2025 Heat Trace Thermostats Market Expansion: Growing to $3.01 Billion with Enhanced Industrial Efficiency in USA, Canada, and Russia

Comprehensive analysis of the global heat trace thermostats market, exploring growth projections, industry trends, technological innovations, and key players. Detailed examination of market dynamics, regional insights, and applications across industrial sectors through 2025.

- Last Updated:

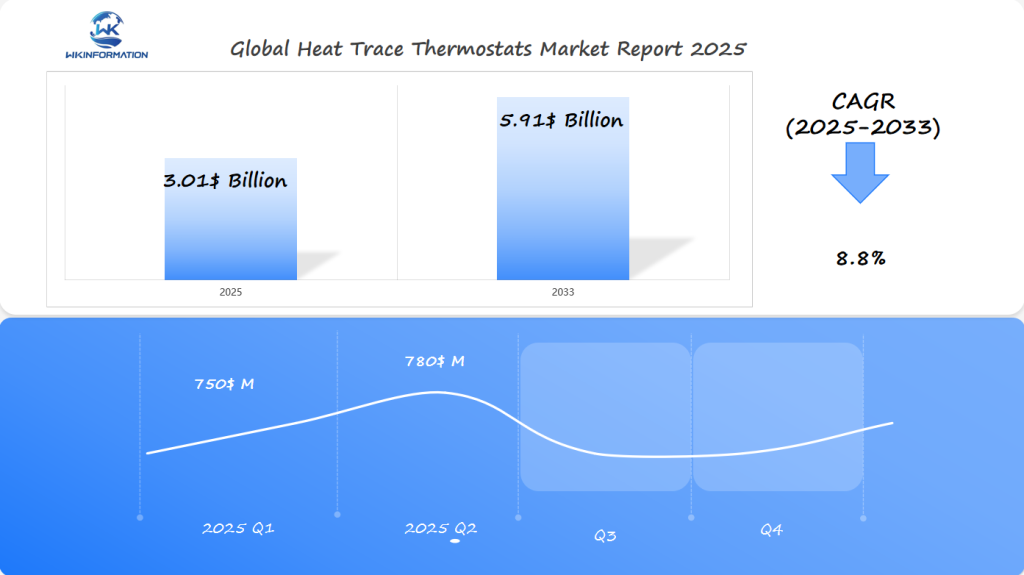

Heat Trace Thermostats Market Q1 and Q2 2025 Predictions

The Heat Trace Thermostats market size in 2025 is projected to be USD 3.01 billion, with a CAGR of 8.8% from 2025 to 2033. In Q1 2025, the market is expected to generate approximately USD 750 million, fueled by increasing applications in industrial heating, infrastructure, and energy efficiency projects. Rising energy costs and the need for temperature control in harsh environments will drive demand for heat trace thermostats in sectors such as oil and gas, construction, and utilities. By Q2 2025, the market is expected to reach around USD 780 million, as advancements in smart thermostat technologies enhance the ability to regulate and monitor heating systems more efficiently.

Market Growth Projections

The market is expected to grow to $3.01 billion by 2025, supported by several key factors:

- Increasing demand for reliable freeze protection in areas with harsh winters.

- Growing use of heat tracing systems in various industrial and residential applications.

- Technological advancements introducing smart features for real-time monitoring and system optimization.

As industries focus more on operational efficiency and sustainability, the adoption of electric heat tracing solutions continues to rise. This growth not only demonstrates the market’s potential but also emphasizes its vital role in supporting modern industrial infrastructures worldwide.

Analyzing the Upstream and Downstream Dynamics of Heat Trace Thermostats

Understanding the supply chain for heat trace thermostats is crucial for grasping the market’s dynamics. Key manufacturers such as nVent Electric plc and Spirax-Sarco Engineering plc play pivotal roles, driving innovation and setting industry standards. These companies are at the forefront, leveraging their expertise to produce high-quality thermostats that meet diverse industrial needs.

Upstream Dynamics: Manufacturing and Raw Material Supply

The manufacturing processes involve sophisticated technologies to ensure precision and reliability. This includes integrating smart features for real-time monitoring and enhanced performance. Suppliers of raw materials, such as semiconductor components and advanced polymers, are integral to maintaining production efficiency and quality standards.

