$299.1 Million Hydraulic Reaming Shoe Market Booms by 2025: Canada, Russia, and the U.S. Fuel Demand

The hydraulic reaming shoe market is set to grow steadily in 2025, driven by demand in construction and oil & gas, with a projected CAGR of 6.23% through 2033.

- Last Updated:

Hydraulic Reaming Shoe Market Q1 and Q2 2025 Forecast

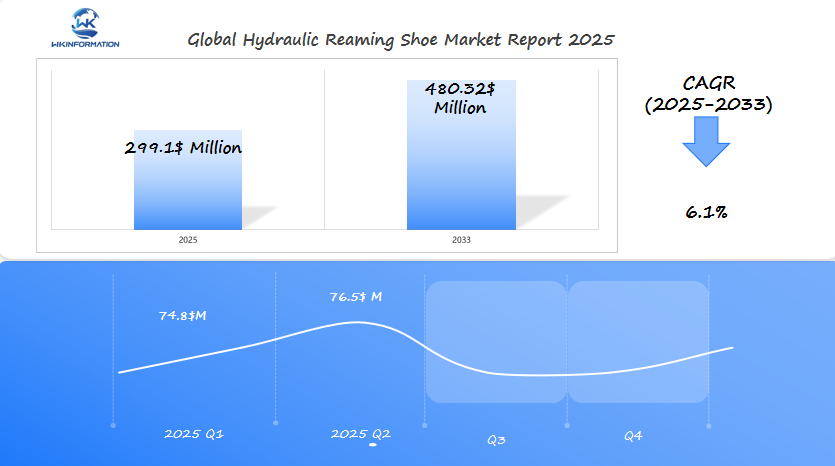

The Hydraulic Reaming Shoe market is estimated to reach $299.1 million in 2025, with a CAGR of 6.1% from 2025 to 2033. In Q1 2025, the market is projected to generate approximately $74.8 million, driven by growing activity in oil and gas exploration, particularly in Canada, Russia, and the U.S. Hydraulic reaming shoes are critical for enhancing drilling efficiency and minimizing wear and tear on drill bits, making them essential for deep drilling operations. The rising exploration of unconventional oil and gas reserves, such as shale gas, and the need for advanced drilling technologies are contributing factors to market growth.

By Q2 2025, the market is expected to reach $76.5 million, with an increased demand for high-performance drilling tools to meet the requirements of deeper and more challenging drilling projects. The demand in Russia and Canada is fueled by high-value oil reserves, while the U.S. remains a key market for advanced hydraulic solutions in deepwater drilling.

Key Takeaways

- The market value is projected to reach $299.1 million by 2025.

- Canada, Russia, and the U.S. are the main countries driving demand.

- Hydraulic drilling tools enhance drilling precision and efficiency.

- The energy and construction industries are leading the way in adopting advanced reaming shoe designs.

- Future growth will be influenced by innovations in materials and smart monitoring technologies.

Understanding the Supply Chain of Hydraulic Reaming Shoe Industry

The hydraulic reaming shoe industry relies on a well-connected supply chain. It’s divided into upstream and downstream stages.

Upstream Stage

The upstream stage starts with raw materials like steel, titanium, and special alloys.

- Suppliers get these materials to meet high engineering standards.

- They make sure they can handle high-pressure drilling.

- Quality checks at this stage are key to the final product’s reliability.

Downstream Stage

The downstream stage focuses on making these raw materials into useful tools.

- Factories shape and test the shoes for a perfect fit in drilling rigs.

- Distributors send these tools to users in oil and gas, mining, and construction.

Advances in oil and gas exploration technology drive the need for better shoes. They need to be lighter yet stronger. This ensures hydraulic reaming shoes meet the changing needs of the industry.

Material suppliers and manufacturers work together to find the right balance. They focus on cost and performance. This chain keeps the market ready for the world’s energy needs.

Key Trends Driving the Hydraulic Reaming Shoe Market: Oil & Gas and Infrastructure Expansion

The demand for hydraulic reaming shoes is growing fast. This is because of more oil & gas extraction and big infrastructure projects. Companies are focusing on reaming shoe innovation to tackle deeper drilling and tough geology. These improvements lead to better performance and cost savings, key for today’s industries.

