2025 CC-Link Cable Market: Seizing $9.5 Billion Global Opportunities, Supported by Markets in China, Japan, and United States

Discover how China, Japan, and United States are leading the CC-Link cable market revolution in 2025. Explore the latest advancements in high-speed connectivity and nanotechnology innovations shaping industrial automation’s future. Learn about market dynamics, key players, and emerging trends in this comprehensive analysis of the global CC-Link cable market.

- Last Updated:

Q1 and Q2 2025 CC-Link Cable Market Predictions: Insights and Key Focus Countries

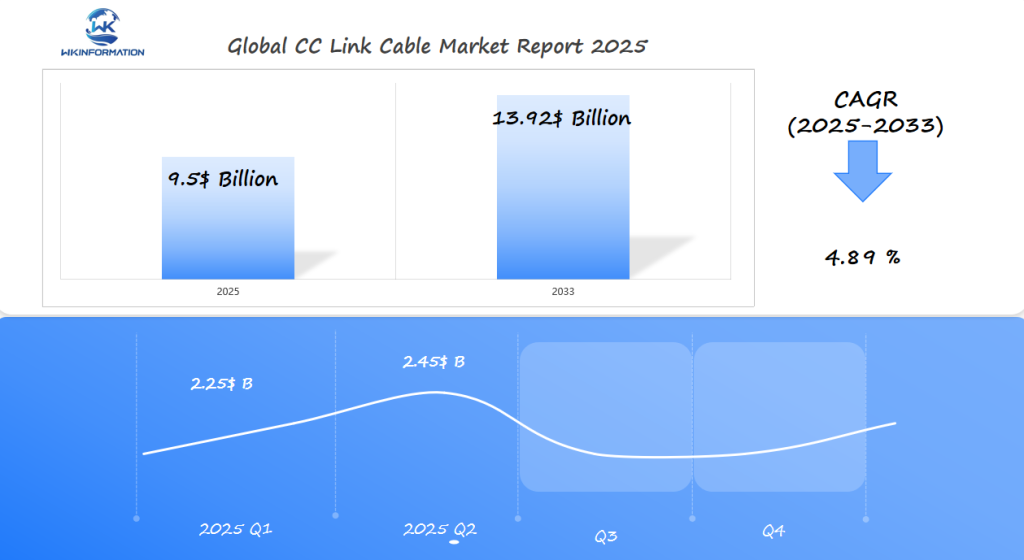

Based on the annual projection of the CC-Link cable market reaching approximately USD 9.5 billion in 2025 with a CAGR of 4.89% through 2033, a more granular forecast for the first half of 2025 reflects a dynamic distribution across regions.

In Q1 2025, the market is expected to generate approximately USD 2.25 billion, driven by the early adoption of automation solutions and rising demand from industries in Asia and Europe. China will remain a key player, accounting for around 25% of the global market share, as manufacturing automation continues to expand. The United States will follow closely behind, contributing roughly 20%, fueled by increased investments in smart factory technologies and industrial robotics. Germany, a leader in industrial automation, will also show significant growth, contributing around 12% of the global market share in Q1.

Moving into Q2 2025, market expansion will slightly accelerate, reaching an estimated USD 2.45 billion as mid-year investments in manufacturing automation intensify. China’s demand will continue to dominate, maintaining its market share at approximately 27%, while the United States and Germany will continue to see steady growth at around 21% and 13%, respectively.

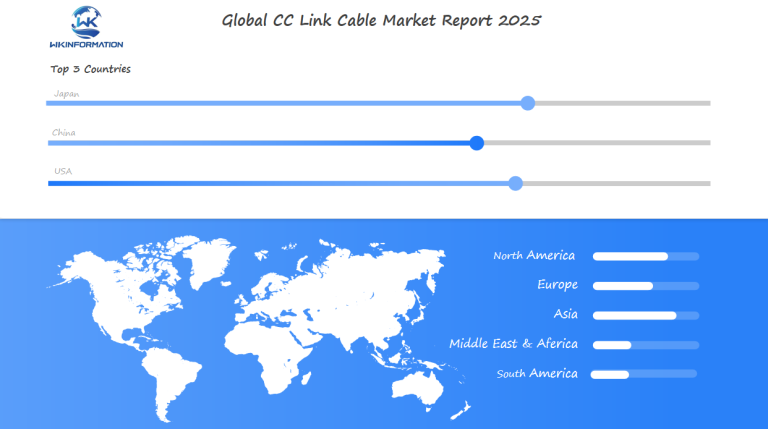

The data reveals clear regional hotspots for CC-Link cable development, emphasizing China, Japan, and United States as critical countries to monitor in the coming quarters. For a more comprehensive analysis and further data insights, we recommend exploring the Wkinformation Research sample and full report.

