$896.4 Million Enamel Wire Testing Equipment Market Surges in 2025: China, South Korea, and the U.S. Drive Electrical Testing Expansion

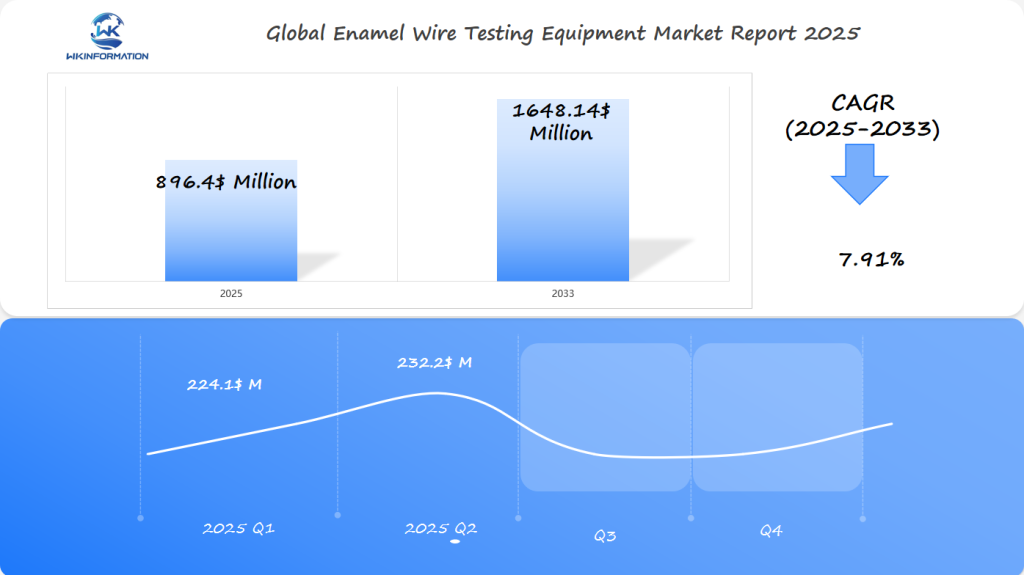

In 2025, the global Enamel Wire Testing Equipment market reached an estimated value of USD 896.4 million, with projections indicating growth to USD 1,648.14 million by 2033 at a compound annual growth rate (CAGR) of 7.91%.

- Last Updated:

Enamel Wire Testing Equipment Market Q1 and Q2 2025 Forecast

The Enamel Wire Testing Equipment market is projected to reach $896.4 million in 2025, with a CAGR of 7.91% from 2025 to 2033. In Q1 2025, the market is expected to generate approximately $224.1 million, driven by robust demand in China, South Korea, and the U.S. due to the growth of the electrical and electronics industries, particularly the electric motor and transformer sectors.

By Q2 2025, the market is forecast to reach $232.2 million, as the U.S., China, and South Korea continue to expand their manufacturing capabilities, with increasing investment in electric vehicles (EVs) and renewable energy technologies requiring high-quality enamel wire testing equipment for ensuring the reliability of windings and transformers.

Understanding the Upstream and Downstream Industries Involved in Enamel Wire Testing Equipment

The enamel wire testing equipment market is a complex web of industries. It starts with the supply chain, which involves many key sectors. These sectors work together to make and deliver precise testing tools.

Upstream Industries: The Backbone of Production

The upstream industry is vital for making the basic parts of enamel wire testing equipment. Important players include:

- Raw material suppliers specializing in high-grade metals

- Electronic component manufacturers

- Precision sensor and instrumentation producers

- Software development companies

Downstream Industries: The End Users of Technology

Downstream industries use these testing technologies in many ways. Electrical manufacturing sectors need advanced testing tools to check wire quality and performance. Main downstream sectors are:

- Electronics manufacturers

- Power generation companies

- Automotive electrical systems producers

- Quality control laboratories

The making of enamel wire testing equipment needs teamwork between upstream suppliers and downstream users. This teamwork leads to new tech and better quality in electrical engineering.

