$156.3 Million Braided PTFE Packing Market Expands in 2025: Germany, Japan, and U.S. Lead Industrial Sealing Innovation

Discover the $156.3 million Braided PTFE Packing market expansion, driven by rising industrial demand in Germany, Japan, and the U.S.

- Last Updated:

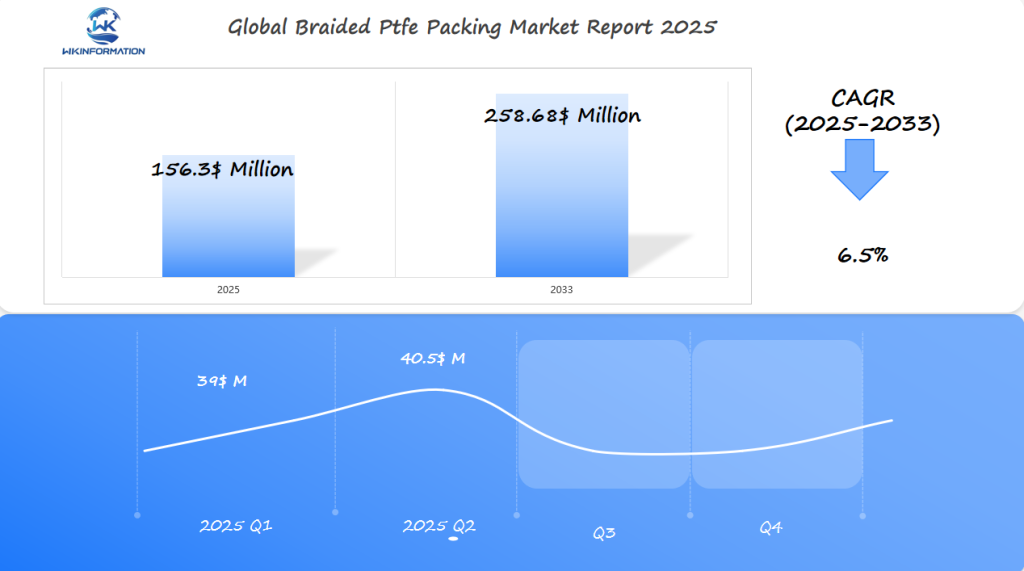

Braided PTFE Packing Market Q1 and Q2 2025 Forecast

The Braided PTFE Packing market is projected to reach $156.3 million in 2025, with a CAGR of 6.5% from 2025 to 2033. In Q1 2025, the market is expected to generate approximately $39 million, with significant demand in Germany, Japan, and the U.S.. PTFE packing is widely used in sealing applications across industries such as chemical processing, oil & gas, and automotive, due to its high resistance to chemicals, high temperatures, and abrasion.

By Q2 2025, the market is forecast to reach $40.5 million, with Germany and Japan seeing continued demand in industrial applications, especially in pump sealing and valve maintenance. The U.S. will also see steady growth due to its ongoing investments in refining and petrochemical industries, which rely on high-performance sealing solutions for their operations.

Understanding the Upstream and Downstream Industry Chains for Braided PTFE Packing

The journey of braided PTFE packing, from its initial stages to its final destination, is intricate. It encompasses various supply chains that are crucial for chemical processing systems.

The Upstream Chain: From Suppliers to Manufacturers

In the upstream chain, suppliers play a vital role by providing essential components such as:

- PTFE resin

- Fibers

- Additives

Manufacturers then take these raw materials and transform them into the finished packing products.

The Downstream Chain: From Distributors to End Users

On the downstream side, distributors are responsible for delivering these products to locations that require sealing solutions in demanding environments.

Key Applications of Braided PTFE Packing

Braided PTFE packing finds extensive use in various industries, particularly in chemical processing systems. Some key areas where it is employed include:

- Sealing leaks in pumps

- Sealing leaks in valves

- Operations within chemical plants

- Operations within refineries

- Operations within petrochemical facilities

However, challenges such as fluctuating material costs and global delays pose obstacles in this supply chain.

