$5.37 Billion High Purity Alumina Beads Market Set to Soar in Japan, the U.S., and China by 2025

Discover key growth drivers and market trends shaping the High Purity Alumina Beads Market across Japan, the U.S., and China. Explore opportunities and industry insights through 2025.

- Last Updated:

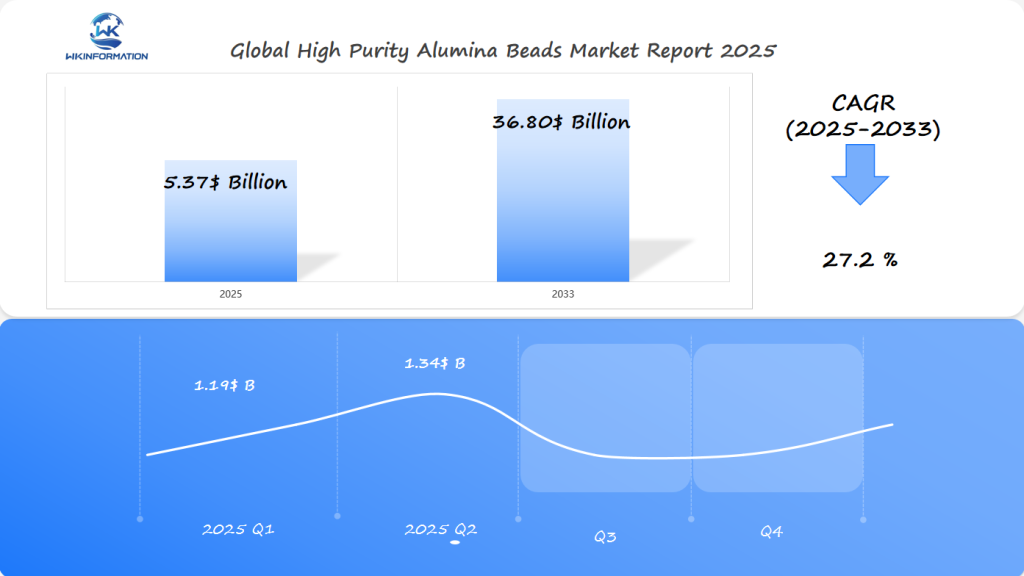

Projected Market Insights for High Purity Alumina Beads in Q1 and Q2 of 2025

The High Purity Alumina Beads market is expected to reach $5.37 billion in 2025, with an impressive CAGR of 27.2% from 2025 to 2033.

Q1 Projections

In Q1, the market is projected to generate approximately $1.19 billion, driven by rising demand in:

- lithium-ion battery separators

- high-performance ceramics

- precision grinding applications

Q2 Projections

By Q2, the market is expected to grow to around $1.34 billion, as industries continue to shift towards advanced materials with superior thermal and mechanical properties.

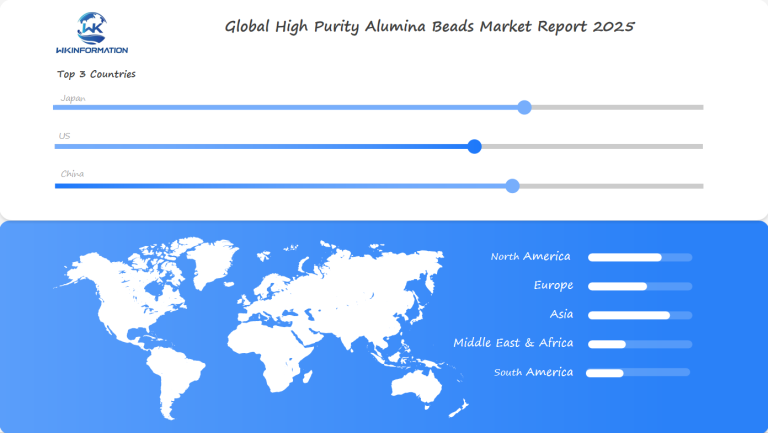

Key Markets

Japan, the U.S., and China are expected to be key markets:

- Japan’s expertise in high-tech ceramics production

- The U.S.’s demand from semiconductor and energy storage sectors

- China’s growing manufacturing base

These factors contribute to strong market expansion.

With the increasing need for high-purity materials in emerging technologies, the demand for alumina beads is set to rise significantly in the coming years.

