Casting Nodulariser Market to Reach $739.23 Million by 2025: Growth in Metallurgy and Casting Industries in the U.S., China, and Germany

The Casting Nodulariser Market is projected to reach $739.23 million by 2025, driven by growth in the metallurgy and casting industries in the U.S., China, and Germany. This market is essential for enhancing the quality and performance of cast iron products, particularly in automotive, construction, and infrastructure applications.

- Last Updated:

Casting Nodulariser Market Outlook for Q1 and Q2 2025

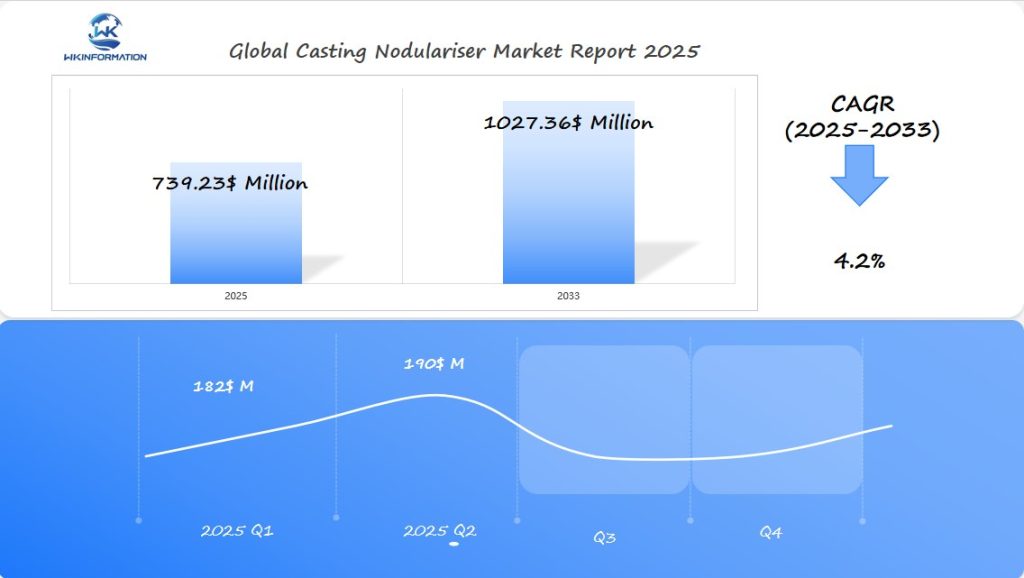

The Casting Nodulariser market is projected to reach $739.23 million in 2025, with a CAGR of 4.2% from 2025 to 2033.

In Q1 2025, the market is expected to be valued at $182 million, supported by the increasing demand for high-strength castings in industries such as automotive and construction in the U.S., Germany, and Japan. Casting nodularisers improve the mechanical properties of cast iron, making them ideal for use in manufacturing durable components.

By Q2 2025, the market is forecast to reach $190 million, with Germany’s automotive industry leading the way in demand, followed by the U.S. and Japan, which continue to use nodularisers to enhance the quality and longevity of industrial machinery.

As manufacturing processes evolve and the demand for stronger materials increases, the market for casting nodularisers will continue to see steady growth.

Casting Nodulariser Upstream and Downstream Industry Chain Analysis

Understanding the upstream and downstream dynamics of the Casting Nodulariser industry is crucial for manufacturers and suppliers alike. The upstream industry chain involves the supply of raw materials such as magnesium, ferrosilicon, and other alloys, which are critical for the production of nodularisers.

Upstream Industry Analysis

The availability and cost of raw materials significantly impact the production cost and quality of nodularisers. Raw material suppliers play a vital role in ensuring a stable supply chain. The quality of raw materials such as ferrosilicon and magnesium directly affects the performance of the nodulariser in ductile iron casting.

Raw Material Suppliers

Raw material suppliers are essential stakeholders in the Casting Nodulariser industry chain. They provide the necessary materials for the production of nodularisers, including magnesium and ferrosilicon. The reliability and quality of these suppliers are crucial for maintaining the consistency and quality of the final product.

| Raw Material | Importance in Nodulariser Production |

| Magnesium | Essential for the nodulizing process, influencing the microstructure of ductile iron. |

| Ferrosilicon | Critical for the inoculation process, enhancing the graphite formation in ductile iron. |

Growing Demand for Ductile Iron Casting and Metallurgy

Due to its outstanding qualities, ductile iron casting is gaining popularity in contemporary manufacturing. Its adaptability makes it a perfect option for a wide range of uses such as automotive, construction, and industrial machinery.