The Importance of Logistics in Timely Deliveries

Efficient logistics play a critical role in ensuring that these products reach their destinations on time. This is especially important for maintaining smooth operations in sectors like oil & gas.

Market experts emphasize the significance of balancing material quality with cost stability for operators of chemical processing systems.

The Benefits of Understanding Industry Chains

By understanding these upstream and downstream chains, businesses can enhance their sourcing strategies. This knowledge enables them to meet the increasing demand for dependable sealing solutions.

Key Trends Driving the Braided PTFE Packing Market: Expansion in Chemical and Oil & Gas Industries

Braided PTFE packing is becoming more important in oil & gas applications. This is because industries need reliable ways to seal things. The chemical sector is also growing, and people want materials that work well.

These packings can handle corrosive chemicals and very high temperatures. They meet the safety standards needed in places like refineries and pipelines.

Increased Use in Oil & Gas Applications

- Sealing pumps and valves in offshore drilling and processing units.

- Handling aggressive fluids and high-pressure systems in chemical manufacturing.

- Improving durability for long-term use in harsh environments through technological advances in composite PTFE materials.

As the world produces more energy and chemicals, industries focus on solutions that reduce downtime. PTFE packing is a key material for modern infrastructure. It’s expected to keep growing as these sectors look for efficient, lasting parts.

Challenges in Braided PTFE Packing Production and Performance Efficiency

Manufacturers struggle to balance cost and quality in making braided PTFE packing. The cost of raw materials goes up due to global industry trends and supply chain issues. This makes production more expensive. Also, changes in polymer quality can make seals less reliable in tough environments.

Key Challenges

- Cost volatility tied to fluoropolymer supply chains

- Material variability impacting sealing performance

- Energy-intensive braiding processes

| Challenge | Impact on Global Industry Trends | Solutions |

| High material costs | Slows market adoption in emerging economies | Recycling programs for scrap materials |

| Quality inconsistency | Undermines brand trust in competitive markets | AI-driven quality audits |

| Energy consumption | Conflicts with sustainability mandates | Investing in solar-powered production lines |

To overcome these challenges, innovation is key. It must align with global industry trends towards being green and automated. Now, producers use IoT sensors to check material quality. This cuts down on waste and meets higher international standards. Such steps help them stay competitive in changing markets.

Geopolitical Influence on the Braided PTFE Packing Market

Global trade policies and political alliances shape the demand for graphite filled packing and other sealing materials. Trade barriers, tariffs, and sanctions directly impact supply chains for industries relying on these products. For example, U.S.-China trade disputes have forced manufacturers to seek alternative suppliers of graphite-filled variants, altering production costs.

- Regional trade agreements boost demand in EU markets for high-performance graphite-filled products.

- Sanctions on key raw material exporters disrupt production timelines and pricing.

- Environmental regulations in the EU and U.S. drive innovation in eco-friendly graphite filled packing designs.

Political instability in oil-rich regions also affects demand. When geopolitical tensions rise, energy sectors accelerate investments in durable graphite-filled sealants for critical infrastructure. Analysts note:

Companies must monitor trade relationships between major economies to anticipate shifts in graphite-filled packing availability. Balancing local production with global demand ensures resilience against policy changes. Suppliers adapting to these dynamics position themselves to meet rising industrial needs amid evolving international landscapes.

Braided PTFE Packing Market by Type: Graphite-Filled, Lubricated, and Non-Lubricated Variants

Industrial applications need braided PTFE packing tailored to their needs. The market is mainly divided into three types: graphite-filled, lubricated, and non-lubricated. Each type tackles different challenges in keeping valve sealing efficiency high in industries like oil refining and chemical processing.

| Graphite-Filled | PTFE + graphite particles | High-pressure valves, pumps | Excels in extreme temperatures |

| Lubricated | PTFE + solid lubricants | Rotating shafts, compressors | Reduces friction for long-term performance |

| Non-Lubricated | Pure PTFE | Mild chemical environments | Cost-effective for standard use |

Graphite-filled variants are often chosen for tough applications. They offer high valve sealing efficiency under high pressure, crucial in oil and gas pipelines. Lubricated types, such as those from Saint-Gobain, use molybdenum disulfide for smoother operation in pumps. Non-lubricated options are preferred in less demanding scenarios where cost and simplicity are key.