Oil & Gas Expansion

Shale gas and deepwater drilling need reaming shoes that can handle tough conditions. This pushes makers to improve materials and designs.

Infrastructure Development

Growing cities and transport systems need strong reaming shoes for building. This drives innovation in durable coatings and automated systems.

Today’s reaming shoe innovation includes monitoring data in real-time and using strong yet light materials. These changes cut down on downtime and boost safety in tough spots. As energy and building sectors grow, hydraulic reaming shoes become key for lasting growth. New features like spiral designs and custom options meet industry needs, helping tackle different drilling and digging challenges.

Challenges in Hydraulic Reaming Shoe Manufacturing and Material Sourcing

Creating hydraulic reaming shoes and finding materials for deep drilling equipment comes with significant challenges. Finding consistent materials and needing high precision are major issues. These problems affect the cost and reliability of the products.

1. Material Scarcity

Rare alloys and composites face supply chain delays, which have been highlighted in a comprehensive 100-day supply chain review report.

2. High Costs

Specialty metals like titanium increase production expenses.

3. Technical Barriers

Ensuring durability under extreme drilling pressures remains a hurdle, a challenge that has been discussed in various scientific articles focused on the subject.

| Material Type | Advantages | Drawbacks |

| Steel Alloys | Cost-effective, widely available | Risk of wear in corrosive environments |

| Titanium | Lightweight, corrosion-resistant | High cost and machining difficulty |

| Composite Materials | Customizable performance traits | Complex quality control processes |

Manufacturers try to balance material costs with the need for high performance. These challenges show the need for new ways to source and make deep drilling equipment. Suppliers must find solutions to meet the growing demand worldwide.

Geopolitical Influence on the Hydraulic Reaming Shoe Market

Global politics greatly affect the hydraulic reaming shoe industry. Trade policies and tariffs change industrial hydraulic systems supply chains. Countries like the U.S., Russia, and Canada face challenges due to sanctions and export controls.

Trade disputes between big economies can delay shipments of steel and alloys. This forces manufacturers to look for new suppliers.

Key Factors Impacting the Hydraulic Reaming Shoe Market

- Trade barriers: Tariffs on hydraulic components increase production costs, making it harder to make a profit.

- Sanctioned markets: Trade restrictions with certain areas limit raw material imports, affecting industrial hydraulic systems reliability.

- Regional alliances: Agreements like the U.S.-EU partnership boost local manufacturing but exclude non-aligned nations.

Companies are finding ways to adapt. For example, U.S. firms are teaming up with suppliers in Latin America to avoid blocked markets. Russia is also focusing on making industrial hydraulic systems on its own, showing how politics can drive innovation.

Analysts say that by 2025, areas with stable trade ties will lead the market. As political situations change, the industry must find a balance between cost and risk. Being flexible in sourcing and technology will help companies succeed in this challenging time.

Types of Hydraulic Reaming Shoes: Standard, Spiral, and Customized Designs

Hydraulic reaming shoes come in three main types. Each is designed to improve drilling efficiency solutions. The right choice depends on the project’s needs and the geological conditions.

- Standard Designs: These are widely used for routine drilling tasks. Their simplicity reduces downtime and lowers maintenance costs.

- Spiral Designs: Ideal for hard rock formations, spiral shoes cut through uneven surfaces smoothly. This enhances precision and reduces wear.

- Customized Designs: Engineered for unique projects, they address site-specific challenges like high pressure or complex terrains.

| Type | Key Features | Benefits |

| Standard | Universal fit, easy installation | Cost-effective, reliable performance |

| Spiral | Helical blades, durable material | Improved bit stability, faster penetration |

| Customized | Client-specific specs | Maximized drilling efficiency solutions for niche applications |

Companies like National Oilwell Varco and Schlumberger offer these variants. They ensure operators select the best fit for their operations. Engineers prioritize these options to optimize workflows and reduce project delays.

Applications of Hydraulic Reaming Shoes in Oil & Gas, Mining, and Construction

Hydraulic reaming shoes are key in high-stakes industries. They use advanced hydraulics design to solve tough drilling and excavation problems.

Oil & Gas

In oil and gas, they make sure boreholes are the right size, saving drill bits and avoiding expensive delays.

Mining

Mining projects rely on them to keep tunnels stable in hard rock.