Downstream Dynamics: Distribution and Logistics

Distribution channels are equally vital in facilitating market expansion. They serve as the bridge between manufacturers and end-users, ensuring that products reach various industries like power generation, oil & gas, and chemical processing efficiently. Distributors employ strategic partnerships to penetrate new markets and enhance product availability.

In terms of logistics, regional distribution centers help optimize delivery times and reduce costs. These channels not only support existing markets but also enable entry into emerging regions by aligning with local regulations and customer preferences. The interplay between these upstream and downstream elements is essential for sustaining growth in the heat trace thermostats market.

Key Trends in the Heat Trace Thermostats Industry

The heat trace thermostats market is undergoing significant changes, mainly driven by the adoption of smart technologies. These advancements are reshaping product development, allowing for real-time monitoring and control capabilities that improve system efficiency. Smart thermostats have the ability to automatically adjust settings based on environmental conditions, resulting in reduced energy consumption and optimized performance.

Energy Efficiency as a Priority

Energy efficiency has become a primary focus for modern heat tracing systems. The push for more sustainable solutions is being driven by regulatory pressures and the demand from industries looking to lower operational costs. By enhancing energy efficiency, these systems not only minimize their impact on the environment but also provide cost savings through decreased energy usage.

Emerging Trends in the Industry

The following trends are currently emerging in the heat trace thermostats industry:

- Smart Technology Integration: Innovations such as IoT-enabled devices are offering improved data analytics and predictive maintenance capabilities.

- Energy Efficiency Initiatives: New materials and designs are being developed with the goal of maximizing thermal performance while minimizing energy wastage.

These trends signify a shift towards more intelligent and sustainable heating solutions that meet both industrial requirements and environmental considerations. As smart technologies continue to advance, their influence on the heat trace thermostats market is expected to grow, creating new opportunities for expansion and progress within this sector.

Overcoming Challenges in Heat Trace Thermostat Design and Application

Designing heat trace thermostats involves navigating a complex landscape of installation issues and safety risks. Engineers often encounter difficulties when installing these systems, particularly on large tanks and vessels. The complexity of ensuring proper coverage without overlaps can lead to uneven heat distribution, posing significant safety concerns.

To address these challenges, several strategies have been developed.

- Advanced Design Software: Utilizing sophisticated design software can help engineers model installations more accurately, reducing the risk of overlapping cables.

- Innovative Materials: Employing new materials that offer better thermal conductivity and flexibility can minimize installation complexities.

- Smart Monitoring Systems: Incorporating smart technology allows for real-time monitoring, enabling quick identification and correction of hot spots or uneven heating.

These solutions not only enhance the Heat Trace Thermostats Market by improving safety and efficiency but also drive innovation in system design and application across various industries. As these improvements continue to evolve, they play a crucial role in overcoming the inherent challenges of heat trace thermostat development.

Geopolitical Impact on Heat Trace Thermostat Demand in Cold Regions

Geopolitical factors significantly shape the demand for heat trace thermostats, especially in regions characterized by harsh climates such as North America and Russia. Trade agreements and political stability play crucial roles in determining market dynamics.

1. Trade Agreements

These can either facilitate or hinder the import and export of heat trace technologies. Favorable trade policies between countries often result in reduced tariffs, encouraging cross-border collaborations and boosting the supply chain efficiency of heat trace products. For instance, agreements between Canada and the USA contribute to a seamless exchange of technologies, enhancing market growth.

2. Political Stability

A stable political environment typically fosters a conducive business atmosphere, encouraging investment in industrial infrastructure where heat trace systems are critical. In contrast, political instability can deter investments and disrupt supply chains, impacting the availability and adoption of heat tracing solutions.

The regional demand is also driven by cold climate applications, where reliable freeze protection is crucial. Countries like Russia experience extreme winters, necessitating robust heat tracing systems to maintain operational efficiency across various sectors such as oil & gas and residential heating. This geographical necessity ensures that geopolitical conditions directly influence how markets prioritize and implement these technologies across industries.

Market Segmentation: Types of Heat Trace Thermostats and Their Applications

Market Segmentation in the heat trace thermostat industry reveals a diverse range of products tailored to various needs. Two primary types dominate the market: self-regulating thermostats and constant wattage thermostats.

Types of Heat Trace Thermostats

1. Self-Regulating Thermostats

These adjust their output based on ambient temperature changes. Ideal for applications requiring precise temperature control, they offer energy efficiency by reducing power consumption when less heat is needed.