Ductile Iron Casting Applications

Ductile iron casting is widely used in the production of high-performance components due to its superior mechanical properties, such as high tensile strength, toughness, and resistance to wear and tear. Some of the key applications of ductile iron casting include:

- Automotive components, such as engine blocks, crankshafts, and camshafts

- Construction equipment, such as pipes, fittings, and machinery components

- Industrial machinery, such as gearboxes, pumps, and valves

The growth in metallurgy is also driving the demand for high-quality nodularisers that can improve the performance and durability of castings. Nodularisers play a crucial role in the production of ductile iron castings by controlling the microstructure and properties of the material.

| Industry | Application | Benefits |

| Automotive | Engine blocks, crankshafts, camshafts | High tensile strength, toughness, and resistance to wear and tear |

| Construction | Pipes, fittings, machinery components | Durability, corrosion resistance, and high pressure resistance |

| Industrial Machinery | Gearboxes, pumps, valves | High performance, reliability, and resistance to wear and tear |

The increasing demand for ductile iron casting is driven by the need for high-performance, durable, and reliable components in various industries. As the metallurgy market continues to grow, the demand for high-quality nodularisers is expected to rise, driving innovation and advancements in casting technology.

Challenges in material composition and performance consistency

Ensuring consistent performance of Casting Nodulariser is a major hurdle due to variations in raw material quality. The quality of the final product is heavily dependent on the consistency of its material composition.

Material Composition Challenges

The Casting Nodulariser Market faces significant challenges in achieving the right material composition. Variations in raw material quality can affect the final product’s performance, making it crucial for manufacturers to implement stringent quality control measures. Raw material sourcing and processing play a critical role in determining the quality of Casting Nodulariser.

To overcome these challenges, manufacturers must adopt advanced quality control measures, including rigorous testing and inspection protocols. This ensures that the Casting Nodulariser meets the required standards for material composition and performance consistency.

Performance Consistency Issues

Performance consistency is critical in the Casting Nodulariser Market. Variations in production processes can lead to inconsistencies in the final product, affecting its overall quality. To address this issue, manufacturers must implement robust production processes and quality control measures.

A key strategy for ensuring performance consistency is to adopt advanced manufacturing technologies and techniques. This includes using high-quality raw materials and implementing precise production processes. By doing so, manufacturers can minimize variations in the final product and ensure consistent performance.

Geopolitical analysis of global manufacturing trends and trade policies

The Casting Nodulariser Market is significantly influenced by geopolitical factors, including global manufacturing trends and trade policies. Changes in these areas can have far-reaching effects on the market’s dynamics, supply chain, and production costs.

Global Manufacturing Trends

Global manufacturing trends are changing because of things like new technology, shifts in what consumers want, and political tensions between countries. The Casting Nodulariser Market is also affected by these trends, with its growth and stability closely linked to them.

Key trends include:

- Increasing demand for high-quality casting products

- Advancements in casting technology

- Shifts in global manufacturing hubs

Trade Policies Impact

Trade policies, such as tariffs and regulations, have a significant impact on the Casting Nodulariser Market. When these policies change, they can affect the supply chain, production costs, and how the market operates.

The impact of trade policies can be seen in:

- Tariffs imposed on imported raw materials

- Regulations affecting the export of casting products

- Trade agreements influencing market dynamics

| Trade Policy | Impact on Casting Nodulariser Market |

| Tariffs on imported raw materials | Increased production costs |

| Regulations on export of casting products | Changes in market dynamics |

| Trade agreements | Influence on supply chain and production costs |

Understanding these geopolitical factors is crucial for manufacturers to navigate the global market successfully. By studying global manufacturing trends and trade policies, businesses can make better decisions and stay competitive in the Casting Nodulariser Market.

Segmentation by nodulariser type and composition

The Casting Nodulariser Market is segmented based on the type and composition of nodularisers, catering to diverse industry needs. Different nodulariser types and compositions are suited for various applications, making it essential to understand the specific requirements of each segment.

Nodulariser Types

Nodularisers are categorized into different types based on their composition and application. The primary types include Magnesium-based, Rare Earth-based, and other specialized nodularisers. Each type has its unique characteristics, and is suited for specific casting applications.

The choice of nodulariser type depends on the desired properties of the cast product, such as ductility, strength, and resistance to corrosion. For instance, Magnesium-based nodularisers are widely used in the production of ductile iron castings, which are essential in automotive and construction industries.

Composition Variations

The composition of nodularisers can vary significantly, influencing their performance and application. Key composition variations include differences in magnesium content, rare earth elements, and other alloying elements. These variations allow for tailored nodulariser compositions that meet specific customer requirements.

