$1.3 Billion Fuel Polishing Service Market Set to Surge in the U.S., Germany, and Japan by 2025

The Fuel Polishing Service Market is expanding rapidly as industries prioritize clean fuel maintenance. Rising demand for preventive solutions drives growth across marine, industrial, and power sectors.

- Last Updated:

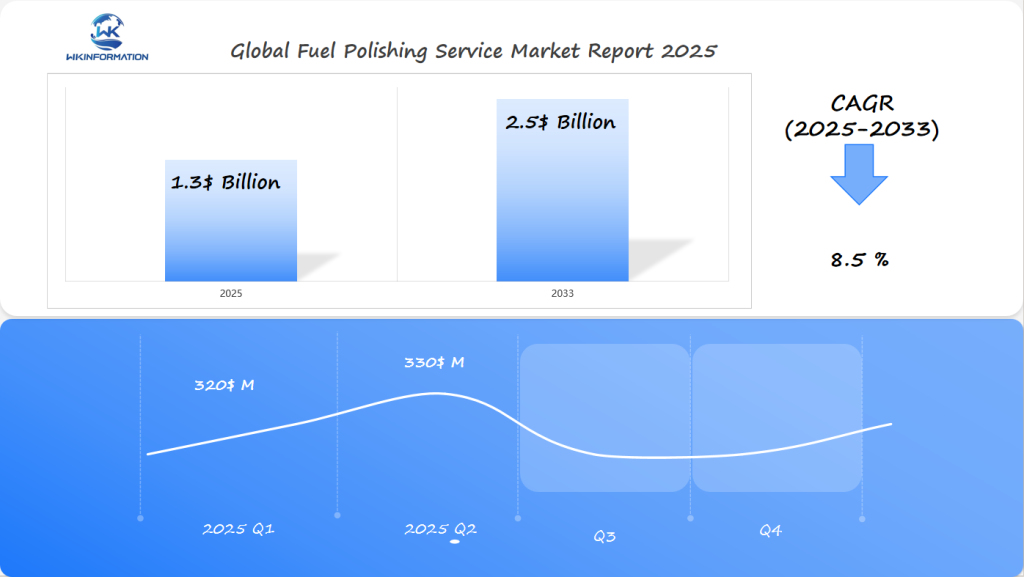

Projected Market Insights for Fuel Polishing Service in Q1 and Q2 of 2025

The Fuel Polishing Service market is projected to reach $1.3 billion in 2025, with a CAGR of 8.5% from 2025 to 2033. In Q1, the market is expected to generate approximately $320 million, driven by growing concerns about fuel quality in both marine and industrial applications. By Q2, the market is expected to grow to about $330 million, reflecting continued demand.

Key Players

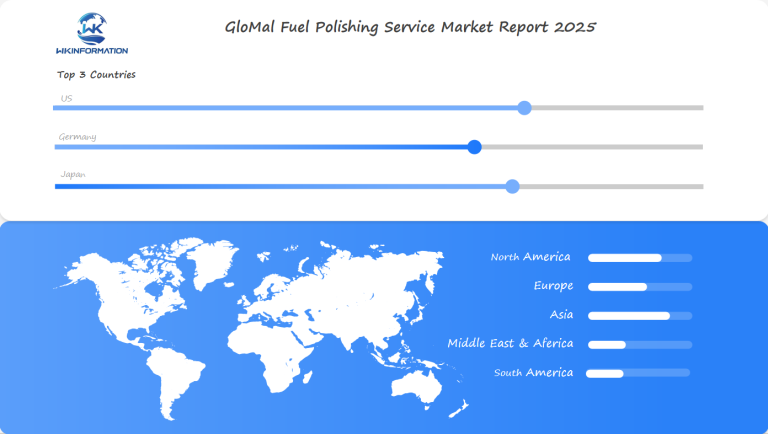

The U.S., Germany, and Japan are expected to be key players in this market:

- The U.S. is leading in fuel service demand due to its large marine and industrial sectors.

- Germany’s strong automotive and manufacturing base contributes significantly.

- Japan’s advanced technology and focus on energy efficiency will continue to drive the market.

As industries prioritize fuel efficiency and contamination-free fuel systems, demand for fuel polishing services will grow steadily in these countries.

Understanding the Upstream and Downstream Industry Chains for Fuel Polishing Services

The fuel polishing service market is a key spot where many industry chains meet. These chains make sure fuel is of high quality and reliable for many sectors. By looking at the network of suppliers, makers, and users, we see how fuel maintenance works.