Construction

Construction sites use them for installing pipelines and stabilizing the ground.

| Industry Application Benefit Oil & Gas | Wellbore conditioning | Enhanced drilling stability with advanced hydraulics design |

| Mining | Underground tunneling | Reduced rock fragmentation risk |

| Construction | Utility pipeline installation | Accurate diameter control for pipelines |

Companies like National Oilwell Varco and Baker Hughes make shoes that adjust to pressure changes. For example, in shale, they keep drilling angles steady, cutting costs by up to 15%. Their use across industries makes them crucial for today’s projects.

Global Insights into the Hydraulic Reaming Shoe Market

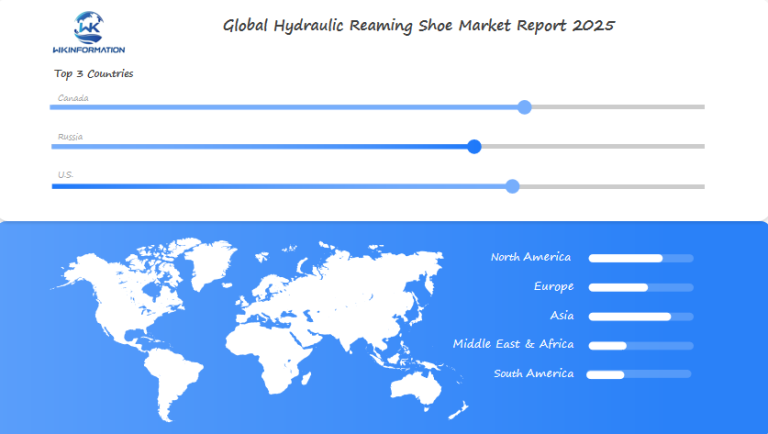

Investment in energy infrastructure is key to global economic growth. It shapes the hydraulic reaming shoe market. The Middle East and Asia-Pacific lead in using advanced drilling tools for oil and gas projects. European nations focus on sustainable solutions for renewable energy.

Key Drivers by Region

- North America: Driven by shale exploration and drilling efficiency demands.

- Asia-Pacific: Rapid industrialization boosts demand for cost-effective drilling equipment.

- Middle East: State-owned energy firms invest in high-capacity hydraulic reaming shoes for deepwater projects.

“Smart energy infrastructure investment today ensures drilling efficiency and long-term operational resilience,” said an engineer at National Oilwell Varco, a leading equipment supplier.

Emerging markets are moving to hybrid systems. These combine traditional drilling with digital monitoring. This change supports global goals for sustainable energy production.

Manufacturers are now making equipment lighter and more resistant to corrosion. This meets the needs of these changing markets.

Market analytics show a 15% increase in hydraulic reaming shoe purchases in regions investing in energy infrastructure. This shows a direct link between investment and demand growth.

Canada’s Market Demand for Hydraulic Reaming Shoes in Energy Exploration

Canada’s energy sector relies heavily on hydraulic reaming shoes for oil sands and shale drilling. The demand for more energy and government support is increasing. These tools are essential for extracting resources from difficult-to-access areas, which is crucial for Canada’s drilling operations.

Factors Driving Demand

Several factors are contributing to the growing demand for hydraulic reaming shoes in Canada:

- Oil Sands Projects: Oil sands projects in Alberta require robust reaming shoes to penetrate hard rock formations.

- Government Support: Government assistance for both clean energy initiatives and traditional drilling practices encourages wider adoption of these tools.

- Technological Advancements: Ongoing advancements in technology aim to minimize environmental impact while enhancing drilling efficiency.

“Innovative drilling solutions are key to unlocking Canada’s vast energy potential sustainably.” – Canadian Energy Association Report, 2023

Industry Requirements

Companies operating in the energy sector are actively seeking reaming shoes that can withstand extreme conditions. Specifically, they are looking for:

- High Pressure Resistance: The ability to endure intense pressure levels encountered during drilling operations.

- Temperature Tolerance: Resistance to elevated temperatures generated by friction and geological factors.

Collaborative Efforts

In addition to domestic advancements, collaboration with U.S.-based companies plays a significant role in improving hydraulic reaming shoe technology. By working together on shared projects, manufacturers can leverage expertise and resources to develop superior equipment solutions.