Understanding the Upstream and Downstream Industry Chains for High Purity Alumina Beads

The alumina production supply chain is complex. It turns raw materials into high-performance products. Manufacturers of high purity alumina beads use advanced technology to make top-notch ceramic products.

Raw Material Sourcing and Processing

High purity alumina beads come from selected bauxite and aluminum oxide. The process includes several key steps:

- Bauxite ore selection with minimal impurities

- Advanced chemical refinement techniques

- High-temperature calcination processes

- Precision grinding and classification

Manufacturing Techniques and Quality Control

Advanced manufacturing methods ensure high-quality alumina beads. Quality control is strict. Manufacturers use the latest technologies to meet high standards.

| Parameter | Specification | Tolerance |

| Purity | ≥ 99.5% Al₂O₃ | ±0.1% |

| Density | 3.6-3.9 g/cm³ | ±0.05 g/cm³ |

| Hardness | Mohs 9 | Standard |

Distribution Channels and End-User Industries

High purity alumina beads have many uses. They are used in electronics, ceramics, and advanced materials. The main ways to get them are:

- Direct manufacturer sales

- Specialized industrial distributors

- Online procurement platforms

- Strategic partnership networks

The supply chain works well when raw materials, manufacturing, and use are all connected smoothly.

Key Trends in the High Purity Alumina Beads Market

The high purity alumina beads market is changing fast. New technologies and changing needs are driving these changes. Companies are finding new ways to make these beads and using them in new ways.

Technological Advancements in Production

New technology is transforming the production of high purity alumina beads. With these advancements, companies now have the capability to produce up to 360,000 tons annually. Henan Superior Abrasives (HSA) is at the forefront of this transformation, making significant progress in various areas:

- Improved purification processes that achieve 99% Al2O3 purity

- Innovative manufacturing techniques that enhance product consistency

- Tailored solutions for specific industrial applications

Emerging Applications Driving Demand

More and more industries are using high purity alumina beads. They are key in:

- Manufacturing electronic components

- Creating high-frequency insulation ceramics

- Producing refractory materials

- Developing wear-resistant ceramics

Sustainability and Environmental Considerations

Making these beads in an environmentally friendly way is very important, especially in Japan. Companies are using less energy to produce these beads, which benefits the planet and maintains high quality. This shift towards eco-friendly manufacturing is a significant change in the market.

The future of high purity alumina beads depends on finding a balance between technological innovation and sustainable production methods.

Challenges in Producing High Purity Alumina Beads

Making high purity alumina beads is tough. It involves technical, economic, and regulatory hurdles. Companies must find ways to meet high standards while keeping costs down.

Getting high purity levels is a big challenge. It needs advanced manufacturing methods. The main issues are:

- Maintaining 92%+ purity levels in alumina beads

- Ensuring consistent performance in extreme environments

- Managing complex manufacturing processes

- Controlling production costs

Technical Challenges in Achieving High Purity Levels

Producing high purity alumina beads is very technical. It requires precise engineering and new technologies. This is to meet strict quality standards.

| Challenge | Impact | Solution Approach |

| Purity Consistency | Rockwell Hardness HRA85-90 | Advanced filtration techniques |

| Temperature Resistance | High-pressure environments | Specialized ceramic processing |

| Wear Resistance | Ceramic liner applications | Precision manufacturing |

Cost Considerations and Economic Viability

The cost of producing high purity alumina beads is a significant concern. The market is experiencing rapid growth, with a compound annual growth rate (CAGR) of 13.1%. Companies need to find ways to keep costs down while also fulfilling the increasing demand.

Regulatory Compliance and Quality Standards

Quality standards are very strict. Companies like SINOCATA and Saint-Gobain spend a lot to meet these standards. They focus on quality control.

The complexity of producing high purity alumina beads requires constant innovation and technological progress.

Geopolitical Factors Affecting High Purity Alumina Beads Demand

The global trade for high purity alumina beads is influenced by complex geopolitical factors. These factors greatly affect market access and how production is done. Regional markets and government policies are key in shaping the industry’s success.

Several important geopolitical elements shape the high purity alumina beads market:

- Intricate trade negotiations between major manufacturing countries

- Shifting government policies affecting industrial production

- Emerging regional manufacturing hubs

- International technology transfer restrictions

Trade Policies and International Relations

Global trade dynamics pose challenges for high purity alumina beads makers. Countries like Japan, the United States, and China are working to lead the market. Bilateral trade agreements and diplomatic ties affect production and market entry.

