2025 Clamping Vise Market Boom: Unlocking a $438.5 Million Opportunity with Enhanced Precision in the China, Germany, and the United States

Discover comprehensive insights into the global clamping vise market, focusing on key regions including China, Germany, and the United States. This analysis explores market dynamics, technological innovations, and consumer preferences shaping the industry through 2025. Learn about leading manufacturers, strategic partnerships, and emerging trends in automated workholding solutions that are transforming industrial efficiency and precision manufacturing.

- Last Updated:

Q1 & Q2 Key Insights into the Clamping Vise Market by 2025

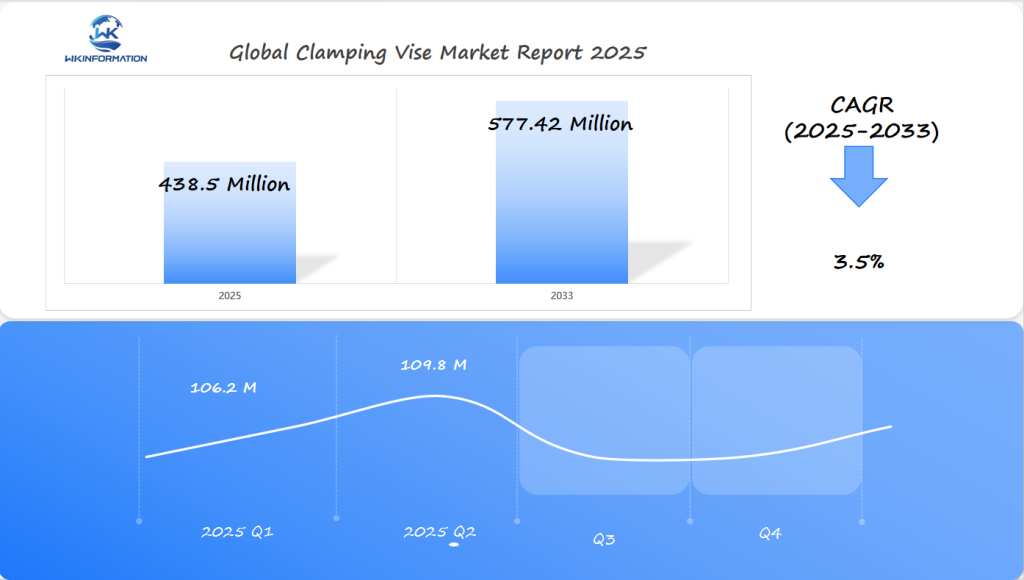

The global Clamping Vise market, valued at USD 438.5 million in 2025, is expected to grow at a CAGR of 3.5% through 2033.

Based on current market dynamics, Q1 2025 is projected to generate revenues of approximately USD 106.2 million, with Q2 showing a modest increase to USD 109.8 million, reflecting seasonal demand fluctuations and regional industrial activity. China, Germany, and the United States are the most significant markets to study, with China leading in manufacturing volume, Germany excelling in precision engineering, and the U.S. driving innovation in industrial automation. These countries are pivotal in shaping the market’s growth trajectory, offering unique opportunities for stakeholders.

For a detailed analysis of market trends, competitive strategies, and regional insights, explore the Wkinformation Research sample and full report. Gain a deeper understanding of the factors driving this market and uncover actionable insights to inform your business decisions.

Key Takeaways

- Clamping vise markets in China, Germany, and the US are experiencing rapid technological advancement

- Industrial clamping solutions play a crucial role in precision manufacturing

- Global demand for high-performance machining tools continues to grow

- Technological innovations are driving improvements in clamping vise design

- Multiple industries rely on advanced clamping vise technologies

Upstream and Downstream Industry Chain Analysis: The Clamping Vise Supply Chain Explained

The clamping vise supply chain is a complex network. It turns raw materials into precise tools for manufacturing. This system shows how these important tools get to markets all over the world.

Raw materials for clamping vises include high-grade metals and special alloys. These are found in:

- Steel foundries known for strong materials

- Aluminum and iron processing plants

- Precision metal fabrication facilities

The distribution of clamping vises goes through many stages. Manufacturers work with:

- Industrial equipment wholesalers

- Specialized manufacturing supply companies

- Direct sales networks for precision tools

Quality control, efficient material sourcing, and innovation are key in the supply chain. Manufacturers aim to keep costs low while ensuring high performance. This meets the needs of many industries.

Partnerships between suppliers, manufacturers, and distributors are crucial. They help keep the flow of clamping vises smooth. These partnerships also help avoid disruptions and keep products available.

