Projected Market Insights for Gravure Printing Inks in Q1 and Q2 of 2025

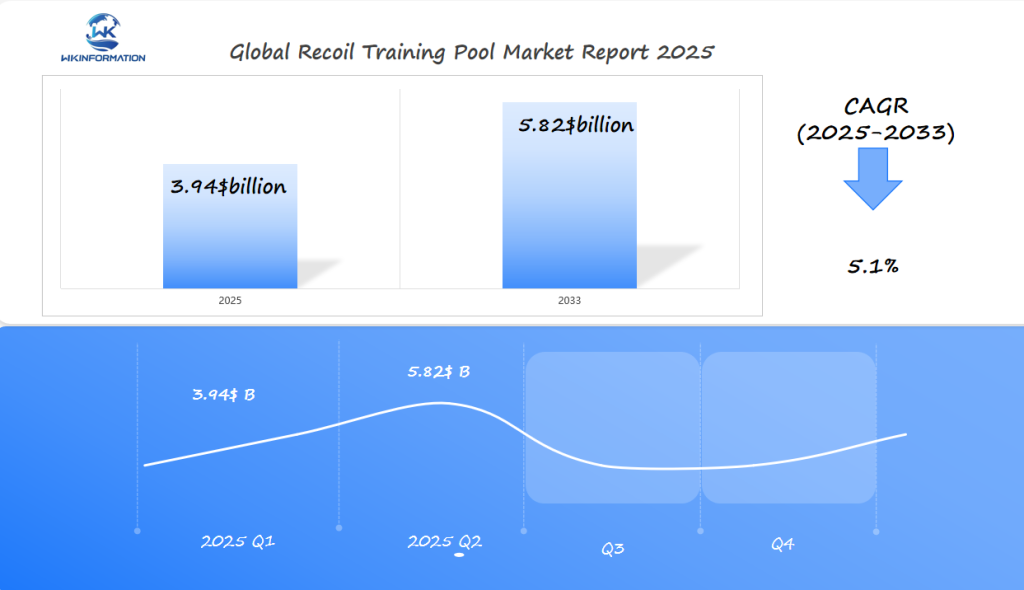

The Gravure Printing Inks market is expected to reach $3.94 billion in 2025, with a CAGR of 5.1% from 2025 to 2033. In Q1, the market is projected to generate approximately $937 million, driven by increased demand in packaging and labeling industries as businesses continue to shift toward high-quality printing solutions. By Q2, the market is expected to grow to around $975 million, reflecting steady growth.

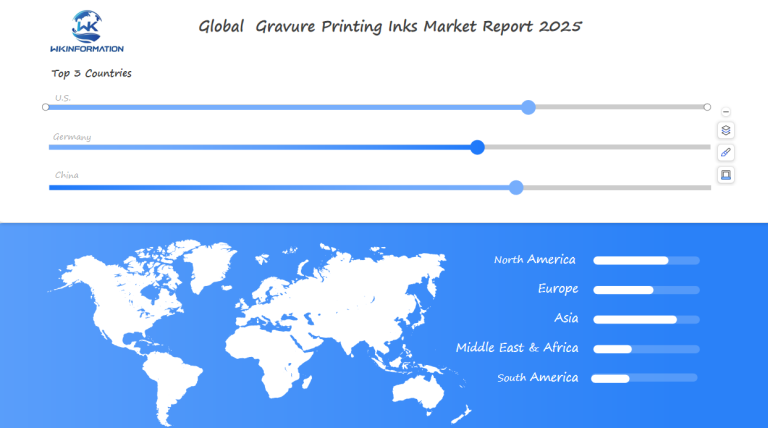

The U.S., China, and Germany are expected to be key contributors, with the U.S. leading due to its advanced packaging sector, China’s massive manufacturing base, and Germany’s well-established printing technologies. As the demand for durable and aesthetically pleasing printed materials increases, the gravure printing inks market will continue to expand in these regions.

Key Takeaways

- Market expected to reach $3.94 billion by 2025

- Strong growth in U.S., China, and German markets

- Packaging sector driving increased ink demand

- Technological advancements in sustainable ink formulations

- Rising consumption of processed foods supporting market expansion

Understanding the Upstream and Downstream Industry Chains for Gravure Printing Inks

The gravure printing inks market has a complex chain. It connects raw material suppliers to many end-user industries. These networks are key to the market’s success and sustainability.