Precision testing equipment represents the critical link between raw materials and high-performance electrical systems.

Today’s advanced testing technologies are changing industry standards. They help build stronger and more reliable electrical systems around the world.

Key Trends Driving the Enamel Wire Testing Equipment Market: Growth in Electrical and Electronics Industries

The global enamel wire testing equipment market is growing fast. This is thanks to big changes in the electrical and electronics industries. New technologies are making electrical systems more complex, leading to a need for better testing tools.

Several factors are making the market grow:

- More people want high-precision electronic components

- Quality checks in electronics are getting stricter

- Modern technology has made electrical systems more complex

- There’s more money going into research and development

New technologies are changing how enamel wire testing equipment works. Companies are adding advanced sensors and AI tools to make tests more accurate and quick. This growth in electronics is opening up new chances for better testing solutions.

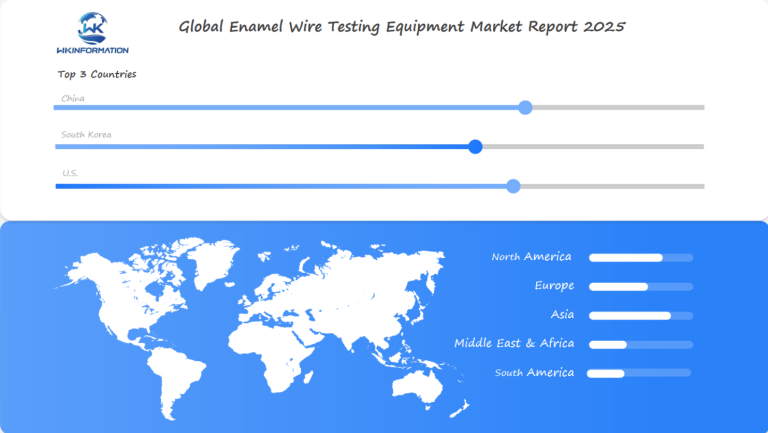

Places like Asia-Pacific are seeing a lot of growth. Countries like China and South Korea are leading in new testing tech. They’re investing a lot in electrical systems and electronics, which is boosting the need for advanced testing tools.

The future of enamel wire testing lies in intelligent, automated systems that can deliver unprecedented precision and reliability.

Challenges in Enamel Wire Testing Equipment Manufacturing and Standardization

The enamel wire testing equipment industry faces significant challenges that hinder its growth and innovation. Companies must navigate through complex technology, maintain high-quality standards, and manage costs effectively.

Key manufacturing challenges include:

- High initial investment for advanced testing equipment

- Rapid technological obsolescence

- Complex quality control requirements

- Diverse regional standardization issues

“Standardization is the backbone of reliable manufacturing processes in the electrical equipment sector.”

Standardization issues pose a major obstacle for manufacturers. Different regions have varying quality regulations, making it difficult to sell products globally. Companies need to develop testing systems that comply with multiple standards.

| Challenge Category | Impact on Manufacturing | Potential Solutions |

|---|---|---|

| Equipment Cost | High initial investment | Modular design, leasing options |

| Technological Complexity | Rapid innovation cycles | Continuous staff training |

| Quality Control | Stringent testing requirements | Automated testing systems |

Innovative manufacturers are actively addressing these challenges. They are investing in adaptive testing technologies and flexible quality checks. Additionally, they are allocating resources towards research and development to stay ahead of the competition and meet global standards.

Geopolitical Influence on the Enamel Wire Testing Equipment Market

The global enamel wire testing equipment market is changing fast. This is because of complex geopolitical factors. Trade policies and international relations are making big changes in the industry.

These changes bring both challenges and opportunities for makers and tech providers.

Key Geopolitical Factors Affecting the Market

The following geopolitical factors are significantly impacting the enamel wire testing equipment market:

- Strategic technology transfer between major electrical equipment manufacturing nations

- Economic partnerships impacting supply chain configurations

- Regional trade agreements affecting market access

- Technological competition among leading industrial economies

Emerging global market dynamics are making countries like China, South Korea, and the United States rethink their enamel wire testing equipment tech. The complex mix of trade policies creates a competitive space. Here, innovation and strategic partnerships are key to success.

