2025 Food Cooling Tunnel Market Surge Exploring $2.42 Billion Opportunities in US, China, and Germany

Discover insights into the 2025 Food Cooling Tunnel Market analysis, exploring Trump’s trade policy impacts on US, China, and Germany’s food industries. Learn how international trade relations shaped market dynamics, technological advancements, and future growth projections in food processing and cooling systems.

- Last Updated:

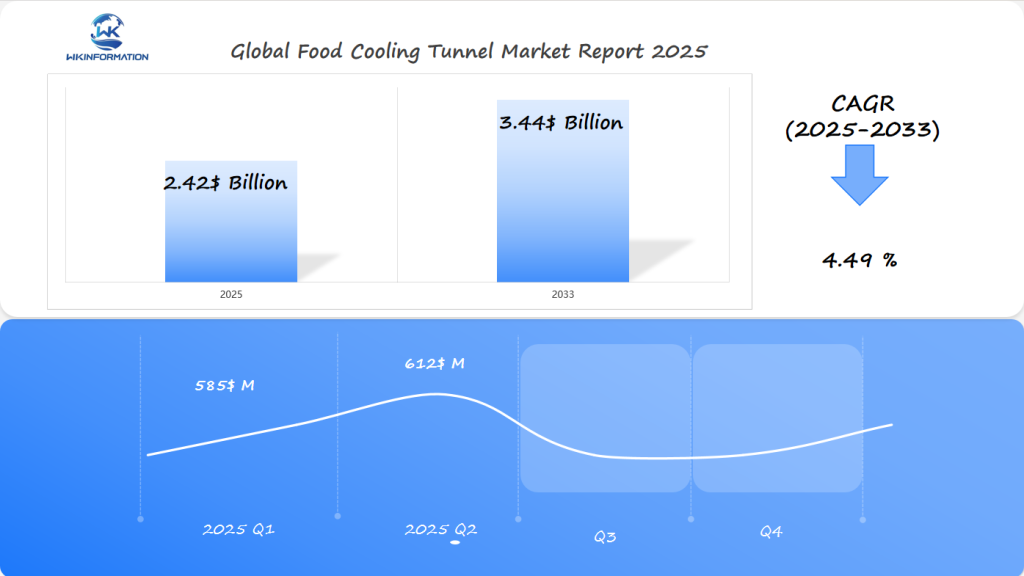

Food Cooling Tunnel Market Projection for Q1 and Q2 2025

The Food Cooling Tunnel market is expected to reach USD 2.42 billion in 2025, with a CAGR of 4.49% from 2025 to 2033. In Q1 2025, the market is anticipated to reach approximately USD 585 million, with Q2 2025 projecting a slight increase to around USD 612 million. The growth in this market is being led by the US, China, and Germany, where the food processing and manufacturing industries are increasingly investing in advanced cooling technologies to improve efficiency and product quality.

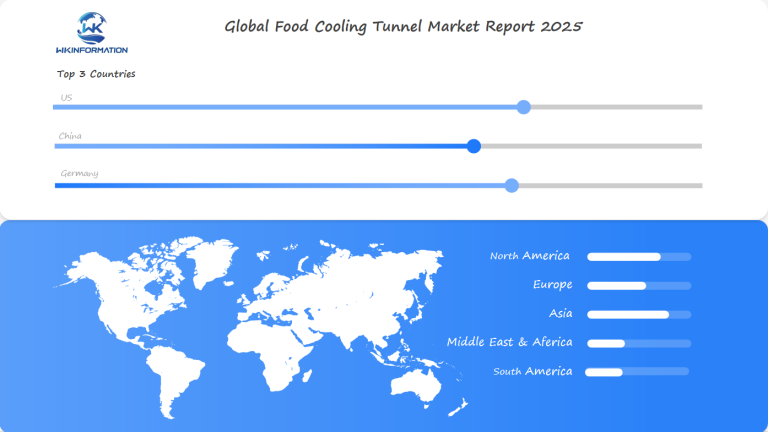

The US remains a significant market due to the country’s large food manufacturing sector, while China and Germany continue to expand their food processing industries to meet growing consumer demand. These three countries are expected to be the driving forces behind the growth in the food cooling tunnel market.

Understanding the Upstream and Downstream Industry Chain of the Food Cooling Tunnel Market

The upstream supply chain of the food cooling tunnel market is integral to its operation and efficiency. Key components include refrigerants and insulation materials.

- Refrigerants are crucial for maintaining low temperatures within the cooling tunnels, directly affecting their performance.

- High-quality insulation materials ensure energy efficiency by minimizing heat transfer, which is essential for cost-effective operations.

Suppliers of these components play a vital role in the manufacturing process, impacting both the quality and sustainability of the end product.

On the other hand, downstream demand factors significantly influence market trends. A notable driver is the shift in consumer preferences towards ready-to-eat frozen products.