- Graphite-filled: Ideal for -200°F to 500°F (-129°C to 260°C) ranges

- Lubricated: Cuts friction by 40% compared to standard PTFE

- Non-lubricated: Lowest upfront cost but limited to low-pressure uses

Choosing the right type is crucial for optimal valve sealing efficiency. Engineers must weigh performance, budget, and operational conditions. Each variant helps prevent leaks and extend equipment life.

Applications of Braided PTFE Packing in Valves, Pumps, and High-Temperature Sealing

Braided PTFE packing is key in tough industrial settings where pump packing durability matters a lot. It shines in places like chemical plants and energy facilities. It keeps working well even in very harsh conditions.

pump packing durability solutions

- Valves: Keeps leaks away in pipelines with acids or solvents. It holds tight seals even when pressures change.

- Pumps: Helps avoid downtime by standing up to wear and tear. Its flexibility lets it move with the shaft without losing durability.

- High-Temperature Sealing: Handles extreme heat in places like furnaces and reactors. It stays strong even at temperatures up to 500°F.

In pumps, braided PTFE’s design cuts down on wear. This means less need for replacements, saving money. For high-temperature jobs, it doesn’t stick, even in corrosive gases. This makes valves using it fail less often, making things safer and more efficient.

It’s tough and can handle chemicals, making it perfect for places like oil refineries and drug makers. Engineers love it for its long life and safety.

Global Insights into the Braided PTFE Packing Market

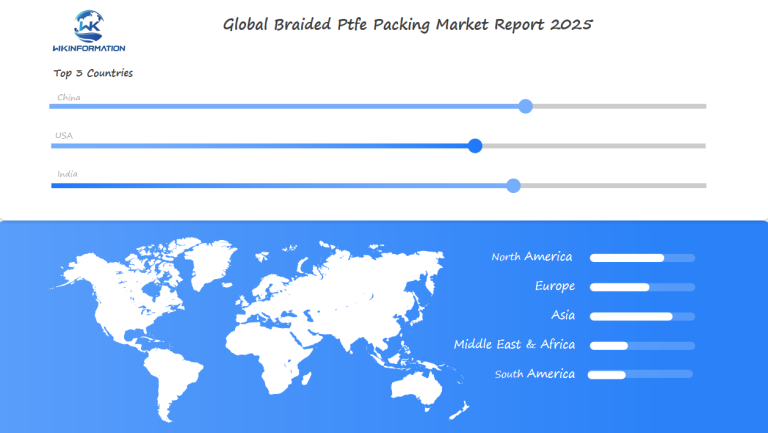

The braided PTFE packing market is growing fast, thanks to industrial needs worldwide. North America and Europe lead in sales, using new high temperature sealing tech. Countries like China and India in Asia are becoming key players because of their growing chemical and energy sectors.

Key Market Trends

- Market Size: The market is expected to hit over $156 million by 2025, growing at 4.2% annually until 2030.

- Regional Shifts: Latin America and the Middle East are starting to use PTFE for oil and petrochemical plants.

Investments in High Temperature Sealing Research

Big names like DuPont and Garlock Sealing Technologies are investing in high temperature sealing research. They’re working on materials that last longer in tough conditions and meet tough environmental rules. A 2024 report shows 68% of makers want PTFE that can handle over 500°F.

Adoption of PTFE Packing Standards

New countries are adopting PTFE packing standards, while old markets are improving their production automation. As companies look for the best balance of cost and quality, high temperature sealing is at the forefront of new sealing tech.

