Headers Wire Housings Market Expected to Exceed $1.95 Billion by 2025: Insights from the U.S., China, and Japan

Headers Wire Housings Market is projected to exceed $1.95 billion by 2025, driven by rising demand in electronics and automotive sectors. Key factors include innovations in materials and design, geopolitical influences on manufacturing, and regional growth in the U.S., China, and Japan. Explore trends, challenges, and future developments shaping the global headers wire housings industry for reliable connectivity solutions.

- Last Updated:

Headers Wire Housings Market Holds Firm Across Electronics Sector in Q1 and Q2 2025

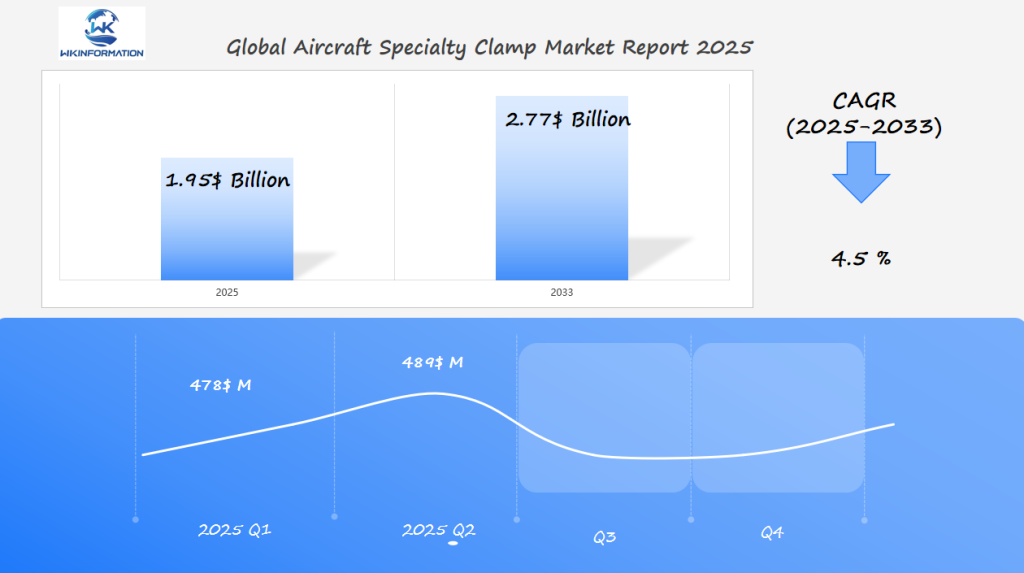

The Headers Wire Housings market is anticipated to reach $1.95 billion in 2025, growing at a CAGR of 4.5% from 2025 to 2033. Q1 2025 revenue was estimated at $478 million, rising to $489 million in Q2, primarily driven by robust demand from consumer electronics, industrial automation, and automotive electronics segments.

In the United States, OEMs and PCB manufacturers saw increased procurement of durable housing components for high-frequency applications. China maintained its lead in high-volume production and exports, while Japan emphasized miniaturization trends in connectors, with Q2 growth stemming from innovation in compact and high-density wire housing formats for automotive electronics and medical devices.

Key Takeaways

- The Headers Wire Housings Market is projected to exceed $1.95 billion by 2025.

- Growing demand from the electronics and automotive sectors is driving market growth.

- Advanced wire housings that can withstand high temperatures are in high demand.

- The U.S. and China are key regions contributing to market expansion.

- Innovative wire housing solutions are crucial for reliable connectivity.

Analysis of Upstream and Downstream Industry Chains in the Headers Wire Housings Market

The Headers Wire Housings market is closely connected to its upstream and downstream industry chains, which are essential for its overall growth and development. The upstream industry chain involves the production of raw materials, while the downstream chain focuses on the application and distribution of Headers Wire Housings.

Upstream Industry Analysis

The upstream industry chain is critical for the production of Headers Wire Housings, as it involves the sourcing and production of raw materials such as plastics and metals. The quality and cost of these materials significantly impact the overall production cost and quality of the final product.

Raw Materials Used in Headers Wire Housings

The primary raw materials used are plastics and metals, which are crucial for the manufacturing process. Plastics offer flexibility and resistance to corrosion, while metals provide strength and durability. The choice of raw material depends on the specific application and requirements of the Headers Wire Housings.

The upstream industry chain is dominated by key players in the raw materials market. Companies that specialize in producing high-quality plastics and metals are crucial for the Headers Wire Housings industry. Their influence on the market is significant, as they determine the availability, quality, and cost of the raw materials.

