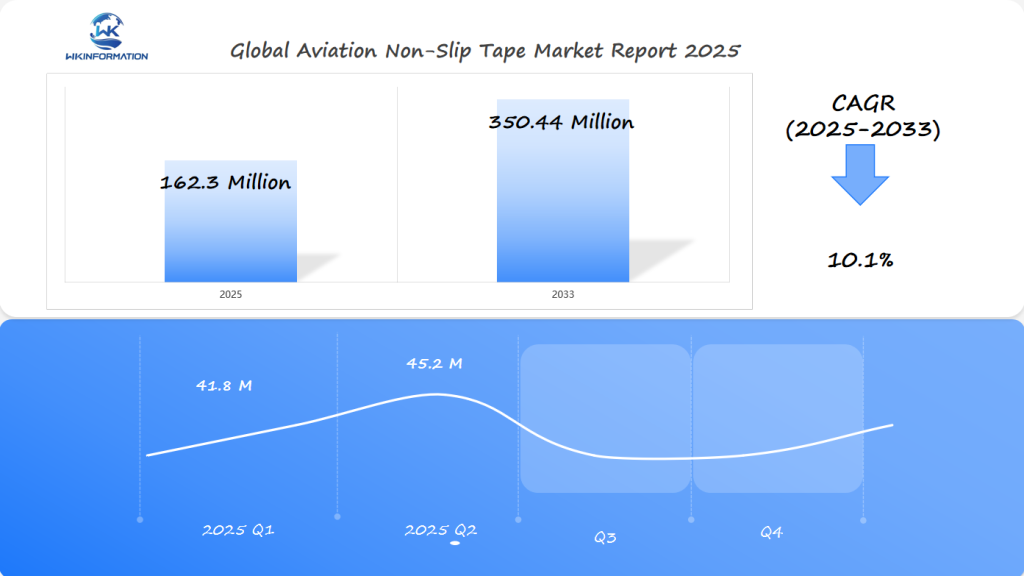

Aviation Non-Slip Tape Market: Unlocking $162.3 Million Opportunities in the US, China, and India

Explore the dynamic aviation non-slip tape market forecast for Q1-Q2 2025, focusing on key players USA, China, and India. Discover crucial safety applications, technological innovations, and market trends shaping this essential aviation safety component. Learn about regulatory challenges, sustainability initiatives, and strategic recommendations for industry success.

- Last Updated:

Q1 and Q2 2025 Forecast: Aviation Non-Slip Tape Market Trends and Insights

The global Aviation Non-Slip Tape market, valued at USD 162.3 million in 2025, is projected to grow at a CAGR of 10.1%, driven by increasing demand for safety solutions in the aviation sector. Based on current trends, Q1 2025 is expected to see market revenues of approximately USD 41.8 million, with Q2 following closely at USD 45.2 million, reflecting seasonal growth and regional demand spikes. The United States, China, and India emerge as the most promising markets, with the U.S. leading in innovation, China dominating production capacity, and India showing rapid adoption due to expanding aviation infrastructure.

For a deeper dive into market dynamics, regional insights, and growth opportunities, explore the Wkinformation Research sample and full report. Don’t miss out on the comprehensive analysis shaping the future of this industry.

Key Takeaways

- United States, China, and India lead the aviation non-slip tape market

- Strategic investments drive market growth and innovation

- Advanced safety technologies are reshaping aviation infrastructure

- Increasing air traffic supports market expansion

- Global leaders are setting new safety performance standards

Upstream and Downstream Industry Chain Analysis: The Aviation Non-Slip Tape Supply Chain

Supply chain analysis is key to understanding how aviation non-slip tape is made. It shows how raw materials, making processes, and getting products to customers work together.

The upstream part of the supply chain is very important. It includes:

- Getting raw materials from special chemical makers

- Creating precise adhesives

- Choosing top-notch substrates

- Testing the quality of base materials

Downstream, these raw materials are turned into useful aviation non-slip tape. Manufacturers face many challenges to make sure the tape works well and is safe.

There are several ways to get aviation non-slip tape to customers:

- Aerospace equipment suppliers

- Direct sales from the manufacturer

- Specialized industrial distributors

- Online stores

Good supply chain management helps companies save money, lower risks, and stay ahead in the market. Companies that do well in this area can make better products and respond faster to customer needs.

Efficient supply chain management is not just about reducing costs, but creating value throughout the entire production ecosystem.