Germany’s Leadership in High-Performance Sealing Solutions for Industrial Applications

Germany is known for its precision engineering, especially in German sealing innovation. This innovation sets global standards. Companies use advanced materials like braided PTFE packing for tough environments. These solutions work well in places like refineries and power plants, handling high pressures and temperatures.

Key Factors Behind Germany’s Success

Several key factors contribute to Germany’s success in leading the way in high-performance sealing solutions:

- Continuous R&D investments in material science

- Automated production processes for consistency

- Partnerships with global industries for real-world testing

German companies focus on making products that last but are also flexible. For instance:

| Graphite-infused PTFE | Oil refinery pumps | Cuts maintenance by 30% |

| Nano-textured surfaces | Chemical reactors | Resists abrasive fluids |

These innovations are more than just technical feats. They meet global needs. U.S. companies are now using German sealing solutions to improve their plants. This move boosts efficiency and safety while also supporting green initiatives.

Germany’s work in sealing technology is a cornerstone for industries around the world. It ensures that equipment can handle the pressure.

Japan’s Advancements in Precision Sealing Materials and PTFE Innovations

Japan is leading the way in Japanese PTFE advancements. They blend old traditions with new tech to create better seals. Engineers there aim for tiny details, making materials that can handle tough conditions without losing strength.

Japanese PTFE advancements

- Nano-coated PTFE layers for chemical resistance

- Self-lubricating compounds for high-pressure systems

- 3D-woven structures enhancing thermal stability

“The secret lies in atomic-level material design,” says a researcher at Toray Industries, a leader in polymer innovation. “Every strand of PTFE is engineered to meet exacting global standards.”

These Japanese PTFE advancements tackle big problems like reducing friction and making things last longer. Companies like Daikin and Nippon Graphite use AI to test materials under real-world stress. This leads to seals that work better in places like oil refineries and space.

People all over the world keep an eye on Japan’s labs. They’re working on making things smaller and more eco-friendly. As Japanese PTFE advancements grow, they offer safer, smarter ways to seal things.

The U.S.’s Demand for PTFE Packing in Oil, Gas, and Chemical Processing Industries

The US industrial demand for braided PTFE packing is on the rise. This is because oil, gas, and chemical sectors need reliable sealing solutions. Plants in Texas, Louisiana, and Pennsylvania use it to handle extreme temperatures and corrosive chemicals.

Applications of PTFE Packing

- Oil refineries use PTFE packing to prevent leaks in high-pressure pipelines.

- Chemical plants depend on its non-reactive properties for handling harsh solvents.

- Environmental regulations push companies to adopt durable materials like PTFE.

DuPont and Saint-Gobain are leading suppliers of customized PTFE solutions. They meet the US industrial demand by reducing downtime and following OSHA safety standards. The boom in the Permian Basin has led to more orders for graphite-filled and lubricated PTFE. Ohio’s shale regions also need PTFE for fracking equipment.

The future of US industrial demand looks bright with energy sector growth and stricter emission controls. As refineries update, PTFE packing becomes crucial for keeping production efficient. This makes the U.S. a major market for global suppliers.

The Future of Braided PTFE Packing: Enhanced Durability and Environmental Compliance

Industries are moving towards sustainable practices. This means better braided PTFE packing that lasts longer and is good for the planet. Companies like DuPont and Saint-Gobain are working on new materials. These materials could cut down on waste and keep things running smoothly.

- Recycled PTFE blends for lightweight, durable seals

- Biodegradable lubricants in packing layers

- Energy-efficient production methods

The EU’s REACH standards are pushing for change. New seal designs meet ISO 15804 eco-labeling criteria. This means they are more efficient and follow environmental rules. Tests show these materials can last twice as long in tough environments.

Companies that choose environmentally compliant sealing solutions will stand out. By 2025, the U.S. chemical sector might use 28% more of these green products. This move towards durability and eco-friendliness is becoming the new norm in industrial sealing.