The industry chain analysis reveals that the Headers Wire Housings market is heavily reliant on the upstream industry for its raw materials. Any fluctuations in the raw materials market can have a direct impact on the production and pricing of Headers Wire Housings.

Trends in Headers Wire Housings for Electronics and Automotive Applications in 2025

Emerging trends in Headers Wire Housings for 2025 are set to revolutionize the electronics and automotive applications. The increasing demand for compact and efficient devices is driving innovation in this sector.

Emerging Trends in Electronics Applications

The electronics industry is experiencing a significant change towards miniaturization, with devices becoming smaller and more complex. Headers Wire Housings are essential in this trend by providing the necessary connectivity solutions.

Increasing Demand for Miniaturization

The demand for miniaturized Headers Wire Housings is increasing due to the growing need for compact electronic devices. This trend is driven by the consumer electronics market, where devices such as smartphones and wearables require smaller, more efficient components.

- Smaller form factors

- Higher density connectors

- Improved thermal management

Manufacturers are responding to this demand by developing innovative Headers Wire Housings that meet the requirements of modern electronic devices.

The trend towards miniaturization is expected to continue in 2025, with Headers Wire Housings playing a vital role in enabling the development of smaller, more efficient electronic devices.

Challenges in the Design and Production of Headers Wire Housings

The wire housings manufacturing process is full of difficulties, from choosing the right materials to testing the final product. Manufacturers have to deal with a complex set of design challenges to create top-notch headers wire housings.

Design Challenges

One of the primary design challenges is ensuring that the wire housings can withstand various environmental conditions while maintaining their structural integrity. This involves careful consideration of factors such as material durability, thermal resistance, and mechanical stress.

Material Selection and Testing

Material selection is a critical aspect of wire housings manufacturing. The chosen material must meet specific industry standards for performance and safety. Manufacturers often conduct rigorous testing to validate their material choices.

The testing process typically involves assessing the material’s properties under different conditions, such as temperature fluctuations, mechanical stress, and exposure to chemicals. Testing protocols may include:

- Thermal cycling tests

- Mechanical stress tests

- Chemical resistance tests

A comparative analysis of different materials used in wire housings manufacturing is shown in the table below:

| Material | Thermal Resistance | Mechanical Strength |

| Plastic | Moderate | Low |

| Metal | High | High |

| Composite | High | Moderate |

Geopolitical Factors Affecting Headers Wire Housings Manufacturing and Distribution

The global Headers Wire Housings market is navigating a complex geopolitical environment that impacts production and supply chains. Geopolitical factors, including trade policies, tariffs, and supply chain disruptions, play a crucial role in shaping the industry.

Impact of Trade Policies on Manufacturing

Trade policies have a significant impact on the Headers Wire Housings market. Tariffs and trade agreements can either facilitate or hinder the growth of the industry. For instance, tariffs imposed on imported raw materials can increase production costs, affecting manufacturers’ profit margins.

Tariffs and Supply Chain Disruptions

Tariffs can lead to supply chain disruptions, affecting the timely delivery of Headers Wire Housings. Supply chain resilience is crucial in mitigating these risks. Companies must adopt strategies such as diversifying their supply chains and investing in local manufacturing to minimize the impact of tariffs.

| Geopolitical Factor | Impact on Manufacturing | Impact on Distribution |

| Tariffs | Increased production costs | Supply chain disruptions |

| Trade Agreements | Reduced production costs | Improved supply chain efficiency |

| Supply Chain Disruptions | Delayed production | Inventory management challenges |

The impact of geopolitical factors on the Headers Wire Housings market is multifaceted. Understanding these factors is crucial for manufacturers and distributors to navigate the complex global landscape effectively.

Type Segmentation: Plastic vs. Metal Headers Wire Housings

The Headers Wire Housings market is divided into two main types: plastic and metal. This division is important as it decides where Headers Wire Housings can be used in different industries.

Characteristics of Plastic Headers Wire Housings

Plastic Headers Wire Housings are known for their lightweight, corrosion resistance, and flexibility in design. They are often used in applications where these characteristics are beneficial.

Advantages and Disadvantages

The advantages of plastic Headers Wire Housings include their low cost, ease of manufacturing, and resistance to corrosion. However, they also have some disadvantages, such as lower thermal stability and lower durability compared to metal counterparts.