The aviation non-slip tape supply chain is complex. It needs constant innovation and flexibility to keep up with new needs and tech.

Trend Analysis: Emerging Trends in Aviation Non-Slip Tape Technology

The aviation world is always looking to improve. They use new materials and tech in non-slip tape. This focus on safety helps make planes better and safer for everyone.

There are some big trends in non-slip tape tech:

- Advanced adhesive formulas that last longer

- Light materials that make planes lighter

- Stuff that works well in very hot or cold places

- Stuff that can handle chemicals and rough surfaces

New research brings nanotechnology into the mix. Innovative materials now have tiny structures. These make the tape stick better and last longer.

“The future of aviation safety lies in developing smarter, more adaptable non-slip technologies that can withstand increasingly challenging operational conditions.” – Aviation Safety Expert

Companies are spending a lot on making things safer. They’re working on self-healing materials and smart sensors. They also want to make things in ways that are better for the planet.

The world of aviation non-slip tape is always getting better. It shows how much the industry cares about safety and making flying better for everyone.

Restriction Analysis: Challenges in the Aviation Non-Slip Tape Market

The aviation non-slip tape market is facing big challenges. These challenges test the strength of manufacturers and suppliers. Rules and regulations make it hard for companies to innovate and compete in this important safety field.

Key market challenges include:

- Stringent safety certification requirements

- High costs of research and development

- Intense global competition

- Fluctuating raw material prices

The competition in the aviation non-slip tape sector is getting tougher. Companies must deal with international trade rules and new technologies. The U.S.-China trade war, for example, has made production costs and supply chains very unstable.

Navigating market challenges requires continuous innovation and strategic adaptation.

Regulatory hurdles are another big problem. Aviation safety rules need strict testing and certification. This means manufacturers have to spend a lot of money to meet these high standards. This can make it hard for smaller companies to get into the market.

| Market Challenge | Impact | Mitigation Strategy |

|---|---|---|

| Trade Restrictions | 10% Increase in Production Costs | Supply Chain Diversification |

| Safety Certifications | Extended Development Timelines | Continuous R&D Investment |

| Raw Material Volatility | Unpredictable Pricing | Long-Term Supplier Contracts |

The future of aviation non-slip tape makers depends on solving these complex challenges. Companies that can innovate, cut costs, and keep quality high will lead in this competitive field.

Geopolitical Analysis: The Impact of Global Politics on Aviation Non-Slip Tape Production and Trade

The aviation non-slip tape market is at a key point where international trade and global politics meet. Recent changes in the global economy have greatly affected how these safety products are made and sent around the world.

Geopolitical tensions are now a major factor in how the global supply chain for aviation non-slip tape works. Companies are making big decisions about where to make their products and how to get them to customers.

- Tariffs have created big problems for manufacturers

- Diplomatic relations directly affect international trade patterns

- Emerging markets are looking to grow their production abilities

The United States has been very careful in managing its trade relationships, especially for aviation non-slip tape. The country’s economic policies have focused on:

- Lessening reliance on just one supplier

- Building up domestic production

- Creating strong supply chain networks

Geopolitical risk management is now very important for companies in the aviation non-slip tape market. Countries are looking at how to avoid trade problems and are coming up with plans to deal with them.

The current global economic situation shows how closely politics and trade are connected. Companies need to be quick to change and adapt to new political situations to stay ahead in the aviation non-slip tape market.

Segmentation Type Market Analysis: Aviation Non-Slip Tape Market Segmentation by Material and Application

The aviation non-slip tape market has complex strategies for different products and uses. Companies are making special tapes for various aviation needs.

There are key material types in the market:

- Rubber-based tapes with better grip

- Silicone-based materials for high temperatures

- Advanced polymers for light use

- Composite materials for extra protection

Technological advancements and strict safety rules are driving the market. This pushes companies to create more advanced and specific non-slip tape products.

Application Market Analysis: The Diverse Uses of Aviation Non-Slip Tape

Aviation non-slip tape has changed aircraft safety in many ways. It’s not just for protecting floors anymore. It’s used for many other important tasks in the aerospace world.

The main uses of aviation non-slip tape are:

- Aircraft safety zones around emergency exits

- Wing walk areas for maintenance personnel

- Temporary surface protection during repair processes

- High-friction areas in cargo compartments

Maintenance in the aerospace field has gotten a lot better. Engineers use advanced non-slip tape to keep workers safe. This tape works well in tough conditions.

