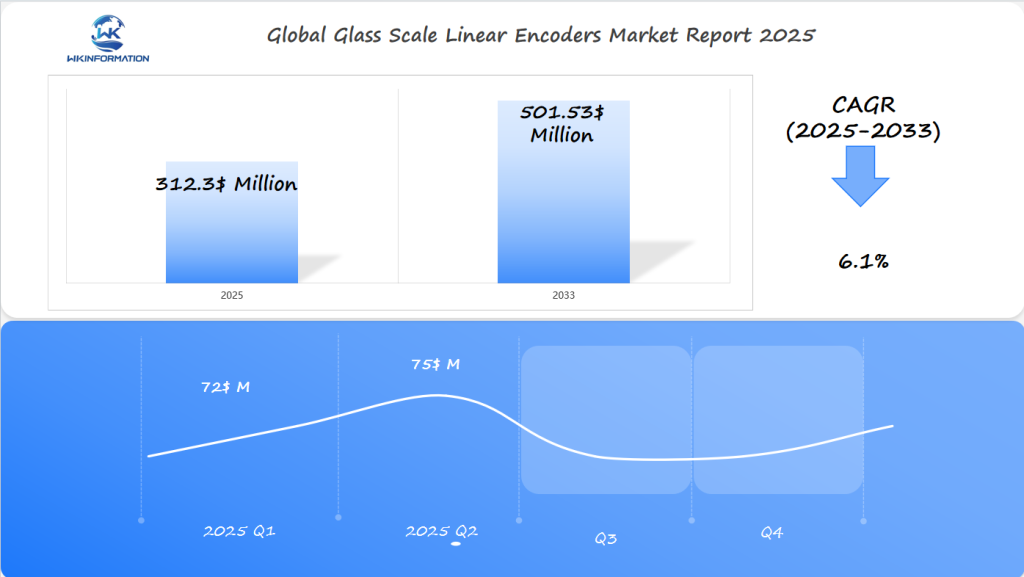

Glass Scale Linear Encoders Market Expected to Reach $312.3 Million by 2025 with Demand in Automation and Precision Engineering in the U.S., Germany, and Japan

The Glass Scale Linear Encoders market is experiencing significant growth, driven by the increasing demand for precision measurement and positioning systems across a variety of high-tech industries. This market is expected to expand as industries continue to seek more reliable and precise solutions for motion feedback and measurement.

- Last Updated:

Glass Scale Linear Encoders Market Outlook for Q1 and Q2 2025

The Glass Scale Linear Encoders market is projected to reach $312.3 million in 2025, with a CAGR of 6.1% from 2025 to 2033.

Q1 2025 Outlook

In Q1 2025, the market is expected to be valued at approximately $72 million, driven by increased demand from precision measurement applications in industries such as manufacturing, robotics, and semiconductor equipment, particularly in the U.S., Germany, and Japan. As automation and the need for high-precision measurements continue to rise, glass scale linear encoders are becoming essential for high-resolution position feedback in various industrial applications.

Q2 2025 Outlook

By Q2 2025, the market is forecast to grow to around $75 million, spurred by technological advancements that enhance the accuracy and durability of these encoders. The U.S. will maintain a strong demand due to its significant manufacturing and robotics sectors. Germany’s emphasis on precision engineering and Japan’s leadership in semiconductor technology will also contribute to steady growth in the market. In Q2, a surge in adoption of advanced automation systems and industrial robots will further drive the demand for glass scale linear encoders.

Glass Scale Linear Encoders Upstream and Downstream Industry Chain Analysis

The glass scale linear encoders industry is a complex web of parts and uses. It’s important to know how suppliers and users work together. This helps us see the market’s potential and new tech.

Upstream: Key Suppliers of Glass Scale Linear Encoders

Suppliers are key in making glass scale linear encoders. They give the raw materials and parts that make the encoder work well and last long.

