2025 Electronic Adhesives Market Expansion: Growing to $5.16 Billion with Increasing Demand in U.S., Japan, and South Korea

Explore the evolving landscape of electronic adhesives market and discover how major players like the U.S., Japan, and South Korea are adapting to post-Trump global dynamics. Learn about market trends, regional dominance, and future projections for 2025, with insights into sustainability initiatives and technological advancements shaping this crucial industry.

- Last Updated:

Electronic Adhesives Market: Q1 and Q2 2025 Predictions

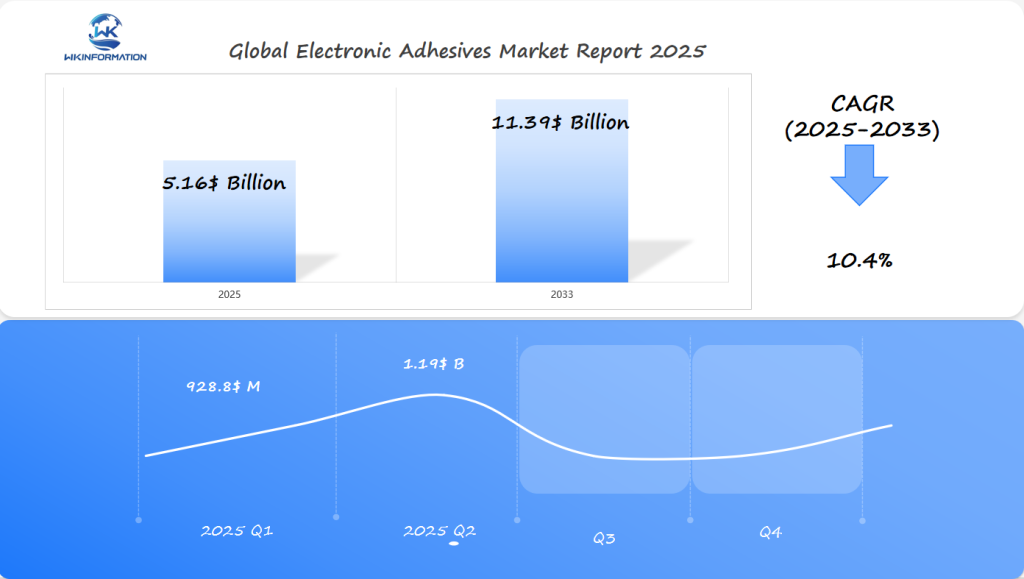

The global Electronic Adhesives market is expected to reach approximately USD 5.16 billion in 2025, with a compound annual growth rate (CAGR) of 10.4% anticipated from 2025 to 2033, driven by the increasing demand for advanced electronics and the growing need for high-performance adhesives in consumer electronics. In Q1 2025, the market is expected to generate around 18% of the total value, or USD 928.8 million, reflecting steady but cautious early-year demand. By Q2 2025, the market is projected to see a notable increase, contributing around 23% of the annual value, or USD 1.19 billion, as manufacturing and electronics sectors ramp up production during the mid-year period.

The U.S., Japan, and South Korea will be critical countries to monitor in the Electronic Adhesives market. The U.S. remains a key player due to its strong presence in the consumer electronics and automotive industries, both of which are significant users of electronic adhesives. Japan’s advanced technology and electronics manufacturing sector will drive demand for high-performance adhesives in devices such as smartphones and automotive components. South Korea, with its dominance in semiconductor manufacturing, is expected to see substantial growth in demand for electronic adhesives as the electronics and tech industries continue to thrive. These markets are central to understanding the future direction of the Electronic Adhesives market in 2025.

Upstream and Downstream Industry Chain Analysis for Electronic Adhesives

Understanding the supply chain dynamics in the electronic adhesives market is crucial for grasping its production processes and market dynamics. The industry chain can be broadly divided into upstream and downstream segments, with each playing a vital role in the overall ecosystem.

Upstream Suppliers and Material Sources

The upstream segment involves suppliers who provide essential raw materials required for manufacturing electronic adhesives. Key materials include:

- Resins: Epoxy, polyurethane, and silicone resins are commonly used due to their excellent adhesive properties.