A comparison between plastic and metal Headers Wire Housings is essential to understand their respective applications. The following table summarizes their key characteristics:

| Characteristics | Plastic Headers Wire Housings | Metal Headers Wire Housings |

| Cost | Low | High |

| Corrosion Resistance | High | Variable |

| Thermal Stability | Low | High |

| Durability | Low | High |

| Weight | Light | Heavy |

The choice between plastic and metal Headers Wire Housings depends on the specific requirements of the application, including factors such as cost, durability, and environmental conditions.

Applications of Headers Wire Housings in Electronics, Automotive, and Industrial Equipment

Headers Wire Housings are integral components in multiple industries, facilitating connectivity and reliability.

Electronics Applications

In the electronics industry, Headers Wire Housings are used to connect various components and peripherals, ensuring secure and efficient data transfer. They are found in consumer electronics, such as smartphones and laptops, as well as in more complex systems like servers and data storage devices.

The demand for miniaturization and higher performance in electronics has driven the development of Headers Wire Housings with advanced materials and designs. For instance, the use of high-density connectors and wire housings has enabled the creation of smaller, more powerful electronic devices.

Headers Wire Housings in Electronics

| Industry Application Key Requirements Electronics | Consumer Electronics, Servers, Data Storage | Miniaturization, High Performance |

Automotive Applications

In the automotive sector, Headers Wire Housings play a critical role in the reliability and safety of vehicle electrical systems. They are used in various applications, including engine control units, infotainment systems, and advanced driver-assistance systems (ADAS).

The automotive industry’s shift towards electric vehicles (EVs) and autonomous driving has further increased the demand for high-quality Headers Wire Housings that can withstand harsh environments and ensure precise connectivity.

Headers Wire Housings in Automotive

| Industry Application Key Requirements Automotive | Engine Control Units, Infotainment, ADAS | Reliability, Safety, Harsh Environment Resistance |

Industrial Equipment Applications

The use of Headers Wire Housings in industrial equipment is characterized by the need for durability and precision. These components are used in manufacturing machinery and control systems, where they must withstand high temperatures and harsh conditions.

Global Market Overview: Regional Demand and Growth for Headers Wire Housings

As the demand for Headers Wire Housings continues to rise, regional markets are experiencing varied growth patterns. The global market is influenced by factors such as technological advancements, economic conditions, and industry-specific requirements in different regions.

Regional Market Analysis

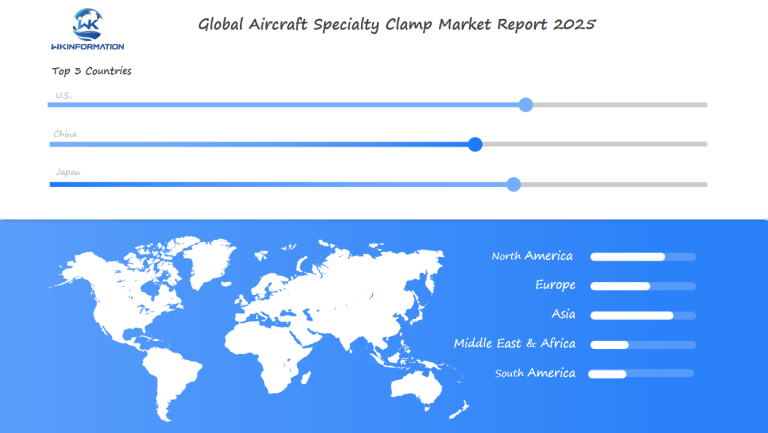

The Headers Wire Housings market is analyzed across key regions including North America, Europe, Asia-Pacific, and the Rest of the World. Each region has its unique market dynamics driven by the presence of major industries such as automotive, electronics, and industrial equipment.

North America

North America is a significant market due to the presence of major automotive and electronics manufacturers. The region is expected to witness steady growth driven by technological advancements and increasing demand for high-quality wire housings.

Europe

Europe follows closely, with a strong emphasis on automotive manufacturing and stringent quality standards. The region’s market growth is influenced by the adoption of innovative technologies and the presence of leading manufacturers.

Asia-Pacific

The Asia-Pacific region is anticipated to exhibit the highest growth rate due to rapid industrialization, increasing automotive production, and expanding electronics manufacturing. Countries like China, Japan, and South Korea are key contributors to this growth.

Growth Prospects

The growth prospects for Headers Wire Housings are promising across these regions, driven by increasing demand from end-use industries.

U.S. Market Insights: Increasing Adoption of Headers Wire Housings in Automotive Manufacturing

Headers Wire Housings are becoming increasingly crucial in the U.S. automotive industry due to their versatility and reliability. The automotive sector’s shift towards more complex electronics and safety features has elevated the demand for high-quality wire housings.

