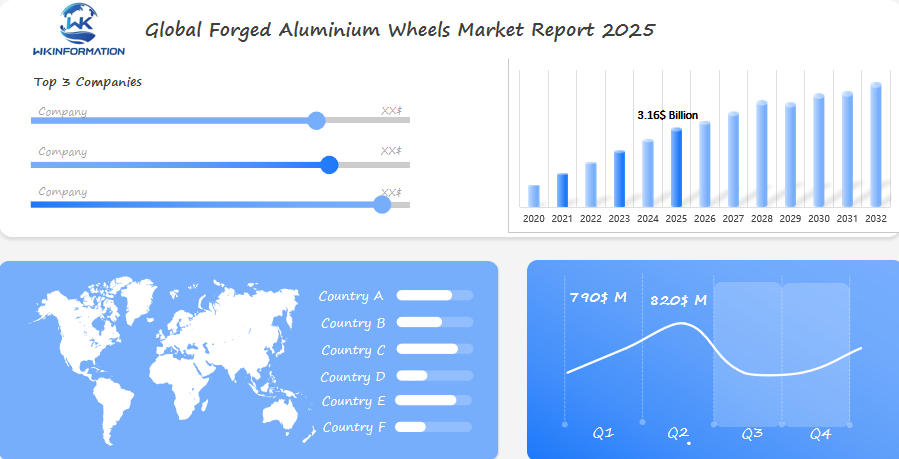

The global Forged Wheels market is projected to grow from USD 3.16 billion in 2025, with an expected CAGR of 6.5% from 2025 to 2033. Forged Wheels are widely used in the automotive sector due to their strength, lightweight, and enhanced performance. These wheels are increasingly being adopted in high-performance and luxury vehicles for their ability to improve fuel efficiency and overall vehicle handling. By the end of Q1 2025, the market size is estimated to reach approximately USD 790 million, driven by the growing demand for lightweight and durable automotive parts. By Q2 2025, the market could expand to around USD 820 million, with the U.S., China, and Germany leading the demand, as these countries continue to invest heavily in automotive manufacturing and performance vehicle segments.

With the automotive industry’s shift toward electric vehicles (EVs) and the demand for sustainable manufacturing, Forged Wheels will continue to see growth.

Key Takeaways

- The global Forged Wheels Market is expected to reach USD 3.16 billion by 2032, growing at a CAGR of 6.5%.

- Alloy aluminum wheels offer superior strength, reduced weight, and improved aesthetics.

- The U.S., China, and Germany are key regions driving Forged Wheels Market demand.

- Fuel efficiency and lightweight components are major growth drivers.

- Leading manufacturers are investing in R&D to meet rising demand.

Forged Wheels Market Overview and Global Industry Trends

The automotive industry is undergoing a notable shift, driven by advancements in lightweight materials and alloy aluminum wheels. These components have become integral to modern vehicles, offering enhanced durability, reduced weight, and improved aesthetics.

Evolution of Forged Aluminium Wheels

Over the years, alloy aluminum wheels have evolved significantly. Manufacturers have developed advanced alloy compositions that combine strength with reduced weight, making them ideal for both passenger vehicles and commercial vehicles. Design improvements have also played a crucial role, contributing to better heat dissipation and overall vehicle performance.

Key Growth Drivers and Market Trends

The Forged Wheels Market is experiencing growth due to several factors. Increasing vehicle production and stricter fuel-efficiency regulations are key drivers. Additionally, the rise in consumer demand for lightweight vehicles has propelled the demand for alloy aluminum wheels. The Forged Wheels Market is segmented into OEM and aftermarket, with each segment showing distinct growth patterns.

According to recent Forged Wheels Market reports, the global Forged Wheels Market size is expected to expand significantly by 2032. This growth is supported by technological innovations and the increasing preference for customizable solutions in the aftermarket segment. Leading manufacturers like Superior Industries and CITIC Dicastal are investing in research and development to meet the rising demand for high-performance wheels.

