2025 Elastomer Injection Machine Market Outlook Unlocking $731 Million Growth in US, Germany, and China

- Last Updated:

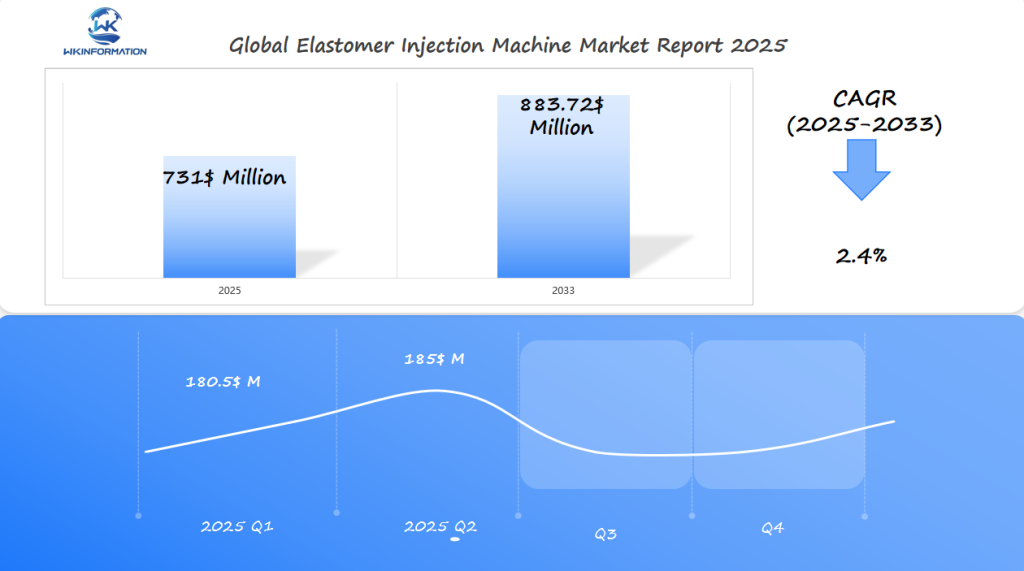

Elastomer Injection Machine Market Projection for Q1 and Q2 2025

The Elastomer Injection Machine market is expected to be valued at USD 731 million in 2025, with a growth rate of 2.4% CAGR from 2025 to 2033. For Q1 2025, the market is anticipated to reach approximately USD 180.5 million, with Q2 2025 seeing a slight increase to around USD 185.0 million.

The growth in this sector is mainly driven by the US, Germany, and China, where industries like automotive, electronics, and medical device manufacturing increasingly rely on elastomer injection molding for precision and high-performance applications. The US remains a strong player due to its advanced manufacturing technology and established industrial base. Germany, known for its high-quality manufacturing standards, continues to show steady demand, while China is expanding rapidly in the sector as it leads in mass production capabilities. These countries are expected to be the primary drivers of growth in the elastomer injection machine market.

Understanding the Supply Chain Dynamics of the Elastomer Injection Machine Market

Understanding the supply chain dynamics within the elastomer injection machine market is crucial for identifying both opportunities and challenges.

Upstream Suppliers: The Backbone of Production

At the core of this industry are key upstream suppliers who play a vital role in providing essential raw materials. These suppliers, often chemical companies like BASF and Shin-Etsu Chemical Co., supply high-quality silicone and thermoplastic elastomers, which are indispensable for producing effective injection machines.

Downstream Users: Diverse Industries Benefiting from Technology

Moving down the chain, downstream users represent diverse industries reliant on elastomer injection technology. The automotive sector prominently utilizes these machines for manufacturing components such as seals, gaskets, and bushings that demand precision and durability. Meanwhile, the medical device industry employs elastomer injection machines to produce items like medical tubing and syringes, benefiting from the biocompatibility and flexibility of silicone elastomers.

The Impact of Supply Chain Advancements on Market Growth

These applications illustrate how advancements in supply chain elements can directly influence market growth by meeting specific industry needs. This interconnectedness between upstream suppliers and downstream users underscores the strategic importance of maintaining robust relationships across the entire supply chain to unlock potential growth within key markets.

