$30.49 Billion Hollow Structural Sections Market Set for Growth in China, the U.S., and Germany by 2025

Discover key growth trends in the Hollow Structural Sections Market as demand surges in construction and infrastructure projects across China, the U.S., and Germany through 2033

- Last Updated:

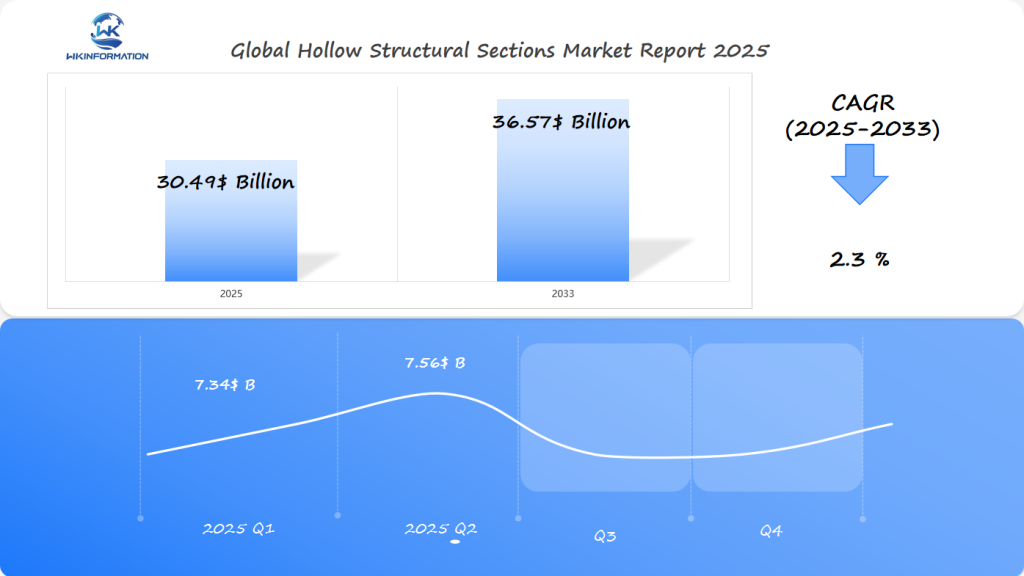

Projected Market Insights for Hollow Structural Sections in Q1 and Q2 of 2025

The Hollow Structural Sections market is forecasted to reach $30.49 billion in 2025, with a CAGR of 2.3% from 2025 to 2033. In Q1, the market is expected to generate around $7.34 billion, driven by steady growth in the construction, infrastructure, and transportation industries. By Q2, market value is projected to reach approximately $7.56 billion, as urban development projects and commercial construction continue to expand.

Key Players in the Hollow Structural Sections Market

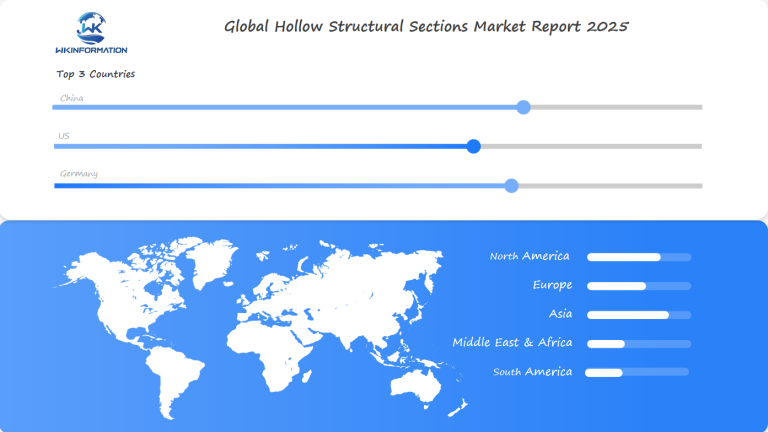

China, the U.S., and Germany are expected to be the leading countries in this sector:

- China benefits from large-scale infrastructure projects and a strong steel production industry.

- The U.S. sees increasing demand from industrial and residential construction.

- Germany’s advancements in sustainable building materials are driving adoption.

As global construction activities remain strong, the market for hollow structural sections is expected to maintain steady growth.

Understanding the Upstream and Downstream Industry Chains for Hollow Structural Sections

The hollow structural sections market is complex. It links raw material suppliers, manufacturers, and end-users across many sectors. Knowing this network is key to understanding the market’s growth.