- Fillers and Additives: These enhance the performance characteristics of adhesives, such as thermal conductivity or flexibility.

- Solvents and Curing Agents: Used to adjust viscosity and facilitate the curing process.

These materials are sourced from chemical manufacturers who specialize in producing high-purity compounds necessary for the exacting standards of electronic applications.

Downstream Applications in Electronics Manufacturing

In the downstream sector, electronic adhesives are extensively used in various applications within electronics manufacturing:

- Component Assembly: Adhesives are crucial for securing components on printed circuit boards (PCBs), ensuring stability during operation.

- Thermal Management: In devices like laptops and smartphones, adhesives aid in heat dissipation by bonding heat sinks to processors.

- Electrical Insulation: Non-conductive adhesives provide necessary electrical isolation between components.

These applications highlight the importance of adhesives in enhancing device reliability and performance.

Interaction Between Suppliers and Manufacturers

The interaction between suppliers and manufacturers forms a critical link in the industry chain. Collaboration is essential as manufacturers rely on consistent quality and supply of raw materials to meet production demands. This relationship often involves:

- Joint Development Initiatives: Manufacturers work closely with suppliers to develop customized adhesive solutions tailored for specific applications.

- Supply Agreements: Long-term contracts ensure a steady supply of essential materials, reducing risks associated with supply chain disruptions.

This interconnectedness ensures that the electronic adhesives market remains resilient while adapting to evolving technological demands.

Emerging Trends in the Electronic Adhesives Market

Eco-Friendly and Bio-Based Adhesives

A significant transformation in the electronic adhesives market is the increasing adoption of eco-friendly adhesives. As environmental regulations become more stringent, companies are turning to bio-based solutions that minimize ecological impact. These adhesives often feature water-based formulations or use renewable raw materials, aligning with global sustainability goals. The demand for low-VOC (volatile organic compounds) and solvent-free products is rising, driven by both regulatory pressures and consumer preferences for greener electronics.

Advancements in UV Curing Technologies

Another pivotal trend is the advancement of UV curing technology. This method offers rapid curing times, which enhances production efficiency—a crucial factor for manufacturers seeking to meet high-volume demands. UV curing adhesives are particularly valued for their precision in assembly processes; they provide a controlled cure that minimizes waste and reduces processing time. This technology not only supports increased productivity but also contributes to energy savings, further bolstering its appeal in an eco-conscious market.

Sustainability Trends Shaping the Market

Sustainability trends extend beyond product formulations to encompass entire manufacturing processes. Companies are investing in technologies that reduce resource consumption and lower carbon footprints. The shift towards sustainable practices is not merely a response to regulations but also a strategic move to capture environmentally aware consumers. This holistic approach to sustainability is reshaping market dynamics, encouraging innovation and competition among industry players.

Incorporating these trends into your business strategy can position you at the forefront of market advancements while meeting regulatory requirements.

Overcoming Challenges in the Electronic Adhesives Industry

Addressing challenges in the electronic adhesives market requires a keen understanding of the pricing and reliability issues that manufacturers encounter. High-tech adhesive pricing concerns are at the forefront, as these specialized adhesives often demand significant investment in research and development. The cost implications can strain budgets, particularly for smaller players striving to remain competitive.

Pricing Concerns

- Material Costs: The raw materials used in high-tech electronic adhesives can be costly, driven by factors such as scarcity and geopolitical tensions affecting supply chains.

- Innovation Investments: As manufacturers innovate to meet emerging demands, such as bio-based or low-VOC adhesives, initial costs can rise steeply.

- Competitive Pricing Strategies: To maintain market share, companies may need to adopt competitive pricing strategies without compromising quality.

Ensuring Reliability in Extreme Conditions

Reliability is another critical aspect, especially when adhesives are used in harsh environments. These conditions could include:

- Temperature Fluctuations: Adhesives must maintain their properties despite temperature extremes encountered in applications like automotive electronics.

- Humidity and Moisture Resistance: Ensuring that adhesives perform consistently under varying humidity levels is essential, particularly for consumer electronics exposed to diverse climates.

Strategies to enhance reliability include:

- Material Innovation: Developing formulations that withstand environmental stressors while maintaining adhesive integrity.