Importance of Hydraulic Reaming Shoes

As Canada continues to expand its energy projects, hydraulic reaming shoes will remain critical for maintaining efficient drilling operations. These tools enable operators to navigate challenging geological formations effectively, minimizing downtime and maximizing productivity.

The increasing demand for hydraulic reaming shoes positions Canada as a key player in the global drilling technology landscape.

Russia’s Growing Investment in Hydraulic Reaming Shoe Technology for Deep Drilling

Russia is significantly increasing its investment in hydraulic reaming shoe technology to tackle the challenges of drilling in remote areas. The use of advanced materials and precise engineering has become crucial for accessing oil and gas reserves in the Arctic and Siberian regions.

Russia’s Hydraulic Reaming Shoe Technology

The focus is now on developing drills that can reach depths exceeding 10,000 meters. This involves forming strategic partnerships with global tech firms to implement AI-driven monitoring systems. Additionally, rigorous tests are being conducted in permafrost zones to enhance equipment durability.

| Old Tech | New Investments |

| Steel-based designs | Composite alloy materials |

| Manual adjustments | Automated pressure sensors |

| 2,000m drilling limits | Target: 12,000m by 2025 |

These upgrades aim to reduce costs associated with harsh environmental conditions while also meeting the growing energy demands. Engineers are currently testing prototypes in Western Siberia’s shale deposits, with the hope of increasing recovery rates by 30%.

The U.S.’s Leadership in Hydraulic Reaming Shoe Innovation for Efficiency and Durability

U.S. companies lead in hydraulic reaming shoe tech. Companies like National Oilwell Varco and Baker Hughes spend a lot on research and development. They aim to make tools that last longer and work better.

Their tools are made from ultra-hardened steel and tungsten carbide. This makes them last longer in tough drilling conditions.

Key Innovations by U.S. Companies

- Material Science Breakthroughs: Enhanced alloys resist wear, extending tool lifespan by 20–30%.

- Digital Integration: Real-time sensors and AI analytics optimize drilling efficiency in real time.

- Industry Partnerships: Collaborations with MIT and Stanford advance smart monitoring systems.

| Company Innovation Focus Key Advancements National Oilwell Varco | Material Engineering | Tungsten carbide coatings for extreme durability |

| Baker Hughes | Smart Technology | IoT sensors for real-time performance tracking |

| Schlumberger | Data-Driven Design | Machine learning for predictive maintenance |

“Innovation defines our edge in global markets. Our tools cut downtime by 15% and boost wellbore precision.”

U.S. leadership ensures hydraulic reaming shoes meet rising demand for cost-effective, long-lasting solutions. As energy projects expand, these advancements position American firms to dominate both domestic and international markets.

The Future of Hydraulic Reaming Shoes: Smart Monitoring and Advanced Materials

Smart technology and material science are changing hydraulic reaming shoes. New features like real-time data tracking and self-adjusting designs are becoming common. These advancements help companies save money and improve safety during drilling.

Intelligent Monitoring for Tool Longevity

- Smart sensors monitor wear and adjust pressure to extend tool life.

- Wireless communication systems send data to engineers for instant adjustments.

- AI algorithms predict maintenance needs before equipment fails.

Advanced Materials for Enhanced Performance

Now, tools are made with advanced materials like titanium alloys and heat-resistant polymers. These materials can handle extreme pressures and temperatures. Companies like Weatherford International and National Oilwell Varco are leading in using carbon-fiber composites. These composites are lighter but just as strong.

A Sustainable Focus Ahead

The future will focus on making tools more sustainable. Eco-friendly coatings and recyclable parts could reduce environmental harm. As oil and gas companies look for safer and more efficient ways to work, they’ll need smarter, stronger tools. The market will move towards tech-driven solutions that are both precise and durable.