This trend is fueled by urbanization and busier lifestyles, leading to an increased demand for convenient food options. As more consumers seek out frozen meals that require minimal preparation time, the need for efficient cooling solutions in food processing rises. This growing consumer demand compels manufacturers to enhance their offerings with advanced freezing technologies to meet expectations for quality and convenience.

Understanding these interconnected elements highlights the complexities of the industry chain and underscores the importance of innovation and adaptation in addressing both upstream supply challenges and downstream demand shifts.

Emerging Trends Transforming the Food Cooling Tunnel Market in 2025

Technological advancements are rapidly reshaping the food cooling tunnel market. Among these, cryogenic freezing technologies stand out as they offer faster freezing times and improve product quality by preserving texture and flavor. With the integration of AI-powered automation, these systems are becoming more efficient, enabling precise temperature controls and optimizing energy usage.

An increasing emphasis on sustainability is evident within the industry. Businesses are seeking eco-friendly innovations to align with global environmental goals. This shift encourages the adoption of cooling systems that reduce carbon footprints without compromising performance. For instance, advanced insulation materials and natural refrigerants are being utilized to enhance energy efficiency while minimizing environmental impact.

These trends indicate a future where technology not only meets the demands of efficiency and quality but also addresses environmental concerns. The fusion of AI and sustainable practices is setting new standards in food processing, offering competitive advantages to businesses that embrace these innovations. This landscape continues to evolve, driven by a commitment to harnessing cutting-edge solutions for both economic and ecological benefits.

Challenges and Market Restrictions Hindering the Growth of Food Cooling Tunnels

The Food Cooling Tunnel Market faces several market challenges that can hinder its growth. One major concern for manufacturers and processors is the strict regulatory requirements governing food safety and environmental standards. Following these regulations requires continuous investment in technology and processes, which can be resource-intensive.

Key Challenges Facing the Food Cooling Tunnel Market

- High Capital Investment Costs: Establishing a state-of-the-art cooling tunnel facility involves substantial financial outlay. This high initial cost can be a significant barrier for small and medium-sized enterprises (SMEs) looking to enter the market or expand their operations.

- Regulatory Constraints: Navigating the complex landscape of regional and international regulations requires expertise and resources, impacting operational efficiency.

Addressing these challenges is crucial for stakeholders aiming to take advantage of the growing opportunities within this sector while ensuring sustainable growth and compliance with industry standards.

Geopolitical Factors and Their Influence on the Food Cooling Tunnel Market

Geopolitical factors are crucial in shaping the food cooling tunnel market in major regions like North America, Asia-Pacific, and Europe. Trade policies have a significant impact on how these markets function and develop.

Key Influences:

1. Trade Policies

Strict trade agreements and tariffs can either support or hinder market growth. For example, favorable trade agreements between North American countries make it easier for goods to move across borders, improving the efficiency of the supply chain for food cooling equipment.

2. International Relations

Diplomatic relationships affect how accessible and competitive markets are. In Asia-Pacific, China’s growing influence often leads to partnerships in the region that promote technological exchange and infrastructure development in the food processing industry.

3. Regulatory Frameworks

European markets are heavily influenced by EU regulations that require strict food safety standards. These regulations demand advanced cooling solutions, which in turn drives up demand for cutting-edge technologies.

The geopolitical situation not only impacts how companies enter markets but also determines how quickly new technologies are developed and adopted. This highlights the importance of staying informed about international policies and adjusting to global changes in order to stay competitive in the food cooling tunnel market.

Food Cooling Tunnel Market Segmentation by Type and Key Growth Sectors

Market segmentation within the food cooling tunnel industry highlights various equipment types that cater to distinct sectors. Each type of cooling tunnel offers unique advantages suited for specific applications:

1. Blast Freezers

Known for their rapid cooling capabilities, blast freezers are essential in the meat processing sector. They effectively reduce the temperature of freshly processed meats, preserving texture and flavor while meeting stringent food safety standards.

2. Tunnel Freezers

Commonly used in large-scale operations, tunnel freezers are ideal for continuous processing lines. Their design supports high-volume production, making them a preferred choice in dairy production where maintaining consistent product quality is crucial.

3. Spiral Freezers

These versatile machines maximize space efficiency with their spiral design, making them suitable for facilities with limited floor space. Spiral freezers find applications across various sectors, including bakery and seafood processing, due to their ability to handle diverse product shapes and sizes.

Innovations in these equipment types continue to advance the food cooling tunnel market, driven by rising demand from industries seeking efficient and reliable freezing solutions. As consumer preferences shift towards frozen convenience foods, these technologies enable processors to maintain quality and extend shelf life, addressing both market needs and regulatory compliance.

