Cold Room Forging Press Market Q1 and Q2 2025 Predictions

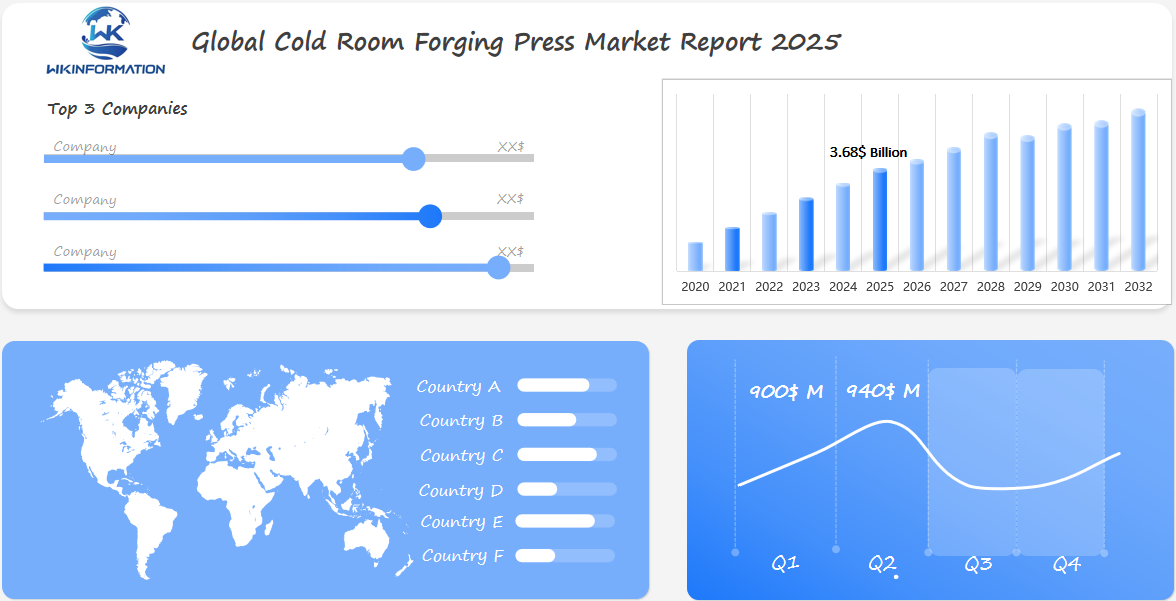

The Cold Room Forging Press market size in 2025 is USD 3.68 billion, growing at a CAGR of 4.36% from 2025 to 2033. In Q1 2025, the market is expected to generate around USD 900 million, driven by demand from industries such as automotive, aerospace, and manufacturing for high-quality forging equipment. Increased focus on efficient production methods and energy savings will also contribute to growth. By Q2 2025, the market is expected to reach about USD 940 million, with key regions like the US, Germany, and China investing in advanced cold forging technologies to enhance production capabilities and reduce costs in high-precision industries.

Types of Forging Processes

Closed-Die Forging

Predominantly used in the automotive industry, closed-die forging involves shaping metal within closed dies under high pressure. This process delivers excellent strength and precision, making it ideal for manufacturing critical components like crankshafts and connecting rods.

Open-Die Forging

Known for its flexibility, open-die forging is often employed in the aerospace sector. It allows for the production of larger and more complex parts such as aircraft landing gear components and engine parts.

Ring Rolling

This process is essential in manufacturing bearing rings, gears, and flanges. It finds applications in both the defense industry and heavy machinery manufacturing due to its efficiency in producing seamless rings with high structural integrity.

Each forging type caters to specific end-user industries such as automotive, aerospace, and defense, which are crucial drivers of market demand. Understanding these processes enables stakeholders to align their strategies with market needs effectively.

Regional Dynamics: Asia-Pacific Dominance and US Manufacturing Reshoring

The Asia-Pacific market is set to reign supreme in the metal forging industry, propelled by rapid industrialization. China stands at the forefront with its formidable manufacturing capabilities, solidifying its position as a global leader. The continuous expansion of China’s manufacturing sector has enabled it to produce a wide range of forged components at scale, efficiently meeting both domestic and international demands.

Japan, on the other hand, distinguishes itself through advancements in manufacturing technologies. Japanese companies are renowned for their precision engineering and innovative approaches, which have significantly enhanced productivity and quality within the forging sector. This technological edge allows Japan to maintain competitiveness in an increasingly crowded marketplace.

The US manufacturing reshoring initiative under Trump’s Industrial Strategy has introduced a new dynamic to the cold room forging press market. By incentivizing companies to relocate production back to American soil, this strategy aims to bolster the local economy and reduce reliance on foreign supply chains. While reshoring presents an opportunity for growth and job creation within the US, it also poses challenges. Local producers must navigate increased operational costs and adapt to evolving market conditions to remain competitive against entrenched international players.

This regional interplay creates a complex landscape where strategic positioning and technological innovation become crucial for success in the global cold room forging press market.

Technological Advancements Shaping the Future of Cold Room Forging Presses

The 2025 Cold Room Forging Press Market is undergoing a significant change with the increased use of automation in forging processes. Automation improves both efficiency and accuracy, minimizing human error and allowing for higher production rates. Leading manufacturers are embracing cutting-edge technologies such as robotic arms for material handling and automated control systems that adjust forging parameters in real-time. For example, companies like Thyssenkrupp AG are incorporating advanced robotics to streamline operations and ensure consistent product quality.