- Rigorous Testing Protocols: Implementing comprehensive testing procedures to simulate real-world conditions and ensure performance consistency.

- Collaborative Development: Engaging with end-users during development phases to tailor products that meet specific application needs.

The electronic adhesives industry continues to adapt by addressing these challenges through innovation and strategic planning. Efforts focus on balancing cost-efficiency with product reliability, ensuring that advancements meet both market demands and environmental standards.

Geopolitical Factors Affecting the Global Electronic Adhesives Market

Geopolitical influences play a crucial role in shaping the global electronic adhesives market. Political tensions and trade policies significantly impact supply chains and market access, creating ripple effects across various regional markets.

Supply Chain Disruptions

- Trade Wars and Tariffs: Escalating trade tensions, such as those between the U.S. and China, can result in tariffs that increase costs for raw materials and finished products. These added expenses can disrupt supply chains, leading to delayed shipments and increased prices for electronic adhesives.

- Regional Conflicts: Political instability or conflict in key regions can hinder the smooth flow of goods. For instance, any disruption in the Middle East could affect the supply of petrochemicals, a critical component for many adhesives.

Market Access Challenges

- Regulatory Barriers: Differences in regulatory requirements across regions create barriers to market entry. Companies must navigate complex legislation to ensure compliance, which can be costly and time-consuming.

- Protectionist Policies: Some countries adopt protectionist measures to support domestic industries, limiting foreign companies’ ability to compete effectively. This can lead to reduced market opportunities for electronic adhesive manufacturers.

Strategic Responses

To mitigate these challenges, companies are:

- Diversifying Supply Sources: By sourcing materials from multiple regions, companies reduce their dependence on a single supplier or country, enhancing resilience against geopolitical disruptions.

- Localizing Production: Establishing production facilities closer to key markets helps companies bypass certain trade barriers and reduce transportation costs.

Understanding these geopolitical factors is essential for stakeholders aiming to navigate the complexities of the global electronic adhesives market successfully. By staying informed and adaptive, companies can better manage risks associated with geopolitical uncertainties.

Market Segmentation: Types of Electronic Adhesives and Their Applications

Understanding the types of adhesives and their respective application areas is crucial for grasping the dynamics of the electronic adhesives market. The market segmentation in this field is largely defined by the composition and properties of the adhesives, which determine their suitability for various uses.

Types of Electronic Adhesives

1. Conductive Adhesives

- Composition and Properties: Typically composed of metal fillers like silver or copper, these adhesives facilitate electrical conductivity.

- Applications: Predominantly used in solar photovoltaic modules and electric vehicles due to their capacity to ensure electrical continuity while providing thermal management. Essential in assembling intricate circuits found in consumer electronics.

2. Non-Conductive Adhesives

- Composition and Properties: Made with epoxy resins or silicones, these adhesives do not conduct electricity but offer strong bonding capabilities.

- Applications: Widely adopted in securing components within electronic devices where electrical insulation is necessary, such as smartphones, laptops, and other consumer electronics.

3. UV Curing Adhesives

- Composition and Properties: Characterized by their rapid curing process when exposed to ultraviolet light, resulting in high precision during assembly.

- Applications: Particularly beneficial in applications requiring quick curing times without compromising on bond strength—ideal for fast-paced electronics manufacturing environments.

Application Areas Across Sectors

- Consumer Electronics: The demand for miniaturized components in devices like smartphones drives the need for both conductive and non-conductive adhesives. These adhesives play an integral role in maintaining device integrity and performance.

- Automotive Sector: As automotive technology advances towards electric vehicles, the use of conductive adhesives becomes critical for battery assembly and sensor integration.

- Renewable Energy Solutions: In solar energy systems, conductive adhesives are vital for connecting solar cells efficiently, contributing to the growing emphasis on sustainable energy sources.

These diverse types of electronic adhesives not only cater to different application needs but also reflect broader industry trends towards innovation and sustainability. By understanding these categorizations, stakeholders can better navigate the evolving landscape of the electronic adhesives market.

Electronic Adhesives in Consumer Electronics and Automotive Applications

Electronic adhesives are crucial in the world of consumer electronics, where they ensure the durability and functionality of devices such as smartphones, tablets, and laptops. These adhesives play a vital role in securing components, improving heat management, and providing electrical insulation. As consumer devices become smaller and more advanced, the need for effective adhesive solutions increases.