Food Cooling Tunnel Applications and Expanding Demand Across Industries

Food cooling tunnels are critical in various food production processes, helping to rapidly reduce the temperature of products, preserving their quality and safety. The demand for cooling tunnels is growing across multiple industries, driven by the need for efficient temperature control and better food preservation.

1. Chocolate Manufacturing

In chocolate production, cooling tunnels are used to quickly solidify chocolate after molding, ensuring a smooth texture and gloss. Rapid cooling prevents the chocolate from developing defects like bloom and ensures it maintains its appearance and taste.

2. Candy and Biscuit Production

For candy and biscuits, cooling tunnels help rapidly lower the temperature of freshly made products, preventing them from becoming too soft or sticky. This cooling process ensures a crisp texture and helps maintain the desired consistency for packaging and storage.

3. Dairy Products (Cheese, Yogurt)

In dairy production, cooling tunnels play a crucial role in quickly cooling milk, cheese, and yogurt after pasteurization. This reduces the risk of bacterial growth and preserves the product’s flavor and texture, ensuring a longer shelf life.

4. Others

Cooling tunnels are also widely used in the production of frozen fruits, vegetables, meats, and ready-to-eat meals, contributing to quality preservation, food safety, and extended shelf life.

As consumer demand for processed and packaged foods continues to rise, the need for food cooling tunnels will grow, expanding across industries to maintain food quality and meet regulatory requirements.

Global Food Cooling Tunnel Market Regional Outlook and Growth Hotspots

The global food cooling tunnel market is witnessing significant growth, driven by increasing demand for processed, frozen, and ready-to-eat foods. The market’s expansion is being shaped by regional demands, technological advancements, and the need for efficient food preservation systems.

1. North America

In North America, the demand for food cooling tunnels is growing rapidly due to the large-scale production of ready-to-eat meals, dairy products, and frozen foods. Stringent food safety regulations and the increasing adoption of advanced cooling technologies further drive market growth in the U.S. and Canada.

2. Europe

Europe remains a major market for food cooling tunnels, particularly due to its well-established food processing industries. Countries like Germany, France, and the UK are witnessing rising demand for cooling solutions in chocolate manufacturing, dairy, and bakery products. The region’s focus on energy-efficient and sustainable technologies is expected to fuel market growth.

3. Asia-Pacific

Asia-Pacific, led by China and India, is emerging as a significant growth hotspot. The increasing population, changing dietary habits, and growing demand for processed foods are propelling the market. Moreover, rapid industrialization and advancements in cold chain logistics boost the adoption of food cooling tunnels in the region.

4. Latin America and Middle East

The Latin American and Middle Eastern regions are also witnessing steady growth in the food cooling tunnel market, driven by expanding food processing capabilities, particularly in countries like Brazil and the UAE. Increased export demand for frozen and packaged foods is contributing to the market’s expansion in these areas.

As global demand for processed foods rises, the food cooling tunnel market is expected to experience significant growth across these regions, with a focus on efficiency and sustainability.

US Food Cooling Tunnel Market Trends and Competitive Overview

The US food cooling tunnel market, accounting for a substantial 30.7% share, is experiencing dynamic growth fueled by several key trends.

Key Trends Driving Growth in the US Food Cooling Tunnel Market

- Technology Adoption: Industry players are rapidly integrating advanced technologies like cryogenic freezing and automation systems to enhance processing efficiency. These innovations not only improve product quality but also streamline operations, making them a crucial factor in maintaining competitiveness.

- Consumer Preferences: With the rise in demand for ready-to-eat and frozen foods, companies are increasingly focused on expanding their cooling capabilities to meet consumer needs effectively.

- Competitive Landscape: The US market is characterized by a competitive landscape where leading companies such as GEA Group and JBT Corporation leverage technological advancements to differentiate their offerings. Their strategies include focusing on sustainability and smart technology integration, ensuring they stay ahead in this competitive arena.

This robust environment positions the US market as a leader in the global food cooling tunnel industry, driving continuous innovation and growth.

China Food Cooling Tunnel Market Performance and Demand Analysis

China’s food cooling tunnel market is experiencing significant growth, driven by increasing disposable incomes and the expansion of retail networks. The growing demand for efficient cooling solutions aligns with the country’s rapid urbanization and changing consumer habits.

Factors Driving Growth

Several key factors are contributing to the growth of the food cooling tunnel market in China:

- Economic Growth: Increased disposable incomes have led to a surge in purchasing power, allowing consumers to explore diverse food options, including frozen and ready-to-eat products.

- Retail Network Expansion: The proliferation of supermarkets and hypermarkets in urban areas boosts demand for advanced cooling technologies to maintain product quality and safety standards.

- Consumer Preferences: A growing preference for convenience foods, driven by busier lifestyles, necessitates efficient food processing systems. This shift contributes to an increased need for state-of-the-art cooling tunnels.