Competitive Landscape in the Hydraulic Reaming Shoe Market

- Caterpillar Inc. – Deerfield, Illinois, United States

- Komatsu Ltd. – Tokyo, Japan

- Eaton Corporation – Dublin, Ireland

- Parker Hannifin Corporation – Cleveland, Ohio, United States

- Kawasaki Heavy Industries Ltd. – Kobe, Japan

- Webtec Products Limited – St Ives, Cambridgeshire, United Kingdom

- Moog Inc. – East Aurora, New York, United States

- KYB Corporation – Tokyo, Japan

- HYDAC International GmbH – Sulzbach, Germany

- Nachi-Fujikoshi Corporation – Toyama, Japan

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Hydraulic Reaming Shoe Market Report |

| Base Year | 2024 |

| Segment by Type |

· Fixed-blade reaming shoes · Rotating-blade reaming shoes |

| Segment by Application |

· Construction · Oil & Gas Exploration · Agriculture and Irrigation |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The Hydraulic Reaming Shoe Market is expected to hit $299.1 million by 2025. Key areas like Canada, Russia, and the U.S. are crucial for its growth. The demand is fueled by oil & gas sectors and infrastructure projects.

Innovations in smart monitoring and advanced materials are changing the game. Companies face challenges in material sourcing and geopolitical shifts. They must stay competitive in this fast-paced market.

In the U.S., leaders focus on durability and efficiency, setting global standards. Customized designs and spiral technologies meet various drilling needs. From deep-sea exploration to mining, the market adapts to these needs.

The market’s success depends on keeping up with technology and managing supply chain issues. Staying updated on trends like automation and sustainability is key. Firms that invest in R&D and partnerships will thrive in the future.

The path forward involves tackling today’s challenges while embracing tomorrow’s opportunities. This dynamic sector requires a balance of innovation and adaptability.

Global Hydraulic Reaming Shoe Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Hydraulic Reaming Shoe Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Hydraulic Reaming ShoeMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Hydraulic Reaming Shoeplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Hydraulic Reaming Shoe Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Hydraulic Reaming Shoe Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Hydraulic Reaming Shoe Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofHydraulic Reaming ShoeMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are hydraulic reaming shoes used for?

Hydraulic reaming shoes are essential tools in drilling. They help make drilling more efficient and safer. This is especially true in oil & gas, mining, and construction.

How much is the hydraulic reaming shoe market expected to be worth by 2025?

The market is set to hit $299.1 million by 2025. This growth comes from strong demand in Canada, Russia, and the U.S. Such demand is indicative of a broader trend in the global energy sector, which has been experiencing significant changes as highlighted in various reports including this World Bank document. Furthermore, the 2010 annual report from Weatherford International provides insights into the industry’s dynamics that could influence future market valuations.

What trends are currently influencing the hydraulic reaming shoe market?

Current trends affecting the hydraulic reaming shoe market include:

- Increased investment in oil and gas projects

- A focus on building more infrastructure

These factors are boosting the market and driving the development of new technology.

What challenges do manufacturers face in producing hydraulic reaming shoes?

Making these shoes is tough. Finding good materials and keeping production consistent is hard. It affects prices, availability, and how well the shoes work.

How do geopolitical factors impact the hydraulic reaming shoe market?

Politics can have a significant impact on the market. Trade policies and international relations can alter supply chains and tariffs, which in turn affects global competition.

What are the different types of hydraulic reaming shoes available?

There are standard, spiral, and custom designs. Each type has its own benefits. They improve drilling efficiency and performance for different needs.

In which industries are hydraulic reaming shoes commonly used?

Hydraulic reaming shoes are commonly used in the following industries:

- Oil and gas

- Mining

- Construction

These shoes utilize advanced hydraulics, which enhances safety and efficiency in drilling operations.

What insights can be gained from the global hydraulic reaming shoe market?

The global market shows trends in energy investments and demand. This helps businesses make smart choices based on market trends and data.

What factors contribute to Canada’s demand for hydraulic reaming shoes?

Canada’s demand comes from energy exploration and tech advancements. Government policies also play a role. These support resource extraction across the country.

How is Russia investing in hydraulic reaming shoe technology?

Russia is investing in new technology for deep drilling. This aims to improve performance and tackle geological challenges. It ensures efficient extraction in diverse landscapes.

What role does the U.S. play in hydraulic reaming shoe innovation?

The U.S. leads in innovation. It’s developing advanced research and designs. These improve the efficiency and durability of drilling equipment.

What future trends are expected in hydraulic reaming technologies?

Future trends include smart monitoring systems and advanced materials. These will change drilling practices. They’ll make it safer and improve performance.

How competitive is the hydraulic reaming shoe market?

The market is very competitive. Companies are using different strategies to stand out, as illustrated in this image. This drives innovation and shapes the industry.