Regional Manufacturing Hubs and Market Access

Important regional markets are becoming centers for specialized manufacturing. This attracts global investments. By focusing in certain areas, companies can use local resources and skilled workers better.

Government Initiatives and Support

Government policies are crucial for the high purity alumina beads market. They include funding for research, tax breaks, and rules that boost innovation and growth.

The future of high purity alumina beads production will be shaped by the combination of geopolitical strategies and industrial development.

Market Segmentation: Types and Applications of High Purity Alumina Beads

The high purity alumina beads market is complex, with many specialized products and uses. Knowing the different types and uses helps us understand this advanced materials field better.

Classification Based on Purity Levels

High purity alumina beads are sorted by their purity levels. This purity affects how well they work in various industries. The main groups are:

- 99.5% Purity Level: Great for making semiconductors

- 99.9% Purity Level: Best for LEDs and optics

- 99.99% Purity Level: Essential for advanced ceramics

Size-based Segmentation and Its Implications

The size of high purity alumina beads is key to their function. Different sizes have unique benefits for different uses.

| Particle Size Range Primary Applications Market Segment 0.1-1 mm | Catalyst Processing | Oil & Gas Industry |

| 1-3 mm | Water Treatment | Environmental Technologies |

| 3-5 mm | Ceramic Manufacturing | Advanced Materials |

Application-specific Variants and Their Market Share

High purity alumina beads are used in many fields. Key areas include:

- Electronics: Making semiconductor substrates and LEDs

- Industrial Processes: Supporting catalysts and making refractories

- Healthcare: Creating biomedical ceramics and precise equipment

Research shows growth in places like Japan, the United States, and China. These areas are pushing for new material solutions.

High Purity Alumina Beads in Electronics and Industrial Applications

High purity alumina beads are key in advanced tech fields. They link new manufacturing steps across many industries. Their special features make them vital in complex electronic and industrial uses.

The semiconductor world heavily uses these ceramic beads for top-notch parts. These materials are crucial for making parts that need extreme purity and uniformity.

Role in Semiconductor Manufacturing

In making semiconductors, high purity alumina beads offer big benefits:

- They help make ultra-precise ceramic powders.

- They support making advanced multilayer capacitors.

- They help create new substrates.

Usage in LED Production and Optics

LED making gets a big boost from high purity alumina beads. These materials help improve light quality and precision in new lighting tech.

| Application Area | Key Contribution | Market Impact |

| Semiconductor Substrates | High-precision ceramic powders | Critical for advanced electronics |

| LED Production | Optical performance enhancement | Improved lighting efficiency |

Applications in Industrial Catalysts

Industrial catalysts are another area where high purity alumina beads shine. They help in chemical processing, making it more efficient and green.

The Asia-Pacific area leads in demand, with 45-50% of global use. This is due to its strong electronics and chemical sectors. North America is growing fast, thanks to more research in pharma and electric car batteries.

Global Performance of the High Purity Alumina Beads Market

The global high purity alumina beads market is growing fast. This is thanks to new technologies and more uses in industry. Market research shows big chances for growth in many areas and countries.

Studies show the market for high purity alumina beads is looking up. Companies are seeing more demand from the semiconductor, electronics, and advanced materials fields.

Regional Market Shares and Growth Rates

Some regions are really showing promise:

- Asia-Pacific: Leading with fast tech progress

- North America: Strong in semiconductors and electronics

- Europe: Investing more in green tech

Competitive Landscape

The high purity alumina beads market is competitive, with a focus on partnerships and new technology. Leading companies are actively engaged in:

- Research and development

- Expanding their product lines

- Growing their presence worldwide

Market Forecasts and Future Projections

Experts predict big growth ahead. The global high purity alumina beads market is set to grow at 27.2% CAGR by 2033.

| Region | Market Share | Projected CAGR |

| Asia-Pacific | 42% | 8.2% |

| North America | 28% | 7.5% |

| Europe | 20% | 6.9% |

| Rest of World | 10% | 6.5% |

New tech and more demand in precise industries will keep the market growing.

Japan's Role in High Purity Alumina Beads Market Growth

The Japanese market is a key player in the high purity alumina beads industry. It drives innovation and sets global standards for advanced materials. Japan’s strong manufacturing base and research efforts are changing the advanced ceramic technology scene.

