$515.6 Million Chocolate Mold Market Set to Grow in the U.S., Switzerland, and Belgium by 2025

Discover how the Chocolate Mold Market is expanding across key regions, driven by artisanal chocolatiers, rising confectionery demand, and innovative manufacturing technologies.

- Last Updated:

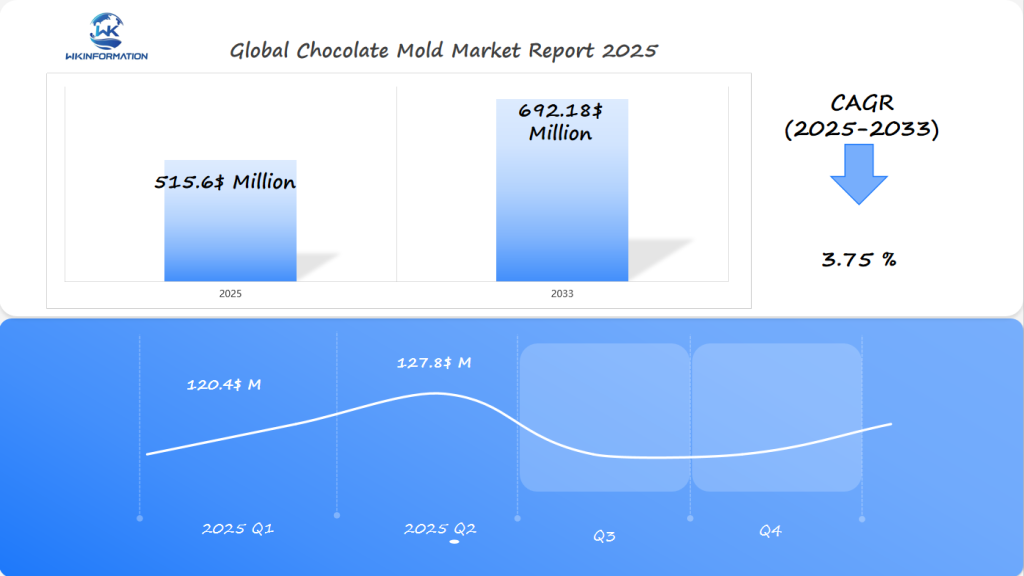

Projected Market Insights for Chocolate Mold in Q1 and Q2 of 2025

The Chocolate Mold market is projected to reach $515.6 million in 2025, with a CAGR of 3.75% from 2025 to 2033.

Q1 Insights

In Q1, the market is expected to generate around $120.4 million, driven by the increasing demand for high-quality, customizable molds in the confectionery industry.

Q2 Insights

By Q2, the market is anticipated to rise to approximately $127.8 million, as artisanal chocolate makers and large-scale manufacturers alike seek efficient, durable, and versatile molds for production.

Leading Markets

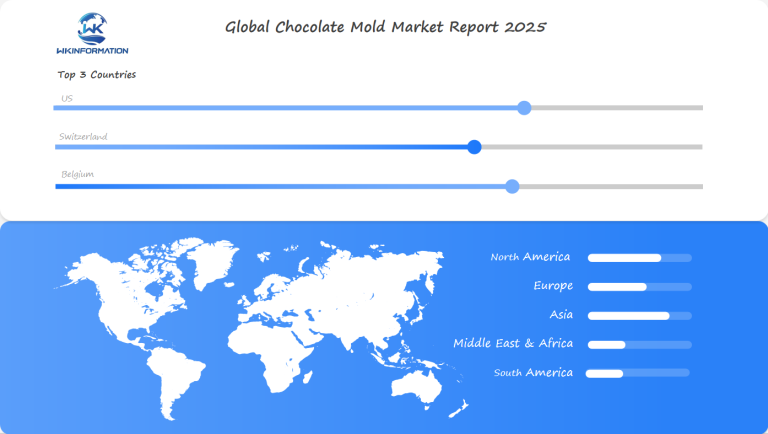

The U.S., Switzerland, and Belgium are the leading markets. The U.S. leads in innovation, with growing demand for premium chocolate products, while Switzerland and Belgium continue to dominate in the global chocolate industry.