Trend Analysis: Innovations and Trends in Clamping Vise Technology

The manufacturing world is seeing a big change, with new clamping vise tech leading the way. These advanced technologies are changing how we do things in manufacturing, making it more precise and efficient.

Smart clamping solutions are making big improvements in many areas:

- Integration of AI-powered sensing technologies

- Development of adaptive grip mechanisms

- Enhanced material durability and performance

- Automation-compatible design features

Companies are spending a lot on research to make clamping vises better. They want them to handle the complex tasks of today’s manufacturing. With smart tech, we can now monitor and maintain equipment in real-time, leading to better results.

New ideas are coming up, like:

- Wireless connectivity for remote control and monitoring

- Materials that last longer and perform better

- Modular designs for easy changes

The global hand tools market, which includes clamping vises, is expected to grow fast. It’s set to increase by 3.5% each year, reaching USD 577.42 million by 2033. This shows how much we need better clamping tech for modern manufacturing.

The future of manufacturing lies in smart, adaptive clamping solutions that can seamlessly integrate with advanced production systems.

As we keep exploring new tech, clamping vise innovations will be key. They will help make our work more productive, precise, and efficient in many fields.

Restriction Analysis: Challenges Facing the Clamping Vise Industry

The clamping vise industry faces big challenges that test its strength and ability to adapt. Rules and new technologies are changing the game, making it hard for companies to keep up.

There are several main challenges in the clamping vise industry:

- Supply chain vulnerabilities

- Raw material price fluctuations

- Technological adaptation requirements

- Increasing production complexity

Companies are under a lot of pressure because of economic uncertainty. Market constraints are especially tough. clamping vise makers facing big supply chain problems. The global market needs new ways to solve these big issues.

Rules and regulations are another big problem. Different countries have different standards and rules, making it hard for companies to grow globally. The automotive and aerospace industries, need very high quality and precision.

The ability to navigate these challenges will determine long-term market competitiveness and sustainable growth.

Technology is always changing, pushing the industry to evolve. Demand for automated clamping vises has gone up. Companies that invest in research and development can better handle these challenges.

Geopolitical Analysis: The Impact of Global Politics on Clamping Vise Production and Trade

The global clamping vise market is facing big challenges due to complex global politics. International tariffs and global manufacturing policies are changing the industry a lot. They create both problems and chances for makers all over the world.

Key geopolitical factors influencing clamping vise trade include:

- Shifting trade regulations between major manufacturing nations

- Economic sanctions impacting raw material supply chains

- Regional diplomatic tensions affecting manufacturing partnerships

The United States and China are very important in setting trade rules for precision tools. Geopolitical factors in clamping vise trade are getting more complicated. Makers are learning to deal with fast changes in the global economy.

“Navigating international tariffs requires strategic flexibility and innovative supply chain management,” says a leading industry analyst.

Recent changes in global manufacturing policies are making companies think differently. They are looking into new places to make things and setting up local factories. This helps them avoid problems with trade.

Strategic considerations for clamping vise producers now include:

- Developing resilient supply chains

- Investing in localized manufacturing capabilities

- Monitoring geopolitical trends closely

The mix of international tariffs and global manufacturing policies is a big challenge for the clamping vise industry. It needs makers to keep adapting and planning ahead.

Segmentation Type Market Analysis: Clamping Vise Market Segmentation by Type and Application

The clamping vise market is complex, with many types and uses. Market segmentation gives us key insights into the changing world of manufacturing. Companies are now making vises for specific needs in industries.

There are three main types of clamping vises:

- Hydraulic Vises

- Pneumatic Vises

- Manual Vises

Each type has its own benefits for different settings. Hydraulic vises offer precise clamping with strong force. They are perfect for tough machining tasks.

“Precision in manufacturing begins with selecting the right clamping solution” – Manufacturing Engineering Insights

Market segmentation by application shows strong growth in various areas:

- Automotive Manufacturing

- Aerospace Engineering

- Electronics Production

- Precision Machining

- General Industrial Applications

Nowadays, there’s a big move towards vises made for specific tasks. These vises perform better and are more reliable. Companies are using new tech to create vises that meet the complex needs of industries.

Application Market Analysis: The Diverse Uses of Clamping Vises in Manufacturing

Clamping vises are key in today’s manufacturing world. They help make production better in many areas. These tools help make things more accurate and efficient.