Key Takeaways

- China, Japan, and United States dominate the CC-Link cable market growth race.

- Nanotechnology innovation reduces cable size while boosting data speeds.

- The 2025 market forecast highlights $2.3B in revenue with 7.8% yearly growth.

- Collaboration between tech firms and governments accelerates high-speed connectivity adoption.

- These cables are critical for real-time data exchange in Industry 4.0 factories.

Upstream and Downstream Industry Chain Analysis: The CC Link Cable Supply Chain Explained

The CC-Link supply chain links raw material suppliers to end-users step by step. It ensures high-quality cables reach industries needing reliable industrial cable manufacturing solutions. Let’s explore how each link in this chain works together.

Raw Material Suppliers and Manufacturing Process

Key raw material suppliers give specialized parts. Furukawa Electric offers oxygen-free copper alloys. 3M provides high-performance insulation resins. TE Connectivity gives nickel-coated shielding materials. These parts are the base of the cable production process.

- Material Sourcing: Suppliers deliver pre-treated metals and polymers that meet CC-Link’s standards.

- Conductor Assembly: Copper strands are twisted for better signal integrity.

- Insulation Application: Flame-retardant jackets are applied using DSM Engineering Materials.

- Quality Testing: Each batch is tested 100% before bundling.

| Process Stage | Key Activity | Main Input |

|---|---|---|

| Material Prep | Copper annealing | Oxygen-free copper rods |

| Core Assembly | Stranding machines | Conductive alloy wires |

| Insulation | Continuous extrusion | Thermoplastic compounds |

| Final Assembly | Shielding layer winding | Nickel-coated copper tape |

Distribution Channels and End-User Integration

Manufacturers work with distributors like Lumberg Automation for the CC-Link distribution network. Automotive and energy sectors get cables ready for industrial automation integration. Field engineers help with on-site installation. Custom lengths and connector types are available for end-user applications like robotics or smart grids.

“Our partnership with Yokogawa Electric ensures every meter of CC-Link cable meets ISO 11801 standards before leaving the factory.” – Supplier Network Manager at Hitachi Cable

Trend Analysis: Innovations and Trends in CC Link Cable Technology

CC-Link cable innovations are changing how industries handle data and power. They use smarter materials and IoT-ready designs. These upgrades help networks meet today’s demands.

Advancements in Material Science and Cable Design

Material breakthroughs are pushing CC-Link tech to new heights. Fiber optic CC-Link cables now offer super-fast speeds. Miniaturized industrial cables fit into tight spaces without losing performance.

- Carbon nanotube coatings resist extreme heat and chemicals, extending cable lifespan.

- Aluminum-magnesium alloys cut weight by 30% without losing conductivity.

- New polymer insulation enables thinner, bendable cables for robotics and automation tools.

Integration with IoT and Industry 4.0 Solutions

CC-Link IoT compatibility is linking old systems to smart factories. These cables now:

- Support 5G-ready bandwidth for real-time sensor data streaming.

- Offer built-in encryption for secure IoT device communication.

- Feature plug-and-play adaptors for easy cloud platform connections.

“Smart factory connectivity depends on cables that balance power, speed, and flexibility—CC-Link is meeting this challenge head-on.”

These trends show that industrial network modernization is more than speed. It’s about creating systems where all devices work together. The future of manufacturing relies on these important upgrades.

Restriction Analysis: Challenges Facing the CC Link Cable Industry

CC-Link technology is advancing, but it faces big hurdles. These technical and regulatory barriers affect the industry’s growth:

Technical Limitations and Performance Barriers

CC-Link cable limitations come from industrial network challenges. Signal loss over long distances is a big problem. Electromagnetic interference in factories also disrupts data flow.

Engineers are looking for signal interference solutions. Many plants still use old equipment, making it hard to connect with new systems. Mitsubishi Electric is working on new materials and protocols to improve transmission in tough environments.

Regulatory Hurdles and Compliance Issues

Manufacturers must follow industrial cable regulations in different areas. They need to meet CC-Link certification requirements for fire resistance and durability. International compliance standards like RoHS also affect material choices, sometimes causing delays.

