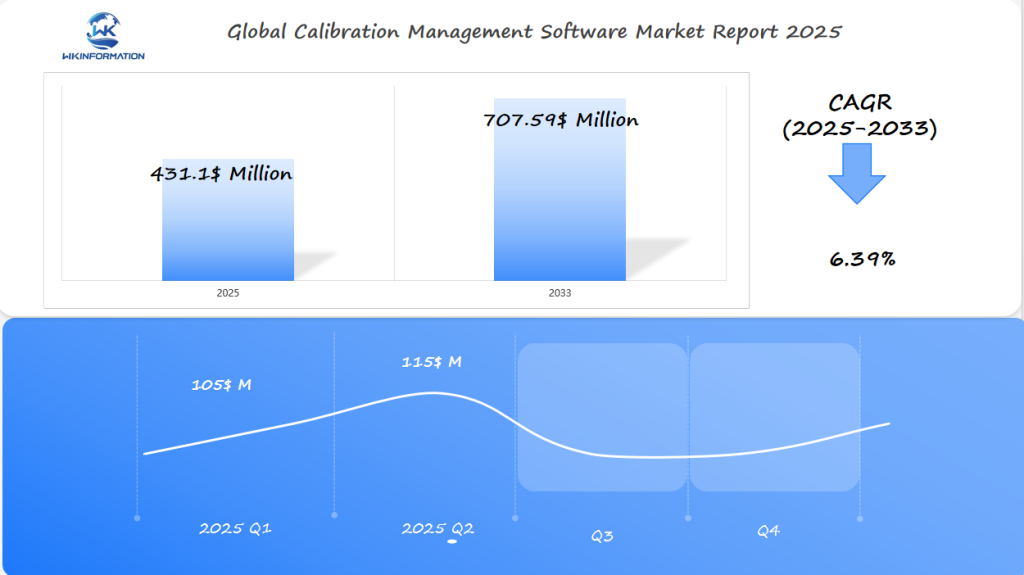

Calibration Management Software Market Forecasted at $431.1 Million by 2025: Digital Validation Accelerates in Germany, India, and the U.S.

The Calibration Management Software Market is projected to reach $431.1 million by 2025, driven by digital validation adoption across industries. Key factors include quality control digitization, integration challenges with legacy systems, geopolitical compliance influences, and sector-specific uptake in pharma, aerospace, and manufacturing. Future trends highlight automation and AI, with significant growth in global markets like Germany, India, and the USA.

- Last Updated:

Calibration Management Software Market: Q1 and Q2 of 2025 Analysis

The Calibration Management Software market is projected to reach $431.1 million in 2025, growing at a CAGR of 6.39% from 2025 to 2033. In Q1 of 2025, the market size is expected to be approximately $105 million, with growth continuing into Q2, reaching $115 million.

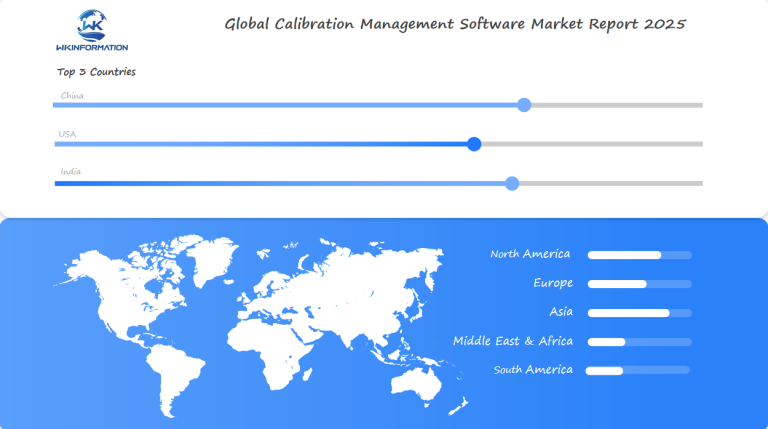

The increasing need for accurate and reliable calibration across various industries such as manufacturing, healthcare, and aerospace is driving the demand for calibration management software. Germany, India, and the U.S. are key markets for this software.

- Germany, with its strong industrial sector, is seeing significant adoption of calibration management systems.

- India’s manufacturing sector is embracing these solutions to enhance operational efficiency.