Clamping vises are used in many ways in different places:

- Automotive manufacturing: Securing complex engine components during machining

- Aerospace engineering: Holding delicate precision parts during fabrication

- Metalworking: Providing stable workpiece positioning for intricate cutting and drilling

- Woodworking: Ensuring precise alignment for custom furniture and carpentry projects

Companies use clamping vises to make their work better. Precision engineering demands absolute stability. These tools give strong grip and repeatable results with different materials and processes.

Adding advanced clamping vises to their work helps companies. They cut down on mistakes, save materials, and speed up making things. These tools are a must for making top-quality products in many fields.

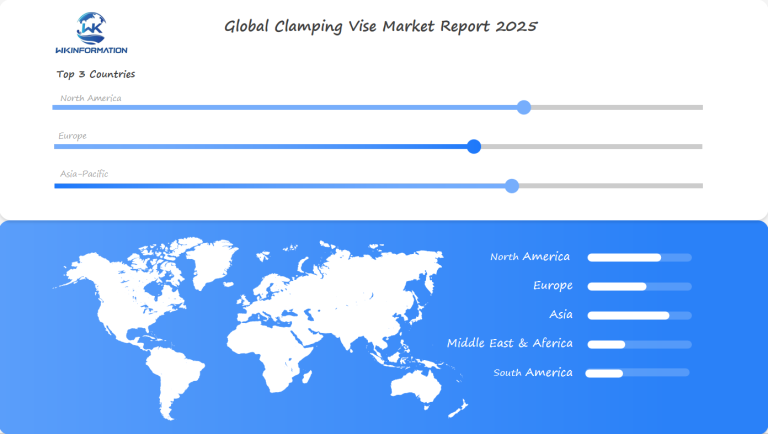

Global Clamping Vise Market Region Analysis: Regional Market Trends

The global clamping vise markets are changing fast in different places. Companies are trying to grab new chances in these areas. From North America to Asia-Pacific, new tech and changing needs are shaping the market.

Looking at the trends, we see big differences in how markets grow. The US and Europe lead in tech, while China and Malaysia are growing fast in making things. Malaysia, for example, is getting ready for better clamping vise tech.

- North America: High-precision manufacturing and aerospace applications drive market growth

- Europe: Strong emphasis on advanced engineering and automation technologies

- Asia-Pacific: Rapid industrialization and increasing manufacturing investments

- Middle East: Emerging market with growing infrastructure development

Each region has its own way of competing. Technological innovation and market adaptation are key to winning. Companies are spending a lot on research to make better clamping vises for each area.

The future looks bright for clamping vise tech. Growth will come from more automation and precision in making things all over the world.

China Clamping Vise Market Analysis

The China clamping vise industry is a major force in global manufacturing. It grows fast thanks to new production methods and tech investments. Chinese makers have changed the game in precision tools, becoming big names worldwide.

What makes the China clamping vise market stand out includes:

- Fast tech progress in making things

- More exports

- Support from the government for growth

- Good prices

The growth in China shows a smart way to make things. Local makers put a lot into research and development. They make top-notch clamping vises that match global standards.

“China’s manufacturing sector continues to demonstrate remarkable resilience and innovation in precision engineering tools.” – Industrial Manufacturing Quarterly

Chinese makers have strong supply chains. This lets them make clamping vises with great precision and low cost. Their focus on new tech makes China key in the global market.

Market trends point to more growth. Chinese companies aim to grow at home and abroad. They do this by improving tech and keeping prices low.

United States Clamping Vise Market Analysis

The US clamping vise market is strong and always innovating. This is thanks to new manufacturing tech and smart industrial moves. American makers are leading the way with new solutions that boost precision in many fields.

What makes the US clamping vise market stand out includes:

- Fast tech growth in precision engineering

- More demand from aerospace, auto, and medical fields

- Focus on top-notch, flexible clamping systems

New tech is changing US manufacturing. Firms are putting a lot into advanced manufacturing tech to improve precision, speed, and output. Smart sensors, auto systems, and better material handling are key for American makers.

Precision engineering is key in the US clamping vise market. Makers are creating advanced tools that meet tough needs in aerospace, robotics, and more.

The future of US manufacturing is all about keeping innovating and getting tech-savvy.

Investing in research and development keeps American makers ahead in clamping vise tech. The market is very adaptable, quickly meeting new industrial needs and tech hurdles.

Germany Clamping Vise Market Analysis

The German clamping vise industry leads in precision engineering in Europe. It shows unmatched technical skill and innovation. Germany’s manufacturing is known for top quality and detailed engineering, especially in industrial tools.

