeping planes safe and running well.

The world of aviation borescopes has many tools for various needs. Each type has special features for aircraft upkeep.

Rigid Borescopes: Precision Imaging Technology

Rigid borescopes provide high-quality images using WiDER™ technology. They are ideal for inspecting straight passages and can capture clear views from a distance.

Key Features of Rigid Borescopes

- Clear, in-focus imaging capabilities

- Unique image processing technology

- Best suited for linear inspection routes

Flexible Borescopes: Enhanced Maneuverability

Flexible borescopes are ideal for accessing difficult areas due to their ability to move in any direction. They can navigate tight spaces in aircraft with precision.

Advantages of Flexible Borescopes

- Full 360-degree range of motion

- Superior navigation in curved areas

- Improved ability to capture inspection targets

Digital Borescopes: Advanced Technological Solutions

Digital borescopes are at the forefront of technology, offering superior imaging and software capabilities. They provide comprehensive inspections.

Here are some key features of digital borescopes:

- HD video recording

- 3D modeling capabilities

- Advanced software tools like 3DAssist™ and InHelp™

Specialized Borescope Features

Today’s borescopes have extra tech for better checks:

| Feature | Benefit |

| UV/IR Illumination | Finds tiny cracks and oil leaks |

| Multiple Tube Lengths | Works in different places |

| Dual-View Camera Systems | Inspects from front and sides |

These new features show how borescopes have grown to tackle tough aviation checks.

Applications of Aviation Borescopes in Aircraft Inspection and Maintenance

Aviation borescopes have changed how we inspect and maintain aircraft. These tools let technicians check complex systems without taking them apart.

- Engine diagnostics to find wear and debris

- Checking aircraft parts

- Testing mechanical systems without damage

- Looking at fuel and hydraulic systems closely

Advanced Imaging Technologies in Aircraft Inspection

Modern borescopes, such as the MFE Series Videoscope, have incredible inspection capabilities. Equipped with dual HD cameras, they provide high-definition images. This enables technicians to identify issues with precision.

Comprehensive Inspection Capabilities

The MFE 4-Way Articulating Scope demonstrates the capabilities of advanced borescopes. With its ability to move in four directions, it can access hard-to-reach areas such as engines, improving the efficiency of maintenance tasks.

Market Impact and Technological Innovation

The borescope market is growing fast. It’s expected to go from $3.36 billion in 2024 to $5.0 billion by 2035. This shows how vital advanced inspection tech is for safety and reliability in aviation.

Global Insights into the Aviation Borescope Market

The aviation borescope market is changing fast, thanks to new tech and growing needs in many fields. Global market insights show a bright future for this important tool.

Regional Market Dynamics

North America leads the aviation borescope market. Growth projections show it will hold a big share of USD 1.6 billion in 2024. This is thanks to strong aerospace and manufacturing sectors.

Technological Advancements

New technology is driving the market’s growth. For example, GE has developed a smart borescope using AI. It quickly inspects engine blades, reducing inspection time from a day to only three hours.

Market Opportunities

Several factors are boosting market size and growth:

- More need for non-destructive testing (NDT)

- Improvements in digital imaging

- More use in aerospace

The aerospace segment is especially important. It’s worth USD 0.8 billion in 2024 and could hit USD 1.15 billion by 2035. This shows how vital borescopes are for checking planes.

U.S. Market Demand for Aviation Borescopes in Aircraft Maintenance and Safety

The U.S. aviation industry leads in technology for aircraft maintenance and safety. Leaders in aircraft maintenance are using advanced borescope technologies. This helps improve inspection accuracy and work efficiency.

There are exciting developments in the U.S. market for aviation borescopes. These include:

- GE Aerospace’s Sensiworm robotic system can explore complex engine shapes

- Advanced sensing for finding defects accurately

- AI cuts down inspection times greatly

Technological Innovation Driving Market Growth

The U.S. market for aviation borescopes is experiencing rapid growth, primarily due to significant investments in new maintenance and inspection technologies. GE Aerospace has invested over $1 billion in upgrading MRO (Maintenance, Repair, and Overhaul) facilities, demonstrating a strong commitment to safety.