Automotive Industry Trends

The U.S. automotive industry is undergoing significant transformations with the integration of advanced technologies such as electric vehicles (EVs) and autonomous driving systems. These advancements require sophisticated wiring systems, thereby increasing the demand for Headers Wire Housings.

The trend towards vehicle electrification and the incorporation of more electronic components for safety and convenience is driving the need for reliable and durable wire housings. As a result, manufacturers are focusing on producing high-quality Headers Wire Housings that meet the stringent requirements of the automotive industry.

Impact on Headers Wire Housings Demand

The growing adoption of EVs and hybrid vehicles in the U.S. is expected to significantly impact the demand for Headers Wire Housings. These vehicles require more complex wiring systems to support their advanced technologies, thereby driving the demand for wire housings.

Furthermore, the increasing emphasis on vehicle safety and the integration of advanced driver-assistance systems (ADAS) are also contributing to the growing demand for Headers Wire Housings in the U.S. automotive manufacturing sector.

As the automotive industry continues to evolve, the demand for Headers Wire Housings is expected to rise, driven by the need for reliable and efficient wiring solutions.

China’s Role in Headers Wire Housings Production for Electronics and Consumer Goods

China’s manufacturing expertise has made it a top producer of Headers Wire Housings, serving the global electronics and consumer goods industries. This leadership is due to China’s vast manufacturing facilities, skilled workers, and supportive business conditions.

China’s Manufacturing Capabilities

China’s manufacturing capabilities in producing Headers Wire Housings are unparalleled, thanks to its advanced technology, efficient supply chain, and competitive labor costs. The country’s ability to produce high-quality Headers Wire Housings at scale has made it an indispensable part of the global electronics and consumer goods supply chain.

Export Trends

China’s export trends for Headers Wire Housings have shown a steady increase, driven by growing demand from countries like the United States, Germany, and Japan. The data indicates a significant rise in exports over the past few years, with a notable increase in shipments to regions with burgeoning electronics manufacturing industries.

Headers Wire Housings Production in China

China’s manufacturing capabilities and export trends underscore its critical role in the global Headers Wire Housings market. The country’s competitive edge in producing high-quality Headers Wire Housings has made it a preferred supplier for many global electronics and consumer goods manufacturers.

Japan’s Advanced Manufacturing Sector and Demand for High-Quality Wire Housings

Japan is known for its advanced manufacturing technology, which has a significant impact on the global demand for high-quality Wire Housings. The country’s advanced manufacturing industry is known for its focus on precision, reliability, and innovation. This directly affects the need for Wire Housings that not only meet but also exceed international quality standards.

The advanced manufacturing capabilities in Japan are driven by a strong emphasis on research and development, along with a highly skilled workforce. This allows for the production of intricate components, such as Wire Housings, that are utilized in various important applications. The demand for top-notch Wire Housings in Japan is especially prominent in sectors like electronics and automotive manufacturing, where dependability and performance are crucial.

Japan’s Manufacturing Technology

Japan’s manufacturing technology is known for its use of advanced machinery and production methods. This includes innovative materials processing, precise molding techniques, and strict quality control measures. As a result, the production environment in Japan is capable of manufacturing Wire Housings with exceptionally high levels of accuracy and dependability.

Quality Standards

The quality standards in Japan’s manufacturing industry are extremely high, driven by both domestic and international requirements. For Wire Housings, this means following strict guidelines regarding material quality, size accuracy, and durability. Manufacturers in Japan often go above and beyond these standards, further enhancing the reputation of Japanese-made Wire Housings for their excellence.

Key aspects of Japan’s quality standards for Wire Housings include:

- Strict material selection and inspection processes

- Advanced production techniques to ensure dimensional accuracy

- Rigorous testing protocols to verify durability and performance

The focus on quality is a defining characteristic of Japan’s manufacturing industry, and it plays a crucial role in driving the demand for high-quality Wire Housings. As global industries continue to change, Japan’s commitment to excellence in manufacturing is likely to remain an important factor in the worldwide Wire Housings market.

Future Development: Innovations in Materials and Design of Headers Wire Housings

The future of Headers Wire Housings is expected to be influenced by innovations in materials and design. As technology improves, the need for better, longer-lasting, and affordable Headers Wire Housings is pushing research and development in this area.

Emerging Materials and Technologies

New materials and technologies are being developed to enhance the performance and functionality of Headers Wire Housings. Some of the emerging trends include:

- The use of advanced polymers and composites that offer improved thermal resistance and mechanical strength.