2. Constant Wattage Thermostats

These provide a consistent heat output regardless of temperature fluctuations. Often used in environments where stable heating is crucial.

Applications of Heat Trace Thermostats

In terms of applications, these thermostats find widespread use across multiple industries:

- Oil and Gas: Ensuring pipelines and storage tanks remain operational during extreme cold.

- Chemical Processing: Critical for maintaining consistent temperatures in chemical reactions.

- Food and Beverage: Used for process heating to maintain product quality and safety.

- Residential Applications: Deployed in underfloor heating systems to enhance home comfort.

With their varied functionalities, heat trace thermostats play an essential role in enhancing industrial efficiency across these sectors, serving both specific and broad heating requirements effectively.

The Role of Heat Trace Thermostats in Industrial Heating and Protection

Heat trace thermostats are crucial in industrial heating solutions, providing accurate temperature control necessary for efficient operations. Their capability to sustain steady temperatures is critical, especially in industries where even minor fluctuations can result in significant operational inefficiencies or safety risks.

Key Applications of Heat Trace Thermostats

Some of the primary uses of heat trace thermostats include:

- Freeze protection systems: In areas with severe winters, it is essential to prevent pipes and other industrial equipment from freezing. Heat trace thermostats manage the temperature, ensuring uninterrupted operation even in extremely cold conditions.

- De-icing: These thermostats are vital in de-icing applications, stopping the buildup of ice that can disrupt and harm infrastructure.

By effectively controlling heat distribution, these devices improve system dependability and lifespan. With the emergence of smart technology, contemporary heat trace systems now provide real-time monitoring features, further enhancing their efficiency and effectiveness. As industries continue to pursue energy-efficient options, the need for advanced heat trace thermostats in industrial environments is expected to increase, fostering further innovation in this area.

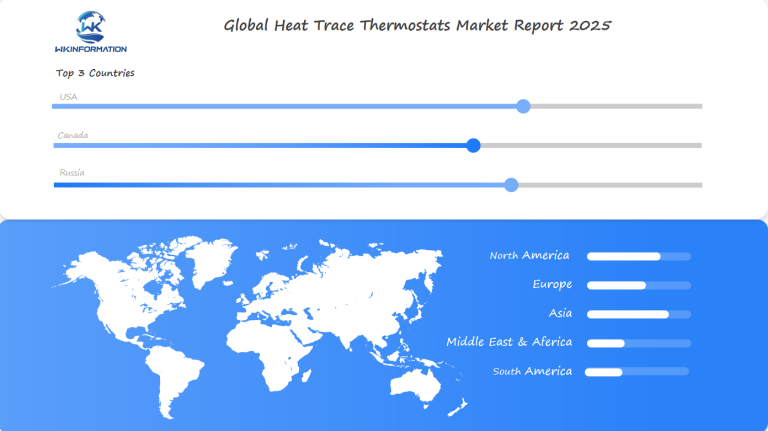

Regional Insights: Heat Trace Thermostat Market Growth Worldwide

The heat trace thermostat market is experiencing different growth trends in various regions, each contributing in its own way to the global picture. Regional analysis shows significant developments in North America, Europe, and Asia-Pacific.

1. North America

This region holds a substantial share of the market, driven by modernization in infrastructure and increased activities in the oil and gas sector. The demand for reliable freeze protection solutions during harsh winters further fuels this growth. Countries like the USA and Canada are at the forefront, using advanced technologies to improve industrial efficiency.

2. Europe

Known for its strict rules on energy efficiency, Europe is increasingly adopting smart heat trace systems. This shift is supported by government initiatives promoting sustainable practices, with countries like Germany and France leading the way. The integration of innovative technologies ensures compliance with environmental standards while optimizing industrial operations.

3. Asia-Pacific

Rapid industrialization and urbanization are defining features of this region’s market dynamics. Countries such as China and India are investing heavily in infrastructure projects that require efficient heating solutions. The growing need for precise temperature control in various applications drives the adoption of heat trace thermostats.

These regional differences highlight the global market’s growth path, showing a combination of technological progress and changing industry needs across continents.

The USA’s Market for Heat Trace Thermostats in Industrial Applications

In the United States, the demand for heat trace thermostats is driven by the need for advanced industrial heating solutions across various sectors. Industries such as oil and gas, chemical processing, and power generation rely heavily on these systems to maintain optimal temperatures, preventing costly downtimes and ensuring safety.