- The U.S. is increasingly adopting this software in regulated industries like healthcare and aerospace.

As industries become more digital and require high levels of precision, the demand for calibration management software will continue to grow.

Calibration Management Software market upstream and downstream industry chain analysis

A comprehensive analysis of the Calibration Management Software market requires examining both its upstream and downstream segments.

- The upstream segment includes suppliers of raw materials and components necessary for software development, such as hardware components and IT infrastructure.

- The downstream segment involves the end-users of the Calibration Management Software, including industries such as pharmaceuticals, aerospace, and industrial manufacturing.

Industry Chain Overview

The industry chain of Calibration Management Software is complex and involves many different people. It includes software developers, system integrators, consultants, and end-users. In the upstream segment, the software development process is critical, where companies focus on creating sophisticated software solutions that meet the evolving needs of industries.

In the downstream segment, end-users play a crucial role in shaping the market dynamics. Their requirements and feedback significantly influence the development and refinement of Calibration Management Software. Industries such as pharmaceutical quality assurance and aerospace validation rely heavily on calibration management software to ensure compliance with regulatory standards.

Key Players in the Industry Chain

Key players in the Calibration Management Software industry chain include software developers like Fluke Calibration and Beamex, system integrators, and consultants who provide implementation and support services. These players work together to ensure the smooth operation of calibration management processes across various industries.

- Software developers creating innovative calibration management solutions

- System integrators providing implementation services

- Consultants offering training and support

- End-users influencing software development through their needs and feedback

Understanding the roles and interactions of these key players is essential for analyzing the Calibration Management Software market and predicting its future trends.

Quality Control Digitization Driving the Evolution of Calibration Management Software

The digitization of quality control is revolutionizing the Calibration Management Software landscape. This transformation is driven by the need for more accurate, efficient, and compliant calibration processes across various industries.

The Role of Digitization in Quality Control

Digitization plays a crucial role in enhancing quality control practices. By leveraging digital technologies, companies can improve the accuracy and efficiency of their calibration processes. Digital validation, a key aspect of this digitization, ensures that calibration data is accurate, reliable, and compliant with regulatory standards.

What is Digital Validation?

Digital validation involves the use of digital tools and software to validate calibration processes. This method not only reduces manual errors but also streamlines the calibration workflow, making it more efficient. Furthermore, digital validation enables real-time monitoring and reporting, which is crucial for maintaining high-quality standards.

Benefits of Digitization in Quality Control

The benefits of digitization in quality control can be summarized as follows:

| Benefits | Description | Impact |

| Improved Accuracy | Reduced manual errors through digital validation | Higher quality standards |

| Increased Efficiency | Streamlined calibration workflow | Faster calibration processes |

| Real-time Monitoring | Enabled by digital tools and software | Better compliance with regulatory standards |

The integration of digital technologies in quality control is transforming the Calibration Management Software market.

The digitization of quality control is driving the evolution of Calibration Management Software by improving accuracy, efficiency, and compliance. As industries continue to adopt digital validation practices, the demand for advanced Calibration Management Software is expected to grow.

Barriers in integration with legacy systems and validation protocols

Despite advancements in Calibration Management Software, legacy system integration and validation protocol compliance remain major challenges. Many organizations struggle to ensure seamless integration with their existing systems, which can lead to significant delays and increased costs.

The integration of Calibration Management Software with legacy systems is a complex process. It requires a deep understanding of both the new software and the existing infrastructure. Moreover, validation protocols must be adhered to, to ensure compliance with regulatory standards.

Challenges in Integrating with Legacy Systems

Legacy systems often have outdated technology and may not be compatible with modern Calibration Management Software. This can lead to compatibility issues that need to be addressed through costly updates or workarounds.

Data migration is another significant challenge. Transferring data from legacy systems to new Calibration Management Software can be a complex and time-consuming process, requiring significant resources and planning.

Regulatory bodies such as the FDA have strict guidelines for validation protocols. Non-compliance can result in significant fines and reputational damage. Therefore, it is crucial to ensure that Calibration Management Software is validated according to these protocols.

The following table highlights some of the key validation protocols and their requirements:

| Validation Protocol | Description | Regulatory Requirement |

| IQ/OQ/PQ | Installation Qualification, Operational Qualification, Performance Qualification | Yes |

| CSV | Computerized System Validation | Yes |

| 21 CFR Part 11 | Regulation for electronic records and signatures | Yes |

To overcome these challenges, organizations should adopt a strategic approach to integrating Calibration Management Software with legacy systems. This includes thorough planning, resource allocation, and compliance with validation protocols.