Key Trends Shaping the Elastomer Injection Machine Market in 2025

The elastomer injection machine market is witnessing significant developments driven by industry trends, technological advancements, and sustainability efforts. Several major trends are shaping the landscape in 2025:

1. Advancements in Liquid Silicone Rubber (LSR) Applications

LSR is gaining traction for its versatility and superior properties in various applications. The automotive and healthcare sectors are seeing increased usage of LSR due to its excellent heat resistance and flexibility. This trend not only enhances product quality but also boosts the demand for elastomer injection machines.

2. Impact of Bio-based Materials

As sustainability becomes a focal point for industries worldwide, bio-based materials are being integrated into elastomer injection processes. These materials reduce environmental impact by offering renewable alternatives to traditional synthetic resources, aligning with global efforts towards eco-friendly manufacturing.

Emerging technologies further influence the future of elastomer injection machines:

3. 3D Printing with LSRs

This innovation is revolutionizing production capabilities by allowing complex geometries and rapid prototyping. 3D printing with LSRs offers customization advantages and efficiency improvements, making it a key area of growth within the industry.

These trends highlight a dynamic shift towards advanced technologies and sustainable practices, positioning the elastomer injection machine market for robust expansion.

Market Restrictions and Challenges in the Elastomer Injection Machine Industry

Navigating the elastomer injection machine market involves overcoming several challenges and restrictions. Key among these are regulatory hurdles that impact production. Compliance with stringent safety and environmental standards can be a significant barrier, especially for new entrants who may lack the resources to meet these demands. Regulations can vary widely across regions, necessitating a comprehensive understanding of each market’s legal landscape.

Competition is another critical factor affecting this industry. Established players like BASF and Dow Corning Inc. have a strong foothold, making it challenging for newcomers to capture market share. The presence of large corporations often leads to pricing pressures, as these companies can leverage economies of scale to offer competitive prices. This environment makes it essential for smaller companies to innovate continuously or focus on niche markets to differentiate their offerings.

Additionally, fluctuations in raw material costs can strain profit margins, requiring companies to employ strategic sourcing and cost management practices. Staying agile and responsive to these market dynamics is crucial for any business aiming to thrive in the elastomer injection machine sector.

Geopolitical Factors Affecting the Growth of the Elastomer Injection Machine Market

Geopolitical influences play a crucial role in shaping trade policies that directly impact the elastomer injection machine market. This is particularly true in regions like the US and China, where these influences are especially strong due to their significant roles in global manufacturing and trade.

1. Trade Policies

Changes in trade agreements or tariffs between these major economies can have a significant impact on the cost and availability of elastomer injection machines. For example, if tariffs are imposed on raw materials or finished products, it can lead to increased production costs and affect market profitability.

2. Regional Stability

The stability of a region is an important factor in determining opportunities for market expansion. Political unrest or economic instability can discourage investment and disrupt supply chains, hindering market growth. On the other hand, stable regions often attract more investments, creating an environment that supports technological advancements and industry growth.

The relationship between geopolitical events and market dynamics highlights the need for strategic planning for businesses operating in this field. It is crucial for companies in the elastomer injection machine industry to stay informed about geopolitical trends in order to navigate potential disruptions and take advantage of new opportunities.

Elastomer Injection Machine Market Segmentation by Type and Key Growth Areas

In the dynamic world of elastomer injection machines, understanding market segmentation by product type is crucial. Two primary categories dominate: thermoplastic elastomers and silicone elastomers.

1. Thermoplastic Elastomers (TPEs)

Known for their flexibility and ease of processing, TPEs are gaining traction in industries like automotive and electronics. Their adaptability to injection molding processes makes them ideal for mass production, driving demand in applications requiring high-resilience materials.

2. Silicone Elastomers

These are pivotal in sectors such as healthcare and automotive due to their excellent thermal stability and biocompatibility. With advancements in medical devices and electrical insulation technologies, silicone elastomers remain a key growth area.

Both segments exhibit promising growth prospects, fueled by industry demands for innovative materials that offer enhanced performance characteristics. These trends suggest a vibrant future for the elastomer injection machine market, with each type catering to specific industrial needs and opening new avenues for expansion.

Exploring the Application Scope of Elastomer Injection Machines

Elastomer injection machines are essential in a variety of industries, providing precise and efficient solutions for molding elastomers into functional products. These machines offer significant advantages in terms of production speed, accuracy, and cost-effectiveness, making them suitable for numerous applications. Below is an exploration of the various industries and sectors where elastomer injection machines are widely used.