As the industry continues to evolve, understanding these market dynamics is essential for grasping the future potential of alloy aluminum wheels in the automotive sector.

Impact of COVID-19 and Supply Chain Disruptions

The COVID-19 pandemic brought unprecedented challenges to the global automotive industry, particularly in the production and supply of alloy aluminum wheels. Lockdowns and social distancing measures led to significant disruptions in supply chains, affecting both production capacities and raw material sourcing.

Economic Effects on Production and Supply

The economic downturn in 2020 forced manufacturers to halt or reduce production. This led to a noticeable contraction in the Forged Wheels Market size, impacting both passenger and commercial vehicles. According to a recent market report, the industry experienced a sharp decline in demand during the crisis.

However, as restrictions eased, the Forged Wheels Market began to recover gradually. Companies like Superior Industries and CITIC Dicastal adapted by implementing safety protocols and diversifying their supply chains. This period highlighted the importance of resilience and adaptive strategies to mitigate future disruptions.The pandemic underscored vulnerabilities in global supply chains, affecting not only alloy aluminum wheels but the entire automotive sector. Moving forward, manufacturers are focusing on building more robust systems to handle unexpected challenges effectively.

Innovations and Technological Advancements

Recent breakthroughs in automotive technology have revolutionized the production and design of alloy aluminum wheels. These innovations are not only enhancing performance but also setting new standards for efficiency and sustainability.

New Manufacturing Techniques and Materials

Manufacturers like Howmet Aerospace and CITIC Dicastal are pioneering novel forging techniques that reduce weight and improve durability. These advanced methods enable the creation of lighter, stronger wheels that meet the growing demand for fuel efficiency.

For instance, CITIC Dicastal has introduced a next-generation forging process that minimizes material waste while maintaining high strength. This approach has significantly lowered production costs and environmental impact, making it a game-changer for the industry.

Advancements in Alloy Composition and Design

Researchers have developed new alloy compositions that offer enhanced strength and corrosion resistance. These advanced materials are being used to produce wheels that are not only more durable but also aesthetically appealing.

Howmet Aerospace, for example, has launched a line of high-performance alloy wheels featuring a unique composition that improves heat dissipation. This innovation is particularly beneficial for commercial vehicles, where thermal management is critical.

These technological advancements are driving growth in the wheel market, particularly in the commercial vehicle segment. As manufacturers continue to innovate, the industry is expected to see even greater improvements in efficiency and sustainability.

Regional Insights: U.S., China, and Germany Market Drivers

The U.S., China, and Germany are pivotal regions driving the global demand for alloy aluminum wheels. Each region’s unique economic conditions, regulatory standards, and consumer preferences shape the market dynamics.

Regional Economic and Consumer Preferences Analysis

In the U.S., the focus on fuel efficiency and lightweight vehicles has surged, driven by stringent environmental regulations. Major manufacturers like Superior Industries are investing in R&D to meet this demand. China, being the world’s largest vehicle producer, emphasizes cost-effectiveness and durability, with CITIC Dicastal leading local production. Germany, known for its automotive excellence, prioritizes high-performance and aesthetics, supported by companies like Ronal Wheels.

Local Regulatory and Environmental Influences

Regulatory standards play a crucial role in shaping product specifications. The U.S. focuses on emission reduction, while China enforces strict safety and efficiency norms. Germany leads in sustainability, promoting eco-friendly manufacturing processes. These regulations have spurred innovations, making alloy aluminum wheels more sustainable and efficient.

Understanding these regional dynamics is key to grasping the future of alloy aluminum wheels in the automotive sector.

Market Segmentation: OEM, Aftermarket, and Application Areas

The global wheel market is divided into distinct segments, each catering to specific demands. Understanding these segments is crucial for grasping the industry’s dynamics.