A detailed analysis of composition variations is crucial for understanding the Casting Nodulariser Market. The table below highlights some common composition variations and their applications:

| Nodulariser Composition | Application | Key Characteristics |

| High Magnesium Content | Ductile Iron Casting | Improved ductility, strength |

| Rare Earth Elements | Specialized Casting Applications | Enhanced corrosion resistance, high-temperature performance |

| Other Alloying Elements | Various Casting Applications | Tailored properties, improved casting quality |

The segmentation of the Casting Nodulariser Market by nodulariser type and composition is crucial for understanding the diverse needs of customers. By analyzing the different types and compositions of nodularisers, manufacturers can develop targeted products that meet specific industry requirements, driving growth and innovation in the market.

Key applications in automotive, construction, and industrial sectors

Casting nodularisers are essential in the production of high-quality castings used in the automotive, construction, and industrial sectors. The use of nodularisers in these industries enhances the mechanical properties of castings, making them more durable and resistant to wear and tear.

Automotive Applications

In the automotive industry, casting nodularisers are used to create high-quality castings for essential parts such as engine components and gearboxes. By using nodularisers in automotive castings, the flexibility and strength of the castings are enhanced, leading to improved performance and increased lifespan of the components.

Key automotive applications include:

- Engine components

- Gearboxes

- Other critical parts

Construction and Industrial Applications

In the construction and industrial sectors, casting nodularisers are employed to manufacture castings for machinery and equipment. The top-notch castings produced with the assistance of nodularisers are crucial for the efficient functioning of heavy machinery and equipment utilized in these industries.

The advantages of utilizing nodularisers in construction and industrial castings consist of:

- Enhanced durability

- Improved mechanical properties

- Superior resistance to wear and tear

| Sector | Applications | Benefits |

| Automotive | Engine components, gearboxes | Improved ductility, strength |

| Construction & Industrial | Machinery, equipment | Improved durability, mechanical properties |

Understanding Regional Demand Trends and Industry Shifts in Key Markets

For manufacturers in the casting nodulariser market, it is crucial to understand regional demand trends and industry shifts. The demand for casting nodularisers differs from one region to another because of variations in industrial activities, manufacturing capabilities, and market trends.

Regional Demand Trends

The regional demand trends for casting nodularisers are influenced by the growth of various industries, including automotive, construction, and machinery. In regions with high industrial activity, the demand for casting nodularisers tends to be higher.

Key regions driving demand include North America, Europe, and Asia-Pacific, where industrial production and manufacturing activities are prominent. For instance, the Asia-Pacific region, driven by countries like China and India, is experiencing significant growth in the automotive and construction sectors, leading to an increased demand for casting nodularisers.

Industry shifts in key markets are also impacting the demand for casting nodularisers. Technological advancements and changes in consumer preferences are driving manufacturers to adapt their production processes and product offerings.

For example, the increasing focus on sustainability and environmental concerns is leading to the development of more eco-friendly casting nodularisers. Additionally, advancements in technology are enabling manufacturers to produce higher-quality casting nodularisers with improved performance characteristics.

- The automotive industry is driving demand for high-performance casting nodularisers.

- The construction sector is also contributing to the growth of the casting nodulariser market.

- Technological innovations are improving the efficiency and effectiveness of casting nodulariser production.

U.S. Demand for High-Performance Casting Solutions in Automotive and Machinery

The U.S. market is experiencing a significant increase in demand for high-performance casting solutions, primarily driven by the automotive and machinery sectors. This rise in demand is mainly due to the need for high-quality castings that can endure strict performance requirements.

Manufacturers are increasingly turning to advanced casting nodularisers as a means to enhance the quality and longevity of their products. High-performance casting solutions play a crucial role in the manufacturing process of intricate parts utilized in automotive and machinery applications.

Automotive Sector Demand

The automotive sector is a significant driver of the demand for high-performance casting solutions in the U.S. As automotive manufacturers continue to evolve and innovate, the need for high-quality castings that meet stringent performance and safety standards is becoming increasingly important.

Some of the key applications of high-performance casting solutions in the automotive sector include:

- Engine components

- Transmission parts

- Other critical automotive components

Machinery Sector Demand

The machinery sector is another significant contributor to the demand for high-performance casting solutions. As machinery manufacturers strive to improve product performance and durability, the need for advanced casting nodularisers is becoming increasingly critical.