The steady demand for customized and high-quality chocolate products will fuel continued growth in this segment.

Exploring the Upstream and Downstream Industry Chains for Chocolate Molds

The chocolate mold industry involves a structured supply chain, from raw material sourcing to end-user applications. Below is an overview of the upstream and downstream industry chains that drive this market.

Upstream Industry Chain

-

Raw Material Suppliers

-

Metals & Alloys (Stainless steel, aluminum for durable molds)

-

Plastics & Silicone (Polycarbonate, food-grade silicone for flexible and reusable molds)

-

Resins & Rubber (Used for custom mold production and food-safe coatings)

-

Machinery & Equipment (Injection molding machines, CNC machines for precision mold manufacturing)

-

-

Manufacturing & Processing

-

Mold Design & Engineering (3D modeling, CAD software for custom and standard mold creation)

-

Material Processing (Casting, molding, or injection techniques)

-

Quality Control & Compliance (Food safety certifications like FDA, LFGB, and EU standards)

-

Downstream Industry Chain

-

Distributors & Retailers

-

Wholesale suppliers

-

Specialty baking and confectionery stores

-

E-commerce platforms (Amazon, Alibaba, Etsy)

-

Food industry supply chains

-

-

End-User Applications

-

Chocolate & Confectionery Manufacturers (Large-scale chocolate producers, artisanal chocolatiers)

-

Bakeries & Pastry Shops (For decorative and specialty chocolates)

-

Home Baking & DIY Enthusiasts (Customized molds for personal use)

-

Foodservice Industry (Restaurants, hotels, catering businesses using chocolate decorations)

-

Market Trends & Growth Drivers

-

Rising demand for customized and artisanal chocolates

-

Growth in food-grade silicone molds for flexibility and ease of use

-

Expansion of e-commerce and DIY baking trends

-

Adoption of sustainable & biodegradable mold materials

With continuous innovation in mold design and material technology, the chocolate mold market is evolving to meet the demands of both large-scale producers and niche confectioners.

Trends Shaping the Chocolate Mold Industry: Design and Customization

The chocolate mold industry is changing fast. New designs and personalization are leading the way. Chocolate makers and chocolatiers are making unique and beautiful chocolates that grab people’s attention.

Now, making chocolate molds is all about customization. New mold shapes are key in the chocolate market. Thanks to 3D printing and laser engraving, we can make detailed and unique chocolate designs.

Some of the trends shaping the chocolate mold industry include:

- 3D-printed custom chocolate molds with complex geometric patterns

- Laser-engraved personalized shapes for special events

- Interactive and themed chocolate mold designs

- Sustainable materials for eco-friendly mold production

People want chocolates that tell a story or show off a unique look. From buildings to art-inspired shapes, chocolate mold design is an art that mixes food creativity with tech.

“Design is not just what it looks like and feels like. Design is how it works.” – Steve Jobs

The future of chocolate mold design is bright. New tech will bring even more creative and personal chocolate experiences. Those who focus on creative design and new production methods will be at the top.

Challenges in the Manufacturing of Chocolate Molds for Various Applications

Creating chocolate molds is a complex task. It needs precise skills and strict quality checks. This ensures the molds are top-notch.

Some big challenges in making chocolate molds include:

- Keeping the temperature right during making

- Finding the best materials for lasting molds

- Following food safety rules

- Scaling up production smoothly

Importance of Temperature Control

Temperature control is very important. Different chocolates melt at different temperatures. This means keeping the temperature just right is key to avoiding mold problems.

| Chocolate Type | Optimal Melting Temperature | Production Challenge |

| Milk Chocolate | 86-90°F | Viscosity control |

| Dark Chocolate | 88-92°F | Emulsifier adjustment |

| White Chocolate | 82-86°F | Fat crystallization |

Role of Quality Control

Quality control is crucial to tackle these issues. Companies use the latest tech to keep an eye on production. This ensures molds work well and meet high standards.