Sustainability is also becoming a key focus. Manufacturers are adopting energy-efficient machinery designed to reduce power consumption during forging cycles. This transition not only lowers operational costs but also supports global efforts to decrease carbon emissions. Furthermore, waste management strategies are being improved, with more companies investing in systems that recycle scrap materials and minimize overall waste production.

These technological advancements highlight the changing landscape of the cold room forging press market. With the integration of automation and sustainable practices, manufacturers are better equipped to meet increasing demands while complying with environmental standards, setting an example for future developments within the industry.

Strategic Recommendations for Stakeholders

Reshoring manufacturing capabilities presents a unique opportunity for U.S. manufacturers in the cold room forging sector, offering potential competitive advantages. With local production, companies can reduce dependency on international supply chains, thereby enhancing their resilience against global disruptions. Localized operations also allow faster response times to market demands and customization requests, essential for maintaining a competitive edge.

Recommendations for Industry Players:

- Invest in Advanced Technologies: Embracing automation and innovative technologies can significantly boost productivity and precision. This investment not only enhances production efficiency but also positions manufacturers at the forefront of technological advancements.

- Focus on Sustainable Practices: Implementing energy-efficient machinery and effective waste management strategies will not only reduce environmental impact but also align with growing regulatory demands and consumer expectations for sustainability.

- Leverage Government Policies: Utilize incentives and supportive policies under Trump’s industrial strategy aimed at boosting local production. This approach can provide financial benefits and strategic advantages in reshoring efforts.

- Risk Management Strategies: Develop robust risk mitigation plans to tackle potential disruptions. Diversifying suppliers and creating flexible manufacturing processes are essential steps to safeguard against unforeseen challenges.

These strategies enable stakeholders to harness emerging opportunities while mitigating potential risks, ensuring a sustainable path forward in the cold room forging market landscape.

Competitive Landscape in the Cold Room Forging Press Market

In the Cold Room Forging Press market, prominent companies such as Mauser Group BV, National Machinery, Stamtec, Inc., Nedschroef Herentals, Sijin Intelligent Forming Machinery Co. Ltd., Zhejiang Dongrui Machinery Industrial, Zhejiang Shengtuo Machinery Co., Ltd., Jyichyng, Zhejiang Yeswin Machinery, and Sacma are competing to provide advanced solutions for metal forming in low-temperature environments. These machines play a vital role in industries like automotive, aerospace, and heavy manufacturing, where precision and durability are crucial. As manufacturing processes evolve, these companies are at the forefront of incorporating new technologies to improve efficiency and product quality.

For more in-depth analysis and market insights, read the Wkinformation Research sample and full report.

Conclusion

| Report Metric | Details |

|---|---|

| Report Name | Global Cold Room Forging Press Market Report |

| Base Year | 2024 |

| Segment by Type |

·Mobile |

| Segment by Application |

·Metal Processing |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Navigating the Cold Room Forging Press Market under Trump’s industrial strategy reveals a complex landscape of opportunities and challenges. The emphasis on reshoring and manufacturing capabilities in the U.S. presents potential growth avenues for local producers. Industry stakeholders must stay vigilant, adapting to technological advancements and sustainable practices to maintain a competitive edge. As the market evolves, understanding these dynamics becomes crucial for strategic planning. The future outlook suggests a robust market trajectory, driven by innovation and regional shifts in manufacturing prowess.

Explore Further Insights with Wkinformation Research Report

For those seeking an in-depth understanding of the 2025 Cold Room Forging Press Market Forecast: US, China, and Japan Under Trump’s Industrial Strategy, the Wkinformation Research report offers comprehensive insights. This report is a valuable resource for stakeholders who wish to gain a detailed perspective on market trends and forecasts.

Key features of the Wkinformation Research report include:

- In-depth Market Analysis: Delve into the specific factors driving growth in various regions, with a particular focus on the implications of industrial strategies and technological advancements.

- Technological Trends: Discover how automation and sustainable practices are influencing the future of cold room forging presses.

- Strategic Recommendations: Gain insights on navigating reshoring opportunities and potential risks within this evolving landscape.

By exploring this report, you equip yourself with essential knowledge to make informed business decisions in an increasingly dynamic market. Whether you are a manufacturer, investor, or industry analyst, these insights will prove invaluable in shaping your strategic approach.

Stay ahead of the curve by accessing the complete Wkinformation Research report today.

FAQs (Frequently Asked Questions)

How does Trump’s industrial strategy impact US manufacturing in the cold room forging sector?

Trump’s industrial strategy aims to bolster US manufacturing capabilities, potentially providing benefits such as increased local production but also presenting challenges for producers in adapting to new market conditions.

What types of forging processes are analyzed in the market forecast?

The market forecast includes an analysis of various forging processes such as closed-die, open-die, and ring rolling, highlighting their applications across sectors like automotive, aerospace, and defense.

What technological advancements are shaping the future of cold room forging presses?

Technological advancements include increased automation within forging processes for enhanced efficiency and precision, as well as sustainable practices aimed at reducing environmental impact through energy-efficient machinery and waste management strategies.

Why is it important for stakeholders to understand trends in the Cold Room Forging Press Market?

Understanding market trends is vital for stakeholders to make informed business decisions, allowing them to leverage emerging opportunities and mitigate potential risks associated with market fluctuations.

Global Cold Room Forging Press Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Cold Room Forging Press Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Cold Room Forging PressMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Cold Room Forging Pressplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Cold Room Forging Press Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Cold Room Forging Press Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Cold Room Forging Press Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofCold Room Forging Press Market Insights

- Actionable Recommendations for Stakeholders