Automotive Industry

In the automotive sector, elastomer injection machines are used to produce components such as seals, gaskets, bushings, and weatherstripping. These components are crucial for ensuring vehicle durability, safety, and performance. Elastomers provide excellent resistance to temperature variations, oils, and chemicals, making them ideal for automotive applications that demand high performance and longevity.

Medical Devices

Elastomer injection machines are used in the production of medical-grade components like seals, diaphragms, and tubing. These parts are essential in medical devices such as syringes, IV lines, and pumps. Elastomers offer biocompatibility and flexibility, which are critical in ensuring patient safety and comfort. The precision and reproducibility of elastomer injection molding ensure the production of high-quality, sterilizable medical components.

Consumer Goods

Elastomer injection molding is widely used in the production of consumer goods such as rubberized handles, phone cases, footwear, and toys. The versatility of elastomers allows for the production of products with various textures, colors, and designs. Injection molding machines enable high-volume, consistent manufacturing, meeting the growing demand for mass-produced consumer goods.

Industrial Applications

In industrial sectors, elastomer injection machines are used to create components like seals, O-rings, and gaskets that are vital in machinery, pumps, and valves. Elastomers provide excellent sealing properties and resistance to environmental conditions, making them ideal for use in heavy-duty industrial equipment and machinery. The precision of elastomer injection machines ensures that these components are made to tight specifications.

Electronics

In the electronics industry, elastomer injection molding is employed to produce components such as gaskets, seals, and vibration dampers for devices like smartphones, laptops, and cameras. Elastomers help protect electronic devices from dust, moisture, and mechanical shock, contributing to the longevity and reliability of electronic products.

Packaging

Elastomer injection machines are used in packaging applications to produce elastomeric seals and closures. These components are essential in ensuring airtight, leak-proof, and tamper-proof packaging for products like food, beverages, and pharmaceuticals. The ability to create components with tight tolerances is critical in maintaining the quality and integrity of packaged goods.

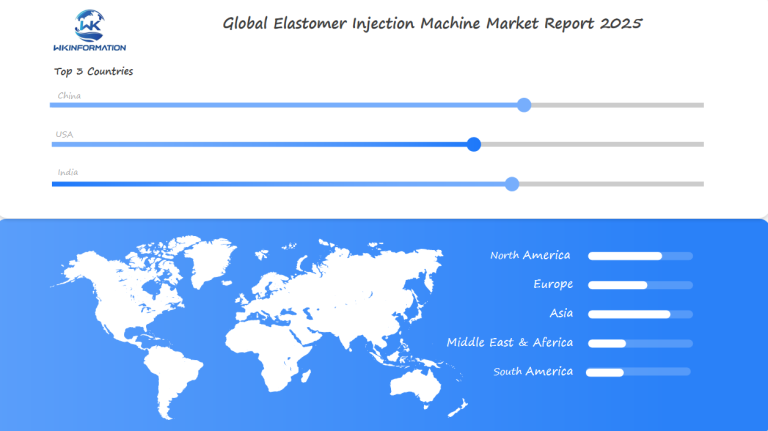

Regional Outlook and Opportunities in the Global Elastomer Injection Machine Market

The global elastomer injection machine market is experiencing significant changes in different regions due to varying demands and investment opportunities.

North America

In the United States, a strong healthcare system and leading medical device manufacturers are crucial for sustaining market growth. The demand for advanced elastomer injection machines is driven by ongoing innovations and the need for high-quality medical components.

Asia-Pacific

China and India are leading the way in rapid growth within the Asia-Pacific region. In China, significant healthcare investments are being made to cater to an aging population, creating favorable conditions for elastomer injection machine applications in medical devices. Additionally, India’s growing automotive sector is further boosting the demand for elastomers used in vehicle manufacturing.

Europe

Germany stands out as a hub of innovation in Europe, primarily due to its robust automotive industry. The focus on sustainability and eco-friendly materials presents lucrative investment opportunities as manufacturers strive to incorporate bio-based elastomers into their production processes.

Each region offers distinct market opportunities supported by technological advancements and specific demands from various sectors. Investors can take advantage of these dynamics to tap into growth prospects within the elastomer injection machine market across these key regions.

USA Elastomer Injection Machine Market Insights and Forecast

The elastomer injection machine market in the USA is experiencing significant growth due to increasing demand across various industries, such as automotive, medical devices, consumer goods, industrial applications, and electronics. These machines are essential for the efficient production of elastomer-based components, offering precision and high-volume production capabilities. The USA market is expected to continue its growth trajectory, driven by technological advancements and the increasing adoption of elastomer injection molding processes in various manufacturing sectors.