Key Factors Contributing to the Demand for Heat Trace Thermostats

Several key factors are contributing to the increasing demand for heat trace thermostats in industrial applications:

- Infrastructure Modernization: Continuous updates and upgrades in infrastructure demand efficient heating solutions. Heat trace thermostats are crucial for maintaining precise temperature control in pipelines and storage tanks.

- Energy Efficiency Requirements: Stricter regulations and a growing emphasis on energy conservation push industries towards adopting heat trace systems for their ability to reduce energy consumption compared to traditional methods.

- Technological Advancements: Integration of smart technologies allows real-time monitoring and control, enhancing operational efficiency. This capability is particularly valued in sectors requiring stringent temperature management.

Leading Companies in the Heat Trace Thermostat Market

Leading companies like nVent Electric plc and Thermon Group Holding Inc. play a pivotal role in advancing the market by offering innovative products tailored to meet these evolving industrial needs. Their strategies often include partnerships and collaborations aimed at expanding their reach within the U.S. market, addressing both current demands and future growth opportunities.

Canada’s Contribution to Heat Trace Thermostat Technologies

Canada has become a key player in the development of heat trace thermostat technologies. Its unique geography and harsh winter conditions create a high demand for dependable heat tracing systems. In response, Canadian companies are innovating and improving technologies to boost energy efficiency and system reliability.

1. Innovation Hubs

Cities like Toronto and Vancouver are becoming innovation hubs, fostering collaborations between tech startups and established engineering firms. This synergy accelerates the development of cutting-edge solutions tailored to the unique challenges posed by extreme cold.

2. Energy Efficiency Focus

Canadian firms prioritize energy-efficient designs, integrating smart technology to optimize performance. These enhancements not only reduce operational costs but also support Canada’s commitment to sustainable energy practices.

3. Industry Applications

Key sectors such as oil and gas, petrochemicals, and power generation heavily rely on advanced heat tracing solutions. This demand drives continuous improvement and adaptation of heat trace thermostats to meet industry-specific needs.

4. Government Support

The Canadian government plays a supportive role by providing incentives for research and development in green technologies, encouraging further advancements in this field.

The combination of innovation, industry demand, and governmental backing positions Canada as a leader in evolving heat trace thermostat technologies.

Russia’s Growing Demand for Heat Trace Thermostats in Extreme Cold Areas

Russia’s large and extremely cold regions face specific challenges that make heat trace thermostats necessary. These thermostats are crucial for preventing freezing and ensuring smooth operations, particularly in important industries like oil and gas exploration that significantly contribute to the country’s economy.

1. Energy Efficiency is Critical

In a country where winter temperatures can drop drastically, it’s essential to maintain energy efficiency. Heat trace thermostats provide accurate temperature control, keeping pipelines and industrial components from freezing while minimizing energy consumption.

2. Industries Require Reliable Solutions

Russia heavily depends on industries such as petrochemicals and mining, which increases the demand for advanced heat tracing solutions. These sectors need strong systems that can work flawlessly in severe climates, making heat trace thermostats essential.

3. Influence of Geopolitical Factors

The geopolitical situation also affects the demand for heat trace thermostats. Economic sanctions and trade dynamics impact the availability of technology and components, leading to domestic innovation and adaptation in Russia’s industrial sectors.

As technology continues to improve, we can expect even smarter and more flexible heat trace thermostats designed specifically for these harsh environments. With Russia’s ongoing efforts to tap into its vast natural resources, the market for these critical devices is set to grow steadily, ensuring industrial efficiency even in tough conditions.

Innovations in Heat Trace Thermostats for Improved Energy Efficiency

Recent technological advancements have significantly boosted the energy efficiency of heat trace thermostats. The integration of smart technology is at the forefront, enabling real-time monitoring and control, which minimizes energy wastage and optimizes performance.

Key innovations include:

- Smart Thermostats: These devices offer enhanced precision in maintaining desired temperature levels by adjusting power output based on ambient conditions. This results in reduced energy consumption and improved system longevity.

- Advanced Materials: Utilizing high-quality insulation materials has led to better thermal retention, reducing the need for continuous heating and thus conserving energy.