Geopolitical factors affecting software compliance across industries

As companies expand globally, they must navigate the complex landscape of software compliance influenced by geopolitical factors. This navigation is crucial for maintaining operational integrity and avoiding legal repercussions.

The relationship between geopolitical factors and software compliance is complex. Regulatory requirements and standards vary significantly across different regions, posing a challenge for companies operating on a global scale.

Impact of Geopolitical Factors on Software Compliance

Geopolitical tensions and changes in international relations can lead to shifts in regulatory policies, affecting how software is developed, deployed, and maintained. For instance, trade wars can result in tariffs and restrictions on software imports and exports, complicating compliance efforts.

Key geopolitical factors influencing software compliance include:

- Regional data protection laws

- Export controls on software and technology

- Intellectual property laws

- Sanctions and trade embargoes

Companies must stay abreast of these factors to ensure their software complies with the relevant laws and regulations. As “The complexity of global regulations demands a proactive approach to software compliance.”

To navigate this complex landscape, businesses are turning to advancedQuality Assurance Software that can help manage compliance across different jurisdictions. This software enables companies to streamline their compliance processes, reducing the risk of non-compliance.

By understanding the impact of geopolitical factors on software compliance, companies can better prepare for the challenges ahead, ensuring their operations remain compliant and competitive in a rapidly changing global environment.

Solution segmentation: Cloud-native suites, Integrated platforms, Modular tools

Diverse Calibration Management Software solutions are emerging to cater to different organizational needs. These solutions can be broadly categorized into cloud-native suites, integrated platforms, and modular tools.

Types of Calibration Management Software Solutions

The Calibration Management Software market offers a range of solutions, each designed to meet specific organizational requirements.

1. Cloud-native Suites

Cloud-native suites are designed for scalability and flexibility, allowing organizations to easily adapt to changing demands.

2. Integrated Platforms

Integrated platforms provide a comprehensive suite of tools that integrate calibration management with other quality control processes, enhancing overall efficiency.

3. Modular Tools

Modular tools, on the other hand, offer flexibility by allowing organizations to select specific modules that meet their needs, reducing costs and complexity.

Benefits of Different Solution Types

Each type of Calibration Management Software solution has its benefits.

| Solution Type | Key Benefits | Organizational Needs |

| Cloud-native Suites | Scalability, Reduced Infrastructure Costs | Organizations with changing demands |

| Integrated Platforms | Comprehensive Quality Control, Improved Compliance | Organizations seeking integrated quality control |

| Modular Tools | Flexible Deployment, Cost-Effectiveness | Organizations with specific calibration needs |

Sector-specific adoption: Pharma QA, Aerospace validation, Industrial manufacturing

Calibration Management Software is being adopted by diverse sectors, each with its own set of requirements and challenges, such as pharma QA, aerospace validation, and industrial manufacturing. The software’s versatility in meeting the stringent calibration needs of various industries is a key factor in its widespread adoption.

Adoption in Pharmaceutical Quality Assurance

In the pharmaceutical industry, quality assurance is paramount. Calibration Management Software plays a crucial role in ensuring that equipment is calibrated regularly and accurately, thereby maintaining compliance with regulatory standards. Pharma QA teams rely on this software to streamline their calibration processes, reduce downtime, and enhance product quality.

Aerospace Validation and Industrial Manufacturing Applications

Aerospace validation and industrial manufacturing also benefit significantly from Calibration Management Software. In aerospace, the software is used to validate the accuracy of complex equipment and instruments, ensuring that they meet the stringent standards required for aerospace applications.

Industrial manufacturing relies on Calibration Management Software to maintain the precision of manufacturing equipment, thereby ensuring product quality and reducing the risk of equipment failure. The software’s ability to track calibration history and schedule future calibrations is particularly valuable in these industries.

| Sector | Key Benefits | Challenges |

| Pharma QA | Streamlined calibration, reduced downtime, enhanced product quality | Regulatory compliance, data integrity |

| Aerospace Validation | Ensured accuracy, compliance with aerospace standards | Complexity of equipment, validation protocols |

| Industrial Manufacturing | Precision maintenance, reduced risk of equipment failure | Integration with existing systems, calibration scheduling |

The adoption of Calibration Management Software across these sectors highlights its versatility and the significant benefits it offers. As industries continue to evolve and regulatory requirements become more stringent, the demand for this software is expected to grow.