These factors position China as a key player in the global food cooling tunnel market, reflecting its dynamic economic landscape and evolving consumer demands.

Germany Food Cooling Tunnel Market Expansion Strategies and Market Forecast

Germany’s food cooling tunnel market is expected to grow significantly due to strategic expansion efforts that align with strict regulations. These regulations highlight the importance of efficient cooling solutions in maintaining food safety standards, which is crucial in this industry.

Regulatory Frameworks

Germany’s emphasis on strict food safety regulations is driving the adoption of advanced cooling technologies. This not only ensures compliance but also increases the demand for top-notch cooling systems.

Efficiency and Sustainability

Companies are focusing on energy-efficient and environmentally friendly cooling solutions. This aligns with the European Union’s sustainability goals, promoting innovations that reduce environmental impact.

Future Outlook

The market is anticipated to witness more investments in smart technology integration, especially AI-driven automation. This will not only improve operational efficiency but also meet the rising demand for premium frozen products.

With these strategic approaches, Germany is strengthening its position in the global food cooling tunnel market, influencing future trends, and setting standards in food safety and sustainability.

Future Developments and Innovations in the Food Cooling Tunnel Market

The Food Cooling Tunnel Market is set for significant changes driven by future innovations and technology integration. One of the key advancements expected involves improving energy efficiency. As manufacturers work to lower operational costs, innovative cooling technologies that reduce energy use are becoming crucial.

Expected Advancements in the Food Cooling Tunnel Market

- Cryogenic Freezing Technologies: These systems promise rapid cooling while preserving food quality, reducing both energy use and processing time.

- AI-Powered Automation: Leveraging artificial intelligence for process optimization ensures precise temperature control, enhancing product consistency and reducing waste.

The growing focus on sustainability is pushing manufacturers to create environmentally friendly cooling solutions. The use of natural refrigerants, which have a lower environmental impact compared to traditional options, is gaining popularity.

These technological advancements aim to improve operational efficiency and align with global sustainability efforts. This ensures that the Food Cooling Tunnel Market remains responsive to environmental concerns while meeting industry demands.

Competitive Landscape and Key Players in the Food Cooling Tunnel Market

In the Food Cooling Tunnel Market, major players are steering the industry through innovation and strategic maneuvers. Notable companies such as GEA Group and JBT Corporation lead the pack.

- Speco Technologies – South Korea

- Proref Engineering B.V. – Netherlands

- MPE Automation – Australia

- Sirane – United Kingdom

- JBT Corp. – United States

- CUTech International – Netherlands

- Frigoscandia AB – Sweden

- BCH Technologies – United States

- Sandinox – Spain

- EnviroPak, Inc. – United States

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Food Cooling Tunnel Market Report |

| Base Year | 2024 |

| Segment by Type |

· Blast Freezers · Tunnel Freezers · Spiral Freezers |

| Segment by Application |

· Chocolate Manufacturing · Candy and Biscuit Production · Dairy Products (Cheese, Yogurt) · Others |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The global food cooling tunnel market is experiencing strong growth driven by the increasing demand for processed, frozen, and ready-to-eat foods across various regions. Food cooling tunnels play a crucial role in maintaining the quality, safety, and shelf life of food products by rapidly lowering their temperature after production. As consumer preferences shift toward convenient and preserved food options, the need for efficient cooling systems becomes more critical.

Technological advancements in cooling systems, including energy efficiency and automation, are further driving market expansion. As the global food industry continues to evolve, the demand for food cooling tunnels will increase, offering growth opportunities for manufacturers in both developed and emerging markets.

Global Food Cooling Tunnel Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Food Cooling Tunnel Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Food Cooling Tunnel Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Food Cooling Tunnel players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Food Cooling Tunnel Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Food Cooling Tunnel Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Food Cooling Tunnel Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Food Cooling Tunnel Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are the key components of the upstream supply chain in the food cooling tunnel market?

The upstream supply chain for food cooling tunnels includes essential components like refrigerants and insulation materials, which are critical for the effective operation of these systems.

What emerging trends are expected to transform the food cooling tunnel market by 2025?

Key trends shaping the future of the food cooling tunnel market include advancements in cryogenic freezing technologies, AI-powered automation solutions, and a growing emphasis on eco-friendly innovations aimed at sustainability.

What challenges do manufacturers face in the food cooling tunnel market?

Manufacturers and processors in the food cooling tunnel market face challenges such as stringent regulatory requirements and high capital investment costs that can hinder growth.

How do geopolitical factors influence the food cooling tunnel market?

Geopolitical conditions, including trade policies and international relations, significantly impact the food cooling tunnel market across major regions like North America, Asia-Pacific, and Europe.

Who are the major players in the food cooling tunnel market?

Leading companies in the food cooling tunnel market include GEA Group and JBT Corporation. These companies focus on maintaining competitiveness through continuous innovation and adapting to current market trends.