New robotic systems, such as Rolls-Royce’s SWARM robots, are indicative of the industry’s significant advancement. These systems have the capability to reduce engine inspection times from five hours to mere minutes, marking a substantial transformation in aircraft maintenance practices.

AI-Powered Inspection Systems

Artificial intelligence is changing borescope technology. AI tools have cut down inspection times by 50%. This makes them very appealing to leaders in the U.S. aviation field.

The future of aircraft maintenance is all about precision, speed, and new technology.

France’s Leadership in Aviation Maintenance and Inspection Technologies

The France aviation industry leads in technology, especially in maintenance and inspection. French aerospace companies are changing aircraft maintenance with new solutions. These solutions make maintenance more efficient and safer.

- AFI KLM E&M started 80 generative AI projects across Air France sectors

- They created Charlie, a smart maintenance tool that saves over an hour per repair

- They also made Voice to Admin, a tool that improves document quality with natural language processing

Innovative Inspection Technologies

French companies are at the forefront of inspection innovations. The CFM LEAP engine, a collaborative project between GE Aerospace and Safran Aircraft Engines, demonstrates France’s dedication to technology. They utilize borescope inspections to comply with FAA regulations, showcasing their expertise in meticulous maintenance.

Export Opportunities in Aviation Technologies

France’s advanced maintenance technology opens up significant export opportunities. With tools like artificial intelligence (AI) in maintenance and advanced borescope technology, French manufacturers are leaders in the global aviation industry.

Japan’s Role in the Aviation Borescope Market and Technological Innovation

Japan is at the forefront of the aviation borescope market, leading in technology and making significant advancements in non-destructive testing for both aviation and automotive industries. Japanese manufacturers are known for their expertise in developing innovative inspection tools that are revolutionizing the way inspections are conducted across various sectors.

Japan’s leadership in the aviation borescope market is evident through:

- Expertise in precision engineering

- Advanced digital imaging technology

- Development of compact inspection tools

- Research and exploration of new materials

Pioneering R&D Initiatives in Borescope Technology

Japanese manufacturers invest heavily in research and development. They are working on creating borescope systems that provide higher levels of detail and precision. These advancements will enable more thorough inspections of aircraft, leading to reduced maintenance costs and enhanced safety in aviation.

“Japan’s commitment to being a leader in technology continues to drive innovation in non-destructive testing methods,” says industry expert Kenji Tanaka.

The Japanese aviation borescope market is continuously evolving. It collaborates with academic institutions, manufacturers, and aerospace companies to foster innovation. This collaborative effort ensures that Japan remains at the forefront of precise inspection techniques.

Global Impact of Japanese Borescope Innovations

Japanese manufacturers have introduced their advanced borescope technology globally, establishing new benchmarks for accuracy and dependability. Their continuous research and development efforts position Japan as a crucial player in the worldwide aviation inspection market. Furthermore, Japan’s influence extends to the vehicle inspection sector, showcasing the versatility and effectiveness of their innovative technology.

The Future of Aviation Borescopes: Digitalization and Enhanced Imaging

The aviation industry is rapidly evolving with the introduction of new borescope technology. Digitalization and improved imaging techniques are at the forefront of this transformation, making aircraft inspections more sophisticated and efficient.

Significant advancements are being made in predictive maintenance, which is revolutionizing the way we inspect equipment:

- AI-powered image recognition systems enhance defect detection accuracy

- Advanced sensor technologies enable real-time visual inspections

- Cloud-based data analytics provide comprehensive maintenance insights

Technological Breakthroughs in Borescope Innovation

Leading companies such as GE and Rolls-Royce are at the forefront of this movement. GE’s Sensiworm employs advanced sensors and artificial intelligence to enhance defect detection, while Rolls-Royce’s SWARM robots utilize miniature cameras for real-time inspections of engines.

The borescope market is experiencing rapid growth. It is projected to increase from $3.36 billion in 2024 to $5.0 billion by 2035. North America is taking the lead, with a target of reaching a $2.32 billion market by 2035.