- Optical glass manufacturers

- Precision metal component suppliers

- Electronic circuit board producers

- Semiconductor and sensor manufacturers

Downstream: Primary Industries Using Glass Scale Linear Encoders

Glass scale linear encoders are used in many precise fields. This shows how versatile and important they are.

| Industry Sector | Primary Applications | Precision Requirements |

| Machine Tools | CNC Machining | ±0.001mm |

| Robotics | Precision Motion Control | ±0.005mm |

| Semiconductor | Wafer Processing | ±0.0005mm |

| Medical Devices | Surgical Equipment | ±0.002mm |

The Interconnectedness of the Industry

The parts of the industry work together, creating a complex system. This system drives the growth of precise measurement tech. The connection between suppliers and users keeps improving encoder quality and reliability.

The Impact of New Technology and Market Needs

New tech and market needs keep changing the glass scale linear encoders industry. It’s a key part of advanced making and precise engineering.

Technological advancements driving demand for glass scale linear encoders

The world of precision measurement is changing fast, with glass scale linear encoders leading the way. These advanced systems are changing how we measure and automate in industries.

Several key advancements are boosting encoder performance across many fields:

- Miniaturization of encoder components

- Enhanced accuracy through advanced optical technologies

- Improved signal processing capabilities

- Integration of smart diagnostic features

Companies are making encoders more precise than ever before. Nanotechnology breakthroughs have made it possible for linear encoders to measure with incredible accuracy.

“The future of industrial automation lies in our ability to measure with extreme precision,” says Dr. Elena Rodriguez, leading researcher in measurement technologies.

New encoder designs use advanced materials like ceramics and special glass. These materials help reduce errors and make encoders last longer in tough environments.

Important upgrades in encoder performance include:

- Reduced signal interference

- Faster data processing

- Greater temperature stability

- Increased resistance to environmental challenges

As technology keeps advancing, the glass scale linear encoder market is growing. This is leading to big improvements in precision and efficiency in fields like robotics and semiconductor manufacturing.

Challenges related to precision, durability, and manufacturing costs

Glass scale linear encoders face big challenges in the industrial automation world. Makers struggle with complex issues that affect their performance and how well they’re accepted in the market. The main problems are keeping high precision and dealing with durability issues in tough industrial settings.

Key challenges in the glass scale linear encoder market include:

- Maintaining consistent accuracy under extreme conditions

- Reducing manufacturing costs for broader market accessibility

- Enhancing durability in harsh industrial settings

- Developing cost-effective precision measurement solutions

For small and medium-sized businesses, high manufacturing costs are a big hurdle. The cost of advanced encoder technology is too high for many. It takes a lot of research and development to make precise engineering.

| Challenge Category | Impact on Market | Potential Solutions |

| Precision Limitations | Reduced Performance | Advanced Calibration Techniques |

| Durability Concerns | Increased Replacement Costs | Robust Material Development |

| Manufacturing Expenses | Limited Market Penetration | Scaled Production Methods |

Research teams are working hard to find new solutions to these encoder challenges. They’re exploring new materials and manufacturing methods. The goal is to make glass scale linear encoders that are both affordable and reliable for today’s industrial needs.

Geopolitical Influences on the Global Glass Scale Encoder Market

The global market for glass scale linear encoders is changing due to complex geopolitical issues. How countries make things plays a big role in how the market moves. Big economic powers are racing to be the best in technology.

Trade policies have a big impact on the glass scale encoder industry. They create both problems and chances for makers all over the world. The Asia Pacific area is leading the way, pushing innovation and making things more precise.

Emerging Economic Blocs and Global Manufacturing Networks

Emerging economic blocs are reshaping global manufacturing networks. These groups of countries are coming together to strengthen their economic ties and compete on a larger scale. As a result, traditional manufacturing powerhouses may face challenges from these new alliances.

Technological Innovation as a Competitive Advantage

Technological innovation becomes a key competitive advantage in the glass scale encoder market. Companies that can develop cutting-edge technologies will have an edge over their competitors. This could include advancements in sensor technology, data processing capabilities, or connectivity solutions.