Key Players in the Fuel Polishing Supply Chain

The fuel polishing supply chain has key parts that work together well. They make sure fuel maintenance services are top-notch. Some big players lead in innovation and growth:

- Equipment Manufacturers: Companies like ASNE and AXI International create advanced fuel polishing systems

- Technology Providers: RCI Technologies and Fueltec offer the latest in fuel cleaning tech

- Service Integrators: Njord and Krampitz Tanksystem provide full fuel management plans

End-User Industries Driving Demand

Many industries need fuel polishing to keep things running smoothly and equipment in good shape. The users of fuel polishing services include:

- Marine Industry: They need reliable power for their systems

- Telecommunications: They keep backup generators running well

- Financial Institutions: They protect their emergency power systems

- Government Facilities: They support critical power needs

- Medical Facilities: They ensure power for life-saving gear

The fuel polishing supply chain shows how tech and industry needs change how services are delivered. This makes the market always evolving and ready to meet new demands.

Key Market Trends Shaping the Fuel Polishing Service Industry

The fuel polishing service industry is changing fast. New technologies and ways of maintaining fuel are leading the way. These changes are making it easier to keep fuel quality high.

Today, fuel polishing trends are showing big changes in many areas. Companies are seeing the value in taking care of fuel before problems start. This approach helps avoid risks and boosts performance.

Technological Advancements in Fuel Polishing Equipment

New fuel polishing tools have cool tech features. These features make the process better and faster:

- Advanced filtration systems that catch tiny particles

- Sensors that watch for contamination in real-time

- Tools that track and diagnose issues digitally

- Systems that clean and fix fuel automatically

Shift Towards Preventive Maintenance Strategies

Companies are moving from fixing things after they break to stopping problems before they start. This change helps in many ways:

- It stops equipment from failing without warning

- It cuts down on costs over time

- It makes fuel storage systems last longer

- It makes systems more reliable

| Technology | Impact | Implementation Rate |

| IoT Sensors | Enhanced Monitoring | 65% |

| Automated Filtration | Contamination Reduction | 72% |

| Predictive Analytics | Maintenance Optimization | 58% |

The future of fuel maintenance looks bright. We can expect even more smart, data-based solutions. These will help keep fuel quality high and operations running smoothly.

Overcoming Challenges in Fuel Polishing Service Delivery

The fuel polishing service industry faces many challenges. These need smart solutions to keep operations top-notch and follow the rules. Companies must deal with complex fuel polishing rules and key service issues that affect their success and growth.

Fuel service challenges come from different areas. They need solutions that mix technical skills with following the rules.

Regulatory Compliance Strategies

Companies are creating strong plans to follow strict fuel polishing rules. Important steps include:

- Using advanced monitoring systems

- Doing regular checks on environmental impact

- Getting training for certifications

- Creating set quality control steps

Workforce Skill Development

Filling skill gaps is crucial for providing excellent fuel polishing service. Companies are investing in specialized training programs to enhance their employees’ skills.

| Training Focus Area | Skills Developed | Industry Impact |

| Technical Expertise | Advanced filtration techniques | Improved service quality |

| Regulatory Knowledge | Compliance understanding | Reduced risk of violations |

| Environmental Awareness | Sustainable practices | Enhanced ecological responsibility |

By addressing fuel service challenges through comprehensive training and adherence to regulations, businesses can establish robust and adaptable fuel polishing service models.

Geopolitical Factors Affecting the Fuel Polishing Service Market

The global fuel polishing service market is influenced by various geopolitical factors. These factors impact international trade, technological development, and strategic resource management. Understanding the geopolitics of fuel polishing is crucial for businesses involved in energy infrastructure and environmental standards.

The global fuel standards and international trade policies create a complex environment for the industry. Strategic partnerships and national investments are also reshaping the competitive landscape of the market.

Impact of International Trade Policies

Recent geopolitical developments have big implications for fuel polishing services:

- The United States is investing to develop domestic processing capabilities

- International partnerships are forming to secure stable fuel supply chains

- Trade regulations for energy services are getting more complex

Regional Differences in Fuel Quality Standards

Global fuel standards vary a lot across regions, posing challenges for fuel polishing service providers. Countries are setting stricter standards to ensure:

- Enhanced environmental performance

- Improved fuel efficiency

- Reduced carbon emissions

| Region | Fuel Quality Focus | Regulatory Approach |

| United States | Environmental Compliance | Strict EPA Regulations |

| European Union | Carbon Reduction | Carbon Border Adjustment Mechanism |

| Asia-Pacific | Technological Innovation | Emerging Market Standards |

The fuel polishing geopolitics landscape is constantly changing. Strategic flexibility and understanding regional nuances are key for success in this dynamic market.