Calibration software expansion across global markets

The global Calibration Software market is expanding rapidly, fueled by advancements in technology and regulatory compliance requirements. As industries worldwide continue to adopt digital transformation strategies, the demand for Calibration Management Software is on the rise.

“The calibration software market is poised for significant growth as industries prioritize precision and quality control,” notes a recent industry report. This growth is driven by the need for efficient calibration processes and compliance with stringent regulatory standards.

Global Market Trends

The expansion of Calibration Management Software across global markets is influenced by several key trends:

- The increasing adoption of Industry 4.0 technologies is driving the demand for advanced calibration solutions.

- The growing emphasis on quality control and regulatory compliance is pushing industries to invest in sophisticated calibration software.

Regional Growth Patterns

- North America is witnessing significant growth due to the presence of major industries and stringent regulatory requirements.

- The Asia-Pacific region is emerging as a lucrative market, driven by rapid industrialization and technological advancements.

- Europe is also experiencing growth, fueled by the region’s strong focus on quality control and precision manufacturing.

The global Calibration Software market is characterized by the presence of several key players, including Fluke Calibration and Beamex, who are driving innovation and setting industry standards.

As the market continues to evolve, we can expect to see further advancements in calibration technology, including the integration of AI and machine learning capabilities. This will enable industries to achieve even higher levels of precision and efficiency in their calibration processes.

Germany’s precision-driven manufacturing accelerating deployment

Germany’s precision-driven manufacturing industry plays a crucial role in the widespread use of Calibration Management Software. This sector is renowned for its commitment to maintaining top-notch quality and adhering to strict regulations, which makes the integration of calibration software an essential part of ensuring quality control.

Overview of Germany’s Manufacturing Sector

Germany’s manufacturing sector is a key player in the European economy, known for its focus on precision, quality, and innovation. The sector’s strong emphasis on precision manufacturing has resulted in a growing need for Calibration Management Software, which is used to ensure that equipment and instruments are properly calibrated.

Key Factors Driving Adoption

The following factors are driving the adoption of Calibration Management Software in Germany’s manufacturing sector:

- Compliance with international quality standards

- Complexity of manufacturing processes

- Increasing use of Industry 4.0 technologies

Calibration Management Software assists manufacturers in achieving these objectives by offering a systematic approach to calibration, minimizing downtime, and enhancing product quality.

India's move towards smart factories boosting software adoption

As India moves towards smart factories, the use of Calibration Management Software is seeing a significant increase. The Indian government’s efforts to promote smart manufacturing are driving the adoption of digital technologies, including calibration software.

India’s Smart Factory Initiative

The Indian government’s Make in India and Smart India initiatives are crucial in promoting the adoption of smart manufacturing technologies. These initiatives aim to transform India into a global manufacturing hub by leveraging technologies like IoT, AI, and robotics.

What is a Smart Factory?

The smart factory concept involves the integration of digital technologies to enhance manufacturing processes, making them more efficient and productive. A critical component in this context is Calibration Management Software which ensures that equipment and instruments are accurately calibrated, thereby maintaining product quality and reducing downtime.

Why is Calibration Important in Smart Factories?

In a smart factory setup, where automation and precision are paramount, the importance of calibration cannot be overstated. Here’s why:

- Maintaining Accuracy: With machines and instruments working at high speeds and volumes, even a slight deviation can lead to significant errors. Regular calibration ensures that these tools remain accurate.

- Quality Assurance: For industries like pharmaceuticals or aerospace, where quality is non-negotiable, calibration acts as a safeguard against defects.

- Reducing Downtime: Unexpected machine breakdowns can halt production. By integrating calibration checks into routine maintenance schedules, potential issues can be identified before they cause disruptions.

How Calibration Management Software Fits In

While traditional methods of calibration involve manual checks and records, this approach can be time-consuming and prone to errors. Here’s where Calibration Management Software comes into play:

- Automation: The software automates scheduling and tracking of calibration tasks, ensuring that nothing falls through the cracks.