The chain starts with top-quality steel production. Raw materials are vital for the product’s strength and durability. Steel makers use iron ore, coal, and recycled steel to make the base materials for hollow sections.

Raw Material Suppliers and Manufacturing Processes

Creating hollow structural sections involves advanced methods:

- Electric arc furnace (EAF) steel production

- Hot-rolled and cold-formed fabrication methods

- Precision cutting and welding technologies

- Advanced quality control measurements

Steel mills use the latest tech to turn raw materials into precise, high-performance products. They aim for strict quality to meet many industrial needs.

Distribution Channels and End-User Industries

Distribution channels for hollow structural sections vary. They are set up to reach different markets:

- Construction supply companies

- Industrial equipment distributors

- Infrastructure project suppliers

- Direct manufacturer sales

Key users include construction, manufacturing, automotive, and infrastructure. Each sector needs hollow sections for important structures. This drives innovation and demand.

The success of hollow structural sections depends on the seamless integration of advanced manufacturing processes and efficient distribution networks.

Key Trends Driving the Hollow Structural Sections Market Forward

The global hollow structural sections market is changing fast. New technologies and economic shifts are leading the way. These changes are altering how we build and choose materials for construction.

Urban growth is fueling demand for hollow structural sections. Cities are getting bigger, and they need strong, efficient materials for buildings.

Urbanization and Infrastructure Development

More people are moving to cities, leading to big projects. These projects use new steel technology. Hollow structural sections are key because they are:

- Lightweight

- Strong for their weight

- Flexible in use

Sustainable Construction Practices

Building green is now a top goal for builders. Hollow structural sections help a lot. They:

- Save on waste

- Help designs use less energy

- Support projects that cut down on carbon

Using this technology can cut carbon emissions by 20-30%. It’s a green choice for today’s buildings.

Technological Advancements in Steel Production

Steel making is getting better, thanks to new tech. Now, hollow sections are made with:

- More precision

- Better materials

- Custom designs

These improvements are changing how we tackle tough building tasks. They offer better flexibility and performance in building and engineering.

Challenges in Hollow Structural Section Production

The hollow structural sections industry faces big challenges. These challenges test manufacturers’ ability to be creative and strong. They must deal with economic, regulatory, and technological hurdles to stay ahead.

Manufacturers face many key challenges in the hollow structural sections market:

- Unpredictable raw material prices affect production costs

- Strict environmental rules push for sustainable practices

- More competition from new material technologies

Raw Material Price Volatility

Raw material prices are a big challenge for producers. Fluctuations in the steel market can greatly change production costs. This uncertainty affects profits and requires careful financial planning.

Environmental Regulations and Compliance

Environmental rules are getting tougher. This means manufacturers must find cleaner ways to make steel. They need to invest in new tech to cut carbon emissions and reduce harm to the environment.

| Challenge | Impact | Mitigation Strategy |

| Raw Material Prices | Increased Production Costs | Long-term Supply Contracts |

| Environmental Regulations | Higher Compliance Expenses | Green Manufacturing Technologies |

| Material Competition | Market Share Pressure | Product Innovation |

Competition from Alternative Materials

There’s more competition from materials like aluminum and composites. These new materials challenge traditional steel. To stay competitive, manufacturers must keep innovating. They need to make high-performance products that are strong, light, and cost-effective.

Geopolitical Impacts on the Hollow Structural Sections Market

The global hollow structural sections market is shaped by complex geopolitical factors. These factors greatly influence trade and economic interactions. Nations navigate through intricate international relationships, with trade policies and economic cooperation playing key roles.

Geopolitical factors are crucial for understanding supply chain resilience and market development. The United States, with 26% of global GDP, has a significant impact on international steel trade and hollow structural sections markets.

Trade Policies and Tariffs

International trade policies directly affect the hollow structural sections industry. Key considerations include:

- Tariff structures affecting steel imports and exports

- Bilateral trade agreements between major manufacturing nations

- Regulatory frameworks governing international steel transactions

Regional Economic Cooperation

Economic partnerships drive market expansion and technological exchange. For instance:

- The European Union maintains €40 billion in annual trade with Hong Kong

- Over 1,500 European companies are integrated into international manufacturing ecosystems

- Strategic collaborations enhance technological innovation

Global Supply Chain Disruptions

Recent global events have shown how fragile international supply chains can be. The hollow structural sections market needs to adjust to:

- Geopolitical tensions affecting raw material availability

- Changes in manufacturing locations

- New approaches for supply chain resilience

The United States is at the forefront of innovation, with half of the world’s venture capital invested there. This gives the country an advantage in creating flexible strategies to keep its hollow structural sections markets strong.