Importance of Sustainability

Being green is also important. Today’s chocolate mold makers focus on being eco-friendly. They want to meet the needs of customers who care about the planet.

Geopolitical Factors Impacting the Global Chocolate Mold Market

The global chocolate mold market is influenced by complex geopolitical challenges. Trade policies and international regulations shape the industry’s dynamics. They create complex networks in manufacturing and distribution.

Key Geopolitical Factors Affecting the Chocolate Mold Market

Key geopolitical factors affecting the chocolate mold market include:

- Tariff structures between manufacturing countries

- Export-import regulations for specialized equipment

- Economic sanctions impacting raw material supply

- Intellectual property protections for design innovations

Recent global events have shown weaknesses in chocolate mold production supply chains. European makers, especially in Switzerland and Belgium, face tough regulatory landscapes. These affect their place in the global market.

Trade talks and changing economic ties affect costs, technology, and market access. Countries with strong diplomatic ties find it easier to enter markets and face fewer rules.

Effective navigation of international regulations determines market success in the chocolate mold industry.

Economic ties mean that global tensions can quickly change market conditions. Manufacturers need to stay quick, ready for rule changes and have plans to keep their market share.

Market Segmentation: Types and Applications of Chocolate Molds

The chocolate mold market is full of different types and uses. It ranges from high-tech professional tools to easy-to-use home baking items. This variety makes the market lively and diverse.

Manufacturers sort chocolate molds in several important ways:

- Material Composition

- Polycarbonate molds for big industrial use

- Silicone molds for skilled chocolatiers

- Plastic molds for those who bake at home

- Shape Specifications

- Bar-shaped molds

- Intricate truffle molds

- 3D sculptural molds

Each mold has its own purpose, fitting into different market areas. Big candy makers need precise molds for quality chocolate. But home bakers look for something more flexible and cheaper.

The variety of chocolate molds shows the creativity and advanced skills of the global chocolate world.

Knowing these market areas helps makers create products that meet certain needs. This leads to new ideas in mold design and how they work.

Chocolate Molds in Confectionery, Artisan Chocolate, and Industrial Production

The world of chocolate production depends on special molds. These molds turn liquid chocolate into detailed shapes and designs. Each part of the chocolate world needs molds that fit their needs.

Artisan chocolate makers focus on precision and creativity. They use molds to make unique shapes that show off their brand. Small-batch makers often get custom molds for detailed designs and artistic touches.

- Confectionery molds support mass production techniques

- Artisan chocolate molds emphasize design complexity

- Industrial chocolate production requires standardized mold specifications

Industrial chocolate making needs molds that can handle lots of chocolate. These molds must be strong, let chocolate come out easily, and cool fast. Stainless steel is the top choice because it’s tough and easy to clean.

| Mold Type | Production Scale | Key Characteristics |

| Artisan Molds | Small Batch | Intricate designs, custom shapes |

| Confectionery Molds | Medium Scale | Repeatable patterns, moderate complexity |

| Industrial Molds | Large Scale | High-volume production, standardized shapes |

Chocolate mold technology is always getting better. It uses new materials and precise engineering. This helps all kinds of chocolate makers, no matter their size or style.

Global Market Insights into the Chocolate Mold Industry

The global chocolate mold market is growing fast. This is thanks to new designs and more people trying different foods. Experts think the market will get even bigger in the next few years. They see promising growth in certain areas.

There are a few important things to know about the chocolate mold market:

- Market size expected to reach unprecedented levels by 2025

- Growing demand in artisanal chocolate production

- Technological advancements enhancing mold manufacturing

Regional markets are growing at different rates. North America and Europe are leading in new mold designs. Countries like Switzerland and Belgium are big players in making molds. The United States is also growing fast, thanks to its focus on quality and design.

People want more unique and detailed chocolate molds now. This desire is helping the market grow. Companies are using new tech and precise engineering to meet this demand.

The chocolate mold industry represents a sophisticated intersection of culinary art and advanced manufacturing technology.