National security and protecting intellectual property are now big in international tech exchanges. Governments are setting stricter rules. These rules affect tech sharing, research partnerships, and how companies enter the market.

“Geopolitical considerations are no longer peripheral but central to understanding market evolution in advanced electrical testing technologies.”

The ongoing geopolitical shifts are pushing manufacturers to create more flexible and strong testing equipment strategies. Companies need to handle complex international ties. They also have to stay competitive and meet the growing global market needs.

Enamel Wire Testing Equipment Market by Type: Voltage Testing, Surface Testing, and Thermal Endurance Testing

The enamel wire testing equipment market focuses on ensuring top-notch quality and reliability in electrical wire coatings. Each type of equipment is vital for maintaining wire performance and safety in various industries.

1. Voltage Testing Equipment

Voltage testing equipment is key in assessing wire quality. These tools measure the wire’s ability to handle specific voltage levels. This helps manufacturers:

- Spot potential electrical insulation weaknesses

- Keep wire insulation consistent

- Avoid electrical failures in important systems

2. Surface Testing Equipment

Surface testing equipment adds another layer to wire evaluation. Precision instruments examine the enamel coating’s physical traits. They check for:

- Uniform coating thickness

- Surface smoothness

- Any tiny defects

3. Thermal Endurance Testing Equipment

Thermal endurance testing is a complex way to test wire performance under harsh conditions. These specialized tools mimic tough environments. They see how enamel wire coatings handle:

- High temperatures

- Fast temperature changes

- Long-term heat stress

The ongoing improvement in these equipment types shows the electrical engineering field’s dedication. It aims to create more reliable and high-performance wire solutions.

Applications of Enamel Wire Testing Equipment in Electrical Motors, Transformers, and Power Generation

Enamel wire testing equipment is key for electrical system reliability in many industries. It ensures the quality of electrical motors, transformers, and power generation systems. This precision is crucial for their performance.

These testing tools are used in several important areas:

- Electrical motors manufacturing and quality control

- Transformer performance verification

- Power generation equipment assessment

- Renewable energy system testing

In electrical motors, these systems check wire insulation, thermal resistance, and electrical conductivity. This is vital for ensuring motors work well and safely in many fields, from cars to big machines.

| Industrial Sector | Testing Focus | Key Parameters |

|---|---|---|

| Automotive | Wire Coating Durability | Thermal Endurance, Voltage Resistance |

| Power Generation | Transformer Wire Quality | Insulation Thickness, Electrical Conductivity |

| Renewable Energy | Wire Performance | Environmental Resistance, Long-term Stability |

Transformers and power generation systems need thorough testing for efficiency and reliability. Enamel wire testing equipment gives vital information on wire coating quality. This helps avoid failures in critical industrial settings.

The growing demand for electric vehicles and renewable energy is pushing the development of enamel wire testing technology. This leads to better quality control and performance in these areas.

Global Insights into the Enamel Wire Testing Equipment Market

The global market for enamel wire testing equipment is changing fast. New technologies and strategies are leading the way. Companies are working hard to grow their share in different markets with advanced testing tools.

Current Trends

Looking at the international scene, we see big changes in various places:

- Asia-Pacific is seeing quick adoption of new electrical testing tech.

- In North America, companies are pouring money into research and development.

Key Factors Influencing the Market

Several key factors are shaping the global market:

- More demand for precise electrical testing tools.

- New tech in quality control systems.

- Increased spending on electrical infrastructure worldwide.

The regional market share shows a competitive field. Companies are trying to grab new chances. New testing methods and automated systems are changing the enamel wire testing equipment world.

The future of enamel wire testing equipment is all about advanced tech and quality checks.

China's Growing Electrical Equipment Industry and Need for Testing Solutions

China’s electrical industry is a technological leader and a major manufacturer. It has experienced rapid growth in the demand for testing equipment, making China a key player in establishing global electrical standards.