- Cutting-edge research and development capabilities

- Commitment to precision manufacturing

- Strong focus on sustainable production techniques

Technological Leadership and Innovation

Companies like Toray Industries and Tosoh Corporation are leading the way. They have created advanced alumina beads that outperform others in the market. Through their significant investments in research and production, these companies have been able to capture a large portion of the market.

Domestic Market Dynamics and Export Potential

The export of Japanese high purity alumina beads is growing rapidly. Known for their quality and precision, Japanese manufacturers are expanding their reach to more markets. They are making a significant impact in the semiconductor, electronics, and advanced materials industries.

Collaborations and R&D Initiatives

Partnerships between Japanese research groups and manufacturers are boosting innovation. These collaborations aim to improve efficiency, reduce environmental harm, and create new alumina bead technologies.

Japan’s dedication to excellence keeps it at the top in advanced material innovations.

U.S. Market Dynamics for High Purity Alumina Beads

The United States is at the forefront of innovation in high purity alumina beads, which has resulted in a significant demand across various advanced technology sectors. Recent market trends indicate the growing importance of these materials in high-quality manufacturing and research activities.

Demand Drivers in Key Industries

US market trends show strong growth in key industries using high purity alumina beads:

- Semiconductor manufacturing

- Advanced electronics production

- Aerospace engineering

- Medical device development

Regulatory Environment and Its Impact

The rules for high purity alumina beads are getting stricter. Federal agencies are setting tough quality control standards. These rules help keep products safe and consistent in important tech fields.

Technological Advancements and Market Trends

New technology is transforming the world of high purity alumina beads. Nanotechnology research and precise manufacturing techniques are creating new opportunities for applications. This presents an opportunity for US manufacturers to become global leaders in the industry.

The U.S. remains a key player in high purity alumina beads tech, setting global standards.

China's Leading Role in High Purity Alumina Beads Production

China has become a major player in the high purity alumina beads market, showcasing top-notch manufacturing skills and a strong global presence. The country’s robust manufacturing sector is crucial in producing advanced materials.

Chinese manufacturers have several strengths that make them competitive worldwide:

- They produce 120,000 tons of high purity alumina beads every year.

- Their products are used in various industries.

- They employ advanced methods to meet international quality standards.

Manufacturing Capacity and Scale Advantages

China’s large manufacturing setup gives it a significant advantage. It produces 360,000 tons of aluminum hydroxide and related products annually, making it the world leader in this industry.

In addition, China also manufactures high-purity mesoporous alumina with an impressive purity level of 99.9661%.

Government Support and Industrial Policies

Government policies play a crucial role in supporting China’s high purity alumina beads industry. These policies assist manufacturers in enhancing their processes by implementing innovative methods such as direct aging and ammonium salt substitution.

Export Strategies and Global Market Impact

China’s export plans have helped it reach more markets. It sends high purity alumina beads to places like Korea, Japan, and Vietnam. China has over 55% of the market share, shaping the global market.

Future Outlook for High Purity Alumina Beads Market

The high purity alumina beads market is at a turning point. New technologies and environmentally friendly practices are changing its direction. These ceramic components are becoming essential for innovative manufacturing processes.

Emerging Technologies and Potential Impact

New tech is opening up new uses for high purity alumina beads. The semiconductor field is especially exciting. These beads are vital for:

- Wafer handling processes

- High-temperature manufacturing techniques

- Precision etching applications

- Advanced packaging technologies

Shifts in Global Demand Patterns

Experts predict big growth for high purity alumina beads. The global activated alumina market is set to grow from USD 5.37 billion in 2025 to USD 36.8 billion by 2033. This is a strong CAGR of 27.2%.

| Region | Market Contribution | Key Focus Areas |

| Japan | Technological Innovation | Advanced Manufacturing |

| United States | Semiconductor Applications | High-Tech Industries |

| China | Industrial Scale Production | Economic Growth |

Sustainability and Circular Economy Considerations

Green practices are key in the high purity alumina beads market. Makers are working on environmentally conscious production methods. This is to cut down waste and use resources better. These changes are due to stricter environmental laws and people wanting greener tech.

The next high purity alumina beads will focus on better heat transfer, strength, and less harm to the environment. They will be crucial for future tech.