Gravure printing ink production needs advanced raw materials. These materials affect the ink’s quality and how green it is. Companies are now looking for new ways to get these materials to stay ahead.

Raw Material Suppliers and Market Impact

Important raw material suppliers are vital to the gravure printing inks world. They focus on:

- Getting bio-based and renewable materials

- Using green production methods

- Lowering carbon emissions with new tech

| Raw Material Category |

Sustainability Focus |

Market Impact |

| Pigments |

Low-VOC formulations |

Enhanced environmental compliance |

| Solvents |

Bio-renewable sources |

Reduced ecological footprint |

| Binders |

Recyclable compositions |

Improved circular economy integration |

End-User Industries Driving Demand

Different industries are key in shaping the gravure printing ink market. The packaging, flexible packaging, and food labeling sectors are growing fast.

- Packaging focuses on eco-friendly inks

- Food and drinks need top-notch inks

- Pharmaceuticals need special ink types

The industry chains are changing. They are moving towards environmentally responsible and high-tech gravure printing ink making.

Key Market Trends Influencing the Gravure Printing Ink Industry

The gravure printing ink industry is going through big changes. These changes are because of a focus on being green and new tech. How ink is made and used is changing a lot.

Companies are now making inks that are better for the planet. This is happening because of a few big changes:

- Development of nitrocellulose-free (NC-free) inks

- Introduction of alternative polyurethane (PU) resin-based inks

- Growth in bio-based and recyclable ink materials

- Investments in sustainable packaging solutions

Sustainable Ink Innovations

New tech is changing the ink world a lot. Energy-cured inks, like UV-curable ones, are becoming more popular. They have less harmful stuff in them and can be used in many ways.

The market for packaging inks is growing fast. It’s expected to grow by 5.1% every year from 2025 to 2033. The Asia Pacific is leading this growth, thanks to fast retail growth and more packaging needs.

New tech is also making packaging better. There are now coatings and barrier tech for recyclable films. These are key for companies wanting to be greener.

Challenges in Gravure Printing Ink Production and Distribution

The gravure printing ink industry faces complex challenges. These challenges test manufacturers’ ability to adapt and innovate. Companies must navigate through technological and regulatory landscapes while staying competitive.

Manufacturers face big hurdles in changing their production strategies. Environmental regulations are pushing for new ink formulations. The shift from traditional solvent-based inks is a major turning point for the industry.

Environmental Regulations Reshaping Ink Development

Environmental regulations are changing ink production processes. Companies need to invest in new technologies to reduce VOCs (Volatile Organic Compounds).

- Significant equipment retrofit investments required

- Substantial research and development costs

- Maintaining print quality during technological transitions

Raw Material Price Volatility Impact

Raw material prices are unpredictable for gravure printing ink manufacturers. These price changes affect production costs and profit margins.

| Production Factor |

Impact Level |

Mitigation Strategy |

| Raw Material Costs |

High Volatility |

Diversified Supplier Contracts |

| Environmental Compliance |

Moderate to High |

Sustainable Ink Formulations |

| Technology Investment |

Significant |

Phased Equipment Upgrades |

The industry’s future depends on strategic adaptations to these challenges. Successful manufacturers will use innovative solutions to environmental regulations and raw material price management.

Geopolitical Factors Impacting the Gravure Printing Inks Market

The global gravure printing inks market is shaped by complex geopolitical factors. These factors affect international trade and regional markets. It’s vital for industry players to grasp these dynamics to succeed in the global market.

Geopolitical factors greatly influence market opportunities and challenges in various regions. The mix of trade policies, economic plans, and rules creates a complex environment for gravure printing inks.

Trade Policies Reshaping Market Dynamics

Trade policy changes are reshaping the gravure printing inks market:

- The U.S. has introduced strategic import tariffs that affect ink production and distribution.

- China’s industrial policies are leading to significant market growth.

- European rules are encouraging more eco-friendly ink formulations.

Regional Regulatory Environments

Regional regulations have a big impact on gravure printing ink production and market strategies. North America, Europe, and Asia-Pacific have different regulatory approaches:

- North America values technological innovation and environmental rules.

- Europe puts a big focus on sustainability and strict environmental standards.

- Asia-Pacific is all about fast industrial growth and market expansion.

The coming together of these regional rules makes the global market for gravure printing inks exciting and challenging. It pushes for innovation and strategic changes.