Market Segmentation: Types and Applications of Hollow Structural Sections

The hollow structural sections market is key in modern construction and manufacturing. It’s all about understanding the different types and uses. Steel makers use smart methods to meet many needs.

There are many types of hollow structural sections, based on shape, size, and use. Each type has special benefits for different needs.

Square and Rectangular Sections

Square and rectangular sections are strong and even. They are perfect for:

- Architectural framing

- Building construction

- Industrial machinery support

- Infrastructure development

Circular Sections

Circular sections spread loads well and look good. They are used in many fields, like:

- Automotive frame manufacturing

- Agricultural equipment

- Transmission tower structures

- Renewable energy infrastructure

Customized Sections

Custom hollow structural sections are becoming more popular. They solve complex engineering problems with precision.

| Section Type | Primary Applications | Key Advantages |

| Square | Building Frames | High Structural Integrity |

| Rectangular | Industrial Equipment | Uniform Load Distribution |

| Circular | Automotive Frames | Aesthetic Flexibility |

| Customized | Specialized Engineering | Precision Design |

Thanks to new tech, engineers can make innovative hollow structural sections. These meet tough design needs in many areas.

Hollow Structural Sections in Construction and Engineering

Hollow structural sections are key in today’s construction and engineering. They offer great strength and flexibility in many fields. They support complex projects with their robust structure.

Engineers and architects love hollow structural sections for their design and performance. They are light but strong, perfect for many construction needs.

Structural Support in Buildings

In tall buildings and big commercial spaces, hollow sections are a big plus:

- They carry more weight

- They make buildings lighter

- They resist earthquakes better

- They help in sleek designs

Bridge and Infrastructure Projects

Projects like bridges and roads use hollow sections for their strength and lasting quality. They help make bridges and roads strong and safe.

| Infrastructure Type | Hollow Section Application | Primary Benefits |

| Bridges | Structural frames | High strength-to-weight ratio |

| Highway Overpasses | Support columns | Corrosion resistance |

| Railway Structures | Truss systems | Long-term structural integrity |

Industrial and Commercial Applications

Industrial and commercial places use hollow sections in many ways. From warehouses to factories, they offer strong support in tough settings.

“Hollow structural sections represent the future of intelligent, efficient construction design.” – Engineering Innovations Journal

Hollow structural sections keep pushing the limits in building and engineering. They offer smart and effective solutions for tough building challenges.

Understanding the Global Hollow Structural Sections Market

The global market for hollow structural sections is constantly changing, with different regions experiencing significant fluctuations. Companies and experts are closely monitoring how trade and new opportunities impact this crucial segment of the steel industry.

Investors and analysts are interested in understanding the factors driving the growth and development of hollow structural sections. The market is intricate, influenced by various aspects such as production, distribution, and consumption of these products.

Regional Market Shares and Growth Rates

Some areas are leading the hollow structural sections market:

- North America: Steady infrastructure development

- China: Massive industrial expansion

- European Union: Advanced manufacturing technologies

- India: Rapid urbanization and construction boom

Emerging Markets and Opportunities

New countries are showing great promise for hollow structural sections. Rapid industrialization in places like Vietnam, Indonesia, and Brazil offers big chances for companies looking to grow.

Global Trade Dynamics

The global trade for hollow structural sections is complex, involving long supply chains and important partnerships. Companies are focusing on:

- Improving their manufacturing processes

- Developing environmentally friendly production methods

- Exploring innovative market entry strategies

Collaboration and the adoption of new technologies will continue to reshape the hollow structural sections market, opening up new opportunities for growth and innovation.

U.S. Market Demand for Hollow Structural Sections

The U.S. market for hollow structural sections is growing fast. This growth comes from the need to fix old infrastructure and new construction trends. Steel makers and experts are watching the market closely.

Several important factors are shaping the demand for hollow structural sections in the U.S.:

- Projects to fix old transportation systems

- More buildings and homes being built

- New tech in making steel

- More focus on green buildings

Infrastructure Renewal Projects

Renewing U.S. infrastructure is a big opportunity for hollow structural sections. Cities and the government are spending a lot to fix bridges, roads, and public buildings. This means a lot of demand for top-quality steel parts.