- The development of smart materials that can adapt to different environmental conditions.

- The integration of nanotechnology to enhance the electrical and thermal properties of Headers Wire Housings.

Design Innovations

Design innovations are playing a crucial role in the evolution of Headers Wire Housings. Some key design trends include:

- Modular Design: Allowing for greater flexibility and customization.

- Miniaturization: Enabling the development of smaller, more compact electronic devices.

- Improved Connectivity: Enhancing the reliability and efficiency of connections within electronic systems.

These innovations in materials and design are expected to significantly impact the Headers Wire Housings industry, driving growth and development in the coming years.

Competitive Landscape: Leading Manufacturers of Headers Wire Housings

Key Players

- TE Connectivity Ltd. – Switzerland

- Molex LLC (a Koch Industries company) – United States

- Amphenol Corporation – United States

- JST Mfg. Co., Ltd. – Japan

- Hirose Electric Co., Ltd. – Japan

- Phoenix Contact GmbH & Co. KG – Germany

- Harwin Plc – United Kingdom

- 3M Company (Electronic Components Division) – United States

- Samtec Inc. – United States

- Kyocera AVX Components Corporation – United States / Japan

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Headers Wire Housings Market Report |

| Base Year | 2024 |

| Segment by Type | ·Plastic

·Metal |

| Segment by Application | ·Electronics

·Automotive ·Industrial Equipment |

| Geographies Covered | ·North America (United States, Canada)

·Europe (Germany, France, UK, Italy, Russia) ·Asia-Pacific (China, Japan, South Korea, Taiwan) ·Southeast Asia (India) ·Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The Headers Wire Housings market is set for significant growth, driven by increasing demand from the electronics, automotive, and industrial equipment sectors.

The market’s growth is driven by advancements in technology and the increasing demand for high-quality wire housings. Key players in the industry are focusing on innovations in materials and design to meet the changing needs of various applications.

Looking ahead, the Headers Wire Housings market is expected to continue its upward trend, with emerging trends in electronics and automotive applications driving further growth. As manufacturers adapt to changing market dynamics, the demand for headers wire housings is likely to increase, driven by the need for reliable and efficient connectivity solutions.

Global Headers Wire Housings Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Headers Wire Housings Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Headers Wire Housings Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Headers Wire Housings Players and Regional Insights

-

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

-

- Key Differentiators and Strategic Moves

Chapter 3: Headers Wire Housings Market Segmentation Analysis

- Key Data and Visual Insights

-

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

-

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

-

- Historical Data and Growth Forecasts

- Regional Growth Factors

-

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Headers Wire Housings Emerging and Untapped Markets

- Growth Potential in Secondary Regions

-

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Headers Wire Housings Consumer Insights

- Demographics and Buying Behaviors

-

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Headers Wire Housings Market Insights

Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected size of the Headers Wire Housings Market by 2025?

The Headers Wire Housings Market is projected to reach $1.95 billion by 2025.

What are the key drivers of growth in the Headers Wire Housings Market?

The growth is driven by increasing demand from the electronics and automotive sectors, particularly in the U.S. and China.

What are the raw materials used in the production of Headers Wire Housings?

The raw materials used include plastics and metals, which significantly impact the overall production cost and quality of the final product.

What is the trend in the electronics industry regarding Headers Wire Housings?

The electronics industry is driving the demand for miniaturized Headers Wire Housings that can be used in compact devices.

What are the challenges faced by manufacturers in designing and producing Headers Wire Housings?

Manufacturers face challenges including material selection, testing, and ensuring compliance with industry standards.

How do geopolitical factors affect the Headers Wire Housings market?

Geopolitical factors such as trade policies, tariffs, and supply chain disruptions can significantly impact the market.

What are the differences between plastic and metal Headers Wire Housings?

Plastic and metal Headers Wire Housings have different characteristics, advantages, and disadvantages, and are used in different applications.

What are the applications of Headers Wire Housings in various industries?

Headers Wire Housings are used in electronics, automotive, and industrial equipment, with specific requirements and applications in each industry.

Which regions are driving the demand for Headers Wire Housings?

The demand is driven by regional markets, including the U.S., China, and Japan, with varying growth prospects.

What is China’s role in the production of Headers Wire Housings?

China is a major producer of Headers Wire Housings for electronics and consumer goods, with significant manufacturing capabilities and export trends.

What innovations are expected to shape the future of the Headers Wire Housings industry?

Emerging materials and technologies, as well as design innovations, are expected to shape the future of the industry.