Asia and South America are also getting into the mold game. This opens up new chances for companies to grow globally.

U.S. Market Demand for High-Quality Chocolate Molds

The U.S. chocolate mold market is changing fast. This is thanks to creative confectionery experts and higher consumer standards. Craft chocolate makers are leading the way by asking for top-notch molds. These molds help them make detailed and special chocolates.

Top names in the American confectionery world are putting a lot of money into new mold tech. These advanced molds help with complex making processes. They also meet the growing need for chocolates that look great and are made with care.

Key Drivers of Demand

The demand for high-quality chocolate molds in the U.S. is being driven by several key factors:

- Artisan chocolatiers seek customized mold designs

- Industrial manufacturers require precision-engineered molds

- Growing interest in specialty chocolate shapes

- Increased investment in mold manufacturing technology

The U.S. chocolate mold market is growing a lot. Companies are making new mold solutions for all kinds of chocolate making. This ranges from small-batch artisan chocolates to big industrial batches.

“Quality molds are the foundation of exceptional chocolate production,” says a leading industry expert.

New trends in the U.S. chocolate mold market include 3D printed molds and eco-friendly materials. There’s also a focus on unique designs. These help chocolatiers stand out in a crowded market.

Switzerland’s Expertise in Chocolate Mold Design and Innovation

Switzerland is at the forefront of designing Swiss chocolate molds, combining traditional craftsmanship with modern technology. The country’s manufacturers are renowned for their imaginative mold designs, which elevate chocolate-making into a true art form.

Key Elements of Swiss Chocolate Mold Production

The Swiss approach to crafting chocolate molds involves several crucial aspects:

- Advanced precision engineering techniques

- Commitment to high-quality manufacturing

- Continuous technological innovation

- Sustainable production practices

The Role of Swiss Expertise in Complex Mold Designs

Swiss manufacturers leverage their expertise in chocolate to create intricate mold designs. These innovative designs empower chocolatiers to produce highly detailed shapes and structures that were previously challenging to achieve.

| Innovation Category | Key Characteristics |

| Precision Manufacturing | Micron-level accuracy in mold creation |

| Material Technology | Advanced food-grade alloys and coatings |

| Design Flexibility | Customizable molds for artisan chocolatiers |

Switzerland’s Position as a Leading Innovator in the European Chocolate Market

The European chocolate market recognizes Switzerland as a prominent innovator in the field of chocolate molds. By blending traditional craftsmanship with cutting-edge technology, Swiss manufacturers maintain a competitive edge in the global chocolate industry.

Belgium’s Role in the Chocolate Mold Market and Consumer Preferences

Belgium leads the world in chocolate molds, thanks to its long history of making chocolate. The country’s chocolate makers are known for their skill in creating detailed molds. These molds are of the highest quality.

In Europe, people want unique and personal chocolate experiences. Belgian makers have answered this by creating advanced molds. These molds have several important features:

- Precision engineering for complex chocolate designs

- Sustainable materials that enhance product quality

- Customizable shapes for artisan chocolatiers

- Advanced technical specifications

The way Belgium makes chocolate molds is special. It shows a deep commitment to chocolate craftsmanship in Europe. Both small and big makers put a lot of effort into their molds. They aim to keep traditional Belgian chocolate-making alive.

Belgian chocolate molds are not just tools, but an expression of culinary art and innovation.

Studies show that Belgian mold makers are setting new standards. They mix old skills with new tech. This makes them leaders in chocolate making worldwide.

The Future of Chocolate Molds: Sustainability and Technology Integration

The chocolate industry is changing fast. It’s moving towards sustainable molds and new ways to make chocolate. Now, makers use eco-friendly stuff that’s good for the planet and still makes great chocolate.