There are special uses for non-slip tape in different types of aircraft:

- Commercial aviation platforms

- Military aircraft operations

- Private jet maintenance

- Helicopter support systems

New non-slip tape solutions are being made. They last longer, handle extreme temperatures better, and stick stronger. These improvements help the tape work better in tough aerospace settings.

More focus on aircraft safety has led to better non-slip tape technology. This has opened up new chances for companies to improve safety in the aerospace field.

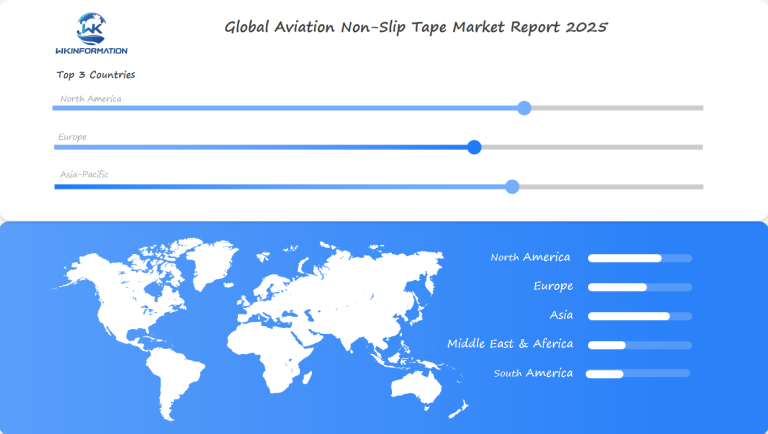

Global Aviation Non-Slip Tape Market Region Analysis: Regional Market Trends

The global aviation non-slip tape market shows big differences in different areas. Regional market dynamics show how each area grows in its own way.

Each key region has its own special traits:

- North America is ahead with the latest tech

- Europe focuses on making everything safe

- Asia-Pacific is all about quick new ideas

This market offers great chances for growth. Technological advancements and what each area needs shape how companies grow.

| Region | Market Growth Potential | Key Influencing Factors |

|---|---|---|

| North America | High | Advanced aerospace infrastructure |

| Europe | Moderate | Stringent safety regulations |

| Asia-Pacific | Rapidly Growing | Increasing aviation investments |

Companies need to make smart moves to grow in the aviation non-slip tape market.

United States Aviation Non-Slip Tape Market Analysis

The United States aviation non-slip tape market is a leader in aerospace safety. It grows fast because of strict rules and strong production. This makes it a key player in recent years.

What makes the US market stand out includes:

- Strong technological innovation from leading aerospace manufacturers

- Comprehensive safety standards enforced by federal aviation regulations

- Significant investment in research and development

Domestic production is key to the market’s success. US makers create top-notch non-slip tape. It meets the highest safety levels for planes and military vehicles.

Market trends show a rise in demand for top-notch non-slip solutions.

The rules set by the Federal Aviation Administration (FAA) are vital. They make sure non-slip tape meets high quality and safety standards. This pushes for new and better products.

Big names like Boeing and Lockheed Martin keep investing in non-slip tape tech. This keeps the US ahead in the global market.

China Aviation Non-Slip Tape Market Analysis

China’s aviation non-slip tape market has grown a lot in recent years. This growth comes from better manufacturing and more exports. The Chinese aerospace industry is now a big player in making safety parts for planes.

The market shows us important things about China’s making things:

- Rapidly expanding aerospace manufacturing infrastructure

- Significant investments in research and development

- Competitive pricing strategies in global markets

Chinese makers are very good at making non-slip tape that meets global safety rules. The growth in the Chinese market is huge. They can now make more to meet both local needs and global demand.

Export trends show a strong plan to get into more markets. Chinese makers are making special non-slip tapes for planes. They are doing well in the world market.

The government’s help has been key. It has given support and helped build up the industry. This has let Chinese companies grow their tech and reach more markets.

India Aviation Non-Slip Tape Market Analysis

The Indian aviation sector is growing fast and changing a lot. The demand for aviation non-slip tape is rising. This is because of new infrastructure and more people flying.