- IoT Integration: Internet of Things (IoT) capabilities allow for seamless connectivity and remote management of heat trace systems, offering insights into system performance and enabling predictive maintenance.

Looking ahead, there’s potential for further development in this space. The industry is moving towards more sustainable solutions with a focus on reducing carbon footprints. Continued innovation could lead to even more effective energy-efficient systems, ensuring compliance with rigorous environmental standards while meeting industrial demands.

These advancements not only promise cost savings but also support global sustainability efforts, marking a significant stride in the evolution of heat trace technologies.

Key Competitors in the Heat Trace Thermostat Market

Several key players have emerged as leaders in the heat trace thermostats market due to their innovative approaches and strategic initiatives.

-

Ascon Tecnologic – Italy

-

Chromalox – United States

-

Danfoss – Denmark

-

Drexan – Canada

-

Emerson – United States

-

ESH Trace Heating – United Kingdom

-

Heat Trace Limited – United Kingdom

-

Heat Trace Specialists – United States

-

Heat-Line – Canada

-

HTD Heat Trace – United States

-

Raychem (part of TE Connectivity) – United States

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Heat Trace Thermostats Market Report |

| Base Year | 2024 |

| Segment by Type | · Heat Trace Digital Thermostats · Heat Trace Mechanical Thermostats · Others |

| Segment by Application | · Commercial Building · Industry · Residential · Others |

| Geographies Covered |

· North America(United States,Canada) · Europe(Germany,France,UK,Italy,Russia) · Asia-Pacific(China,Japan,South Korea,Taiwan) · Southeast Asia(India) · Latin America(Mexico,Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast,company share,competitive landscape,growth factors and trends |

The future outlook for the heat trace thermostats market is promising, with projections indicating significant growth and innovation opportunities by 2025. As the demand for energy-efficient heating solutions continues to rise, the market is poised to expand significantly across key regions such as the USA, Canada, and Russia.

Key Factors Driving Market Growth

Several factors are expected to drive the growth of the heat trace thermostats market in the coming years:

- Market Potential: The transition from traditional steam tracing to more efficient electric heat tracing systems will drive market expansion. The integration of smart technology enhances temperature control and operational efficiency, presenting lucrative opportunities for businesses in this sector.

- Growth Opportunities: In North America, modernization efforts and exploration activities within the oil and gas industry create a fertile ground for market expansion. Similarly, Russia’s harsh climate conditions ensure a consistent demand for reliable freeze protection solutions.

- Innovation Drivers: The focus on developing smarter, more efficient heat trace thermostats will likely accelerate technological advancements. Real-time monitoring capabilities and improved safety features are expected to become standard offerings, enhancing product appeal and functionality.

Importance of Anticipating Future Developments

Anticipating future developments requires a keen eye on evolving technologies and shifting industry demands. Investing in research and development will be crucial for companies aiming to capitalize on these growth opportunities and establish a strong foothold in the expanding heat trace thermostats market.

Global Heat Trace Thermostats Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Heat Trace Thermostats Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Heat Trace ThermostatsMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Heat Trace Thermostatsplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Heat Trace Thermostats Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Heat Trace Thermostats Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Heat Trace Thermostats Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofHeat Trace Thermostats Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected growth of the heat trace thermostats market by 2025?

The heat trace thermostats market is expected to expand significantly, with projections indicating a growth to $3.01 billion by 2025.

What are the key trends influencing the heat trace thermostats market?

Current trends in the heat trace thermostats market include the integration of smart technologies and a growing emphasis on energy efficiency in modern heat tracing systems.

What challenges do engineers face when designing heat trace thermostats?

Engineers encounter several challenges in designing heat trace thermostats, including installation difficulties, safety risks associated with uneven heat distribution, and design complexities.

How do geopolitical factors impact the demand for heat trace thermostats in cold regions?

Geopolitical situations, such as trade agreements and political stability, significantly influence market demand for heat trace thermostats, particularly in cold regions like North America and Russia.

What types of heat trace thermostats are available and what are their applications?

The market offers various types of heat trace thermostats, including self-regulating and constant wattage variants. These thermostats are commonly used across multiple industries for applications such as freeze protection and de-icing.

Who are the key competitors in the heat trace thermostat market?

Key players in the heat trace thermostat market include nVent Electric plc and Spirax-Sarco Engineering plc. Their strategies play a crucial role in maintaining their leadership positions within the industry.