Market Drivers

-

Automotive Industry Demand The automotive sector is one of the major drivers for elastomer injection machines in the USA. With the growing demand for automotive parts such as seals, gaskets, bushings, and weatherstripping, manufacturers are increasingly investing in elastomer injection machines. These components are essential for enhancing vehicle performance, safety, and durability.

-

Rising Demand in Medical Devices The medical devices sector has been a significant contributor to the growth of the elastomer injection machine market. Elastomers are used in medical components like seals, diaphragms, tubing, and valves. With a growing emphasis on precision and high-quality standards, elastomer injection machines are crucial in ensuring the safe and reliable production of these medical components.

-

Consumer Goods Industry Growth The consumer goods market in the USA, including products like rubberized handles, footwear, and toys, is expanding. Elastomer injection machines help meet the demand for customized, durable, and aesthetically appealing consumer products. The ability to produce these goods at a high volume and with consistent quality is driving the adoption of elastomer injection molding technologies.

China Elastomer Injection Machine Market Growth and Demand Trends

The elastomer injection machine market in China is experiencing rapid growth, fueled by increasing demand across a variety of industries such as automotive, healthcare, consumer goods, and electronics. China, being one of the largest manufacturing hubs in the world, offers significant growth potential for elastomer injection molding technologies. The market is expected to expand at a steady pace as demand for high-quality elastomer components rises and manufacturers increasingly turn to advanced production methods to meet industry requirements.

Market Drivers

-

Expansion of the Automotive Industry China is one of the largest automotive markets globally, with increasing production of vehicles each year. Elastomer injection machines are critical for producing automotive components such as seals, gaskets, bushings, and weatherstripping. The growing demand for high-performance vehicles, including electric vehicles (EVs), which require lightweight, durable components, further drives the demand for elastomer injection molding technologies in the automotive sector.

-

Healthcare and Medical Device Applications The healthcare industry in China is rapidly expanding, particularly in medical device manufacturing. Elastomer injection molding is widely used to produce precision medical components such as seals, gaskets, and diaphragms for medical devices like syringes, IV lines, and pumps. The rising focus on healthcare and patient safety, along with advancements in medical technology, is propelling the demand for elastomer injection machines capable of producing high-quality, biocompatible components.

-

Rising Consumer Goods Demand The consumer goods sector in China, which includes products like rubberized handles, footwear, toys, and electronic accessories, continues to experience strong growth. Elastomer injection machines allow manufacturers to produce a variety of consumer goods with durability, flexibility, and aesthetic appeal. The increasing demand for personalized and customizable consumer products has also contributed to the growing adoption of elastomer injection molding technologies.

Germany Elastomer Injection Machine Market Performance and Competitive Landscape

Germany is one of the leading markets in Europe for elastomer injection machines, benefiting from its well-established industrial base, strong manufacturing capabilities, and technological expertise. The country’s robust automotive sector, advanced manufacturing technologies, and focus on precision engineering make it a key player in the elastomer injection machine market. The German market is experiencing steady growth, supported by the increasing demand for high-quality elastomer components across industries such as automotive, healthcare, consumer goods, and electronics.

Market Drivers

-

Strong Automotive Industry Germany is home to some of the world’s most well-known automotive manufacturers, including Volkswagen, BMW, and Mercedes-Benz. The demand for elastomer components such as seals, gaskets, bushings, and weatherstripping is growing, driven by the need for lightweight, durable, and energy-efficient automotive parts. The shift towards electric vehicles (EVs) is further increasing the demand for elastomer injection machines, as EVs require specific components like battery seals and gaskets that elastomer injection molding can produce efficiently.

-

Focus on Healthcare and Medical Devices Germany’s healthcare sector is one of the most advanced in Europe, with significant demand for medical devices and components. Elastomer injection machines play a critical role in producing precision parts such as seals, gaskets, diaphragms, and tubing for medical devices, including syringes, IV lines, and pumps. The rising demand for advanced medical technology, coupled with strict regulatory requirements for biocompatibility and sterilization, is driving the market for elastomer injection machines in the medical sector.