Shifts in Regional Manufacturing Capabilities

Shifts in regional manufacturing capabilities alter market dynamics. Certain regions may become more attractive for production due to factors such as lower labor costs, favorable government policies, or access to resources. This can impact the supply chain and pricing strategies of glass scale encoder manufacturers.

Strategic thinking in the global encoder market includes:

- Impact of international trade negotiations

- Technological transfer restrictions

- Regional economic development strategies

Geopolitical tensions create unique challenges for glass scale encoder manufacturers, requiring adaptive strategies and robust supply chain management. Countries like China, Japan, and Germany are becoming major players in making things with precision.

The future of glass scale encoders depends on navigating complex international economic relationships and technological innovation.

Manufacturing skills are getting better, with countries getting smarter about making things. The mix of tech skills, economic policies, and global market trends will decide if glass scale encoder makers do well in the future.

Segmentation analysis: Types and applications of linear encoders

The glass scale linear encoders market is complex. It has different encoder types for various needs. Incremental and absolute encoders are the main types. They help in precise engineering tasks.

Incremental encoders are key in tracking position. They send out pulse signals to show movement from a start point. They work well for tracking continuous motion in:

- Machine tool positioning

- Robotic system synchronization

- High-speed motion control

Absolute encoders offer a more advanced way to measure position. They can find exact position right away. This is useful for:

- Precision measurement instruments

- CNC manufacturing equipment

- Advanced motion control systems

There are many encoder types for different industrial needs. Market research shows a growing need in many areas. New technologies are making both incremental and absolute encoders more popular.

Key applications in robotics, CNC machines, and industrial automation

Glass scale linear encoders have changed how we measure things in many industries. They play a big role in robotics, CNC machines, and automation. These sensors help make machines work more accurately and reliably.

Robotics

In robotics, these encoders help control movement and position. Robots use them to:

- Track their movements precisely

- Position themselves with high accuracy

- Work well in tough conditions

CNC Machining

CNC machining also benefits a lot from these encoders. They help make products with:

- Very tight measurements

- Instant feedback on position

- Better quality control

Automation

Automation uses these encoders to make things run smoother. Cutting-edge manufacturing facilities use them to improve machine performance. This leads to fewer mistakes and more work done.

Precision is not just a measurement—it’s a competitive advantage in modern manufacturing.

As glass scale linear encoder technology gets better, we’ll see even more uses in robotics, CNC machines, and automation. This will keep driving innovation in these fields.

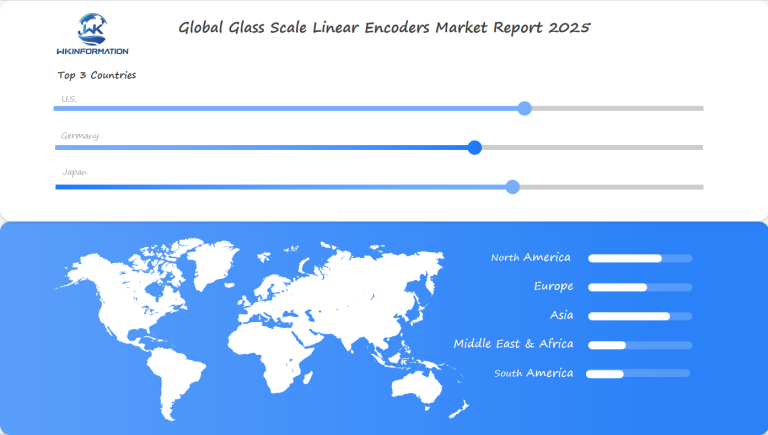

Regional growth trends in the glass scale encoder market

The global glass scale encoder market shows different growth patterns in each region. Market dynamics, technology adoption, and industrial growth vary greatly.