Understanding Market Segmentation: Types and Uses of Fuel Polishing Services

The fuel polishing service market offers many specialized solutions for different needs. It’s important for businesses to know the various fuel polishing types and applications. This knowledge helps in choosing the best fuel maintenance strategies.

Fuel polishing services have grown to tackle specific challenges in many sectors. They provide customized ways to keep fuel quality and performance high.

On-Site vs. Off-Site Fuel Polishing Services

Companies have two main fuel polishing service options:

- On-Site Services: Technicians clean fuel right at the client’s place. This reduces disruption and lowers transportation risks.

- Off-Site Services: Fuel is taken to special cleaning facilities. Here, it gets a thorough treatment and advanced purification.

Industry-Specific Fuel Cleaning Applications

Each industry needs its own fuel polishing method:

- Maritime Sector: Removes water, microbial contamination, and sediment from marine diesel.

- Power Generation: Keeps generators running by maintaining fuel quality.

- Transportation: Improves fuel efficiency and protects engines in commercial fleets.

Choosing the right fuel polishing service depends on specific needs, equipment, and environmental conditions.

Fuel Polishing Services for Industries and Businesses

Industrial fuel polishing is essential for companies with backup power systems and intricate fuel arrangements. Businesses across various industries recognize the importance of maintaining clean fuel to guarantee the smooth operation and longevity of their systems.

Ensuring fuel quality is vital to prevent system breakdowns and minimize unplanned downtime. Cutting-edge fuel polishing services address several significant issues:

- Eliminating impurities from stored fuel

- Stopping the growth of microorganisms in fuel systems

- Prolonging the lifespan of generators and engines

- Preserving peak fuel efficiency

Critical Role in Backup Power Systems

Backup power systems in places like data centers, hospitals, and emergency services must be reliable. Industrial fuel polishing keeps standby generators ready by keeping fuel quality high and preventing mechanical issues.

| Sector | Fuel Polishing Benefit | Impact |

| Healthcare | Emergency Generator Reliability | Patient Safety |

| Data Centers | Continuous Power Availability | Minimal Service Interruption |

| Emergency Services | Rapid Response Capability | Public Safety |

Maintaining Fuel Quality in Transportation Fleets

Transportation companies use commercial fuel maintenance to boost fleet performance. Regular fuel polishing cuts down engine wear, boosts fuel efficiency, and lowers the chance of breakdowns in long-haul vehicles and heavy machinery.

With thorough fuel management, businesses can lower risks and costs linked to dirty or bad fuel systems.

Global Performance of the Fuel Polishing Service Market

The global fuel polishing market is growing fast. This is because of more industrial needs and new technologies. Companies in many fields see how important it is to keep fuel quality high. This helps their equipment work better and lowers risks.

Looking into the global fuel polishing service market shows big growth in different areas. Many countries are investing in fuel cleaning to improve energy use and protect the environment.

Regional Market Share Analysis

The market has different trends in main regions:

- North America has about 35% of the market share

- Europe adds around 28% to global earnings

- Asia-Pacific grows the fastest, at 15% each year

- The Middle East is seeing new chances

Emerging Markets and Growth Opportunities

Developing countries offer big chances for the global fuel polishing market. Technological innovations and more industrial setups are opening up new chances for fuel cleaning services to grow.

Potential growth spots include:

- Renewable energy sector integration

- Advanced manufacturing capabilities

- Stringent environmental regulations

- Infrastructure modernization projects

The fuel polishing service industry is showing strong growth. It’s expected to hit big market values in the next few years.

U.S. Market Drivers for Fuel Polishing Services

The American fuel maintenance industry is changing fast. This is due to old infrastructure and new rules. Many fuel storage systems in the U.S. are old and need better fuel polishing services.

What’s driving the US fuel polishing market includes:

- Deteriorating infrastructure built before modern environmental standards

- Increasing regulatory pressure from environmental protection agencies

- Growing awareness of fuel quality preservation

- Economic incentives for preventative maintenance

Aging Infrastructure and Fuel Storage Concerns

Fuel storage facilities in the U.S. face big challenges due to their age. Many places use systems from decades ago. These systems are at risk of contamination and not working well.

Fuel quality preservation has become a paramount concern for industries dependent on reliable energy sources. Companies like generators, transportation fleets, and emergency backup systems need to keep their fuel clean. This is to make sure they work right.