Comparative Analysis of Passenger vs. Commercial Vehicle Demand

Passenger vehicles dominate the market, driven by consumer preference for lightweight and aesthetically appealing alloy aluminum wheels. In contrast, commercial vehicles prioritize durability and load capacity, with manufacturers like Superior Industries and CITIC Dicastal offering reinforced designs.

The aftermarket segment is thriving, with customization options attracting vehicle owners seeking unique styles or performance enhancements. This trend is particularly strong in the passenger vehicle sector.

Role of Application Areas in Market Structure

Application areas significantly influence production strategies. High-performance sports cars require lightweight, high-strength alloy aluminum wheels, while heavy-duty trucks need rugged, durable designs. This diversity drives innovation and tailored solutions across the industry.

Competitive dynamics vary between segments. In the OEM sector, cost efficiency and scale are key, whereas the aftermarket focuses on customization and brand differentiation. This segmentation ensures manufacturers can cater to a broad spectrum of customer needs.

In conclusion, market segmentation plays a pivotal role in shaping the Forged Wheels Market. By understanding these dynamics, manufacturers can align their strategies to meet evolving demands and drive sustainable growth.

Forged Aluminium Wheels Market Outlook and Forecasts

Looking ahead, the Forged Wheels Market is poised for steady growth, driven by technological advancements and increasing demand for lightweight vehicle components. This section explores the projected market size, growth rates, and competitive dynamics shaping the industry.

Market Size and Growth Projections

The Forged Wheels market is projected to grow from USD 3.16 billion in 2025, at a CAGR of 6.5% from 2025 to 2033. This growth is fueled by the automotive industry’s shift towards fuel efficiency and reduced emissions. The increasing adoption of alloy aluminum wheels in both passenger and commercial vehicles is a key driver.

Competitive Analysis of the Forged Wheels Market

The Forged Wheels market is growing due to the increasing demand for lightweight and high-performance wheels in the automotive and transportation sectors. Alcoa Wheels is a dominant player in this market, known for its innovation and high-quality Forged Wheels that offer superior strength, durability, and reduced weight for vehicles. CITIC Dicastal and Borbet are significant competitors, providing forged wheels that are designed to meet the needs of both commercial and passenger vehicles. Ronal Wheels is another key player offering custom-designed Forged Wheels for high-end cars and motorsport vehicles. Superior Industries and Iochpe-Maxion are also prominent manufacturers, serving the Forged Wheels Market with high-performance forged wheels that combine strength, weight reduction, and aesthetic appeal. Uniwheel Group and Wanfeng Auto continue to expand their manufacturing capabilities to meet the growing demand in the automotive industry. Lizhong Group and Enkei Wheels are strong competitors focusing on quality and durability, offering Forged Wheels that cater to the passenger vehicle and motorsport industries.

The increasing emphasis on fuel efficiency, safety, and aesthetics is driving the demand for Forged Wheels, and these market leaders are at the forefront of innovation and production.

CITIC Dicastal has pioneered next-generation forging techniques, minimizing material waste and lowering production costs. This innovation underscores the industry’s focus on sustainability and efficiency. Ronal Wheels, known for its customizable solutions, is gaining traction in the aftermarket segment, offering unique designs that appeal to consumers seeking personalized styles.

As the Forged Wheels Market evolves, these key players are expected to maintain their dominance through strategic investments and innovative product offerings. Their ability to adapt to changing consumer demands and regulatory requirements will be crucial in sustaining growth.

Investment Opportunities, Challenges, and Sustainability Trends

The automotive industry is at a crossroads, with investment opportunities emerging in innovative production technologies and sustainability initiatives. However, challenges such as rising raw material costs and energy demands pose significant hurdles.

Impact of Raw Material Costs and Production Technologies

Manufacturers are grappling with escalating costs of raw materials, particularly aluminum, which is crucial for producing lightweight alloy aluminum wheels. Energy expenses in extraction and production further strain profitability. Despite these challenges, companies like Superior Industries and CITIC Dicastal are investing in automation and precision technologies to enhance efficiency and reduce waste.