1. Asia Pacific: The Leader in Market Growth

The Asia Pacific region is a key driver of market growth. It benefits from fast industrial growth, new technologies, and more automation. This makes it a leader in the use of glass scale linear encoders.

2. North America and Europe: Steady Growth with a Focus on Precision

In North America and Europe, the adoption of encoder technology is unique. These mature markets grow steadily but focus on precision in advanced manufacturing.

“The future of glass scale encoder technology lies in understanding regional nuances and technological adaptation capabilities.” – Industry Analyst

Emerging markets offer big chances for glass scale encoder makers. Investing in research and making products locally are key to success.

U.S. Demand for Precision Measurement Solutions in Automation

The U.S. market for precision measurement technologies is growing fast. This growth is due to more automation in many industries. Companies are spending a lot on new measurement tools to work better and stay ahead.

Some key areas driving the need for precise measurements are:

- Aerospace engineering

- Automotive manufacturing

- Advanced robotics

- Medical device production

Especially, glass scale linear encoders are key in automation. They help make products with high accuracy and consistency.

New technologies are making encoders better. U.S. makers are working on high-resolution measurement solutions for tough industrial needs.

Government support and industry standards are also helping. Companies see the value in using the latest automation tools to stay on top globally.

Germany's Leadership in Industrial Automation and Encoder Adoption

The German industry leads the world in automation, making big strides in encoder tech. With a strong manufacturing base, Germany is key in the precision measurement solutions market.

German makers are always pushing tech limits in industrial automation. They have several key strengths:

- Advanced precision engineering skills

- Big investments in research and development

- Strong ties between industry and schools

- Use of Industry 4.0 principles

The car and machine tool industries are key in using encoder tech. Precision measurement solutions help Germany stay ahead in making things.

“German engineering excellence continues to set global standards in industrial automation” – Industrial Technology Research Group

Germany is all in on tech innovation, especially in encoder systems. Its research groups and makers work together to make top-notch solutions for tough industrial needs.

The German industry keeps showing top skills in encoder tech. They meet the changing needs of global making.

Japan's role in precision manufacturing and encoder technology

Japan leads in precision technology, showing unmatched skill in making advanced encoder systems. The country’s focus on new tech makes it a top player in Asia for glass scale linear encoders. This has led to big steps forward in measuring and automating things.

Japan’s key strengths in precision manufacturing

Japan’s key strengths in precision manufacturing are:

- Exceptional quality control processes

- Continuous technological refinement

- Deep investment in research and development

- Sophisticated engineering capabilities

Top Japanese companies have come up with new ways to improve encoder technology. They use their kaizen (continuous improvement) philosophy to make better measurement solutions.

| Japanese Encoder Manufacturers | Global Market Share | Technology Specialization |

| Mitsubishi Electric | 22% | High-precision linear encoders |

| Fanuc Corporation | 18% | Robotic automation encoders |

| Sony Corporation | 15% | Miniature precision encoders |

The Asia Pacific region, led by Japan, is expected to lead the glass scale linear encoders market. Japanese makers keep pushing the limits, creating encoder tech that sets the world standard for precision and dependability.

Innovations in Encoder Design and Their Impact on Future Market Growth

The world of encoder design is changing fast. New technologies are making a big impact on how we measure things. Companies are coming up with new ways to make encoders better, solving big problems in different fields.

These new ideas in encoder design are leading to big changes in the market:

- Nanoscale techniques for better accuracy

- Stronger materials for tougher environments

- Smart features for quick checks

- Wireless options for more uses

The future trends show a big move towards smarter, more flexible encoders. Companies are making encoders that last longer, are more precise, and work well in tough places.

Precision is no longer just a measurement—it’s a competitive advantage.

New technologies are bringing big changes to encoder design. Miniaturization and advanced sensing are opening up new areas like robotics and medical devices. These changes mean encoders will soon be key parts of smart systems.

Adding artificial intelligence and machine learning will change encoders even more. They will become more responsive and able to adjust to changing needs in industries.