Market Segmentation: Types and Applications of Gravure Printing Inks

The gravure printing inks market is always changing with new technologies and special solutions. Understanding the different ink types and their uses is key to seeing how they fit into various industries.

Gravure printing inks mainly fall into two groups: solvent-based and waterbased. Each type has its own strengths that meet different needs in industries.

Solvent-Based vs. Water-Based Gravure Printing Inks

Solvent-based inks have long been popular for their flexibility and strong sticking power. They work well on many materials. Water-based inks, on the other hand, are becoming more popular because they are better for the environment and follow strict rules.

- Solvent-based inks: Great for tough printing surfaces

- Water-based inks: Good for the planet and meets strict rules

- Emerging trend: Less harm to the environment

Specialized Inks for Industry Applications

The gravure printing inks market is full of special ink types. Each industry needs its own ink to solve specific printing problems.

- Plastic Gravure Printing Ink: Perfect for plastic packaging

- Organic Glass Printing: Offers precision and clearness

- PP and ABS Printing: Works well with advanced materials

- Pipe and Plastic Toys Printing: Focuses on durability and safety

Regions like North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa are leading the market growth. They are seeing more demand for new and green printing ink options.

Gravure Printing Inks in Packaging and Labeling Applications

The packaging industry is now a key player for gravure printing inks. New solutions are changing how we present and protect products. This has led to fast growth in packaging applications and advanced printing tech.

The global printing ink market is growing fast. It’s expected to jump from $3.94 billion in 2025 to $5.82 billion by 2033. This growth is mainly seen in food and flexible packaging.

Growth Drivers in Food and Beverage Packaging

Food packaging is a big area for gravure printing inks. The main reasons for growth are:

- More people want products that look good

- There’s a need for stronger packaging

- There’s a push for eco-friendly packaging

Innovations in Flexible Packaging

Flexible packaging has seen big tech leaps. Bio-based printing inks are becoming popular. They’re better for the environment and cut down on emissions. Companies like Röltgen are making special inks for fast printing on plastic.

Online shopping is making packaging even more important. Companies are working on packaging that looks great and can handle shipping well.

Global Market Overview of Gravure Printing Inks

The global market for gravure printing inks is growing fast. This is thanks to new technologies and more uses in industry. As companies look for better printing, the market is changing a lot in different places.

The gravure printing inks market has a lot of potential. Important changes are happening in key areas around the world. The way the market is growing and improving in each region is quite interesting.

Regional Market Shares and Growth Projections

Looking at the global market, three main areas are important:

- United States: A mature market with advanced printing tech

- China: Fast-growing manufacturing sector boosts ink demand

- Germany: A leader in precision engineering and ink making

The market is expected to grow by 10.2% each year. This is especially true for packaging and flexible packaging. This growth shows more people want eco-friendly and top-quality prints.

Emerging Markets and Their Potential

Emerging markets offer big chances for gravure printing inks. Southeast Asia and Latin America are growing fast. They are becoming key places for companies looking to grow.

Big players like EBS Ink Jet Systeme GmbH, Marabu, and Siegwerk Group are getting ready to take advantage of these new markets. They are shaping the global market.

U.S. Market Demand for Gravure Printing Inks

The U.S. market for gravure printing inks is growing fast. New technologies and changing needs are driving this growth. Packaging and printing are leading the way.

Several key industries are pushing the gravure printing inks market forward in the United States:

- Flexible packaging sector

- Food and beverage packaging

- Consumer product labeling

- E-commerce packaging solutions

Key Industries Driving Growth in the U.S. Market

The demand for gravure printing inks in the U.S. is growing fast. Flexible packaging is leading this growth. Online shopping has made durable, attractive packaging more important.

| Industry Sector |

Growth Potential |

Market Impact |

| Flexible Packaging |

High |

Driving market expansion |

| Food Packaging |

Moderate |

Increasing demand for sustainable inks |

| Consumer Goods |

Significant |

Enhancing product branding |

Regulatory Landscape and Its Impact on Market Development

The rules and regulations are key in the U.S. gravure printing inks market. They are pushing for bio-based and sustainable ink formulations. The market is expected to grow by 5.1% from 2025 to 2033, focusing on eco-friendly solutions.

China's Dominance in the Gravure Printing Inks Market

The China market has become a key player in the global gravure printing inks industry. It drives big changes and new ideas. China’s strong factories and growing number of customers make it a major force in printing technology.