Sustainability trends are gaining momentum, with a focus on recycled aluminum. This approach not only lowers production costs but also aligns with global environmental goals. Leading manufacturers are adopting eco-friendly practices, such as minimizing material waste and optimizing energy use, to maintain competitiveness in the Forged Wheels Market .

As the industry evolves, understanding these dynamics is crucial for investors and manufacturers alike. By addressing challenges and embracing innovation, the alloy aluminum wheel sector can achieve sustainable growth and meet the increasing demand for efficient, lightweight vehicle components.

| Report Metric | Details |

|---|---|

| Report Name | Global Forged Aluminium Wheels Market Report |

| Base Year | 2024 |

| Segment by Type |

· OEM · Aftermarket |

| Segment by Application |

· Passenger Vehicle · Commercial Vehicle |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Conclusion

The automotive industry is on the brink of a new era, driven by innovative solutions and sustainable practices. The Forged Wheels market is projected to grow from USD 3.16 billion in 2025, at a CAGR of 6.5% from 2025 to 2033, reflecting a steady demand for lightweight components and fuel efficiency.

Technological advancements, such as advanced forging techniques and high-performance alloy compositions, are reshaping the industry. Regional dynamics, particularly in the U.S., China, and Germany, highlight the importance of regulatory standards and consumer preferences in driving growth.

Sustainability initiatives, including the use of recycled materials and energy-efficient production, are gaining momentum. These efforts not only reduce environmental impact but also align with global Forged Wheels Market trends and consumer demands.

In conclusion, the future of the automotive industry lies in continuous innovation and strategic investments. By embracing these changes, manufacturers can position themselves for long-term success in an evolving market landscape.

FAQ

What is the current size of the commercial vehicle wheel market?

The commercial vehicle wheel market is experiencing steady growth, driven by increasing demand for durable and lightweight options. As of the latest report, the market size is valued at USD 3.16 billion, with a notable contribution from aluminum alloy wheels due to their strength and corrosion resistance.

What factors are driving the growth of the aluminum alloy wheel market?

Key growth drivers include stringent fuel efficiency standards, the need for reduced vehicle weight, and rising consumer preference for aesthetics. Additionally, advancements in manufacturing technologies and the expansion of the automotive industry in emerging markets are significant contributors.

Who are the key manufacturers in the aluminum alloy wheel industry?

Leading manufacturers include Superior Industries and CITIC Dicastal, known for their high-quality products and innovative solutions. These companies are at the forefront of research and development, ensuring they meet evolving market demands.

How does the market differ between passenger and commercial vehicles?

Passenger vehicles focus on design and fuel efficiency, while commercial vehicles prioritize durability and load capacity. The aftermarket for commercial vehicles is particularly robust due to the need for frequent replacements and customization.

What regions are leading the market growth?

The Asia-Pacific region, particularly China, is a major contributor due to rapid industrialization and infrastructural development. Europe and North America also show significant growth, driven by stringent environmental regulations and technological advancements.

What is the forecast for the market in terms of CAGR and key trends?

The market is projected to grow at a CAGR of 6.5%, with key trends including the adoption of advanced manufacturing techniques and a shift towards eco-friendly materials. These factors are expected to shape the industry’s future.

What challenges and opportunities are there for investors?

Investors face challenges such as fluctuating raw material costs and competition. However, opportunities arise from increasing demand for lightweight wheels and the expansion of the automotive aftermarket, making strategic investments potentially rewarding.

Global Forged Aluminium Wheels Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Forged Aluminium Wheels Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Forged Aluminium Wheels MarketSegmentation Overview

Chapter 2: Competitive Landscape

- Global Forged Aluminium Wheels Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Forged Aluminium Wheels Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Forged Aluminium Wheels Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Forged Aluminium Wheels Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Forged Aluminium Wheels Market Insights

- Actionable Recommendations for Stakeholders