Key traits of the German clamping vise market are:

- Cutting-edge technological developments

- High-performance precision engineering solutions

- Strong focus on industrial automation

- Robust export-oriented manufacturing capabilities

Companies like Schunk and Römheld are top in Europe for clamping technology. They keep improving through research and development. Their focus on innovation is clear in their advanced manufacturing technologies.

The German clamping vise industry is very resilient and adaptable. They are adding smart technologies and digital solutions to their products. This meets the need for smart, connected tools in manufacturing.

Market trends show German clamping vise makers are on the rise. The global need for precise industrial parts is driving their growth and innovation.

Future Development Analysis: The Future of Clamping Vises in Precision Manufacturing

The future of clamping vises is changing fast. This is thanks to Industry 4.0 and smart manufacturing. Now, makers are moving towards smarter workholding tech. This tech makes work more precise and efficient.

Some big changes in clamping vise tech include:

- Advanced sensor-based monitoring systems

- Real-time data collection and analysis capabilities

- Adaptive clamping mechanisms

- Enhanced connectivity with digital manufacturing platforms

The market for CNC workholding products is growing fast. This growth is driven by the need in key sectors like aerospace, automotive, and healthcare.

New trends in smart manufacturing are changing how clamping vises are made:

- Integration of artificial intelligence for predictive maintenance

- Automated tool configuration

- Self-adjusting clamping parameters

- Enhanced precision through machine learning algorithms

Looking at different markets, there are big chances for growth:

The tech revolution is bringing new levels of precision and efficiency to making things. Clamping vises are leading the way in this industrial innovation.

Competitor Analysis: Major Players in the Clamping Vise Market

The global clamping vise market is very competitive. Top manufacturers are always trying to improve their tools.

- BISON USA Corp.

- OK-VISE

- Jergens Inc.

- Kurt Manufacturing

- Wilton Tools

- Yost Vises

- Gerardi S.p.A.

- Parlec, Inc.

- Forward Bench Vise

- Schunk

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Clamping Vise Market Report |

| Base Year | 2024 |

| Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The global clamping vise market is growing fast and full of new ideas. The forecast shows big chances in many manufacturing areas. Growth is expected to keep going up thanks to new tech and more uses in industry.

Investing in precision engineering, cars, and space tech looks very promising. New tech like AI and IoT will help make things better and faster. Big names like SCHUNK, RÖHM, and ROEMHELD Gruppe are ready to take on new trends.

Changes in markets, especially in Southeast Asia and the Asia-Pacific, are changing the game. Going green and using digital tools are key. Companies that keep up with tech and what people want will stay ahead.

In the future, the clamping vise market will keep changing. It will focus more on being precise, automated, and eco-friendly. Companies that keep learning, making new things, and stay flexible will do best in this changing world.

Global Clamping Vise Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Clamping Vise Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Clamping Vise MarketSegmentation Overview

Chapter 2: Competitive Landscape

- Global Clamping Viseplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Clamping Vise Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Clamping Vise Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Clamping Vise Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofClamping Vise Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are the key markets for clamping vises globally?

The main markets for clamping vises are China, Germany, and the United States. Each is a big industrial hub with its own tech and market styles.

How do technological innovations impact clamping vise manufacturing?

New tech is changing how clamping vises are made. We see smart solutions, designs for automation, and new materials. These advancements boost precision, efficiency, and flexibility in making things.

What types of clamping vises are most commonly used in manufacturing?

You’ll mostly find hydraulic, pneumatic, and manual vises in factories. They’re used in car making, aerospace, and fine engineering.

What challenges does the clamping vise industry currently face?

The industry faces many challenges. These include rules, tough competition, money changes, and the need to keep innovating to stay ahead.

How do geopolitical factors influence clamping vise production?

Politics play a big role in making clamping vises. Trade rules, tariffs, and diplomatic ties shape supply chains and how things are made and sold worldwide.

What industries primarily use clamping vises?

Clamping vises are key in car making, aerospace, fine machining, metalwork, and making industrial gear. They’re vital for holding things in place and keeping them steady.

How are clamping vises adapting to Industry 4.0 technologies?

Clamping vises are getting smarter with Industry 4.0. They’re using smart tech, AI, real-time monitoring, and sensors for better, smarter making.

What makes the German clamping vise market unique?

Germany stands out for its precision, quality, innovation, and famous makers. It’s a hub for top-notch industrial gear.

What are the future growth prospects for the clamping vise market?

The market looks bright, thanks to more demand for precision, automation, and tech. Also, new markets are growing, which is good for the future.

How do supply chain dynamics affect clamping vise availability?

Supply chains are shaped by where materials come from, the economy, and how companies work together. They also need to keep up with fast changes and problems.