Regulatory Landscape Influencing Adoption

The fuel maintenance industry in America is changing because of strict environmental rules. The Environmental Protection Agency (EPA) has set higher standards. This means companies must use better fuel polishing technologies.

Proactive fuel maintenance is no longer optional but a critical operational requirement for modern businesses.

These rules are making companies spend more on fuel polishing services. This is creating big opportunities for growth in the US fuel polishing market.

Germany's Technological Advancements in Fuel Polishing Services

German fuel polishing technology is a world leader in precision and green solutions. It has set a high standard in Europe for fuel care. This has changed how industries handle and improve fuel quality.

Germany has made significant technological advancements in fuel polishing services, including:

- Advanced filtration systems with microscopic precision

- Intelligent monitoring technologies

- Automated fuel cleaning equipment

- Sustainable contamination removal processes

Innovation in Fuel Cleaning Equipment

German manufacturers have developed high-quality fuel cleaning equipment. Precision engineering is used to eliminate contaminants such as microbes and dirt, resulting in cleaner fuel than ever before.

Integration of IoT and Data Analytics

IoT technology has transformed fuel polishing in Germany. Companies now utilize real-time data to schedule maintenance and ensure optimal fuel quality. This proactive approach also aids in preventing system malfunctions.

Germany’s emphasis on fuel maintenance reflects its commitment to innovation. The country seeks solutions that are environmentally friendly and technologically advanced.

Japan's Role in Fuel Polishing Service Market Expansion

The Japanese fuel polishing market leads in new fuel maintenance strategies in Asia. Japan’s advanced technology and focus on detail make it a world leader in fuel cleaning and optimization.

Japanese companies have created top-notch fuel polishing methods. They excel in many important areas:

- Advanced maritime fuel maintenance systems

- High-precision industrial fuel cleaning technologies

- Environmentally sustainable fuel optimization solutions

Breakthrough in Maritime Sector Applications

The maritime industry is key for Japanese fuel polishing breakthroughs. Japanese engineers have made top-notch filtration systems. These systems greatly improve fuel quality and cut down on environmental harm. Precision engineering meets ecological responsibility in these groundbreaking technologies.

“Japanese fuel polishing technologies represent the gold standard in global maritime maintenance,” says a leading industry analyst.

Technology Export and Global Expansion

Japanese manufacturers are sending their fuel polishing tech to Asian markets. These solutions are great for countries wanting to boost industrial efficiency and lower environmental impact. Japanese engineers offer complete solutions for tough fuel maintenance problems.

Japan keeps pushing the limits of innovation in fuel polishing services. It solidifies its status as a technological leader in the Asian fuel maintenance industry.

The Future of Fuel Polishing Services: Opportunities and Innovations

The fuel polishing service industry is on the verge of big changes. New technologies and green practices are changing how we keep fuel clean and of high quality.

New technologies are making fuel polishing better and greener. The industry is moving towards smarter and more eco-friendly ways to keep fuel clean.

Emerging Technologies in Fuel Maintenance

New tech is bringing big improvements to fuel polishing services:

- Nanomaterial-based filtration systems

- Advanced sensor technologies for real-time fuel quality monitoring

- AI-driven predictive maintenance algorithms

- Automated fuel cleaning equipment

Sustainable Practices in Fuel Polishing

Keeping fuel clean in a green way is now a big deal. Companies are using eco-friendly methods to keep fuel quality high without harming the environment.

| Sustainable Practice | Environmental Benefit |

| Bio-based fuel additives | Reduced carbon emissions |

| Renewable energy integration | Lower energy consumption |

| Circular economy approach | Minimized waste generation |

The mix of new tech and green practices is shaping the future of fuel polishing. Companies that invest in these new methods will have a big edge in the changing energy world.

Competitive Landscape in the Fuel Polishing Service Market

Companies are using new strategies to stand out. They’re focusing on technology and partnerships to grow their market share.

Big companies are using bold moves to get more market share. They’re merging with other companies to get stronger. They’re also spending a lot on research to make better fuel cleaning technologies.