Some of the key applications of high-performance casting solutions in the machinery sector include:

- Machinery components

- Heavy equipment parts

- Other critical machinery components

The demand for high-performance casting solutions in the U.S. is driven by the need for high-quality castings in the automotive and machinery sectors. As manufacturers continue to innovate and improve product performance, the demand for advanced casting nodularisers is expected to remain strong.

China’s growing industrial sector driving casting nodulariser demand

China’s industrial sector is on the rise, leading to an increasing need for advanced casting solutions, including nodularisers. This growth is driven by China’s expanding manufacturing base, infrastructure projects, and a thriving automotive industry. As a result, the demand for high-quality casting nodularisers is surging.

China’s Industrial Growth

China’s industrial sector has been experiencing significant growth, driven by government initiatives and investments in infrastructure and manufacturing. This growth is contributing to an increased demand for casting nodularisers, which are critical in the production of high-quality castings.

The country’s industrial growth is also driven by its expanding automotive industry, which requires high-performance casting solutions. As the industry continues to evolve, the demand for advanced casting nodularisers is expected to rise.

Casting Nodulariser Demand in China

The demand for casting nodularisers in China is driven by the need for high-quality castings in various industries, including automotive, construction, and machinery. As China’s industrial sector continues to grow, the demand for casting nodularisers is expected to increase.

Some of the key factors driving the demand for casting nodularisers in China include:

- Increasing demand for high-quality castings in the automotive industry

- Growing infrastructure projects requiring high-performance castings

- Expanding manufacturing base driving demand for advanced casting solutions

China’s growing industrial sector is driving the demand for casting nodularisers, driven by its expanding manufacturing base, infrastructure projects, and automotive industry. As the country’s industrial sector continues to evolve, the demand for high-quality casting solutions is expected to rise.

Germany’s focus on precision casting for automotive and engineering industries

Germany’s engineering expertise is evident in its precision casting industry, which provides top-quality parts to the automotive and engineering sectors. The country’s unwavering commitment to excellence, creativity, and accuracy fuels the need for advanced casting nodularisers that can fulfill the strict standards of these industries.

Precision Casting in Germany

Precision casting in Germany is known for its high degree of accuracy and attention to detail. The industry has developed sophisticated techniques and technologies to produce complex components with precise dimensions and surface finishes. This level of precision is critical in the automotive and engineering sectors, where components are subject to high stresses and strains.

The use of advanced materials and manufacturing processes is also a key feature of Germany’s precision casting industry. High-quality casting nodularisers play a crucial role in producing ductile iron castings that are used in various applications, including automotive and engineering components.

Automotive Applications

In the automotive sector, precision casting is used to produce components such as engine parts, gearboxes, and other critical components. High-performance casting solutions enable manufacturers to produce lighter, stronger, and more efficient vehicles that meet increasingly stringent emissions and safety regulations.

Engineering Applications

In the engineering sector, precision casting is used to produce complex components for a range of applications, including machinery, equipment, and infrastructure projects. The use of precision casting techniques enables manufacturers to produce components with complex geometries and precise dimensions, which is critical in these applications.

A key factor driving the demand for precision casting in Germany is the country’s strong engineering heritage and its commitment to innovation and quality. The industry is supported by a highly skilled workforce and a strong network of suppliers and manufacturers.

- The use of advanced materials and manufacturing processes

- A strong focus on quality and precision

- A highly skilled workforce and a strong network of suppliers and manufacturers

These factors combine to make Germany a leading player in the global precision casting industry, with a strong reputation for producing high-quality components for the automotive and engineering sectors.

Innovations in casting technology and nodulariser efficiency

The casting industry is undergoing a significant change with new developments in casting technology and nodulariser efficiency. These improvements are vital for creating top-notch castings, which are crucial in many fields such as automotive, construction, and various industrial areas.

Casting Technology Innovations

These innovations are enhancing the performance and sustainability of casting processes. Modern casting technologies, such as 3D printing and advanced molding techniques, are improving the precision and complexity of castings. These innovations enable manufacturers to produce castings with intricate designs and precise dimensions, meeting the increasing demands of modern industries.

Casting Technology Innovations

The development of new casting technologies is driven by the need for more efficient and sustainable production processes. Advanced casting techniques, such as squeeze casting and lost foam casting, are being adopted to produce high-quality castings with reduced waste and energy consumption.

Nodulariser Efficiency Improvements

Nodulariser efficiency is critical in the production of ductile iron castings, which are widely used in automotive and industrial applications. Improvements in nodulariser efficiency are achieved through the development of new nodulariser compositions and production processes. These advancements enable manufacturers to produce ductile iron castings with improved mechanical properties and reduced production costs.