- Centralized Records: All calibration data is stored in one place, making it easy to access for audits or compliance checks.

- Integration with Other Systems: Many Calibration Management Software solutions can integrate with existing ERP or MES systems, providing a holistic view of operations.

The adoption of Calibration Management Software in India’s smart factories is driven by the need for improved quality control, reduced costs, and enhanced operational efficiency. The software helps in automating calibration processes, reducing manual errors, and ensuring compliance with regulatory standards.

| Industry | Benefits of Calibration Software | Impact on Smart Factories |

| Automotive | Improved manufacturing precision | Enhanced product quality |

| Aerospace | Reduced calibration time | Increased operational efficiency |

| Pharmaceuticals | Regulatory compliance | Reduced risk of non-compliance |

Key Benefits of Calibration Management Software in Smart Factories

Here are some key benefits:

- Improved Accuracy: Ensures that equipment is calibrated to precise standards, reducing errors and improving product quality.

- Operational Efficiency: Automates calibration processes, reducing manual labor and increasing productivity.

- Regulatory Compliance: Helps in maintaining compliance with regulatory standards by ensuring that calibration records are accurate and up-to-date.

U.S. FDA compliance strengthening software integration in healthcare

The U.S. FDA compliance requirements are significantly influencing the adoption of Calibration Management Software in the healthcare industry. Healthcare organizations are under increasing pressure to ensure that their medical devices and equipment are calibrated accurately to maintain patient safety and comply with regulatory standards.

Ensuring Compliance with U.S. FDA Regulations is crucial for healthcare organizations to avoid legal repercussions and maintain their reputation. Calibration Management Software helps in streamlining the calibration process, ensuring that all equipment is calibrated according to the required standards.

U.S. FDA Compliance Requirements

The U.S. FDA sets strict rules for medical device manufacturers and healthcare providers to ensure the safety and effectiveness of medical devices. Calibration Management Software is crucial in helping organizations meet these requirements by making sure that all medical devices are correctly calibrated and maintained.

Impact on Healthcare Industry

The impact of U.S. FDA compliance on the healthcare industry is complex. It not only ensures patient safety but also helps in reducing costs associated with non-compliance. A well-implemented Calibration Management Software can lead to significant improvements in operational efficiency.

| Benefits | Description | Impact |

| Improved Patient Safety | Ensures medical devices are calibrated accurately | Reduces risk of device failure |

| Regulatory Compliance | Meets U.S. FDA guidelines | Avoids legal repercussions |

| Operational Efficiency | Streamlines calibration processes | Reduces maintenance costs |

The integration of Calibration Management Software in the healthcare industry is significantly driven by the need to comply with U.S. FDA regulations. By understanding and implementing these requirements, healthcare organizations can ensure patient safety, maintain regulatory compliance, and improve operational efficiency. This regulatory compliance not only safeguards patients but also streamlines processes, thereby enhancing overall operational efficiency.

The Future of Calibration Management Software: Automation and AI

The future of Calibration Management Software is set to be transformed by automation and AI-based calibration ecosystems. This change is driven by the demand for more efficient, precise, and compliant calibration processes in different industries.

Future Trends in Calibration Management Software

The integration of AI and automation in Calibration Management Software is expected to enhance calibration processes, reduce manual errors, and improve overall efficiency. Predictive maintenance and real-time monitoring are some of the key features that are likely to become more prevalent.

Role of AI in Calibration Ecosystems

AI is anticipated to play a crucial role in calibration ecosystems by enabling predictive analytics and automated decision-making. This can lead to more proactive maintenance and reduced downtime.

The role of AI in calibration ecosystems can be further understood by examining its potential applications:

- Enhanced predictive maintenance capabilities

- Automated calibration processes

- Real-time data analysis and insights

To illustrate the potential impact of AI and automation on Calibration Management Software, consider the following comparative analysis:

| Feature | Traditional Calibration | AI-based Calibration |

| Calibration Process | Manual | Automated |

| Error Rate | Higher | Lower |

| Maintenance | Reactive | Predictive |

The future trends in Calibration Management Software indicate a significant shift towards more automated and intelligent calibration ecosystems. As industries continue to adopt these technologies, we can expect to see improvements in efficiency, accuracy, and compliance.