Several factors are driving this growth:

- Rapid expansion of domestic air transportation networks

- Government initiatives supporting aerospace manufacturing

- Increased investment in aviation safety technologies

- Growing fleet size of domestic and international carriers

India is making big steps to improve its aviation infrastructure. This has opened up great chances for non-slip tape makers. The domestic market is growing fast, with new aerospace companies looking for advanced safety solutions.

Indian makers are creating special non-slip tape products for aviation. These innovations are making India a potential global leader in aviation safety technology.

Indian aerospace companies are teaming up with international partners. This is speeding up the development of new products. The market is seeing more research and development to make high-quality non-slip tape that meets strict safety standards.

The future of India’s aviation non-slip tape market looks promising, with projected steady growth in the coming years.

Future Development Analysis: The Future of Aviation Non-Slip Tape in Safety Enhancements

The aviation world is changing fast, with new safety innovations leading the way. These changes are making non-slip tape better. Now, making safety products for planes is all about using sustainable materials.

New tech is making aviation non-slip tape even better. Scientists are working on smart materials that change with the weather. This means safer flights. The use of high-performance films shows how safety can get even better.

- Development of adaptive non-slip materials

- Enhanced durability and performance

- Eco-friendly manufacturing processes

- Advanced chemical compositions

Using sustainable materials is changing safety in the skies. Companies are spending on research to make things better for the planet. They want to keep safety high while being kind to the environment.

| Innovation Area | Expected Impact | Timeline |

|---|---|---|

| Nanotechnology | Improved grip performance | 2-3 years |

| Recyclable Materials | Reduced environmental impact | 3-5 years |

| Smart Sensing Technologies | Real-time safety monitoring | 4-6 years |

The future of aviation non-slip tape looks very promising. Safety is getting better, thanks to new tech. Everyone is working hard to make flying safer and greener.

Competitor Analysis: Major Players in the Aviation Non-Slip Tape Market

The aviation non-slip tape market is very competitive.

- Jessup

- Heskins Ltd

- 3M Company

- Heskins

- Brown Aircraft Supply

- Advance Tapes International

- Avery Dennison Corporation

- Berry

- Saint-Gobain

- DeWAL Industries

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Aviation Non-Slip Tape Market Report |

| Base Year | 2024 |

| Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The aviation non-slip tape market is set for exciting growth. New technologies and strategies are opening up big opportunities worldwide. Companies are working hard to create safer and longer-lasting materials for planes.

Investing in aviation non-slip tape is looking good, with the US, China, and India leading the way. These countries are seeing big increases in demand. This is thanks to more planes being made, stricter safety rules, and new materials.

Different parts of the world face their own challenges and chances. The US is at the forefront of new tech, while China and India are growing fast. Companies that keep up with changes and invest in research will do well.

Success in this market will come from staying ahead with new ideas, forming strong partnerships, and meeting tough safety standards. As air travel grows, so will the need for better non-slip tapes. This offers great chances for makers and investors.

Global Aviation Non-Slip Tape Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Aviation Non-Slip Tape Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Vacuum Arc Remelting Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Aviation Non-Slip Tape players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Aviation Non-Slip Tape Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Aviation Non-Slip Tape Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Aviation Non-Slip Tape Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Aviation Non-Slip Tape Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is aviation non-slip tape?

Aviation non-slip tape is a specialized adhesive solution designed to improve traction on various surfaces within aircraft. These tapes are crucial for preventing slips and falls, particularly in areas that may become wet or greasy. Common applications include interior flooring, maintenance areas, and airport facilities.

Why is non-slip tape important in aviation?

Non-slip tape plays a vital role in enhancing safety by reducing the risk of accidents related to slipping. This is especially important in aviation settings where the safety of passengers and crew is paramount. By providing additional grip, these tapes contribute to a safer travel experience.

Which materials are commonly used in non-slip tapes?

Non-slip tapes are typically made from materials such as PVC or rubber-based foam. These materials offer durability and resistance to various environmental conditions encountered during flights. Advances in adhesive technology have further improved their performance.

How do safety regulations impact the use of non-slip tape?

Safety regulations enforced by authorities like the FAA necessitate the use of effective non-slip solutions within aircraft. Compliance with these regulations ensures that products meet strict industry standards, which is essential for manufacturers looking to supply the aviation sector.

Are there eco-friendly options available for non-slip tapes?

Yes, as sustainability becomes increasingly important, manufacturers are developing eco-friendly non-slip tapes. These products aim to meet regulatory standards while offering biodegradable or recyclable options without compromising on performance.