Commercial and Residential Construction Trends

There is a growing demand for hollow structural sections in various sectors. Architects are increasingly incorporating these durable, versatile, and aesthetically pleasing steel components into their designs for both commercial and residential properties.

Domestic Production vs. Imports

U.S. makers of hollow structural sections are doing well. They’re making smart choices to stay competitive. This helps them maintain their market share against foreign competitors.

“The U.S. steel industry is transforming, focusing on innovation and efficiency in hollow structural section manufacturing.” – Steel Market Research Institute

Experts believe that the demand for hollow structural sections in the U.S. will continue to grow. This growth will be driven by the need to repair old infrastructure and the adoption of new building technologies.

China's Influence on Hollow Structural Section Technology

The global market for hollow structural sections has seen significant changes due to Chinese technology and manufacturing. China has become a key player in transforming the steel industry and the global market.

Chinese manufacturers are at the forefront of technology for hollow structural sections. Their research and development efforts have improved production processes and enhanced product quality.

Innovations in Manufacturing Processes

Chinese steel makers use the latest tech to improve production:

- Advanced computer-controlled production lines

- Precision welding techniques

- High-temperature forming processes

- Automated quality control systems

Research and Development Initiatives

“Innovation distinguishes between a leader and a follower” – Chinese manufacturing philosophy

China’s focus on R&D has moved hollow structural section tech forward. Key areas of research include:

- Lightweight steel alloy development

- Corrosion-resistant materials

- Enhanced structural performance

- Sustainable manufacturing processes

Export Strategies and Global Market Impact

Chinese export plans have changed the global hollow structural sections market. They offer good prices and quality, building strong trade networks worldwide.

Their strategy is to focus on infrastructure projects, invest in global sales, and keep improving tech to stay ahead.

Germany's Role in Hollow Structural Section Advancements

German engineering leads in hollow structural section innovation. It’s a top spot in steel manufacturing technology. The country’s focus on precision and quality makes it a world leader in structural solutions.

German high-quality steel production is known worldwide. It comes from decades of engineering skill and strict manufacturing standards. Companies keep improving, making hollow structural sections that meet tough standards.

Cutting-Edge Steel Production Techniques

- Advanced precision manufacturing processes

- Ultrasonic testing for structural integrity

- Computer-assisted design and production

Innovation in Manufacturing

German engineers have made big strides in hollow structural section performance. They’ve worked on making materials stronger, lighter, and more efficient.

| Innovation Area | Key Developments |

| Material Composition | Advanced alloy development |

| Production Technology | Precision rolling techniques |

| Quality Control | Non-destructive testing methods |

Sustainable Manufacturing Initiatives

Sustainable manufacturing is key for German steel producers. Eco-friendly production methods are now a big part of their work. They aim to cut carbon emissions and reduce environmental harm while keeping quality high.

German engineering, high-quality steel, and eco-friendly practices lead the way in hollow structural sections. They set the bar high for the industry worldwide.

The Future of Hollow Structural Sections: Innovations and Opportunities

The hollow structural sections industry is on the verge of big changes. New innovations are changing how we make things, what materials we use, and how we care for the planet. Companies are using the latest technology to make production better and products more advanced.

Smart Manufacturing and Industry 4.0

Smart manufacturing is making a big difference in making hollow structural sections. Companies are using digital tools to make things more precise and efficient. Some key advancements include:

- Automated systems that watch production in real-time

- AI for checking quality

- Digital twins for predicting when things might break

- IoT for better manufacturing processes

Advanced Materials and Composites

Scientists are working on new materials that could change hollow structural sections. Nano-engineered steel alloys and composites are showing great promise. They could make things stronger and last longer.

| Material Type | Key Characteristics | Potential Applications |

| Nano-enhanced Steel | Increased strength, reduced weight | Aerospace, construction |

| Carbon Fiber Composites | High tensile strength, lightweight | Infrastructure, automotive |

| Hybrid Metal Alloys | Improved corrosion resistance | Marine, industrial structures |

Sustainable and Recyclable Products

Creating sustainable products is a big focus in the hollow structural sections market. Companies are finding new ways to recycle and make things more eco-friendly. This helps reduce harm to the environment.