Competitive landscape of companies in the glass scale encoder market

The glass scale linear encoders market is very competitive.

Leading manufacturers:

- Novanta —— United States

- Renishaw —— United Kingdom

- GDXH —— China

- Electronica —— India

- Mitutoyo —— Japan

- AIKRON —— United States

- DR. JOHANNES HEIDENHAIN —— Germany

- Precizika Metrology Micro Optical —— India

- Versoix —— Switzerland

- Innovative Automation Products —— United States

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Glass Scale Linear Encoders Market Report |

| Base Year | 2024 |

| Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The global market for glass scale linear encoders is set for big growth. Experts predict a strong increase in demand. The sector is expected to grow at a rate of 6.1% annually.

This growth will take the market from USD 312.3 million in 2025 to USD 501.53 million by 2033. This shows a big need for precise measurement tools in advanced manufacturing.

Factors driving growth

Technological advancements are key to the growth of glass scale linear encoders. New technologies like Industry 4.0 and smart manufacturing are driving the demand for better measurement systems. Companies are working on making encoders smaller, more accurate, and affordable.

These advancements are crucial for:

- Robotics

- CNC machines

- Advanced automation

The focus is on creating solutions that meet the needs of these technologies.

Industries contributing to market growth

Automation in various industries is driving the market for glass scale linear encoders. The outlook is positive, with a focus on improving encoder performance and integration. Partnerships between tech companies and industrial equipment providers will help bring new technologies to market.

The key industries contributing to this growth include:

- Aerospace

- Semiconductor

- Medical devices

As global manufacturing focuses on precision and efficiency, glass scale linear encoders will be essential. The market looks promising, with opportunities for companies that offer advanced measurement solutions.

Global Glass Scale Linear Encoders Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Glass Scale Linear Encoders Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Glass Scale Linear EncodersMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Glass Scale Linear Encodersplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Glass Scale Linear Encoders Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Glass Scale Linear Encoders Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Glass Scale Linear Encoders Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofGlass Scale Linear EncodersMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are Glass Scale Linear Encoders?

Glass Scale Linear Encoders are devices that measure position with great accuracy. They use high-quality glass scales to track motion. This makes them reliable in many industrial settings.

How do Glass Scale Linear Encoders contribute to industrial automation?

They help machines move with precision by giving accurate position feedback. This is key for better manufacturing and quality.

What industries primarily use Glass Scale Linear Encoders?

Industries such as CNC machining, aerospace, and automotive rely on Glass Scale Linear Encoders. Additionally, sectors like semiconductor production, measuring instruments, and robotics require these encoders for accurate control.

What is the projected market value for Glass Scale Linear Encoders?

The market is expected to reach $312.3 million by 2025. This growth is driven by increased automation and technological advancements in precision engineering.

What technological innovations are improving Glass Scale Linear Encoders?

New technology includes making them smaller, more accurate, and durable. They also use advanced materials and sensing technology for better performance.

What challenges do manufacturers face in Glass Scale Linear Encoder production?

Manufacturers face several challenges in producing Glass Scale Linear Encoders:

- Achieving precision while ensuring durability in harsh environments

- Controlling production costs

- Maintaining long-term accuracy and reliability of the encoders

How do geopolitical factors impact the Glass Scale Linear Encoders market?

Trade policies and economic changes affect the market. The Asia Pacific is becoming a big player in production and use.

What is the difference between incremental and absolute encoders?

Incremental encoders track changes in position. Absolute encoders provide exact position information immediately, without needing a reference point.

Which regions are experiencing the fastest growth in Glass Scale Linear Encoders?

The Asia Pacific, especially Japan, China, and South Korea, are growing fast. This is due to their strong manufacturing and investment in automation.

What role do Glass Scale Linear Encoders play in Industry 4.0?

They are key in smart manufacturing by offering precise data for automation. These encoders help in digital transformation and boost production efficiency.