- CommTank – United States

- Crown Oil – United Kingdom

- Shenton Group – United Kingdom

- Fluid Polishing – United Kingdom

- Hart – United Kingdom

- JC Fuel Polishing Services – United Kingdom

- Bio Clean Jetting – United Kingdom

- Pacific Power – United States

- JWH Tanks – United Kingdom

- SDM Fuel Solutions – United Kingdom

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Fuel Polishing Service Market Report |

| Base Year | 2024 |

| Segment by Type |

· On-Site Fuel Polishing Services · Off-Site Fuel Polishing Services |

| Segment by Application |

· Healthcare · Data Centers · Emergency Services · Others |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The fuel polishing service market is poised for remarkable growth, driven by advancements in technology and the increasing demand for clean fuel. Industries relying on large-scale fuel storage, such as healthcare, marine, and construction, benefit significantly from these services. Diesel fuel polishing systems ensure operational efficiency by preventing contamination that could lead to costly repairs or downtime. Emerging markets, particularly in Asia-Pacific and Africa, present vast opportunities due to rapid industrialization and urbanization. With innovations like mobile fuel polishing systems enhancing flexibility, the diesel fuel polishing service market is set to thrive, meeting the evolving needs of global industries.

Global Fuel Polishing Service Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Fuel Polishing Service Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Vacuum Arc RemeltingMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Fuel Polishing Serviceplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Fuel Polishing Service Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Fuel Polishing Service Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Fuel Polishing Service Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofFuel Polishing Service Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is fuel polishing and why is it important?

Fuel polishing is the process of removing contaminants and water from stored fuel. It is important because it ensures that engines and power systems operate efficiently. By preventing equipment failure and extending the lifespan of machinery that relies on fuel, this process can save money in the long run.

Which industries usually need fuel polishing services?

Fuel polishing is essential for various industries, including:

- Marine

- Power generation

- Data centers

- Hospitals

- Emergency systems

- Automotive fleets

- Aviation

- Manufacturing

These sectors rely on clean fuel to ensure their operations run smoothly.

What are the main challenges in the fuel polishing service industry?

The fuel polishing service industry faces several significant challenges, including:

- Regulatory compliance: Companies must adhere to various rules and regulations governing their operations, which can be complex and subject to change.

- Environmental concerns: There is a growing emphasis on sustainability and minimizing environmental impact, requiring companies to adopt eco-friendly practices.

- Skilled labor shortage: Finding and retaining skilled workers with expertise in fuel polishing can be difficult, leading to potential skill gaps in the workforce.

- Technological advancements: Keeping up with new technologies and innovations in the industry is crucial for staying competitive.

To address these challenges, companies in the fuel polishing service industry are implementing various strategies such as:

- Employee training: Investing in training programs to upskill existing workers and attract new talent.

- Eco-friendly solutions: Developing and adopting environmentally friendly solutions that meet regulatory requirements and customer expectations.

- Advanced filtration systems: Implementing advanced filtration systems and technologies to improve efficiency and effectiveness in fuel polishing processes.

What technologies are emerging in fuel polishing services?

New technologies in fuel polishing services include:

- Nanomaterial filters

- Internet of Things (IoT) for monitoring

- Bio-additives

- Data analytics for maintenance

These advancements have several benefits, including:

- Improving fuel quality

- Reducing pollution

- Increasing efficiency

How does fuel polishing differ across regions like the U.S., Germany, and Japan?

Each region has its own approach: The U.S. relies on outdated infrastructure, Germany embraces innovation, and Japan prioritizes maritime solutions and green technology. These differences arise from various factors such as industry requirements, regulations, and technological advancements.

What are the types of fuel polishing services available?

There are two main types: on-site and off-site.

- On-site: This type of service cleans the fuel where it is stored, without moving it to another location.

- Off-site: In this case, the fuel is transported to a designated facility for a thorough cleaning process.

How often should fuel polishing be performed?

The frequency of fuel polishing depends on factors such as storage time, weather conditions, and industry requirements. Generally, it is recommended to perform fuel polishing every 6 to 12 months, or more frequently in areas that are wet or dirty.

What are the environmental benefits of fuel polishing?

Fuel polishing, a process that involves cleaning and refining fuel, offers several environmental benefits, including:

- Longer fuel lifespan, which reduces the frequency of fuel disposal

- Reduced emissions from cleaner fuel combustion

- Fuel savings due to improved efficiency

- Improved engine performance leading to less fuel consumption

By minimizing waste and lowering carbon emissions, fuel polishing contributes positively to the environment.

How do companies choose a fuel polishing service provider?

When selecting a fuel polishing service provider, companies consider several factors. These include the technology used by the provider, their experience in the industry, compliance with regulations, and their track record of success stories. Additionally, they evaluate the range of services offered, the cost of these services, and whether the provider can offer custom solutions tailored to their specific needs. The ultimate goal is to find the best fit for their unique requirements.