1. Smartphones and Laptops

Electronic adhesives are essential for maintaining the integrity of these devices. They are used to bond components securely while also facilitating heat dissipation, which is vital for device longevity and performance.

In the automotive industry, electronic adhesives have become essential, especially with the rise of electric vehicles (EVs). The shift towards more environmentally friendly modes of transportation has required advancements in adhesive technology to meet new challenges.

2. Electric Vehicles (EVs)

Adhesives in EVs perform critical functions by ensuring battery pack stability, enhancing thermal management systems, and contributing to lightweight vehicle construction. These adhesives help improve energy efficiency and safety standards.

The increasing complexity of electronics in both consumer goods and automobiles highlights the importance of specialized adhesive solutions. As industries strive for innovation, particularly with trends like miniaturization and electrification, electronic adhesives will continue to lead technological advancements. This ever-changing landscape offers significant growth opportunities within the Electronic Adhesives Market.

Global Growth Insights in the Electronic Adhesives Market

The electronic adhesives market is experiencing robust expansion. Such acceleration is fueled by evolving technological demands and the increased integration of electronics across various sectors.

Key Market Growth Statistics

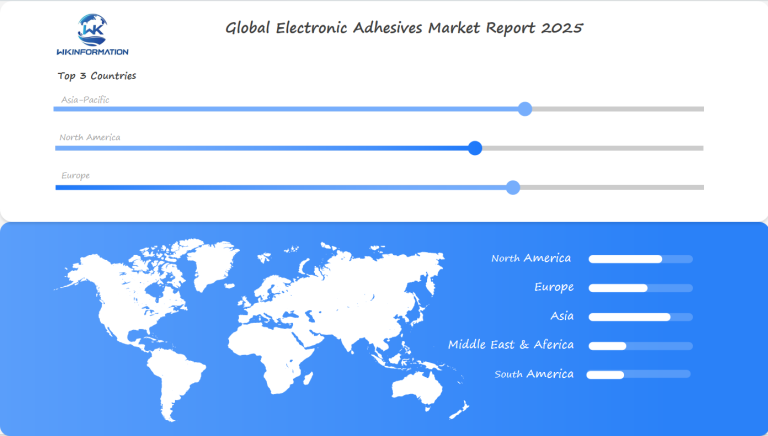

- Asia-Pacific: This region stands out as the powerhouse for electronic adhesives, driven by countries like China, Japan, and South Korea. The extensive electronics production capabilities catalyze significant market share, positioning Asia-Pacific as a leader in this domain.

- North America: With its strong electronics and semiconductor industry, North America follows closely. The region benefits from substantial R&D investments that promote innovation and product development within the adhesives sector.

- Europe: As environmental regulations tighten, Europe is witnessing a shift towards sustainable adhesive solutions. The market here focuses on eco-friendly products that align with regulatory standards.

Regional Insights and Trends

- Asia-Pacific Region:

- Dominates due to large-scale manufacturing and export activities.

- Rapid adoption of advanced technologies like 5G networks and electric vehicles fuels demand for high-performance adhesives.

- North America:

- Emphasis on innovation with significant investments in research and development.

- A robust automotive sector enhances demand for adhesives used in electric vehicle battery assembly.

- Europe:

- Increasing focus on sustainability promotes the use of bio-based adhesives.

- Automotive manufacturers in Germany and France drive growth through innovations in lightweight materials and electrification.

The market’s trajectory indicates a promising future characterized by technological advancements and sustainable practices. As regions adapt to these trends, electronic adhesives continue to play a crucial role in meeting the complex requirements of modern electronics manufacturing.

USA’s Leading Role in Electronic Adhesives Innovation

The United States is a leader in electronic adhesives innovation, thanks to its strong focus on research and development (R&D). This leadership is driven by the country’s commitment to technological advancements and growth through innovation.

Key Factors Behind U.S. Leadership in Electronic Adhesives

Here are some key factors that contribute to the U.S.’s leadership in electronic adhesives:

1. Research & Development (R&D) Investments

The U.S. benefits from substantial investments in R&D, fostering the development of cutting-edge adhesive technologies. This includes partnerships between universities, private companies, and government entities that drive innovation in adhesive formulations and applications.