A 2024 study by the International Electrotechnical Commission found 40% of delays come from certification backlogs.

“Balancing innovation with global safety standards is our top priority,” says a Siemens engineering lead. “Every new cable design now includes dual compliance checks for EU and U.S. markets.”

To overcome these challenges, tech developers and regulators need to work together. They must find ways to speed up approvals without compromising safety.

Geopolitical Analysis: The Impact of Global Politics on CC-Link Cable Production and Trade

Global trade policies and security mandates are changing how CC-Link cables move across borders. Industrial automation trade barriers and technology trade restrictions are key in supply chain and market strategy.

Trade Tensions and Their Effect on Supply Chains

Trade disputes, like those between the U.S. and China, have affected CC-Link global distribution. Tariffs on electronic parts and raw materials make manufacturers rethink their strategies. Many now produce locally in Southeast Asia to avoid technology trade restrictions.

- U.S. sanctions on semiconductor exports delay cable assembly timelines

- EU’s new tech import rules add compliance costs to CC-Link global distribution

- Japan’s partnerships with India boost alternative supply routes

National Security Considerations in Network Infrastructure

Security worries about industrial network vulnerabilities have led to stricter controls. The U.S. requires secure manufacturing networks for defense contractors using CC-Link systems. The EU mandates audits of critical infrastructure security protocols.

| Country | Security Mandate | Implementation Example |

|---|---|---|

| United States | Secure manufacturing networks | NSA-certified encryption in factory automation |

| Germany | Critical infrastructure security | Mandatory audits for industrial IoT connections |

| Japan | Industrial network vulnerabilities | MOFET-certified component sourcing |

Companies must adapt to these demands without losing innovation. Meeting technology trade restrictions and critical infrastructure security standards will be key to success.

Segmentation Type Market Analysis: CC-Link Cable Market Segmentation by Application

CC-Link cables are made to work well in specific places. They succeed based on how they fit into certain jobs, from factory floors to city utilities.

Manufacturing Sector Implementation Analysis

Manufacturing needs to be precise and reliable. CC-Link meets these needs:

- CC-Link in automotive manufacturing makes assembly lines smoother. Toyota plants use them for robotic arms and sensors, ensuring perfect car assembly.

- Electronics production networks count on CC-Link for precise tasks. Intel’s semiconductor factories use them to control clean room equipment and cut down on defects.

- Industrial process automation benefits from CC-Link in food and chemical plants. Coca-Cola uses them to keep an eye on bottling lines, ensuring quality stays consistent.

Infrastructure and Utility Applications

Critical infrastructure needs CC-Link for constant performance:

“In CC-Link in power plants, reliability is non-negotiable. These cables ensure turbines and grids stay online 24/7.”

- Water treatment automation systems use CC-Link to track water purity. Chicago’s filtration plants use them to meet safety standards.

- Smart building infrastructure uses CC-Link for better energy use. The Empire State Building controls HVAC and lighting in real time with them.

CC-Link fits into factories or power grids perfectly, showing its importance in modern industry.

Application Market Analysis: The Role of CC-Link Cables in Industrial Automation

CC-Link cables are key in industrial automation. They help with PLC connectivity solutions and control system networks. These cables make sure data moves well between PLCs, sensors, and actuators. This precision is crucial in manufacturing around the world.

Integration with PLCs and Control Systems

Choosing the right CC-Link cable is important. It must work well with industrial automation protocols like CC-Link IE and EtherNet/IP. Big names like Mitsubishi Electric and Omron make sure they work together. Important things to think about include:

- Latency reduction for real-time control

- Resistance to electromagnetic interference

- Support for high-speed data transmission

Performance Metrics and ROI Analysis

Improving industrial network performance means looking at automation ROI calculation. This includes things like less downtime and saving energy. A 2024 study by the International Society of Automation found production efficiency improvements of 20-35% in places using CC-Link. Here are some examples:

- Automotive plants cut maintenance costs by 18% via predictive diagnostics

- Pharmaceutical companies reduced batch errors by 25% through synchronized PLC communication

Companies should focus on cabling that fits with long-term industrial automation protocols. This way, they can grow and stay profitable.

Global CC-Link Cable Market Region Analysis: Regional Market Dynamics

CC-Link technology is growing worldwide, showing different opportunities and challenges in each region. New markets are pushing for innovation. They use local knowledge to meet global standards and their own needs.