Companies are investing heavily in new quality control technologies to stay competitive in the international market.

Key factors driving growth in the Chinese market include:

- Significant investments in research and development

- Expanding manufacturing capabilities for enamel wire testing equipment

- Enhanced focus on precision testing technologies

Strategic initiatives are transforming how electrical equipment is tested. Manufacturers are adopting advanced quality assessment methods to ensure their products perform at the highest level.

China’s dedication to technological innovation is reshaping the electrical equipment industry. Government support and private investments are accelerating the development of advanced testing solutions that comply with international standards.

The future of electrical equipment testing lies in precision, reliability, and continuous technological advancement.

There is expected to be more growth in testing equipment demand. Chinese manufacturers are becoming global leaders in electrical testing technologies. The use of artificial intelligence and advanced diagnostic tools will likely change the industry’s quality control approach.

South Korea's Role in High-Tech Electronics and Quality Assurance for Wire Coatings

South Korean electronics are leaders in advanced manufacturing and wire coating technology. Their focus on precision and innovation has made them successful in the enamel wire testing equipment market.

The country’s success comes from several key areas:

- Cutting-edge research and development infrastructure

- Rigorous quality assurance protocols

- Strategic investment in semiconductor technologies

- Highly skilled engineering workforce

South Korean manufacturers have changed wire coating technology with advanced testing methods. Precision engineering is their focus, ensuring top performance and reliability in electronic parts.

| Technology Focus Area | Key Innovations | Market Impact |

|---|---|---|

| Enamel Wire Testing | Advanced Thermal Endurance Systems | Increased Reliability |

| Wire Coating Techniques | Nano-layer Precision Coating | Enhanced Performance |

| Quality Control | AI-Driven Inspection Processes | Reduced Manufacturing Errors |

The nation’s electronics industry keeps pushing the limits, creating advanced testing equipment that sets global standards. Their method combines technology with careful quality control. This creates solutions that meet the toughest international standards.

The U.S.'s Innovation in Advanced Testing Systems for Industrial Applications

The United States is a leader in advanced testing systems for industries. Companies like Superior Essex and Axalta are leading the charge. They create top-notch enamel wire testing equipment that meets global standards.

U.S. industries need strict quality control. This need has led to big steps forward in testing tech. Research groups and industry leaders work together to make smart testing solutions for tough challenges in many fields.

- Aerospace industry relies on precise wire testing for critical components

- Automotive manufacturers require advanced quality assurance methods

- Renewable energy sector depends on high-performance electrical systems

Technological innovation in enamel wire testing has changed how manufacturers check quality. Now, advanced tools let them check wire coating in real-time. This helps avoid failures in important industrial settings.

Advanced testing systems represent the future of industrial quality assurance, providing unprecedented levels of precision and reliability.

The U.S. is a global leader in electrical engineering tech thanks to its commitment to top testing equipment. By always pushing the limits of research and development, U.S. companies stay ahead in the fast-changing global market.

The Future of Enamel Wire Testing Equipment: Automation and AI-Based Quality Control

The enamel wire testing equipment market is changing fast. New automation and AI technologies are making wire testing more precise and efficient. This is a big change for manufacturers.

There are exciting new trends in the industry:

- Advanced machine learning algorithms for defect detection

- Real-time sensor integration for continuous monitoring

- Predictive maintenance capabilities

- Enhanced data analytics for comprehensive quality assessment

Companies are now using smart systems to test wire coatings. These systems can analyze complex wire coating characteristics with little human help. These AI solutions bring big benefits.

“Automation is not just about replacing human labor, but augmenting human capabilities with intelligent technologies.” – Industry Expert

AI is making quality control better. Sophisticated neural networks can now find tiny flaws that old methods miss. This makes products more reliable and better performing.

As new tech keeps coming, enamel wire testing equipment will get smarter and more precise. This will raise the bar for making top-quality products.

Competitive Landscape in the Enamel Wire Testing Equipment Market

The enamel wire testing equipment market is very competitive. Global leaders are fighting for a big share of the market. They do this by introducing new technologies and forming partnerships.