2. Industry Leaders

Prominent companies such as 3M Company and Dow Inc. are pivotal players in this space. These corporations not only lead in product development but also focus on sustainable and efficient manufacturing processes that align with global environmental standards.

3. Diverse Applications

Innovation is further enhanced by the diverse applications within the U.S. market, spanning sectors such as automotive, aerospace, healthcare, and consumer electronics. The push towards electric vehicles (EVs) creates demand for advanced adhesive solutions capable of withstanding extreme conditions while ensuring safety and reliability.

4. Regulatory Environment

A favorable regulatory framework encourages experimentation and adoption of new adhesive technologies, facilitating rapid market penetration for innovative products.

The U.S.’s leading role is characterized by a combination of technological ambition, industrial expertise, and strategic investments, setting a high standard globally for electronic adhesives innovation.

South Korea’s Increasing Demand for Electronic Adhesives

South Korea is seeing a significant increase in the demand for electronic adhesives, thanks to its strong electronics manufacturing industry. The country is home to major global electronics companies, which are playing a big role in the growth of this market.

1. Consumer Electronics Boom

South Korea’s successful consumer electronics industry is a major driving force behind this demand. The production of advanced devices like smartphones, tablets, and laptops requires specialized adhesive solutions that guarantee durability and functionality.

2. Automotive Innovations

In the automotive industry, especially with the rise of electric vehicles (EVs), electronic adhesives are becoming increasingly important. These adhesives are vital for assembling batteries and other components in EVs, supporting the country’s goal of promoting eco-friendly transportation.

3. Advanced Manufacturing Techniques

South Korean companies are leading the way in adopting new adhesive technologies by using state-of-the-art manufacturing methods. This includes incorporating UV curing techniques that improve accuracy and productivity.

4. Research and Development

These advancements are backed by substantial investments in research and development, which are driving innovations in environmentally friendly and bio-based adhesive products that align with global sustainability trends.

With all these factors coming together, South Korea is set to keep growing in the electronic adhesives market, solidifying its position as an important player worldwide.

Japan’s Growth in the Electronic Adhesives Market

Japan plays a crucial role in the electronic adhesives market, thanks to its strong electronics and automotive industries. The country’s focus on producing high-quality products and embracing new ideas drives the need for advanced adhesive solutions designed for complex applications.

Key Factors Contributing to Growth:

1. Technological Advancements

Japan’s emphasis on cutting-edge technologies such as 5G networks, IoT devices, and electric vehicles requires dependable adhesive solutions that provide excellent heat management and electrical conductivity.

2. Automotive Sector Expansion

As a major hub for automotive industry leaders, Japan is witnessing a rise in electric vehicle production. This surge in demand calls for specialized adhesives that ensure the efficiency and durability of components under various conditions.

3. Consumer Electronics Demand

The Japanese market has a strong preference for compact, high-performing consumer electronics like smartphones and laptops. This trend drives the need for adhesives capable of securely integrating smaller parts with utmost precision.

Innovation and Sustainability Initiatives

Japanese manufacturers are increasingly adopting eco-friendly practices, promoting water-based and bio-based adhesives that align with global sustainability goals. This shift not only meets regulatory standards but also appeals to environmentally conscious consumers.

Japan’s growth in the electronic adhesives market is driven by technological innovation, the needs of the automotive industry, and a commitment to sustainable practices. These factors position Japan as a key player in the global expansion of this market.

Future Innovations in Electronic Adhesive Technologies

The Electronic Adhesives Market is about to undergo a significant change due to upcoming technologies and innovation trends. As industries continue to grow, electronic adhesives are evolving to meet the needs of various applications, including renewable energy solutions.

Emerging Technologies Shaping the Market

Several emerging technologies are expected to have a significant impact on the electronic adhesives market:

- Nanotechnology Integration: The use of nanomaterials in electronic adhesives is expected to improve their electrical conductivity, thermal stability, and mechanical strength. These enhancements can result in more efficient connections in small electronic devices and advanced sensors.

- Smart Adhesives: These adhesives are designed to change their properties when exposed to external factors such as temperature or electric fields. This adaptability can enhance performance reliability in different conditions, making them ideal for dynamic environments like wearable electronics and automotive applications.