Key vendors and strategic partnerships in the software space

In the software space, key vendors and strategic partnerships often play a crucial role in driving innovation, expanding market reach, and enhancing product offerings.

- Baker Hughes Company – United States

- Beamex Oy Ab – Finland

- CompuCal Calibration Solutions – United Kingdom

- CYBERMETRICS CORPORATION – United States

- Fluke Corporation – United States

- MasterControl, Inc. – United States

- Prime Technologies – United States

- Productivity-Quality Systems, Inc. – United States

- Qualer – United States

- Verse Solutions – USA

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Calibration Management Software Market Report |

| Base Year | 2024 |

| Segment by Type |

· Cloud-native Suites · Integrated Platforms · Modular Tools |

| Segment by Application |

· Pharma QA · Aerospace Validation · Industrial Manufacturing |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The Calibration Management Software Market is expected to grow significantly, driven by the increasing use of digital validation and quality control practices. As industries continue to change and regulatory requirements become stricter, the demand for calibration software will increase.

Future Outlook

The future of the Calibration Management Software Market looks promising, with advancements in automation and AI-based calibration ecosystems expected to drive further growth. The integration of digital validation and quality control practices will continue to play a crucial role in shaping the market.

As the market continues to expand globally, industries such as pharmaceutical quality assurance, aerospace validation, and industrial manufacturing will remain key adopters of calibration management software. The focus on quality control and regulatory compliance will drive the demand for these solutions.

Global Calibration Management Software Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Calibration Management Software Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Calibration Management SoftwareMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Calibration Management Softwareplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Calibration Management Software Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Calibration Management Software Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Calibration Management Software Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofCalibration Management SoftwareMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is Calibration Management Software?

Calibration Management Software is a type of software used to manage and track the calibration of equipment and instruments in various industries, ensuring compliance with regulatory standards.

What are the benefits of using Calibration Management Software?

Using Calibration Management Software offers several advantages, including:

- Improved accuracy in measurements and calibrations

- Increased efficiency in managing calibration processes

- Reduced costs associated with manual calibration methods

- Enhanced compliance with regulatory requirements and industry standards

How does Calibration Management Software support digital validation?

Calibration Management Software supports digital validation by providing a digital platform for managing calibration data, automating calibration processes, and ensuring compliance with regulatory standards.

What are the challenges in integrating Calibration Management Software with legacy systems?

The challenges in integrating Calibration Management Software with legacy systems include:

- Ensuring compatibility between the new software and the existing legacy systems

- Managing data migration from the legacy systems to the new software

- Maintaining existing workflows during the integration process

How do geopolitical factors affect software compliance across industries?

Geopolitical factors can affect software compliance across industries by introducing variations in regulatory requirements and standards, posing challenges for companies operating globally.

What are the different types of Calibration Management Software solutions available?

There are several types of Calibration Management Software solutions available:

- Cloud-native suites: These are comprehensive software solutions that are hosted in the cloud and can be accessed from anywhere. They are ideal for organizations that have multiple locations or remote teams.

- Integrated platforms: These are software solutions that integrate with other systems used by the organization, such as Enterprise Resource Planning (ERP) or Computerized Maintenance Management System (CMMS). They are suitable for organizations that want to streamline their processes and improve efficiency.

- Modular tools: These are standalone software applications that focus on specific aspects of calibration management, such as scheduling, tracking, or reporting. They are best suited for organizations with specific needs or requirements.

Each type of solution has its own benefits and is suited to different organizational needs.

How is Calibration Management Software adopted across various sectors?

Calibration Management Software is used in different industries such as pharmaceutical quality assurance, aerospace validation, and industrial manufacturing. Each industry has its own specific needs and challenges.

What is driving the expansion of Calibration Management Software across global markets?

The expansion of Calibration Management Software across global markets is driven by increasing demand for digital validation and quality control, with regions having high growth potential including those with strong manufacturing sectors.

How will AI affect the future of Calibration Management Software?

AI is expected to improve calibration processes, increase efficiency, and allow for automation in Calibration Management Software, shaping the future of the industry.

What is the role of Calibration Management Software in ensuring U.S. FDA compliance in the healthcare industry?

Calibration Management Software plays a vital role in ensuring U.S. FDA compliance in the healthcare industry by providing a platform for managing calibration data, automating calibration processes, and ensuring compliance with regulatory requirements.