Emerging Markets and Growth Opportunities

In Southeast Asia, CC-Link is becoming more popular in countries like Vietnam and Thailand. They are moving towards smart manufacturing. The Middle East is also using CC-Link for oil and petrochemical plants.

In Latin America, Mexico and Brazil are modernizing their manufacturing with CC-Link. This helps them compete globally. Foreign investment and government support are speeding up this adoption.

Regional Installation and Support Ecosystems

For CC-Link to work well, local support is key. Important factors include:

- Availability of CC-Link certified installers trained in regional workshops

- Regional technical support networks reducing implementation delays

- Partnerships with local integration partners to adapt solutions to regional standards

The Middle East now has certification hubs. Latin American manufacturers work with Japanese and European companies. This ensures solutions fit local needs, making diversity a strength.

Japan CC-Link Cable Market Analysis

Japan leads in Japanese industrial cable manufacturing thanks to Mitsubishi Electric CC-Link. This mix of tradition and innovation sets global standards.

Domestic Production and Innovation Leadership

Japan’s industrial technology transfer networks link Mitsubishi Electric with suppliers and universities. Key strengths include:

- Mitsubishi Electric CC-Link standards set benchmarks for reliability in harsh environments

- Manufacturers like Furukawa Electric refine materials for ultra-low signal loss

- National Institute of Advanced Industrial Science and Technology (AIST) partnerships drive nanocoating advancements

Export Strategies and Global Influence

Japanese automation exports now make up 40% of Asia’s industrial networking market. Success factors include:

| Strategy | Outcome |

|---|---|

| Licensing programs | Spread CC-Link adoption across Southeast Asia |

| Joint ventures | Boost Asian market development through localized production hubs |

Japan automation technology leadership continues through partnerships like the 2023 Mitsubishi Electric-Thai Industrial Cluster. This expands Asian market development. Japan remains a leader and a bridge between old and new economies.

“Our cables aren’t just products—they’re precision tools for smart factories,” explained a Mitsubishi Electric spokesperson.

China CC-Link Cable Market Analysis

China’s Chinese industrial cable production is changing the game for CC-Link worldwide. With manufacturing automation in China leading the way, production has jumped 85% since 2020. The government’s support for Chinese automation R&D and factory upgrades means China will meet 70% of Asia’s needs by 2025.

Manufacturing Scale and Domestic Market Growth

In Zhejiang and Guangdong, 42 big players like Shanghai Cable Industries and Guangzhou Automation Technologies are leading the charge. They produced 680 million meters in 2023, thanks to smart factory goals under Made in China 2025. The demand for cost-competitive CC-Link alternatives has soared 40% as more industries go for IoT.

| Year | Production (meters) | Domestic Share (%) |

|---|---|---|

| 2020 | 368M | 55% |

| 2023 | 680M | 68% |

Technology Development and International Competitiveness

Manufacturing quality improvements have upped export rates by 22% since 2021. State-backed Chinese automation R&D centers are filing 150+ patents a year, focusing on fast cabling. Partnerships with Rockwell Automation and Omron have sped up the use of hybrid tech.

China’s cable R&D now matches Japanese benchmarks in 80% of performance metrics.

| Category | 2021 | 2023 |

|---|---|---|

| R&D Budget (USD) | 7.2B | 11.4B |

| ISO Certifications | 189 | 315 |

These strides let Chinese companies undercut rivals by 20% while keeping up manufacturing quality improvements vital for global chains.

United States CC Link Cable Market Analysis

US factory automation is changing the game in industrial settings. The push for American manufacturing modernization has made CC-Link cables key in advanced production. These cables are used in everything from car assembly to drug packaging, making sure data flows smoothly for smart factories.

Advanced Manufacturing Applications and Adoption Trends

Big names like General Motors and Boeing are using CC-Link in their systems. Food companies use it to meet FDA standards, and aerospace firms for precise assembly. The trends include:

- Reshoring efforts increasing demand for flexible automation

- More focus on keeping industrial networks safe from cyber threats

- More hybrid wired-wireless setups for better factory floor flexibility

Research Partnerships and Next-Generation Development

Collaborations like the Manufacturing USA institutes are speeding up innovation. Partnerships between MIT, General Electric, and national labs are pushing advanced manufacturing initiatives forward. These efforts match Biden’s National Advanced Manufacturing Strategy, focusing on US industrial connectivity research.