- Circular economy design principles

- Reduced carbon footprint manufacturing

- Enhanced material recyclability

- Energy-efficient production processes

These new trends show the industry’s dedication to innovation, smart manufacturing, advanced materials, and sustainability in hollow structural sections technology.

Competitive Landscape in the Hollow Structural Sections Industry

The hollow structural sections market is very competitive. Many big names are fighting for a share of the global market.

These companies use smart strategies to stay ahead. They form partnerships to grow their reach and skills.

- Yuantai Derun Group – China

- Youfa Steel Pipe Group – China

- Zhengda Steel Pipe – China

- Zekelman Industries – USA

- Nippon Steel – Japan

- APL Apollo – India

- Nucor Corporation – USA

- ArcelorMittal – Luxembourg

- JFE Steel Corporation – Japan

- Vallourec – France

- Severstal – Russia

- SSAB – Sweden

- Tata Steel – India

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Hollow Structural Sections Market Report |

| Base Year | 2024 |

| Segment by Type |

· Square · Rectangular · Circular |

| Segment by Application |

· Bridges · Highway · Railway · Buildings |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The global hollow structural sections market demonstrates significant potential, driven by evolving trends and robust growth drivers. Increasing demand for lightweight, durable materials and the adoption of sustainable practices highlight the market’s dynamic nature. Challenges such as fluctuating raw material prices and competition from alternatives persist, yet innovation and technological advancements continue to propel the market forward. The report underscores the importance of sustainability and customization in shaping future opportunities. With a forecast projecting substantial growth, the market is poised to redefine construction and industrial applications, offering immense possibilities for stakeholders worldwide.

Global Hollow Structural Sections Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Hollow Structural Sections Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Vacuum Arc RemeltingMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Hollow Structural Sectionsplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Hollow Structural Sections Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Hollow Structural Sections Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Hollow Structural Sections Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofHollow Structural Sections Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are hollow structural sections and why are they important?

Hollow structural sections are steel tubes used in construction and engineering. They provide critical support for buildings, bridges, and industrial projects. They offer superior strength, versatility, and design flexibility compared to traditional solid structural elements.

What industries primarily use hollow structural sections?

Key industries include:

- Construction

- Automotive manufacturing

- Machinery production

- Infrastructure development

- Industrial engineering

These sections are used in high-rise buildings, bridges, warehouses, industrial facilities, and specialized mechanical applications.

What challenges do manufacturers face in the hollow structural sections market?

Manufacturers face challenges such as:

- Fluctuating steel prices: The cost of steel can vary significantly, affecting profit margins and pricing strategies.

- Increasing environmental regulations: Manufacturers must comply with stricter regulations aimed at reducing carbon emissions and promoting sustainability.

- Competition from alternative materials: Materials like aluminum are gaining popularity and pose a threat to the demand for steel hollow structural sections.

- Need for cleaner production methods: To meet environmental standards, manufacturers may need to invest in new technologies and processes that reduce their ecological footprint.

- Maintaining competitive pricing: Despite the additional costs associated with sustainable practices, manufacturers still need to offer competitive prices to attract customers.

How are technological advancements impacting hollow structural sections?

Innovations such as improved manufacturing processes and the use of smart manufacturing technologies are making a difference. Additionally, advanced steel production methods and a commitment to creating sustainable and recyclable products are important factors as well.

What types of hollow structural sections are available?

Common types include square, rectangular, and circular sections. Manufacturers also produce specialized and customized shapes to meet specific project requirements across various industries.

How do geopolitical factors affect the hollow structural sections market?

Geopolitical factors such as trade policies, tariffs, international economic cooperation, and global supply chain dynamics have a significant impact on the hollow structural sections market. This is particularly true in major markets like China, the United States, and the European Union.

What role does sustainability play in hollow structural sections production?

Sustainability is becoming increasingly important in the production of hollow structural sections. Manufacturers are now focusing on:

- Using environmentally friendly production methods

- Developing recyclable products

- Meeting stringent environmental regulations

How are different countries contributing to the hollow structural sections market?

Countries like China lead in manufacturing innovations. The United States drives infrastructure renewal projects. Germany is known for high-quality engineering and sustainable production techniques.

What future trends are expected in the hollow structural sections industry?

Anticipated trends include smart manufacturing technologies and advanced material research. There will be increased customization, sustainable production methods, and greater integration of digital technologies in design and production processes. These advancements may be visualized in the following image, which represents the potential of these emerging trends in the hollow structural sections industry .