- Bio-based and Eco-friendly Formulations: There is a growing trend towards developing adhesives from renewable resources due to environmental regulations. These formulations aim to reduce carbon footprints while maintaining performance standards.

Impact on Renewable Energy Solutions

Electronic adhesives play a crucial role in assembling solar panels and wind turbines. Future innovations hold the promise of improvements in:

- Durability and Longevity: New adhesive formulations are expected to withstand harsh weather conditions, prolonging the lifespan of renewable energy equipment.

- Efficiency Enhancements: High-performance conductive adhesives will enable more efficient energy transfer within solar cells, potentially increasing the overall output of photovoltaic systems.

These advancements not only indicate a move towards greater sustainability but also towards cost-effectiveness as production processes become more streamlined. As these technologies develop, they are likely to redefine industry standards and create new opportunities in sectors beyond electronics, particularly influencing the growth of next-generation renewable energy solutions.

Key Competitors in the Electronic Adhesives Market

Major Competitors

- Henkel AG & Co. KGaA

- 3M Company

- H.B. Fuller Company

- Dow Inc.

- BASF SE

- Avery Dennison Corporation

- Covestro AG

- Arkema

- Ashland

- Master Bond Inc.

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Electronic Adhesives Market Report |

| Base Year | 2024 |

| Segment by Type | ·Conductive Adhesives ·Liquid Encapsulant ·UV Curing Adhesives ·Others |

| Segment by Application | · Consumer Electronics · Automotive Sector · Renewable Energy Solutions · Others |

| Geographies Covered | · North America (United States, Canada)

· Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The electronic adhesives market is on the verge of significant growth, driven by technological advancements and increasing demand across various applications. It is expected to reach around USD 11.39 billion by 2033, with important developments shaping its future.

Key drivers include:

- Rising demand for specialized adhesives in smaller, sophisticated electronics and flexible devices.

- The dominance of electrically conductive adhesives in solar modules and electric vehicles.

- Rapid growth of UV curing adhesives due to their precision and quick curing times.

The Asia-Pacific region, especially China, Japan, and South Korea, leads in electronics production capabilities, while North America benefits from a strong semiconductor industry.

Emerging trends indicate a shift towards eco-friendly solutions:

- Adoption of water-based and bio-based products aligning with environmental goals.

- Increased focus on low-VOC, solvent-free adhesives in response to regulatory demands.

Challenges such as high-tech adhesive pricing and reliability under extreme conditions remain, but there are opportunities in sectors like 5G networks, electric vehicles, and renewable energy solutions. The competitive strategies of industry leaders like Henkel AG & Co. KGaA and 3M Company further enhance this landscape. This dynamic environment sets the stage for a promising future in electronic adhesives.

Global Electronic Adhesives Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Electronic Adhesives Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Electronic AdhesivesMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Electronic Adhesivesplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Electronic Adhesives Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Electronic Adhesives Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Electronic Adhesives Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Electronic AdhesivesMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected growth of the electronic adhesives market by 2030?

The electronic adhesives market is projected to grow to USD 10.85 billion by 2033, driven by increasing demand in key regions such as the U.S., Japan, and South Korea.

What are the main applications of electronic adhesives in manufacturing?

Electronic adhesives are utilized in various downstream applications within electronics manufacturing, including consumer electronics like smartphones and laptops, as well as automotive innovations, particularly in electric vehicles.

What emerging trends are shaping the electronic adhesives market?

Key trends include the rise of eco-friendly and bio-based adhesives due to environmental regulations, alongside advancements in UV curing technologies that enhance adhesive performance.

What challenges do manufacturers face in the electronic adhesives industry?

Manufacturers encounter pricing challenges for high-tech adhesives and must ensure reliability in extreme conditions where these adhesives are applied.

How do geopolitical factors influence the electronic adhesives market?

Geopolitical tensions can significantly impact supply chains and market access for electronic adhesives, affecting trade policies and regional market dynamics.

Who are the key competitors in the electronic adhesives market?

Major players in the electronic adhesives market include Henkel AG & Co. KGaA and 3M Company, with various strategies focused on innovation and market positioning to maintain competitive advantages.