The use of advanced nodularisers is resulting in significant benefits, including improved casting quality, reduced production time, and lower costs. As the casting industry continues to evolve, innovations in casting technology and nodulariser efficiency will remain crucial for meeting the demands of modern industries.

Key competitors in the casting nodulariser market

A few large players dominate the competitive landscape of the casting nodulariser market. These key competitors are driving innovation, improving product quality, and expanding their market share through various competitive strategies

Key Players:

-

Elkem ASA – Norway

-

Ferroglobe PLC – USA

-

Sanxiang Advanced Materials Co., Ltd. – China

-

Saint-Gobain – France

-

Nanjing Pujiang Alloy Materials – China

-

Vesuvius – UK

-

Anyang Huatuo Metallurgy – China

-

Longnan Longyi Heavy Re Technology – China

-

Inner Mongolia Shengquan Keliyuan New Material Technology – China

-

Xi’an Yuanda Metallurgy Materials – China

-

Ferroglobe – USA

Overall

| Report Metric | Details |

|---|---|

| Report Name | Casting Nodulariser Market |

| Base Year | 2024 |

|

Segment by Type |

· Magnesium-based · Rare Earth-based · Others |

|

Segment by Application |

· Automotive · Construction · Industrial sectors |

|

Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The Casting Nodulariser Market is set for significant growth, driven by the expanding metallurgy and casting industries. As the demand for high-quality castings continues to rise, the market is expected to reach $739.23 Million by 2025.

To take advantage of these opportunities, manufacturers must effectively navigate the changing landscape, addressing challenges in material composition and performance consistency. Innovations in casting technology and nodulariser efficiency will be crucial in driving market growth and meeting the demands of various industries.

As the Casting Nodulariser Market continues to evolve, understanding the market dynamics, trends, and challenges will be essential for manufacturers to stay ahead of the competition and capitalize on emerging opportunities. With a growing demand for high-performance casting solutions, the market is expected to witness significant growth in the coming years, driven by Industry Trends and Market Growth.

Global Casting Nodulariser Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Casting Nodulariser Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Casting Nodulariser MarketSegmentation Overview

Chapter 2: Competitive Landscape

- Global Casting NodulariserPlayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Casting Nodulariser Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Casting Nodulariser Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Casting Nodulariser Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Casting Nodulariser MarketInsights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected size of the Casting Nodulariser Market by 2025?

The Casting Nodulariser Market is expected to reach $739.23 million by 2025.

What drives the growth of the Casting Nodulariser Market?

The growth is driven by the expanding metallurgy and casting industries in key markets such as the U.S., China, and other regions.

What are the key raw materials used in the production of Casting Nodulariser?

The raw materials used include magnesium, ferrosilicon, and other alloys.

Why is Ductile Iron Casting Important in the Market?

Ductile iron casting is in high demand due to its superior mechanical properties and versatility in various applications, including automotive, construction, and industrial machinery.

What are the challenges faced by the Casting Nodulariser Market?

One of the significant challenges is achieving the right material composition and ensuring performance consistency.

How do geopolitical factors impact the Casting Nodulariser Market?

Geopolitical factors, such as global manufacturing trends and trade policies, have a significant impact on the market. They influence the supply chain, production costs, and overall dynamics of the market.

How is the Casting Nodulariser Market segmented?

The market is segmented based on the type and composition of nodularisers, with different types and compositions suited for various applications and industries.

What are the key applications of Casting Nodulariser?

Casting Nodulariser is primarily used in the following industries:

- Automotive: For manufacturing engine blocks, transmission cases, and other critical components.

- Construction: In the production of heavy machinery parts, structural elements, and equipment used in construction projects.

- Industrial: To create castings for various machines, tools, and equipment used across different industrial applications.

What is the demand trend for Casting Nodulariser in the U.S.?

The U.S. market has a significant demand for high-performance casting solutions, particularly in the automotive and machinery sectors.

How is China’s growing industrial sector impacting the demand for Casting Nodulariser?

China’s growing industrial sector is driving the demand for casting nodularisers due to the country’s expanding manufacturing base, infrastructure projects, and automotive industry.

What is Germany’s focus in the Casting Nodulariser Market?

Germany is known for its precision casting capabilities, particularly in the automotive and engineering industries, driving the demand for high-performance casting nodularisers.

What innovations are happening in the Casting Nodulariser Market?

The market is seeing new developments in casting technology and improvements in nodulariser efficiency, which are enhancing the performance and sustainability of casting nodularisers.

Who are the key competitors in the Casting Nodulariser Market?

The market is competitive, with several key players operating globally. Understanding the competitive landscape is essential for manufacturers to develop effective market strategies.