-

Technological Innovation Germany is known for its engineering excellence, and this extends to the elastomer injection molding industry. Manufacturers in Germany are increasingly adopting advanced technologies such as automation, AI, and real-time monitoring to improve the efficiency, precision, and flexibility of elastomer injection molding processes. These innovations allow manufacturers to produce high-quality elastomer components while reducing production costs and improving sustainability.

-

Sustainability and Environmental Regulations Germany has some of the strictest environmental regulations in the world, and these regulations are shaping the elastomer injection machine market. There is a growing emphasis on sustainability in manufacturing processes, with a focus on reducing waste, energy consumption, and using eco-friendly materials. Elastomer injection machine manufacturers are investing in energy-efficient machines and exploring the use of recyclable elastomers to meet these environmental standards.

Future Development and Technological Advancements in Elastomer Injection Machines

Technological advancements continue to shape the elastomer injection machine industry, paving the way for future developments that enhance both production efficiency and product capabilities.

1. Automation and Robotics

The integration of automation and robotics is revolutionizing production lines, reducing manual intervention, and increasing precision in manufacturing processes. This leads to higher quality outputs with reduced error margins.

2. Smart Manufacturing Technologies

IoT-enabled machines provide real-time data analytics, optimizing operational efficiency by allowing predictive maintenance and minimizing downtime.

3. Advanced Material Applications

Innovations such as Liquid Silicone Rubber (LSR) applications in 3D printing are pushing the boundaries of design flexibility and customizability, catering to diverse industry needs from automotive to healthcare.

4. Sustainability Efforts

The shift towards bio-based materials supports environmental sustainability, aligning with global trends and consumer demand for eco-friendly products.

These technological strides ensure the elastomer injection machine market remains dynamic, meeting evolving industry standards and customer expectations.

Competitive Landscape and Market Share in the Elastomer Injection Machine Market

A competitive landscape analysis reveals that major players such as BASF and Dow Corning Inc. are crucial in the elastomer injection machine market. These companies have developed strong strategies to maintain or grow their market share despite intense competition.

-

Sumitomo (SHI) Demag – Japan

-

Arburg – Germany

-

Haitian International – China

-

Toshiba Machine – Japan

-

Sepro Robotique – France

-

Engel – Austria

-

Wittmann – Austria

-

Milacron – USA

-

Negri Bossi – Italy

-

Yizumi – China

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Elastomer Injection Machine Market Report |

| Base Year | 2024 |

| Segment by Type |

· Thermoplastic Elastomers (TPEs) |

| Segment by Application |

· Automotive Industry |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The future outlook 2025 for the Elastomer Injection Machine Market reveals promising growth across key regions such as the US, Germany, and China. With advancements in technology and increased demand in automotive and healthcare sectors, the market is set to unlock substantial opportunities.

To dive deeper into these insights, consider exploring the detailed analysis available in the Wkinformation Research report on this dynamic market. Engaging with these resources can provide valuable perspectives on strategic investments and industry trends shaping the future landscape.

Global Elastomer Injection Machine Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Elastomer Injection Machine Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Elastomer Injection Machine Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Elastomer Injection Machine players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Elastomer Injection Machine Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Elastomer Injection Machine Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Elastomer Injection Machine Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Elastomer Injection Machine Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected growth of the elastomer injection machine market by 2025?

The elastomer injection machine market is expected to unlock a growth potential of approximately $731 million, particularly in key regions such as the US, Germany, and China.

What are the key factors affecting the supply chain dynamics of elastomer injection machines?

Key factors include upstream suppliers who provide essential materials and components, as well as downstream users in industries like automotive and medical devices that utilize elastomer injection machines for production.

What major trends are shaping the elastomer injection machine market in 2025?

Significant trends include advancements in liquid silicone rubber (LSR) applications, increased use of bio-based materials for sustainability, and emerging technologies such as 3D printing that are influencing future developments.

What challenges does the elastomer injection machine industry face?

The industry faces various challenges including regulatory hurdles that affect production standards, competition leading to pricing pressures, and barriers to entry for new players looking to enter the market.

How do geopolitical factors influence the elastomer injection machine market?

Geopolitical events can significantly impact trade policies related to elastomer injection machines, especially in major markets like the US and China. Regional stability also plays a crucial role in determining market expansion opportunities.

What are the key segments of the elastomer injection machine market based on product types?

The elastomer injection machine market is segmented primarily by type, such as thermoplastic and silicone machines. Identifying growth areas within these segments is essential based on evolving industry demands.