Impact on Aircraft Maintenance Strategies

Digital borescope technology is reducing aircraft downtime and costs. The use of Internet of Things (IoT) and cloud technology makes inspections smarter and more efficient.

As the aviation industry embraces these new tools, borescopes are becoming crucial for identifying issues before they occur. They’re no longer solely used for internal inspections; they’re now vital for ensuring the uninterrupted operation of airplanes.

Competitive Landscape in the Aviation Borescope Market

The aviation borescope market is highly competitive, with companies such as Olympus, Baker Hughes, and Fluke Corporation at the forefront, making significant advancements in inspection technology.

- Olympus Corporation – Japan

- Baker Hughes – USA

- Teledyne FLIR LLC – USA

- JME Technologies – USA

- Fluke Corporation – USA

- Gradient Lens Corporation – USA

- Asian Contec Ltd – India

- PCE Instruments India – India

- USA Borescopes – USA

- Ome-top Systems – China

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Aviation Borescope Market Report |

| Base Year | 2024 |

| Segment by Type |

· Rigid Borescopes · Flexible Borescopes · Digital Borescopes |

| Segment by Application |

· Commercial Aviation · Military Aviation · General Aviation |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The aviation borescope market is projected to grow significantly, reaching $603.2 million by 2025, driven by increasing demand for advanced aircraft inspection technologies in countries such as the U.S., France, and Japan. Borescopes are vital tools used for non-destructive internal inspections of aircraft engines, turbines, and other components. This growth is influenced by the rising focus on aircraft safety, maintenance efficiency, and stringent regulations in the aviation industry. As airlines and maintenance providers strive for cost-effective and precise solutions, the market for aviation borescopes is set to expand, particularly in regions with high aviation activity and advanced technological adoption.

Global Aviation Borescope Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Aviation Borescope Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Vacuum Arc RemeltingMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Aviation Borescopeplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Aviation Borescope Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Aviation Borescope Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Aviation Borescope Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofAviation Borescope Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is an aviation borescope and how is it used in the aerospace industry?

An aviation borescope is a special tool for looking inside aircraft engines and other parts. It lets technicians check for damage or problems without taking things apart. This helps keep planes safe and running well.

What are the primary types of aviation borescopes available in the market?

There are three main types of aviation borescopes:

- Rigid borescopes: These are straight and used for direct inspections.

- Flexible borescopes: These can bend and are useful for accessing tight areas.

- Digital borescopes: These provide high-quality images and in-depth information for comprehensive examinations.

How do technological advancements impact aviation borescope capabilities?

New technology has improved borescopes significantly. They now offer higher resolution images, greater flexibility in reaching tight spaces, and the integration of artificial intelligence for more efficient inspections. These advancements enable faster and more precise detection of issues in aircraft components.

What industries primarily use aviation borescopes?

Borescopes are essential tools in various industries, including:

- Airlines

- Military organizations

- Aircraft repair shops

- Aircraft manufacturers

These industries rely on borescopes to ensure the safety and proper functioning of aircraft.

What are the key challenges in aviation borescope manufacturing?

Making borescopes is tough. It needs precise engineering, top-notch parts, and strict rules. It also requires new tech and training for users.

How do geopolitical factors influence the aviation borescope market?

Politics and global events shape the borescope market. They impact growth, supply chains, and the use of new tech. This affects how and where these tools are used.

What is the projected market size for aviation borescopes?

The market is expected to grow to $603.2 million by 2025. This growth comes from more testing needs, new tech, and a focus on safety in flying.

How are artificial intelligence and machine learning integrated into modern borescope systems?

Today’s borescopes use AI and machine learning. They help spot problems, analyze images, and give quick diagnoses. This makes checks more accurate and fast.

Which regions are leading in aviation borescope technology development?

The United States, France, and Japan are at the forefront of borescope technology. These countries have robust aerospace industries, conduct extensive research, and actively invest in emerging technologies.

What future trends are expected in aviation borescope technology?

The future looks digital and advanced. We’ll see better images like this , IoT connections, data analysis, and predictive maintenance. These changes will change how we inspect planes.