Market leaders:

- Axis Electrical Components (I) Pvt. Ltd. — India

- Bharat Insulation Co. (India) Ltd. — India

- Dongguan Vcan Testing Technology Co., Ltd. — China

- Elektrisola Inc. — United States

- Lecroy Corporation — United States

- MWS Wire Industries — United States

- Nexans S.A. — France

- Rea Magnet Wire Company Inc. — United States

- Shanghai Kingrun Instrument Co. Ltd. — China

- Superior Essex Inc. — United States

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Wire Testing Equipment Market Report |

| Base Year | 2024 |

| Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The enamel wire testing equipment market is ripe for investment. It’s expected to jump from $896.4 million in 2025 to $1648.14 million by 2033. This growth shows a steady CAGR of 7.91%. Advanced testing technologies are key to ensuring electrical equipment quality and performance.

Driving Factors Behind Market Growth

Technological progress in the electrical and electronics sectors is driving market expansion. The United States, China, and South Korea are at the forefront of innovation. Emerging markets offer big opportunities, especially in automated systems that use AI and precision measurement.

Investment Potential

Investors should look at companies making the next big leap in enamel wire testing. The market needs equipment that can accurately test surface, voltage, and thermal endurance. Those who offer smart, integrated testing platforms will likely lead the market and attract investors.

Future Demand for Advanced Testing Gear

Experts say the demand for advanced testing gear will keep growing. This is due to the expansion of electrical infrastructure and manufacturing. To stay ahead, focus on R&D, form partnerships with tech innovators, and keep up with changing standards. Investing wisely and embracing new tech can lead to success in this field.

Global Enamel Wire Testing Equipment Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Enamel Wire Testing Equipment Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Enamel Wire Testing EquipmentMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Enamel Wire Testing Equipmentplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Enamel Wire Testing Equipment Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Enamel Wire Testing Equipment Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Enamel Wire Testing Equipment Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofEnamel Wire Testing EquipmentMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market size for enamel wire testing equipment by 2025?

The market is expected to hit $896.4 million by 2025. This growth is fueled by tech advancements and rising demand in the electrical and electronics sectors. China, South Korea, and the United States are leading this charge.

Why is enamel wire testing equipment critical for industries?

These tools are vital for ensuring the reliability and safety of electrical components. They are used in various sectors such as:

- Electronics

- Automotive

- Aerospace

- Power generation

These industries conduct tests like voltage, surface, and thermal endurance evaluations using enamel wire testing equipment.

Which regions are leading in enamel wire testing equipment innovation?

China, South Korea, and the United States are leading the innovation in electrical testing. Each brings unique tech expertise and manufacturing skills to the global market.

What are the main challenges in manufacturing enamel wire testing equipment?

Manufacturers face high production costs, the need for constant tech upgrades, and the complexity of standardizing tests. These challenges vary across regions and industrial applications.

How are emerging technologies impacting enamel wire testing equipment?

New technologies such as IoT, artificial intelligence, and automation are transforming quality control. They enhance testing accuracy, efficiency, and reliability in the industry.

What types of testing do enamel wire testing equipment perform?

These tools perform voltage, surface, and thermal endurance testing. They comprehensively evaluate the quality and performance of electrical wire coatings.

What industries most commonly use enamel wire testing equipment?

Key users include:

- Electrical motor makers

- Transformer producers

- Power generation

- Renewable energy

- Electric vehicle sectors

Precise wire coating quality is crucial here.

How do geopolitical factors influence the enamel wire testing equipment market?

Trade policies, international relations, and economic partnerships shape the market. They affect growth, technology transfer, and supply chain dynamics, especially among major players like China, South Korea, and the United States.

What are the future trends in enamel wire testing equipment?

Future trends include more automation, AI integration, advanced sensors, better data analytics, and machine learning in quality control. These advancements are expected to improve testing processes.

What is the current competitive landscape of the enamel wire testing equipment market?

The market is characterized by ongoing technological innovation, mergers, new entrants, and fierce competition. This dynamic environment drives continuous improvement in the capabilities of testing equipment.