Competitive Forces in the High Purity Alumina Beads Industry

The high purity alumina beads market is very competitive. This is due to strategic market strategies and global manufacturing dynamics. Companies like Toray Industries Inc. and Tosoh Corporation from Japan lead the market. They have a big share of revenue thanks to their advanced research and strong production.

- Integra LifeSciences – USA

- Aesculap AG – Germany

- Biomet – USA

- Conmed Corporation – USA

- Medtronic – USA

- Terumo Corporation – Japan

- Stryker Corporation – USA

- Zimmer Biomet Holdings Inc. – USA

- B. Braun Melsungen AG – Germany

- Orthofix Medical Inc. – USA

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global High Purity Alumina Beads Market Report |

| Base Year | 2024 |

| Segment by Type |

· 99.5% Purity Level · 99.9% Purity Level · 99.99% Purity Level |

| Segment by Application |

· Electronics · Industrial Processes · Healthcare |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The High Purity Alumina Beads Market demonstrates remarkable growth potential, driven by advancements in electronics, renewable energy, and healthcare applications. Segmentation insights reveal the diverse roles of spherical and non-spherical beads across industries, while competitive dynamics highlight the influence of key players and their innovative strategies. Future projections emphasize sustained expansion, supported by investments in R&D and eco-friendly technologies. Businesses can leverage these insights to navigate challenges, optimize supply chains, and capitalize on emerging opportunities. Strategic planning, guided by market data, ensures informed decision-making and positions stakeholders for long-term success.

Global High Purity Alumina Beads Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: High Purity Alumina Beads Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Vacuum Arc RemeltingMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global High Purity Alumina Beadsplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: High Purity Alumina Beads Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: High Purity Alumina Beads Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: High Purity Alumina Beads Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofHigh Purity Alumina Beads Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

Which industries primarily use high purity alumina beads?

High purity alumina beads are essential in various industries, such as:

- Semiconductor manufacturing

- LED production

- Optics

- Electronics

- Ceramics

- Catalyst applications

They play a critical role in advanced technologies and industrial processes.

How do production challenges impact the high purity alumina beads market?

Manufacturers face big hurdles like keeping purity levels high, controlling costs, and meeting strict standards. These issues vary by region. They need constant innovation and quality control to overcome these challenges.

Which countries are leading in high purity alumina beads production?

Japan, the United States, and China are the top producers of high purity alumina beads. Japan is known for its technological innovation, the U.S. specializes in industrial applications, and China has a strong focus on large-scale manufacturing.

What technological trends are influencing the high purity alumina beads market?

Trends influencing the high purity alumina beads market include:

- Improved production efficiency

- Innovative manufacturing techniques

- Applications in renewable energy and advanced electronics

- Emphasis on sustainable production practices

How are geopolitical factors affecting the high purity alumina beads market?

Geopolitical factors such as trade policies, international relations, and regional strategies have a significant impact on the high purity alumina beads market. These factors influence the flow of goods, investment opportunities, and market access for manufacturers and suppliers.

Additionally, government support for technology, innovation, and exports plays a crucial role in shaping the global market for high purity alumina beads. Policies that promote research and development, as well as financial incentives for companies involved in production and distribution, can create a favorable environment for growth in this industry.

Overall, understanding the geopolitical landscape is essential for businesses operating in the high purity alumina beads market. By staying informed about trade agreements, political developments, and government initiatives, companies can make strategic decisions that align with global trends and capitalize on emerging opportunities.

What are the key applications of high purity alumina beads in electronics?

In electronics, high purity alumina beads are used for:

- Semiconductors

- LEDs (Light Emitting Diodes)

- Optical components

- Manufacturing advanced electronic components

What is driving the growth of the high purity alumina beads market?

Growth is being driven by:

- Industry demand: The high-tech industry requires high purity alumina beads for various applications.

- Technological advancements: Ongoing advancements in technology are creating new opportunities for the use of high purity alumina beads.

- Renewable energy and electronics: There is an increasing demand for high purity alumina beads in renewable energy and electronics sectors.

- Need for high-performance materials: Industries are constantly seeking high-performance materials to enhance their products and processes.

How are sustainability considerations impacting the market?

Sustainability is becoming more important. There’s a focus on green production, circular economy, and eco-friendly manufacturing, especially in Japan and the U.S.

What future developments are expected in the high purity alumina beads market?

Expect new production technologies, potential new uses, shifts in demand, and a continued focus on innovation and sustainability. .