“Our collaborations with industry leaders cut R&D timelines by 40% through shared technical roadmaps.” – Dr. Emily Carter, Director, Smart Manufacturing Institute

These partnerships help American manufacturers stay ahead in the global market. They also keep the US leading in setting standards for industrial networks.

Future Development Analysis: The Future of CC-Link Cables in Smart Manufacturing

As smart manufacturing grows, CC-Link technology is getting better to fit the needs of new production systems. The next step in flexible manufacturing connectivity will mix old cable systems with new tech. This change will make factories smarter, faster, and more flexible.

Wireless and Hybrid Connectivity Solutions

CC-Link IE TSN is at the forefront of this change. It combines wireless-wired hybrid networks to let factories change production lines quickly. It offers:

- Real-time communication for robots and automation

- Smooth IT/OT network integration

- Less downtime with quick changes

Data-Centric Manufacturing and Real-Time Analytics

Future factories will use manufacturing data infrastructure to turn sensor data into useful information. Industrial edge computing at production sites will process important data fast, improving:

- Predictive maintenance networks that forecast equipment failures

- Quality control systems using AI-driven analytics

- Energy optimization through real-time monitoring

For example, car plants using CC-Link IE TSN reduced downtime by 40% thanks to predictive maintenance. These advancements make hybrid networks key for Industry 5.0.

Competitor Analysis: Major Players in the CC Link Cable Market

- 3M

- Belden Inc.

- HELUKABEL USA, Inc.

- Quabbin Wire & Cable Co.

- igus, inc.

- Mitsubishi Electric Corporation

- DYDEN CORPORATION

- BizLink

- Siemens AG

- CRXCONEC

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global CC Link Cable Market Report |

| Base Year | 2024 |

| Segment by Type |

· Copper Cable · Optical Cable |

| Segment by Application |

· Data Communications · Electric Power |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The CC-Link market is set for a big change, driven by the need for fast connectivity and smart manufacturing. Over the next five years, growth will come from new tech like nanotechnology and IoT. Japan, China, and the U.S. will lead in innovation, while new markets will adopt solutions that fit their needs.

Five-Year Forecast and Growth Drivers

The CC-Link market is expected to grow by double digits by 2029. This growth will come from more factory automation and the spread of 5G. Asia-Pacific will lead in sales, with North America and Europe focusing on hybrid cable systems.

Advances in material science will make cables thinner and faster. This will help in sectors like energy and logistics.

Strategic Considerations for Industry Stakeholders

Companies need to match their automation plans with new network standards. Investing in R&D and getting sustainability certifications will help them stay ahead. They should also keep up with updates in connectivity infrastructure.

Stakeholders in the U.S. should look for federal grants for smart manufacturing. They should also work with tech hubs like Silicon Valley for new ideas.

Global CC Link Cable Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: CC-Link Cable Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- CC Link CableMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global CC Link Cableplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: CC Link Cable Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: CC Link Cable Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: CC Link Cable Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofCC Link CableMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are CC-Link cables, and why are they important?

CC-Link cables are used for fast data transfer in factories. They help devices talk to each other quickly. This is key for making things efficiently.

Which countries are leading in CC-Link cable advancements?

Japan, China, and the US are leading. They’re pushing the tech forward with new ideas and strategies.

What role does nanotechnology play in the CC-Link cable market?

Nanotechnology is making CC-Link cables better. It boosts speed, strength, and size for different uses in factories.

How is the supply chain for CC-Link cables structured?

The supply chain has raw material suppliers, makers, distributors, and users. It shows how complex and connected it is.

What are some current trends in CC-Link cable technology?

New trends include better materials and working with IoT and Industry 4.0. These make connections faster and smarter.

What challenges does the CC-Link cable industry face?

The industry faces issues like signal loss and interference. There are also rules to follow, like safety and environmental ones.

How do trade tensions impact the CC-Link cable market?

Trade tensions can change costs and availability. This makes companies look for new sources and ways to make things.

What applications benefit from CC-Link cables?

CC-Link cables help in many areas. They’re used for robots, electronics, and keeping important systems running smoothly.

How do CC-Link cables integrate with PLC systems?

CC-Link cables connect PLCs to other devices. They make sure data moves fast and work with many automation tools.

What is the future outlook for CC-Link cables in smart manufacturing?

The future will see new ways to connect, like wireless. There will also be better networks for more data and monitoring.

What factors influence the competitiveness of CC-Link market players?

Things like market share, new ideas, reliability, and partnerships matter. Big players keep up with new tech and models.