How Technology is Changing Chocolate Making

New tech in mold making is changing how chocolate is made. Companies are using smart tech to make chocolate better and faster. This includes things like:

- Materials that change with temperature for perfect chocolate

- RFID tags to track how chocolate is made

- Molds that can break down easily

The Importance of Sustainable Molds

Making molds that are good for the earth is key now. Makers are finding new ways to cut down on waste and help the planet. Renewable energy and recycling are big in modern chocolate making.

| Technology | Sustainability Impact | Production Efficiency |

| Smart Mold Sensors | Less waste | More precise |

| Biodegradable Materials | Less carbon | Good for the earth |

| Digital Tracking Systems | Better resource use | Higher quality |

The future of chocolate molds is all about being green and smart. By using eco-friendly stuff and new tech, makers are making chocolate better for us and the planet.

Competitive Landscape in the Chocolate Mold Market

The chocolate mold market is full of life and variety. It’s shaped by creative makers from all over. Leaders from the United States, Switzerland, and Belgium are leading the way with new ideas and tech.

- Micelli – Italy

- Cabrellon – Spain

- Tomric – USA

- Hans Brunner – Germany

- Pavoni – Italy

- Chocolate World – Belgium

- Selmi Group – Italy

- MFS Chocolate Molds – USA

- Schneider GmbH – Germany

- Martellato – Italy

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Chocolate Mold Market Report |

| Base Year | 2024 |

| Segment by Type |

· Polycarbonate Molds · Silicone Molds · Plastic Molds |

| Segment by Application |

· Artisanal and Boutique Chocolatiers · Industrial Chocolate Manufacturers · Home Bakers and Hobbyists |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The chocolate mold market continues to evolve, driven by shifting chocolate trends and consumer preferences. Key growth factors include rising demand for artisanal chocolates, advancements in mold manufacturing, and a focus on sustainable materials. Emerging markets, fueled by urbanization and higher disposable incomes, present significant opportunities for expansion.

Innovation and sustainability remain pivotal in shaping the industry’s future. Manufacturers increasingly collaborate with chocolatiers to develop customized molds that cater to niche demands. The growing interest in eco-friendly designs further underscores the importance of sustainable practices.

The chocolate mold market offers immense potential for stakeholders. By embracing technological advancements and prioritizing sustainability, the industry can meet evolving consumer demands and maintain its trajectory of growth.

Global Chocolate Mold Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Chocolate Mold Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Vacuum Arc RemeltingMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Chocolate Moldplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Chocolate Mold Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Chocolate Mold Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Chocolate Mold Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofChocolate Mold Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are the current trends in chocolate mold design?

Today, trends focus on customization, 3D printing, and laser engraving. These innovations aim to meet consumer cravings for distinctive chocolate shapes and presentation styles.

What materials are typically used for chocolate molds?

Common materials for chocolate molds include plastic, silicone, and polycarbonate. These materials are chosen for their durability, food safety, and ability to shape chocolate precisely.

How do geopolitical factors impact the chocolate mold market?

International trade policies, economic relationships, and regulatory standards influence the chocolate mold market. These factors have an impact on production, distribution, pricing, and availability in various regions.

What challenges do manufacturers face in producing chocolate molds?

Manufacturers face hurdles like choosing the right materials and ensuring food safety. They also need to maintain mold durability, scale up production, and enforce strict quality checks.

How are different sectors using chocolate molds?

The use of chocolate molds varies by sector:

- Large confectionery makers use them for bulk production.

- Artisan chocolatiers create unique designs.

- Industrial producers need molds for consistent quality.

What makes Swiss chocolate mold manufacturing unique?

Swiss makers are known for their precision, innovative designs, and high-quality craftsmanship. They create advanced molds that meet global standards.

What future trends are emerging in chocolate mold manufacturing?

New trends include sustainable practices, eco-friendly materials, and smart technologies like RFID tracking. Advanced temperature-sensitive production methods are also becoming more popular.

How is the U.S. market responding to chocolate mold innovations?

The U.S. market is experiencing a significant increase in demand for high-quality and specialized molds. This growth can be attributed to the rise of artisanal chocolate producers and consumers’ craving for one-of-a-kind chocolate experiences.

What role do Belgian manufacturers play in the chocolate mold market?

Belgian makers draw on their long chocolate-making heritage. They design molds that cater to specific consumer tastes, keeping a strong presence in the European market.