Several important factors help China lead in gravure printing inks:

- Massive industrial manufacturing capabilities

- Growing packaging and printing sector

- Significant investments in technological research

- Expanding food and beverage packaging demand

Manufacturing and Economic Dynamics

The Chinese market is changing how printing ink is made. It’s doing this by investing in new tech and making better ink. This is to meet global quality standards.

Strategic Market Opportunities

Despite challenges, China offers big chances for gravure printing ink makers. Strategic innovation and keeping up with new rules are key for growth and staying competitive worldwide.

Germany's Influence on Gravure Printing Ink Technology

Germany leads in gravure printing ink technology, pushing innovation and setting global standards. The country’s advanced technology makes it a key player in creating new ink solutions. These solutions meet the changing needs of the market.

The German ink technology scene is marked by several key developments:

- Cutting-edge ink innovations focused on sustainability

- Advanced research in eco-friendly formulations

- Strict adherence to environmental regulations

Siegwerk Druckfarben, a leading German company, shows the nation’s dedication to technology. Dr. Nicolas Wiedmann, CEO of Siegwerk, talks about the company’s focus on sustainable inks. This includes water-based and recyclable ink systems.

Shaping European Market Trends

Germany plays a crucial role in shaping European market trends through its strict regulations. The German Printing Ink Ordinance and the European Green Deal are examples of Germany’s leadership in promoting environmental responsibility.

Germany’s approach to ink technology combines scientific advancements with a strong commitment to environmental protection. This unique blend ensures that German innovations remain at the forefront of the global printing ink market.

The Future of Gravure Printing Inks: Innovations and Opportunities

The gravure printing inks industry is on the verge of big changes. New technologies and innovations will change how we make and package things. These changes will open up new chances in many fields.

New advancements are making gravure printing inks key players in innovation. The market is growing fast, with big growth expected.

- Energy-cured ink systems with reduced volatile organic compounds

- Nanotechnology-enhanced ink formulations

- Smart ink technologies for intelligent packaging

- Digital integration with advanced printing platforms

Potential New Applications and Markets

The mix of new tech and market needs is opening up new paths for gravure printing inks in many areas.

Investing in research and development is key for companies wanting to grab these new chances in gravure printing ink tech.

Key Players Defining Market Dynamics

-

CHEMICOAT — Italy

-

Flint Group Italia s.r.l — Italy

-

Mac-Mixu Coating and Chemicals — India

-

MITSU Inks Pvt. Ltd. — India

-

Siegwerk Druckfarben AG — Germany

-

Skata Inks Ltd. — India

-

Sun Chemical — USA

-

Technocrafts India Pvt. Ltd. — India

-

VirBandhu Industries — India

-

Worldtex Speciality Chemicals — India

Overall

| Report Metric |

Details |

| Report Name |

Global Gravure Printing Inks Market Report |

| Base Year |

2024 |

| Segment by Type |

· Solvent-Based Inks

· Water-Based Inks |

| Segment by Application |

· Packaging and Labeling Applications

· Food and Beverage Packaging

· Flexible Packaging |

| Geographies Covered |

· North America (United States, Canada)

· Europe (Germany, France, UK, Italy, Russia)

· Asia-Pacific (China, Japan, South Korea, Taiwan)

· Southeast Asia (India)

· Latin America (Mexico, Brazil) |

| Forecast units |

USD million in value |

| Report coverage |

Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The gravure printing inks market is growing fast and full of new ideas. The global commercial printing market is expected to hit $5.82 billion by 2033, growing at 5.1% each year. This means big opportunities for businesses in many places, especially in the United States, China, and Germany.

Investments in green tech and digital printing are making the market bigger. Companies like Quad/Graphics Inc., Toppan Printing Co., Ltd., and Heidelberg Druckmaschinen AG are ready to take advantage of new trends. The demand for packaging, ads, and retail is rising, pushing the market forward.

Sustainability and new tech will set companies apart in the gravure printing inks market. Those using eco-friendly inks, AI, and advanced methods will stand out. The Asia-Pacific area, with its fast growth and big healthcare needs, is a key place for growth in gravure printing ink tech.

As the market changes, businesses need to stay flexible and open to new ideas and green practices. The future of gravure printing inks looks bright, with big chances for impact worldwide in manufacturing, packaging, and special printing.