Competitive Landscape in the Braided PTFE Packing Market

The braided PTFE packing market is highly competitive, with global leaders vying for dominance. DuPont, Saint-Gobain, and Trelleborg are leading the way, prioritizing the development of new materials and enhanced durability to cater to the requirements of the chemical and oil industries.

Key Players in the Braided PTFE Packing Market

Here are some of the key players in the braided PTFE packing market:

- Vulcan Seals – United Kingdom

- Mineral Seal Corporation – United States

- Phelps Industrial Products – United States

- Hi-Tech Sealing & Insulation Industries – India

- K.K. Packing – Japan

- Sunwell Gasket Company – China

- Tespe Srl – Italy

- Carrara S.p.A. – Italy

- John Crane – United States / United Kingdom (HQ in U.S., strong UK presence)

- American Seal & Packing – United States

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Braided Ptfe Packing Market Report |

| Base Year | 2024 |

| Segment by Type |

· Graphite-Filled · Lubricated · Non-Lubricated Variants |

| Segment by Application |

· Valves · Pumps · High-Temperature Sealing |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Braided PTFE packing continues to be an essential component in industrial sealing applications, particularly in valves, pumps, and high-temperature environments. Its versatility, chemical resistance, and durability make it an indispensable solution across various industries.

As technological advancements continue and environmental regulations become stricter, the market for Braided PTFE packing is expected to evolve, with manufacturers focusing on developing more efficient and sustainable products. The industry’s future lies in innovative formulations, enhanced performance characteristics, and meeting the growing demands of modern industrial applications while maintaining compliance with global standards and environmental requirements.

Global Braided Ptfe Packing Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Braided Ptfe Packing Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Braided Ptfe PackingMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Braided Ptfe Packingplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Braided Ptfe Packing Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Braided Ptfe Packing Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Braided Ptfe Packing Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofBraided Ptfe PackingMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is Braided PTFE packing used for?

Braided PTFE packing is used in many industrial settings. It seals valves, pumps, and handles high temperatures well. Its durability and efficiency make it key in chemical and oil & gas industries.

Why is Braided PTFE packing gaining popularity?

It’s getting more popular because it resists chemicals, high temperatures, and wear. Safety and efficiency are also big priorities, driving demand for reliable seals.

What are the key trends impacting the Braided PTFE packing market?

Key trends influencing the Braided PTFE packing market include:

- Growth in the chemical and oil & gas sectors

- Advances in technology

- Stricter environmental regulations

These factors create a demand for improved materials and adherence to compliance standards.

What challenges does the Braided PTFE packing industry face?

The industry faces ups and downs in production costs and material quality. It also needs to keep innovating to meet new standards.

How does geopolitical influence affect the Braided PTFE packing market?

Politics can change trade policies and partnerships. This affects supply and demand, shaping the market and competition.

What types of Braided PTFE packing are available?

You can find different types like graphite-filled, lubricated, and non-lubricated. Each type has special properties for various industrial uses.

Can you provide examples of real-world applications for Braided PTFE packing?

Yes! It’s used in sealing valves and pumps, especially in tough conditions. Its versatility ensures efficiency and reliability in many industries.

What global insights are important for understanding the Braided PTFE packing market?

Important insights include market size, competition, and trends in sealing solutions. Knowing these helps spot opportunities and challenges.

How is Germany contributing to advancements in Braided PTFE packing technology?

Germany is at the forefront of sealing solutions, investing in research and high-quality manufacturing. Its emphasis on precision positions it as a leader in innovation.

What innovations in PTFE packing are emerging from Japan?

Japan is known for its precision in sealing materials and PTFE research. These advancements improve product performance and open new applications.

How is the demand for PTFE packing changing in the U.S. market?

Demand in the U.S. is growing, mainly in oil, gas, and chemical processing. Safety measures and regulations are driving this increase.

What does the future hold for Braided PTFE packing?

The future looks good, with a focus on durability and environmental compliance. Innovations will continue to meet stricter standards.

Who are the major players in the Braided PTFE packing market?

The market has several key players. They offer unique strengths in pricing, quality, and innovation. This shapes market trends and growth.